Patents

Literature

130results about How to "High color contrast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display apparatus of adjusting gamma and brightness based on ambient light and its display adjustment method

InactiveUS20090237423A1Enhance colour contrastHigh color contrastCathode-ray tube indicatorsInput/output processes for data processingColor temperatureStorage cell

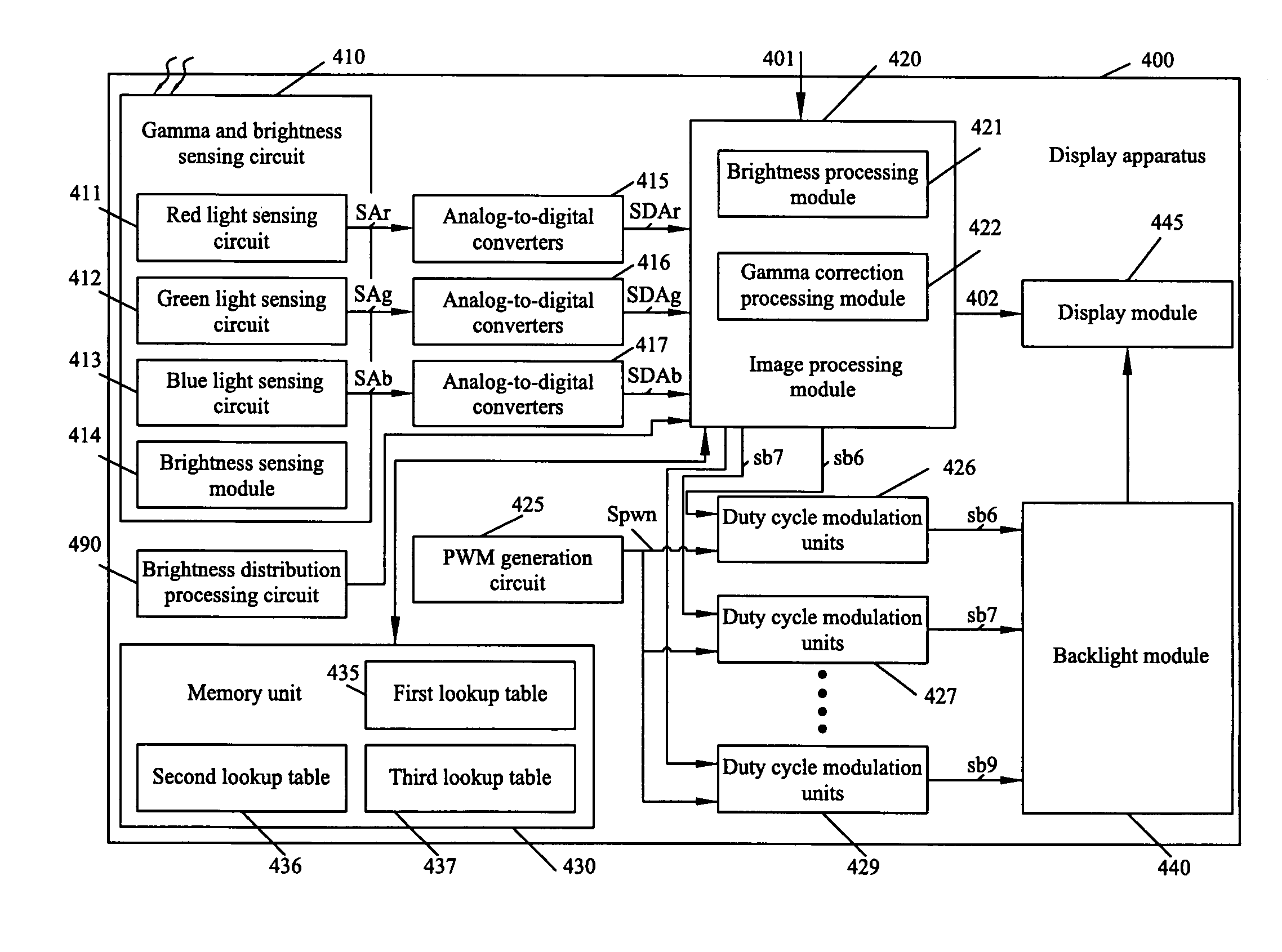

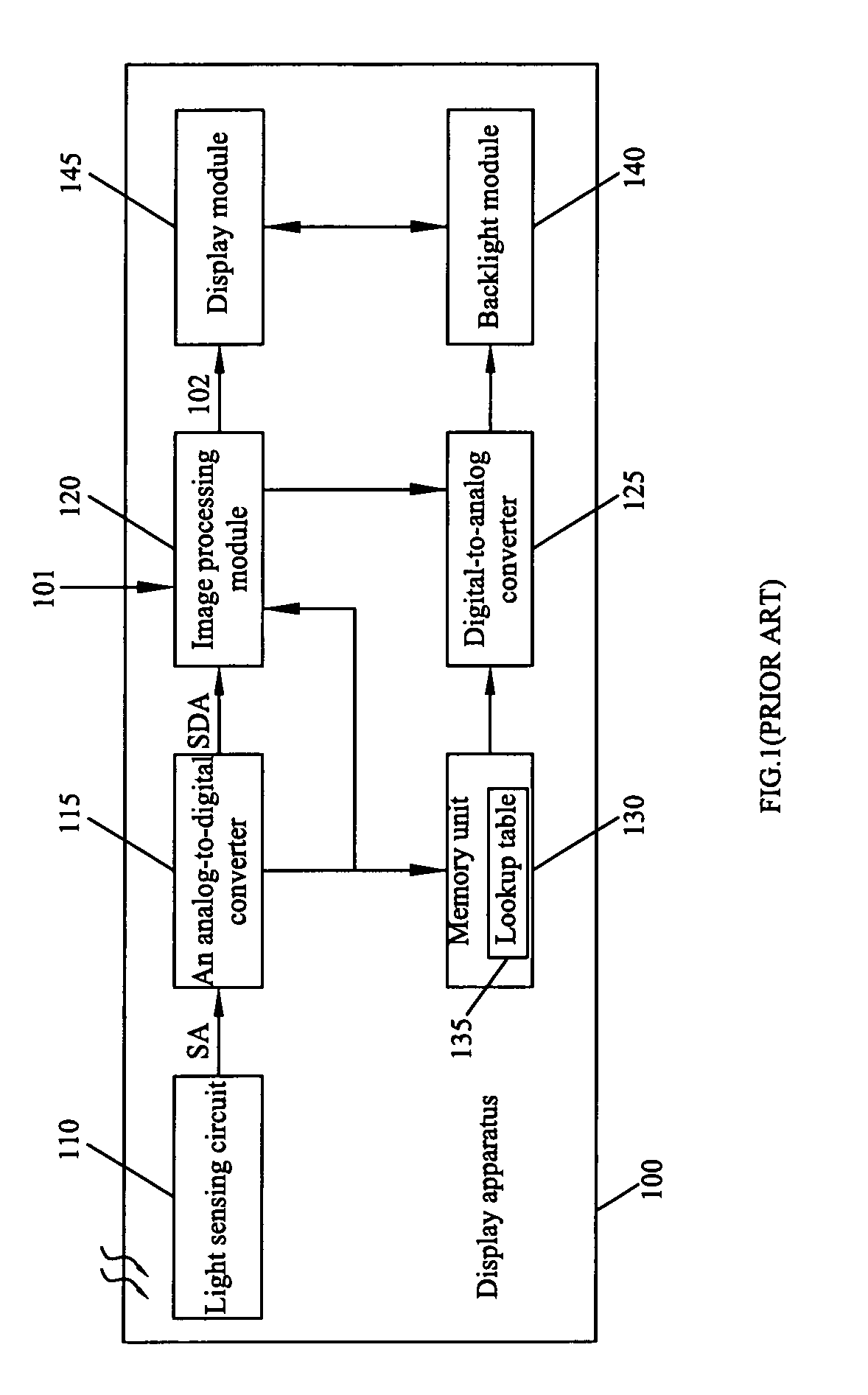

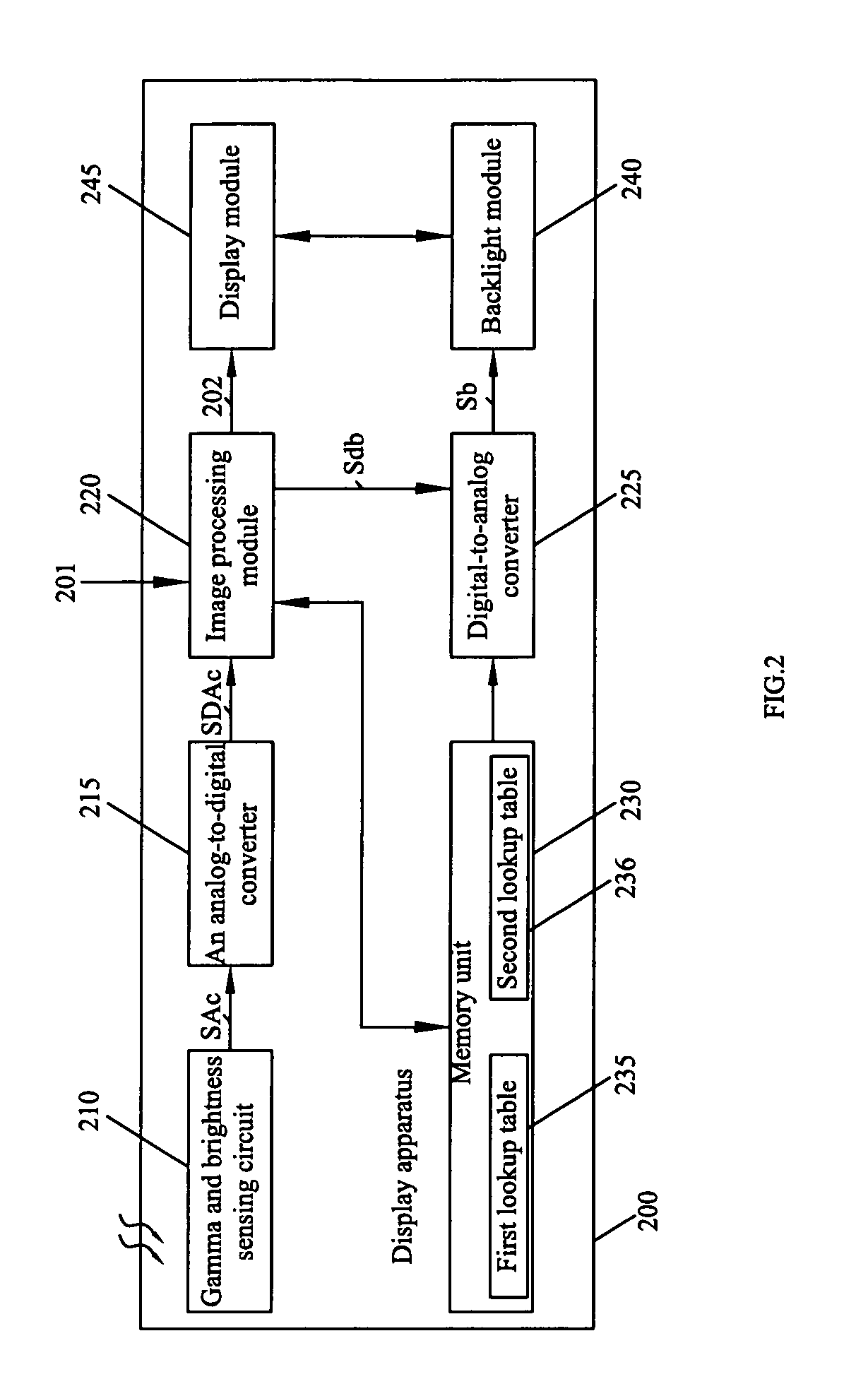

This invention discloses a display apparatus capable of adjusting gamma and brightness based on ambient light and its display adjustment method. The display apparatus is adjusted to display an image output signal based on an image input signal and the correlated color temperature and brightness of an ambient light. The display apparatus includes a plurality of light sensing circuits, a memory unit, an image processing module, and a display module. The light sensing circuit senses the ambient light to produce a digital ambient color temperature index value. The memory unit stores a lookup table of brightness expression rates and gamma adjustment parameters corresponding to different color temperature index values. The image processing module produces a gamma adjustment parameter by a lookup table based on the color temperature index value and generates the gamma expression rate of the image input signal. The image processing module adjusts the image input signal to generate the image output signal based on the gamma adjustment parameter. The display module displays the image output signal.

