A kind of method for preparing polyaniline electrochromic film by hydrothermal self-assembly

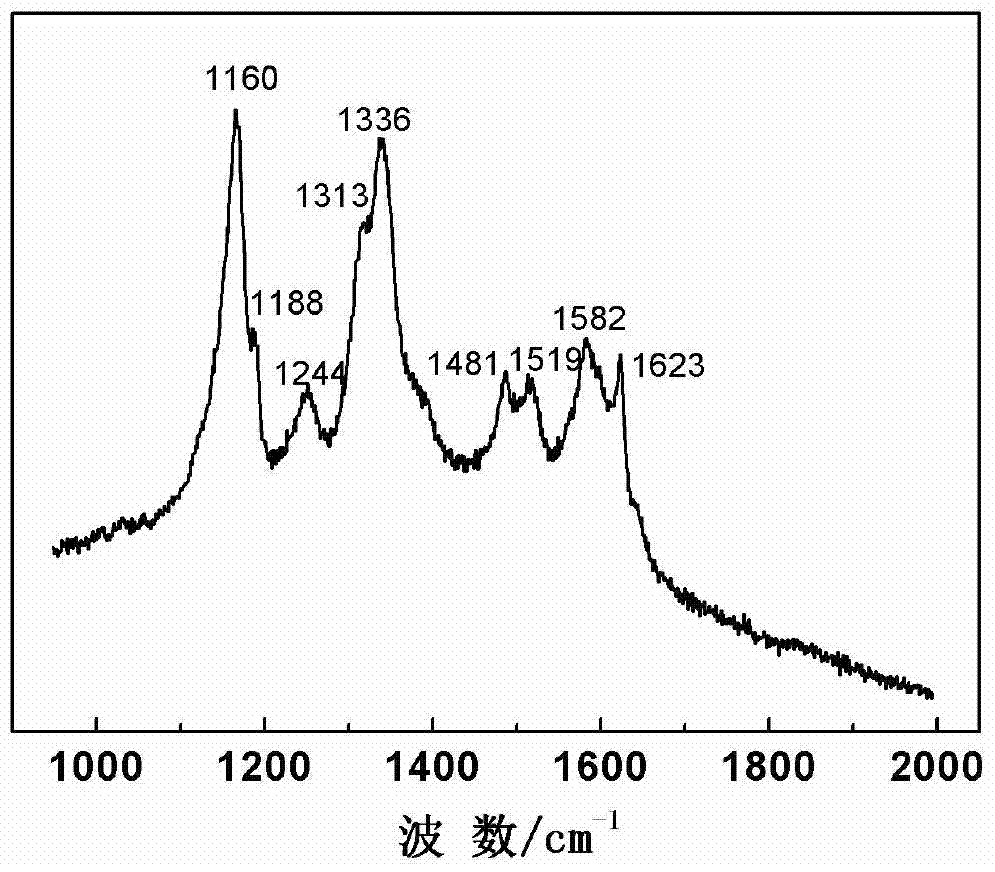

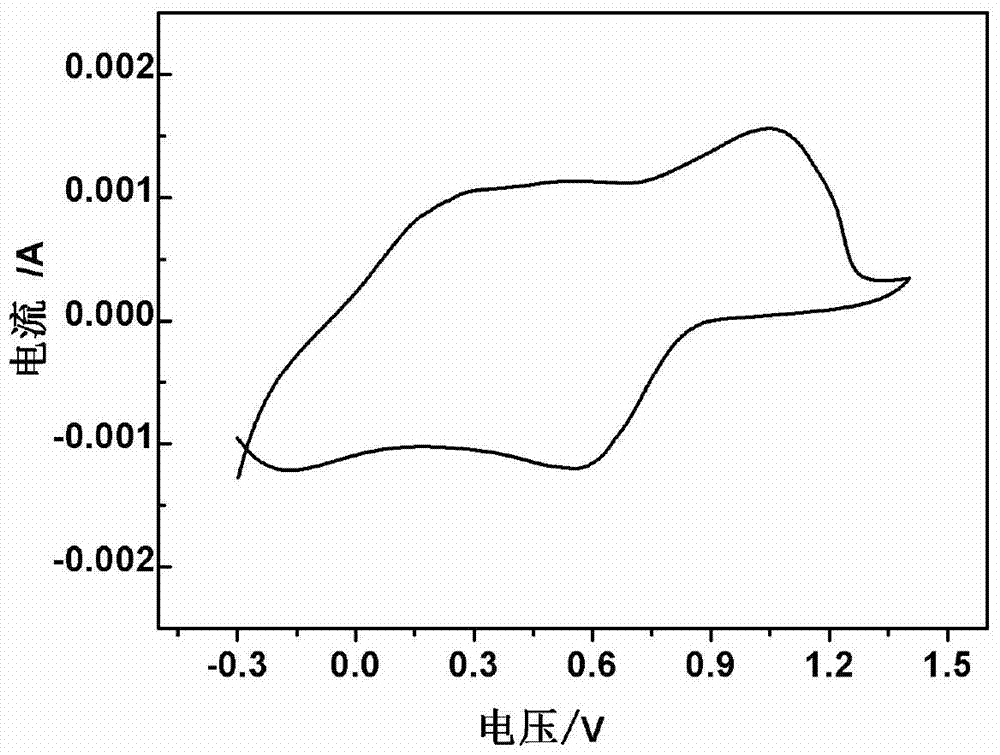

An electrochromic and polyaniline technology, which is applied in the synthesis of polymer materials and materials, can solve the limitations of electrochromic and display device applications, the poor bonding strength of polyaniline and conductive glass, and the difficulty of large-scale production of polyaniline electrode areas, etc. problems, to achieve the effect of low preparation cost, excellent electrochromic performance and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

