A kind of antimony sulfide-based heterojunction photocathode and its preparation method and application

A technology based on antimony sulfide and antimony sulfide, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of difficult to obtain industrial application, high technical process requirements, high cost of ALD method, etc., achieve excellent utilization prospects, simple operation, Slow down the effect of photocorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of an antimony sulfide-based heterojunction photocathode comprises the following steps:

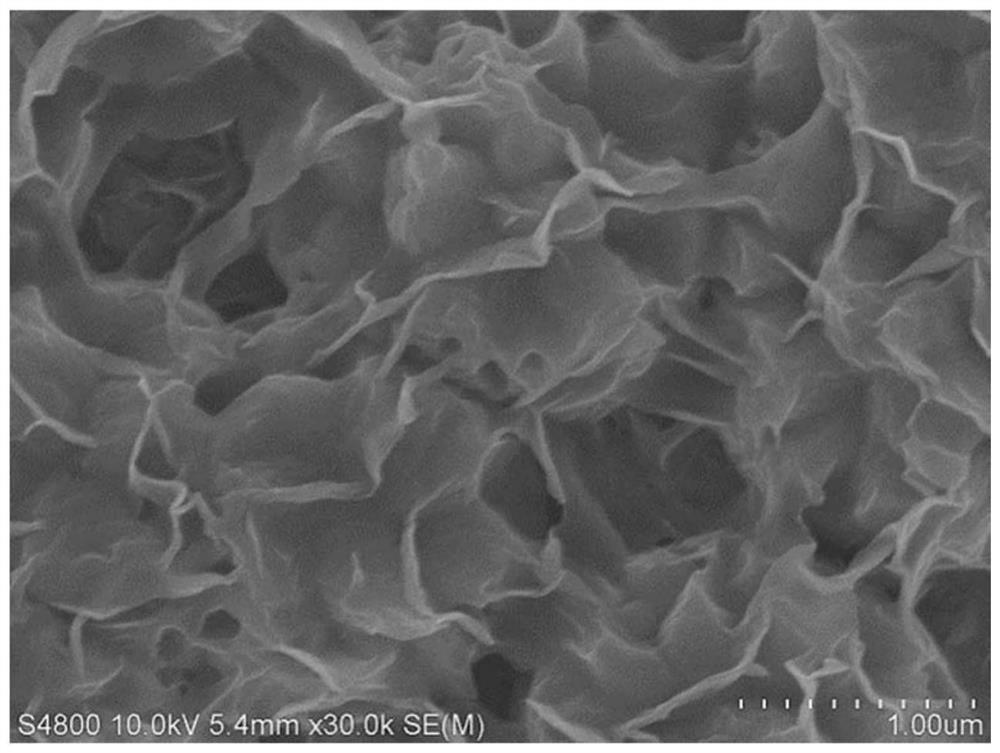

[0042] 1) A network-like antimony sulfide thin film was grown on an ITO glass substrate by a hydrothermal method. The specific steps are:

[0043] ① Prepare an aqueous solution containing 30mM antimony potassium tartrate and 60mM thioacetamide;

[0044] ② Put the solution in step ① in a hydrothermal kettle containing a polytetrafluoroethylene liner, place the cleaned ITO glass substrate vertically in a polytetrafluoroethylene shelf, transfer them to the hydrothermal kettle together, and carry out Hydrothermal reaction, heat preservation at 150°C for 8 hours and then cool in the furnace. After the reaction is completed, the reaction product is cleaned and dried to obtain a dark red antimony sulfide film;

[0045] 2) The ultra-thin titanium dioxide layer was prepared by cathodic electrodeposition. Specific steps are as follows:

[0046] ① Configure 20ml of 0.1M me...

Embodiment 2

[0051] Preparation method is with embodiment 1, and difference is:

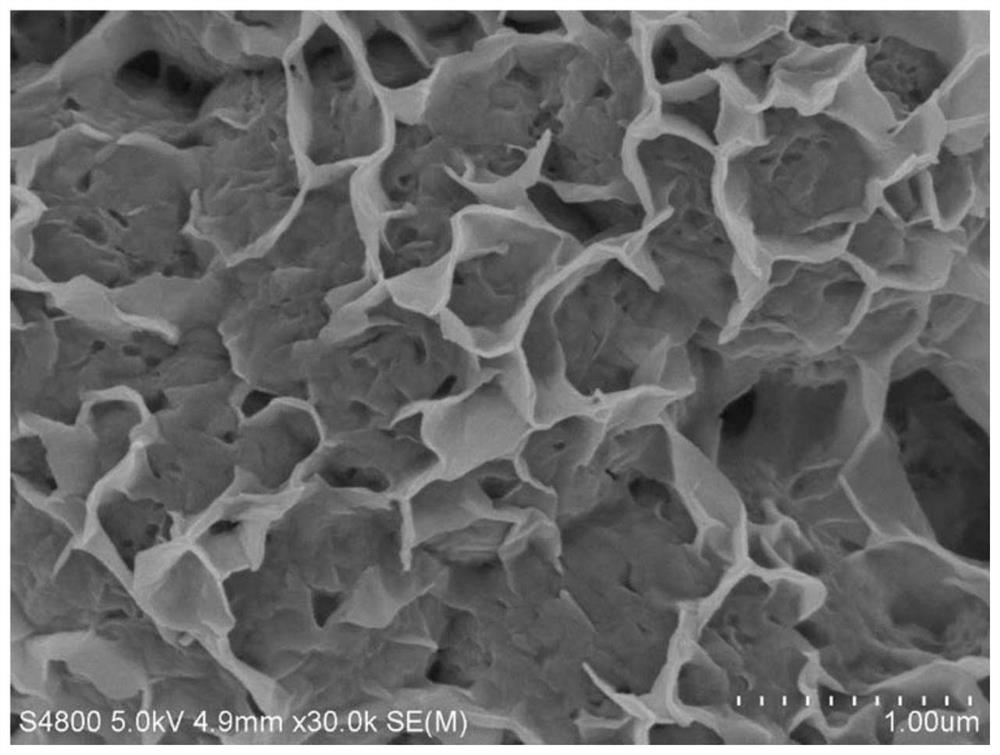

[0052] In step 1), the concentration of antimony potassium tartrate is 50mM; the concentration of thioacetamide is 100mM; the time of hydrothermal reaction is 16h.

[0053] The surface SEM image of the antimony sulfide-based heterojunction photoelectrode obtained after heat treatment is as follows figure 2 As shown, it is a uniform network structure.

[0054] In the above-described embodiment, in step 2), the three-electrode system used in the electrodeposition method uses a standard Ag / AgCl electrode as a reference electrode, a platinum wire as a counter electrode, and a conductive glass deposited with an antimony sulfide light-absorbing layer as a working electrode; The current is -0.1mA / cm 2 to -1mA / cm 2 , the time is 100s-1000s.

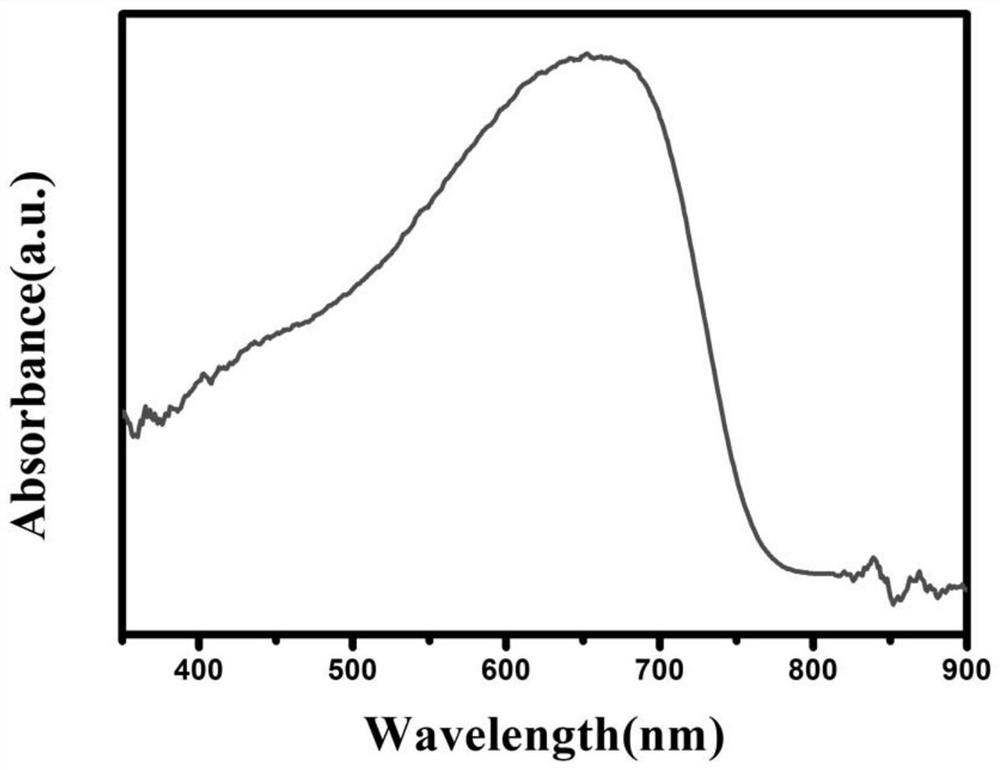

[0055] The UV absorption spectrum of the antimony sulfide-based heterojunction photocathode prepared above is as follows image 3 As shown, the absorption cut-off edge is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com