Owner:CAPELLA MICROSYSTEMS (TAIWAN) INC

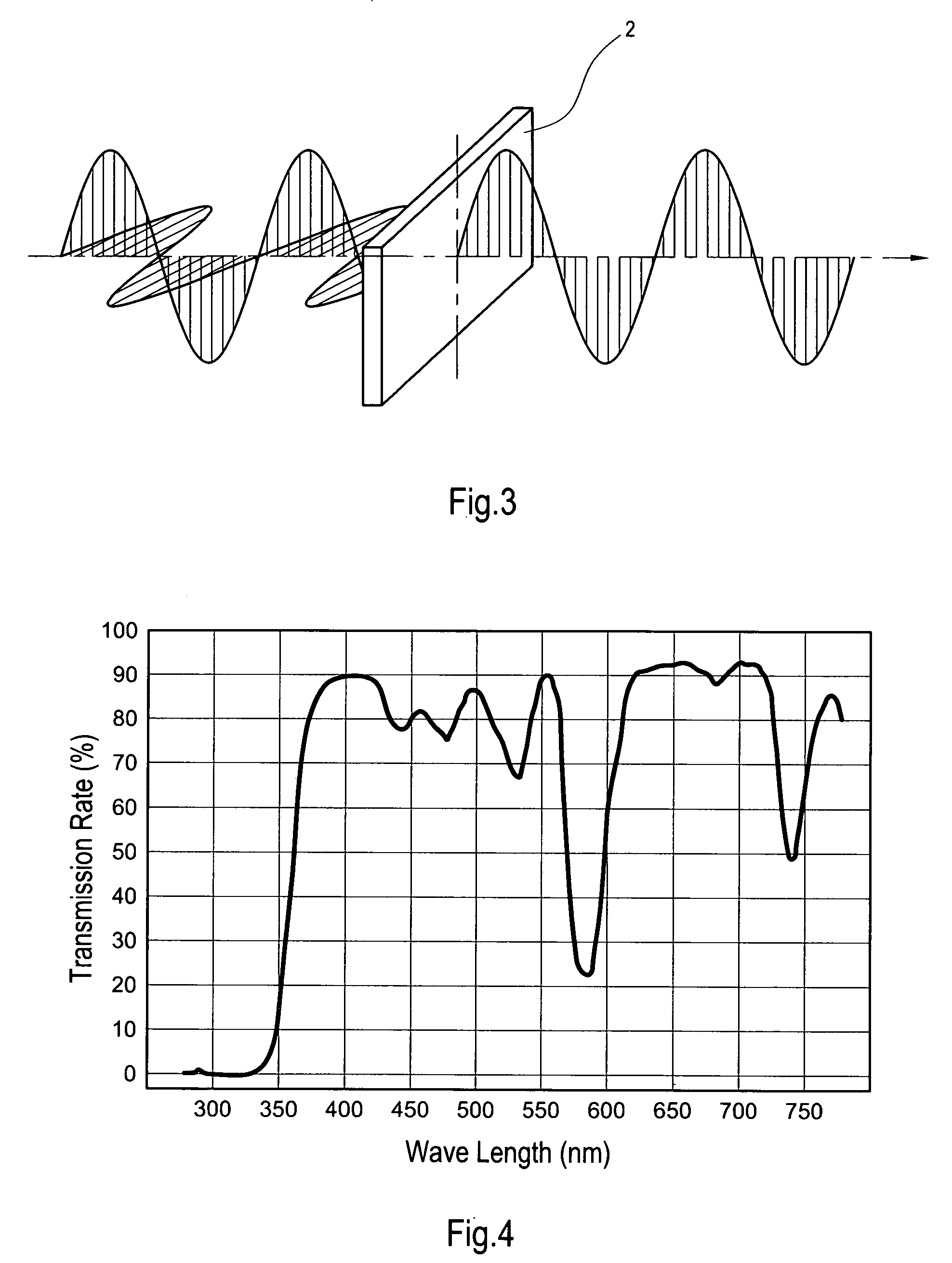

Optical system for increasing contrast of object viewed through it

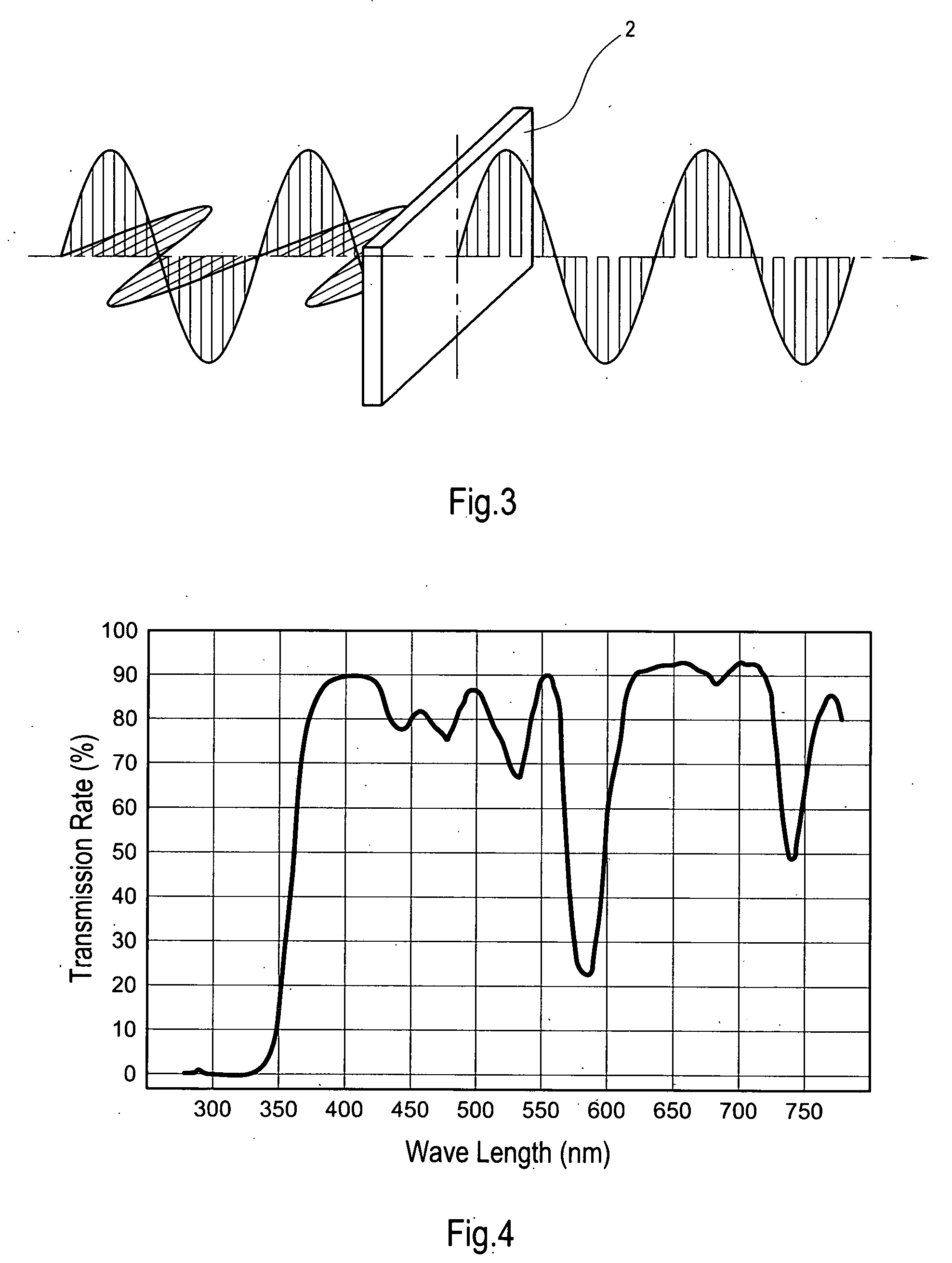

InactiveUS20010005281A1Increase contrastHigh color contrastPolarising elementsTelescopesTransmittancePolarizer

An optical system for providing a viewer with contrast between a golf ball and its environment, including a light filter and at least one polarizer mounted in a viewing device. The light filter has no more than about 20% transmittance of light in one of the range of wavelengths of from about 500 nm to about 700 nm. The viewing device allows for the light filter and the polarizer to be arranged in front of at least one eye of the viewer. The optical system can be provided in a spotting scope, a pair of eyeglasses or an attachment to eyeglasses for ease of use.