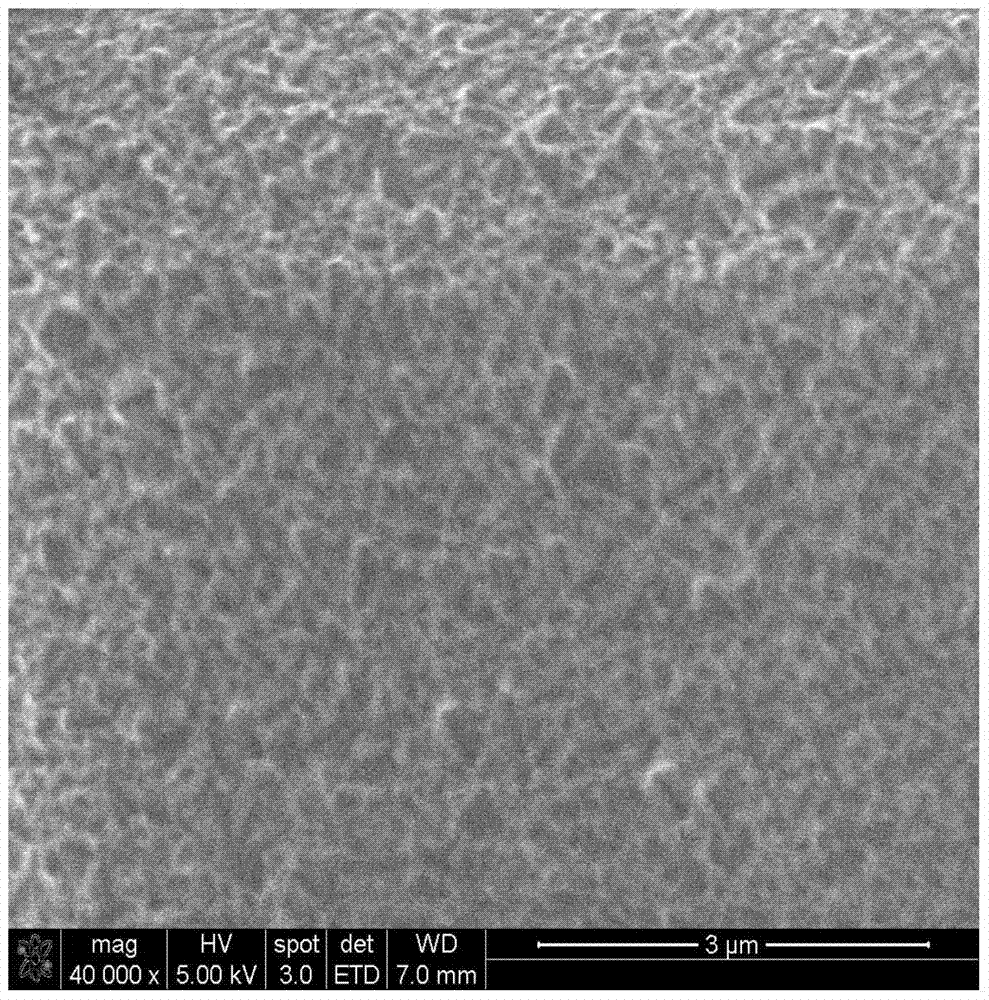

[0029] The growth of polyaniline film on the surface of FTO glass by hydrothermal method includes the following steps:

[0030] 1) Hydroxylation treatment of FTO glass, ultrasonic cleaning of FTO glass with acetone, absolute ethanol and deionized water in sequence, and the cleaning time is 40-60 minutes.

[0031] 2) Immerse the cleaned FTO glass in a mixture of hydrogen peroxide and concentrated sulfuric acid with a volume ratio of 7:3, the heating temperature is 60-80°C, and the time is 12-24h. The hydroxylated FTO glass was rinsed several times with deionized water and treated with N 2 Air-dried for later use to obtain a surface hydroxylated FTO substrate.

[0032] 3) Add 0.7290 g of cetyl trimethyl ammonium bromide to 76 mL of deionized water, leave it to stand until the solution becomes clear and transparent, place the solution in an ice-water bath and stir for 2 minutes, and then dropwise add 0.2 mL of the solution under reduced pressure. After the distilled aniline, 4 ...

Embodiment 2

[0040] 1) Same as Example 1.

[0041] 2) Same as Example 1.

[0042] 3) Add 0.730 g of cetyl trimethyl ammonium bromide to 76 mL of deionized water, leave it to stand until the solution becomes clear and transparent, place the solution in an ice-water bath and stir for 2 minutes, and then dropwise add 0.2 mL of the solution under reduced pressure. After the distilled aniline, 4 mL of dodecylbenzenesulfonic acid was added after the aniline was uniformly dispersed, and after stirring for about 20 minutes, the solution became a uniform milky white, and then 4 mL of ammonium persulfate solution with a concentration of 0.24 mol / L was added and stirred for 5 minutes.

[0043] 4) The conductive surface of the hydroxylated FTO glass is tilted downward and put into the stainless steel reactor lined with PTFE, and then the above-mentioned mixed solution is transferred into the 50ml reactor, and the volume of the reaction solution does not exceed 2 / 2 of the entire reactor. 3. Hydrothermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com