Owner:YU CAROLINE

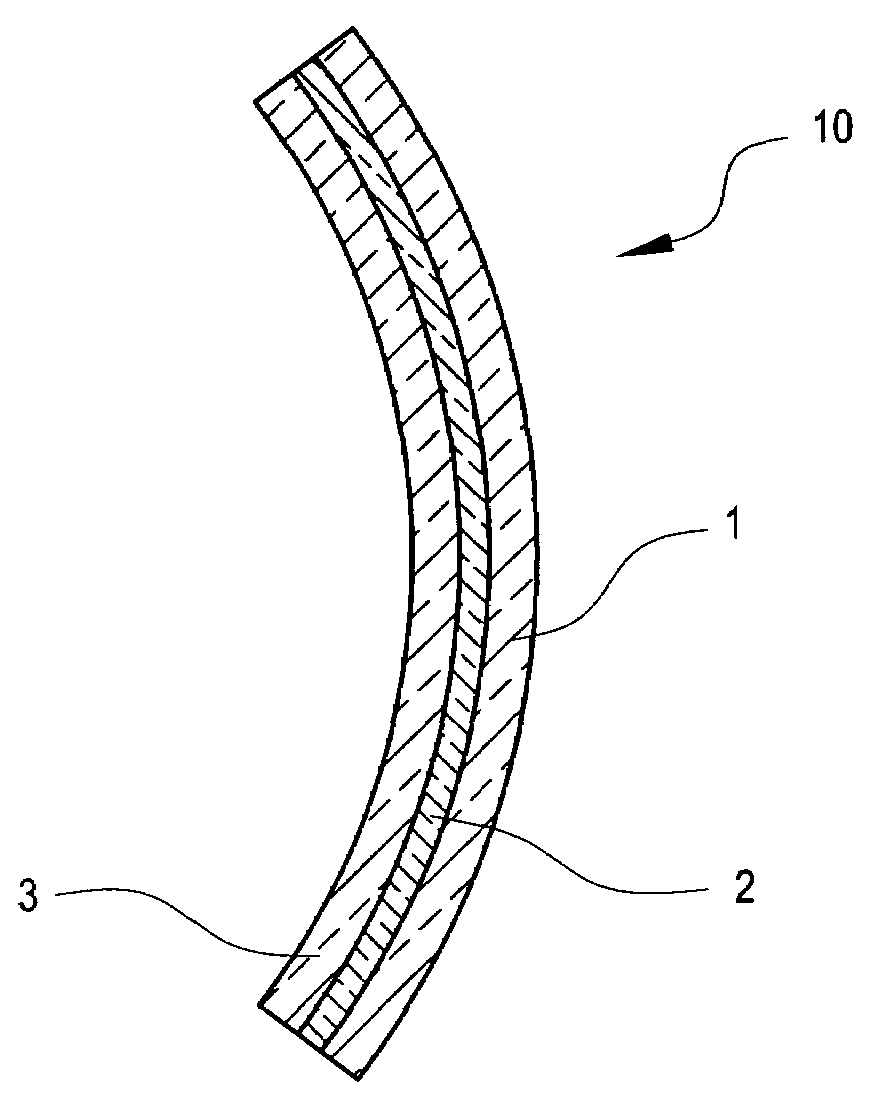

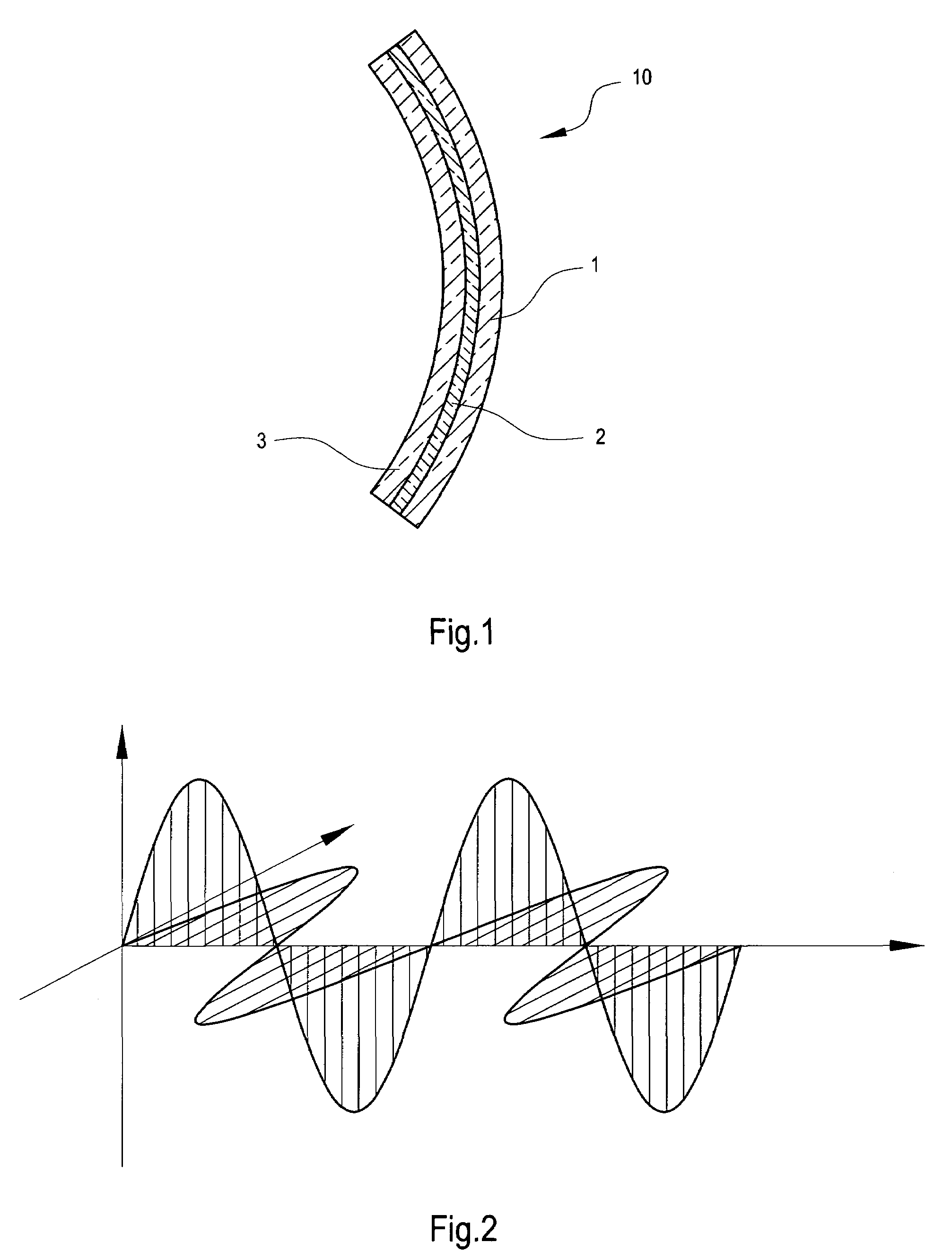

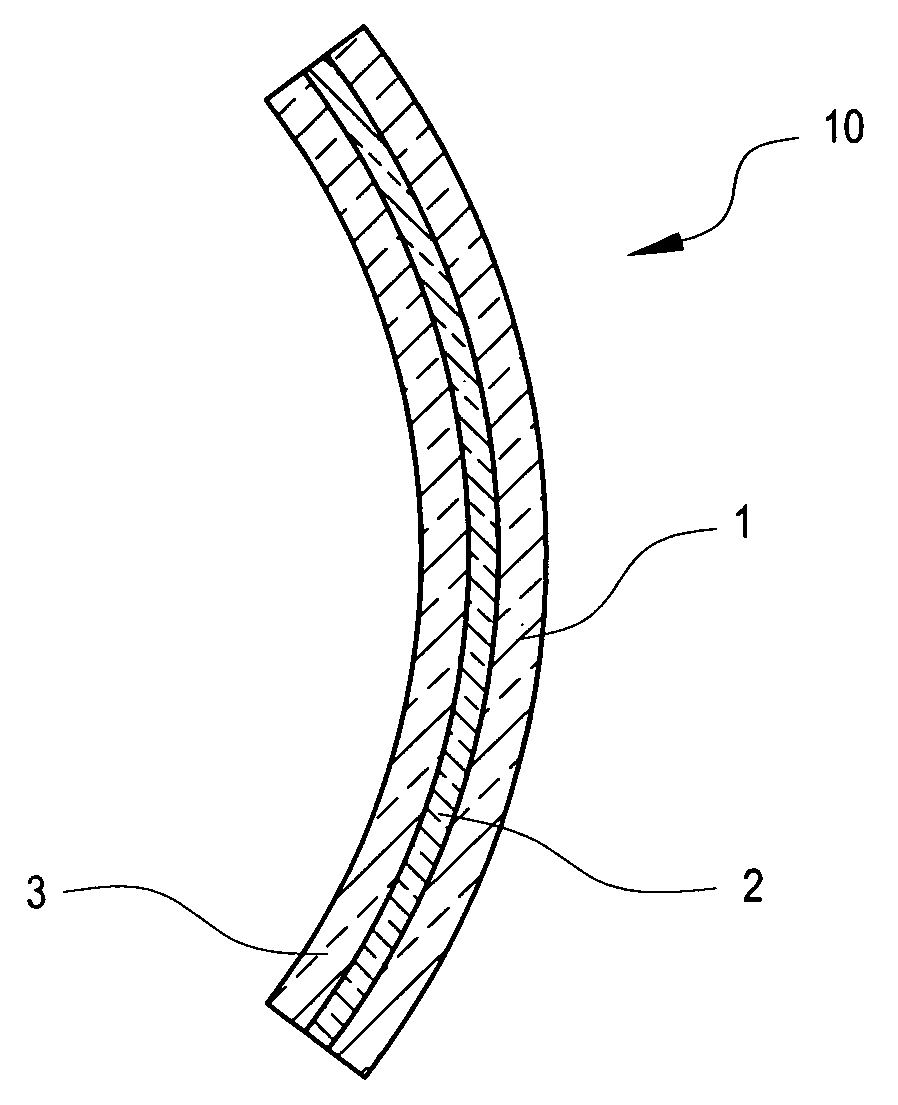

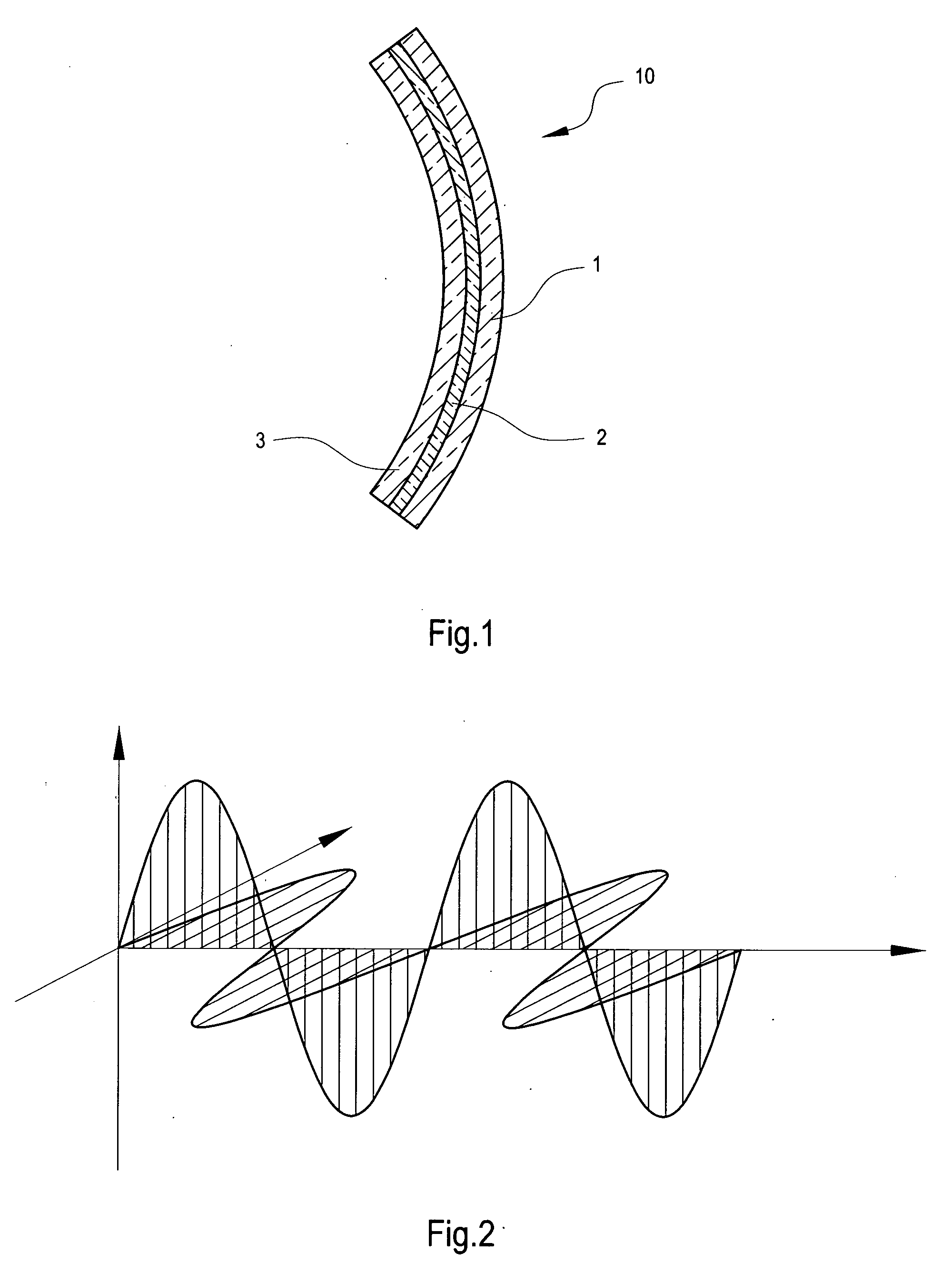

Enhanced color contrast lens

InactiveUS7372640B2Increase contrastAdvanced technologySpectales/gogglesMountingsCamera lensConfocal

A color contrast enhancing lens made from adhering two different lenses and a membrane together. It includes a color enhancing lens whose specific component will selectively absorb the yellow light in the visible spectrum, which enhances the user vision by enhancing the distinction between red and green. It also includes an ultraviolet blocking lens whose special compounds will absorb the majority of violet light and a part of blue light. It also includes a light polarization membrane whose special structure can reduce strong light. It can also absorb the majority of violet light and keep a low transmission rate of blue light, thus reduced the retina injury caused by overexposure to blue light. It can also block the invisible ultraviolet and reduce strong light. So while the users' eyes are protected, they can also enjoy their view.

Owner:EASY POWER

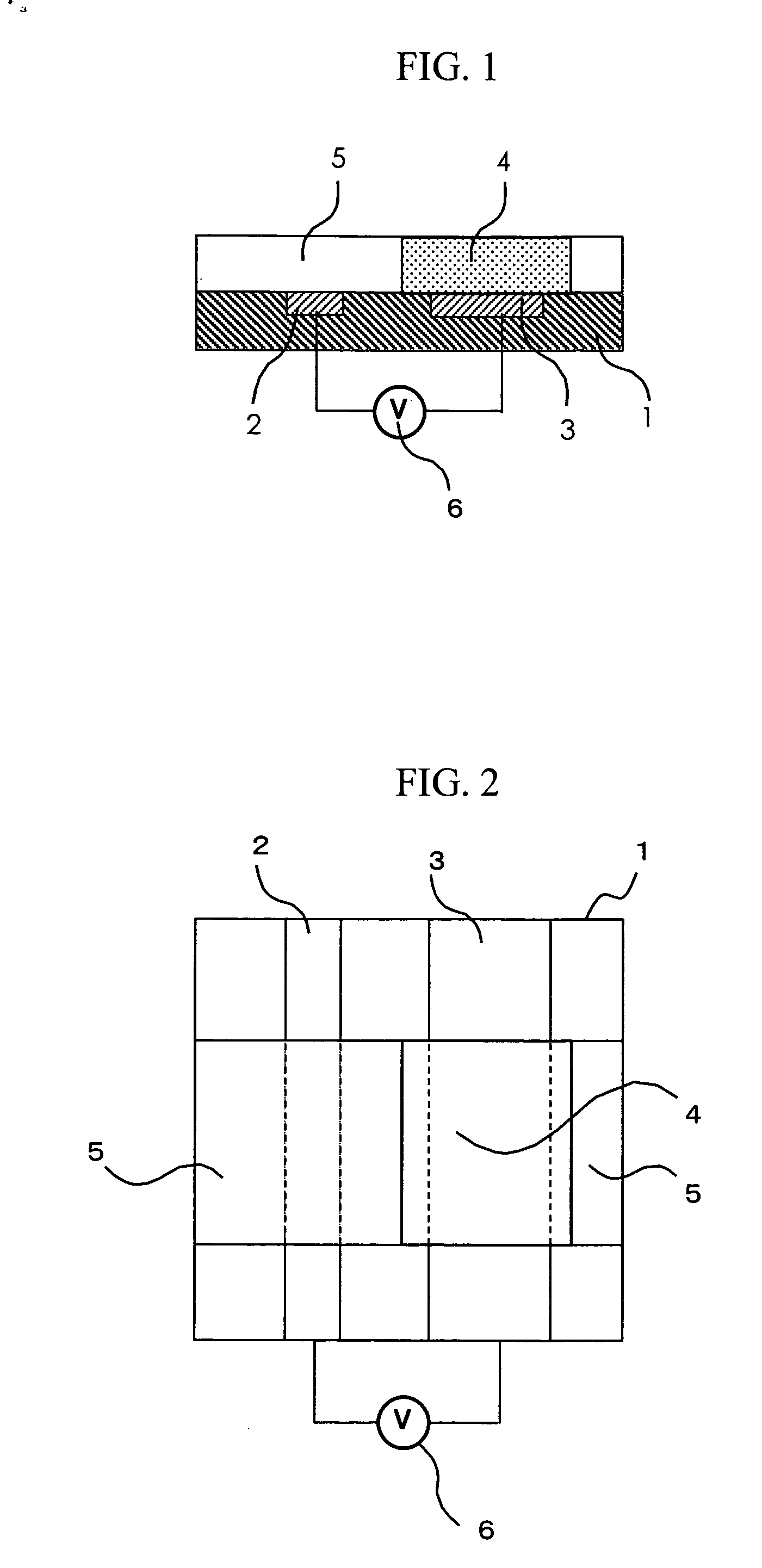

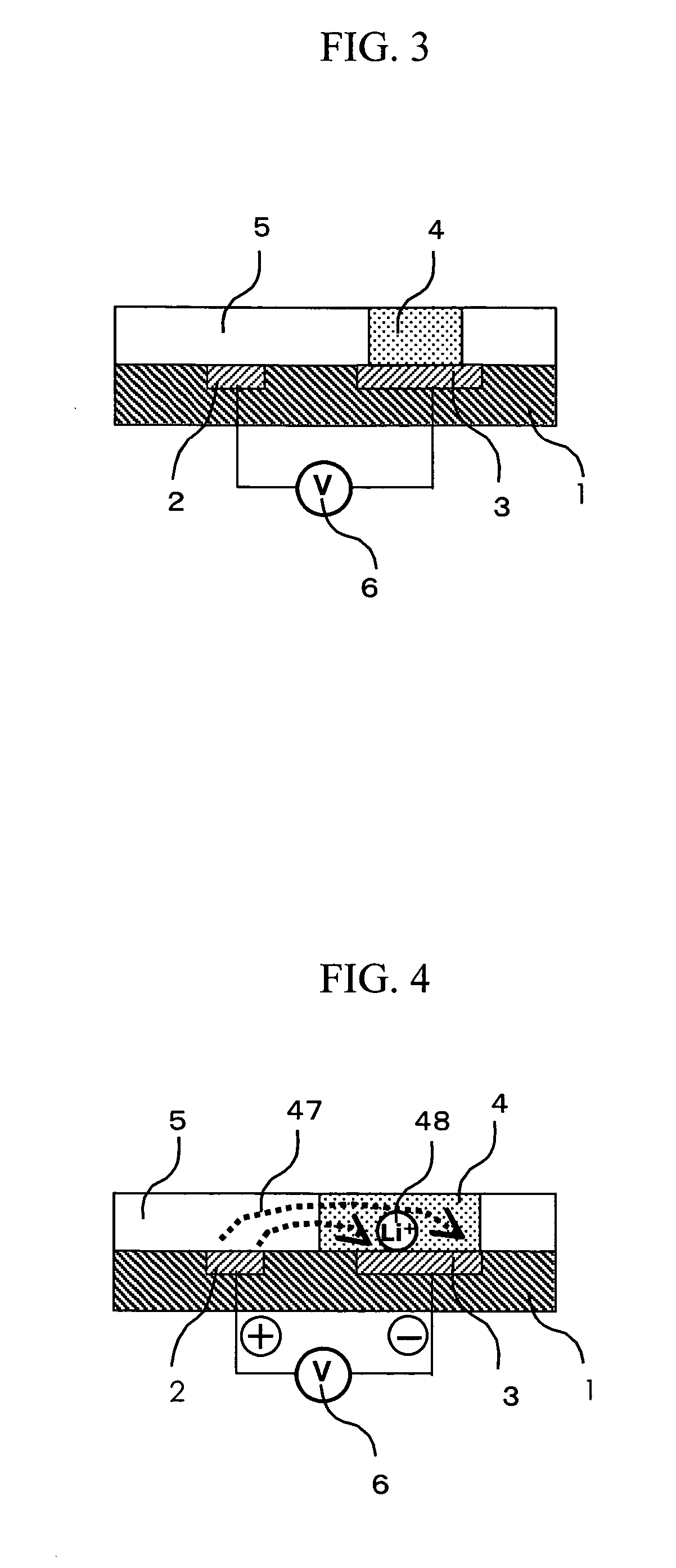

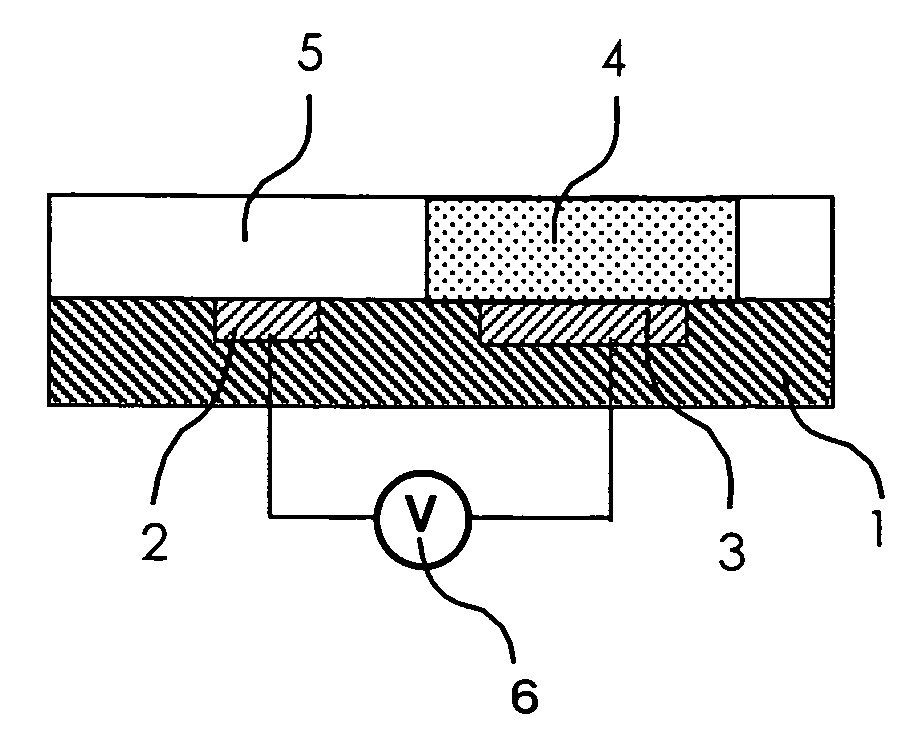

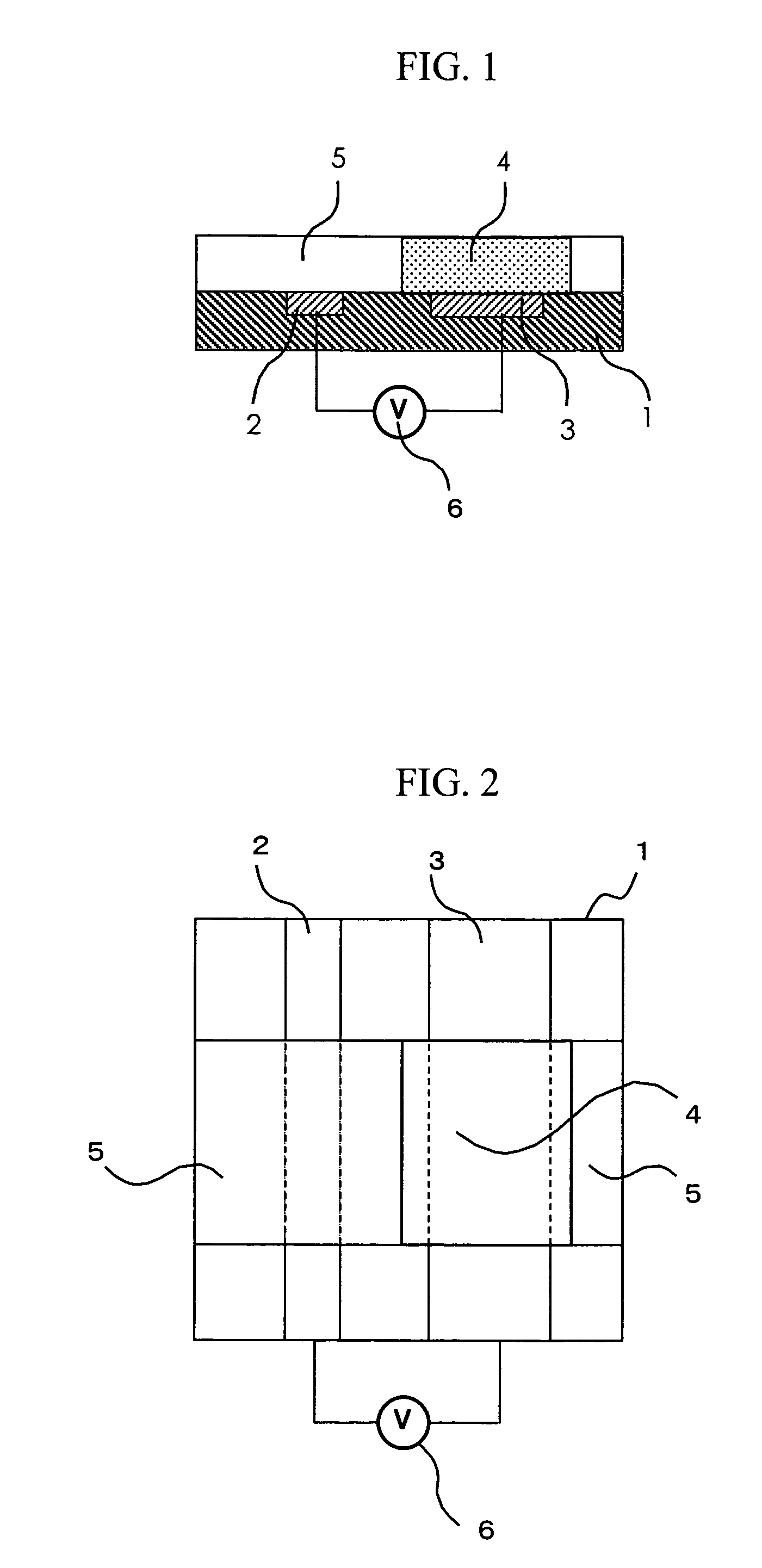

Electrochromic device

This invention provides an electrochromic device which has superior coloration repeat properties, high light transmittance and small thickness. A film is provided comprising a first electrode and second electrode in the same plane, and an electrochromic region and electrolyte region laminated in this plane. The electrochromic region is provided on the second electrode, the electrolyte region is provided on the first electrode, and the boundary between the electrochromic region and electrolyte region lies in the planar direction of the film.

Owner:HITACHI LTD

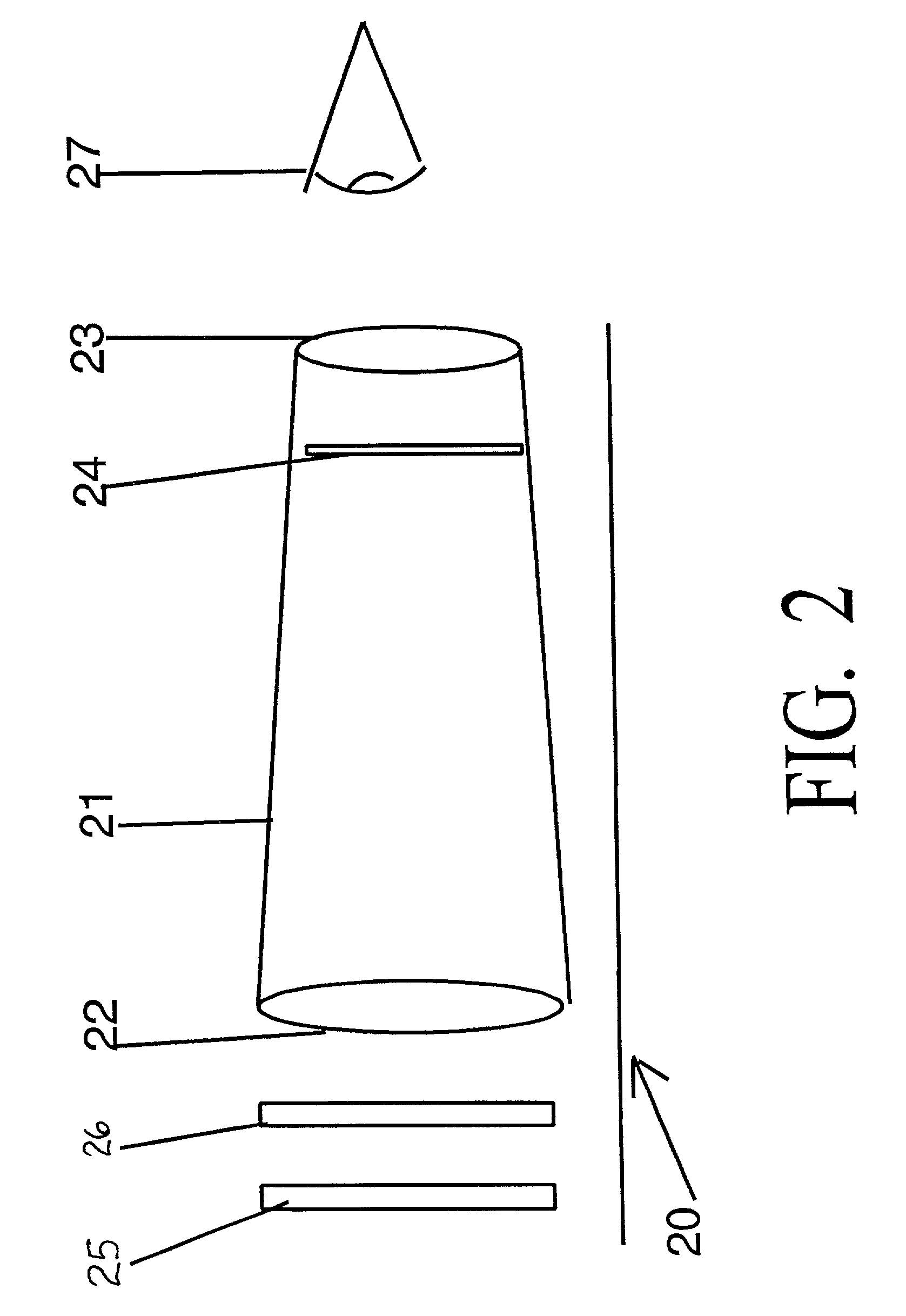

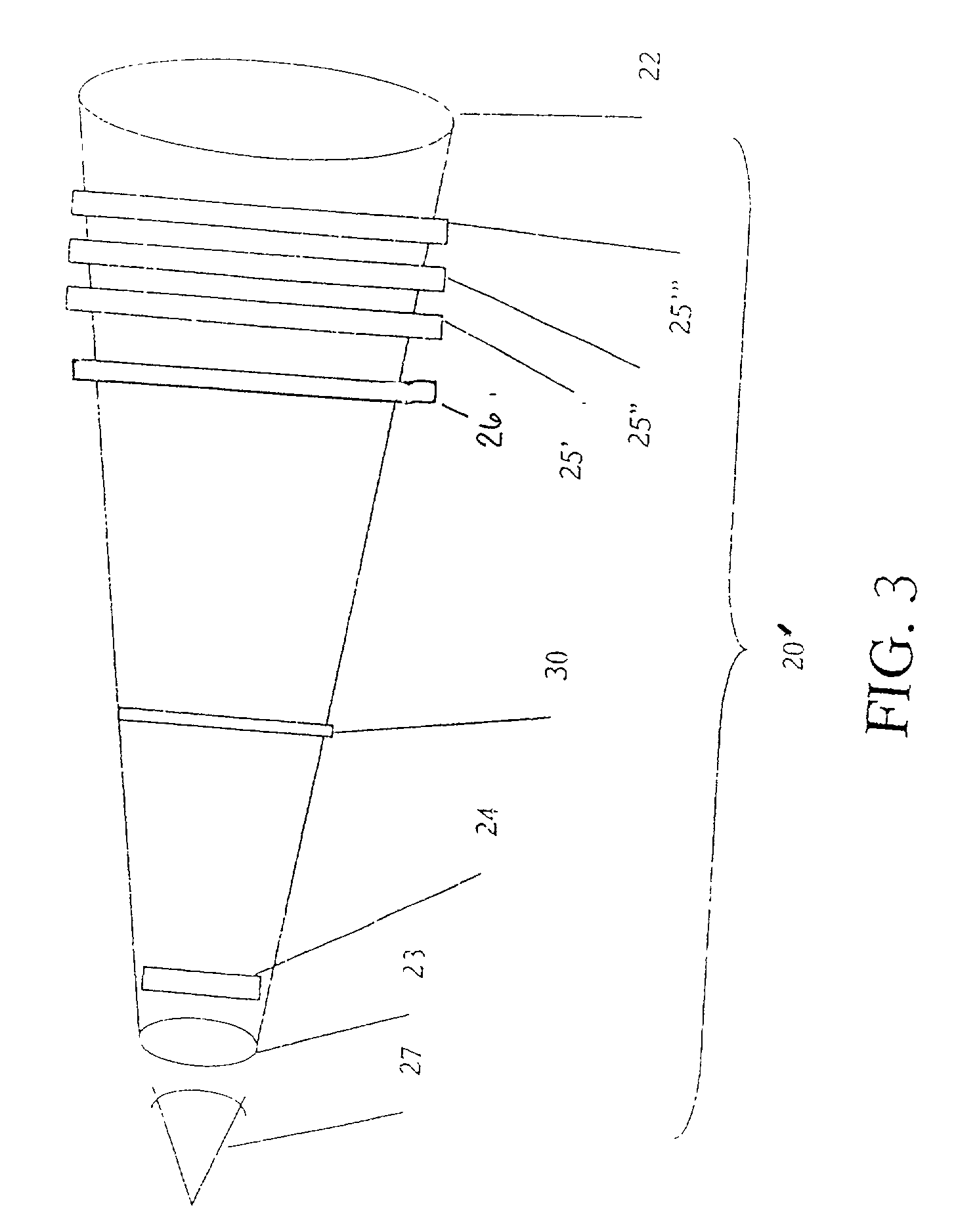

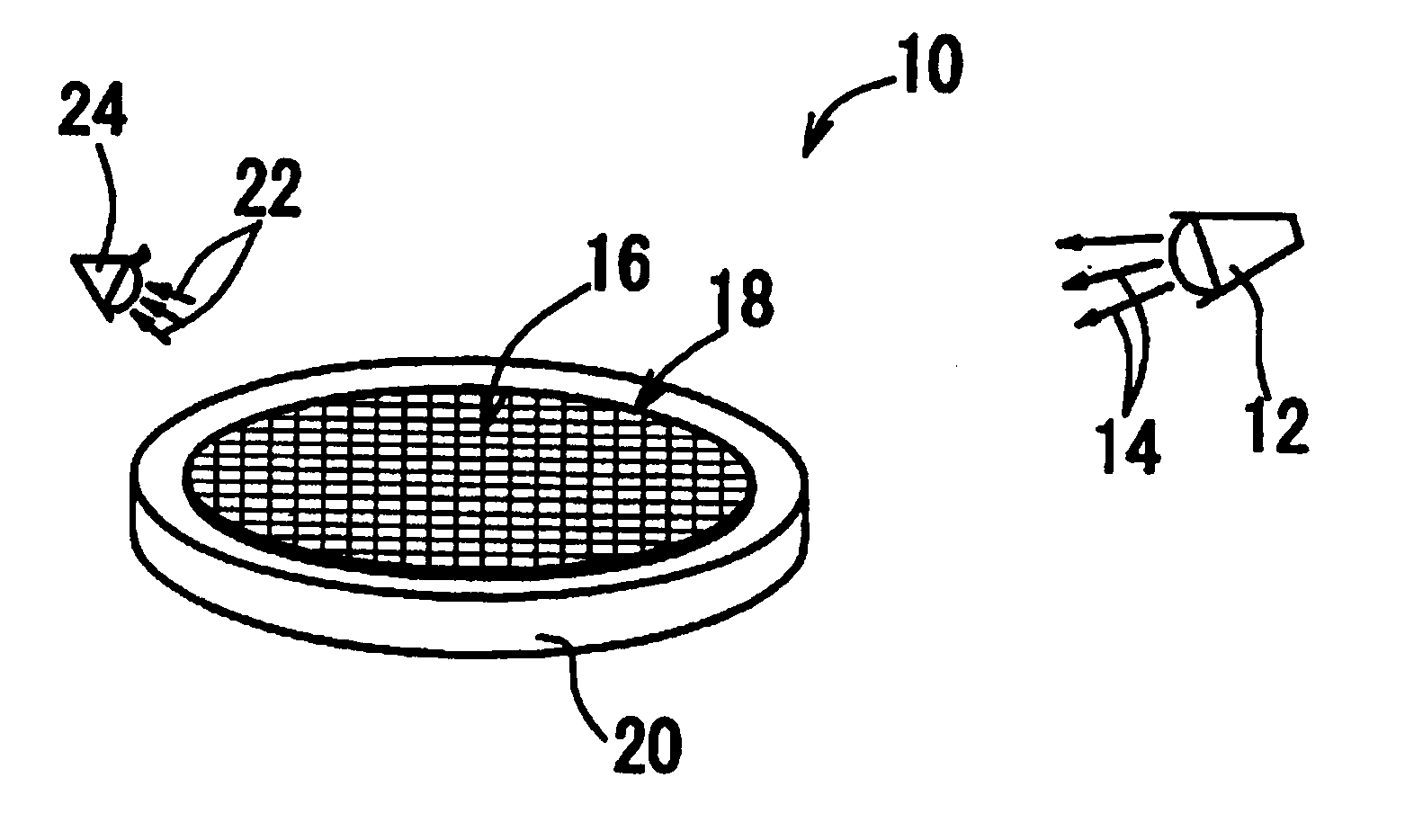

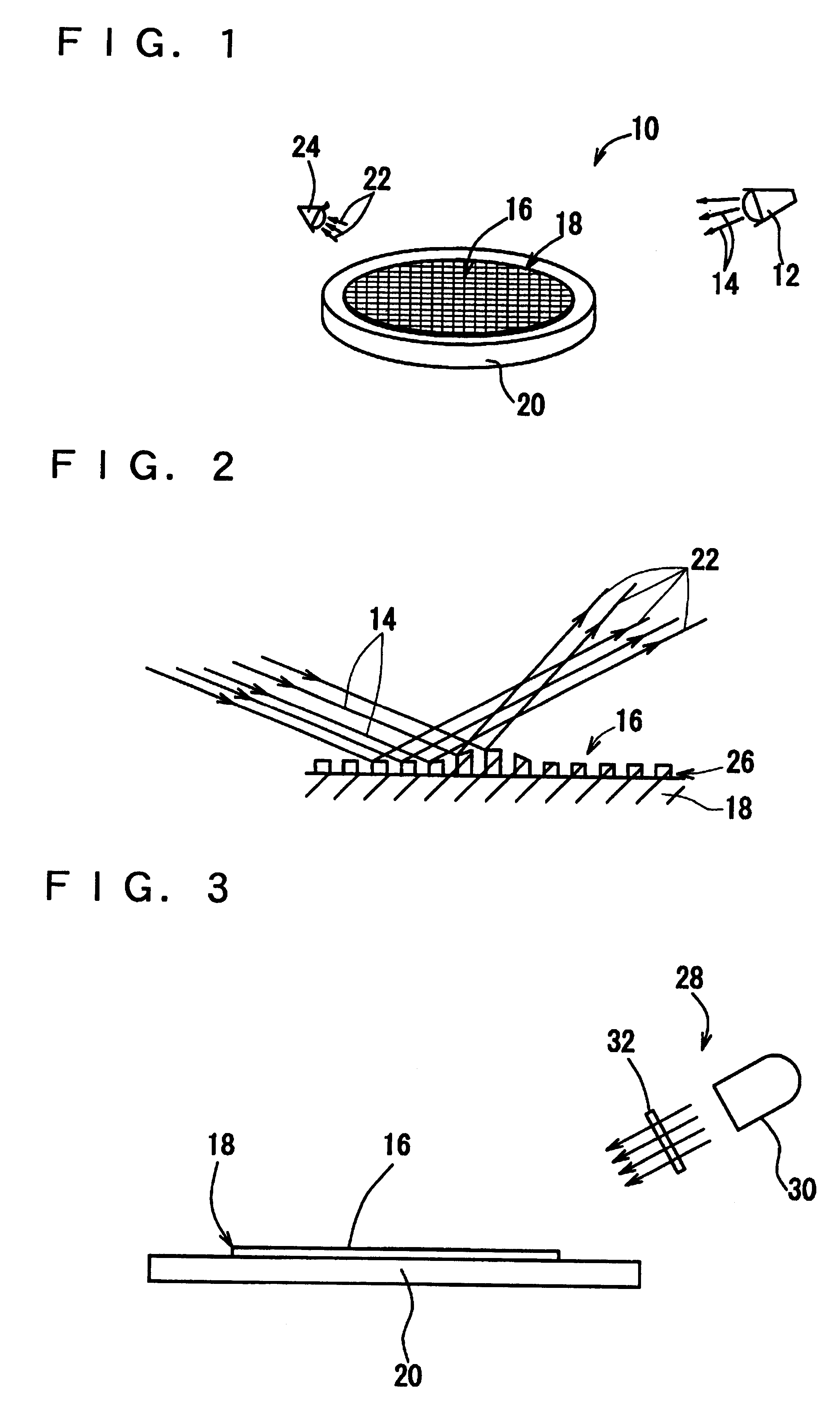

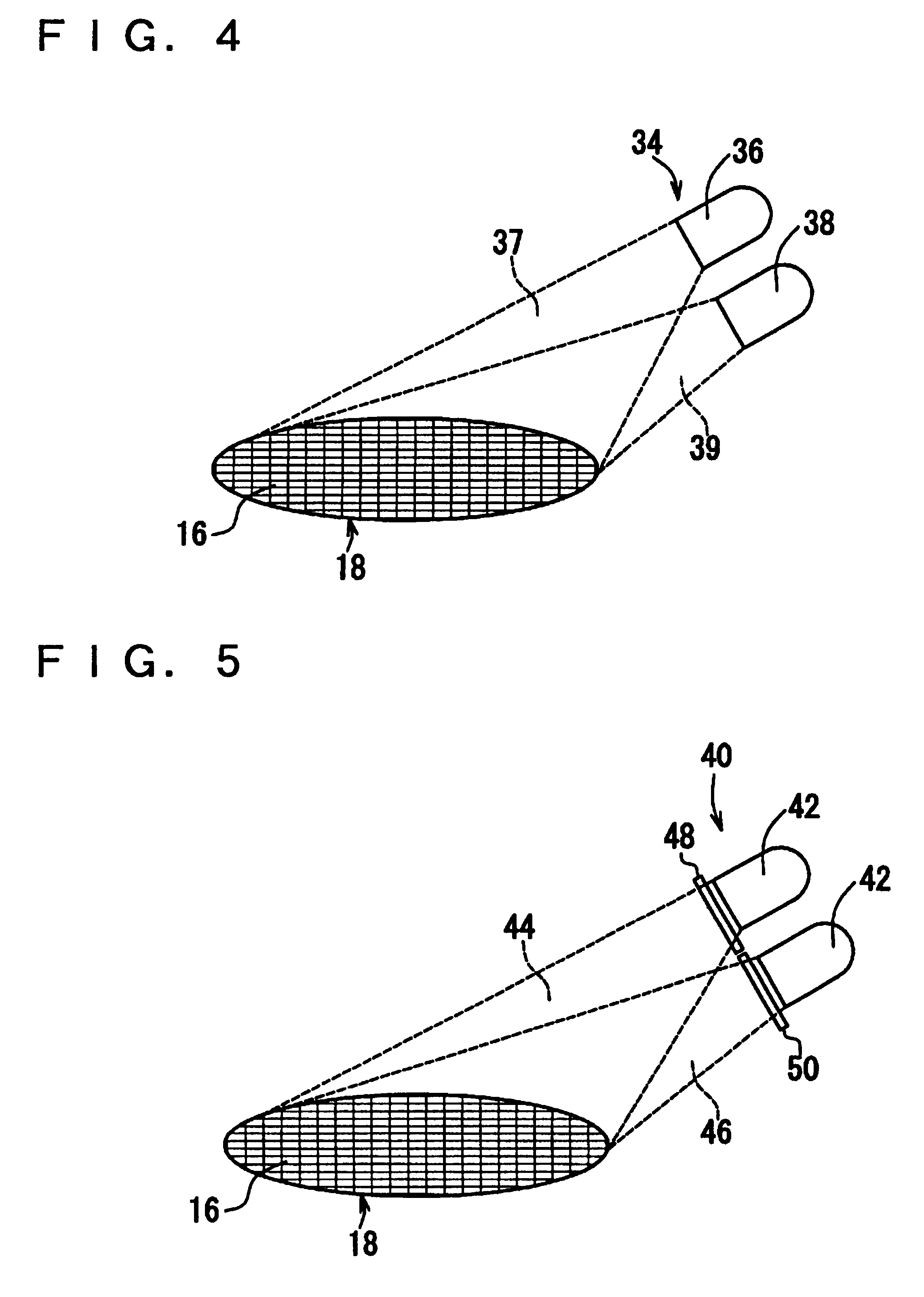

Illuminator for macro inspection, macro inspecting apparatus and macro inspecting method

InactiveUS6452671B1Sharp contrastHigh color contrastSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAcousticsComplementary colors

The inspecting apparatus according to the present invention includes an illuminator for emitting radiation onto a substrate having a surface on which a fine feature pattern is formed. Inspection for defects in the pattern is performed by visually inspecting radiation diffracted by the surface. The illuminator provides radiation including two different complementary colors.

Owner:IBM CORP

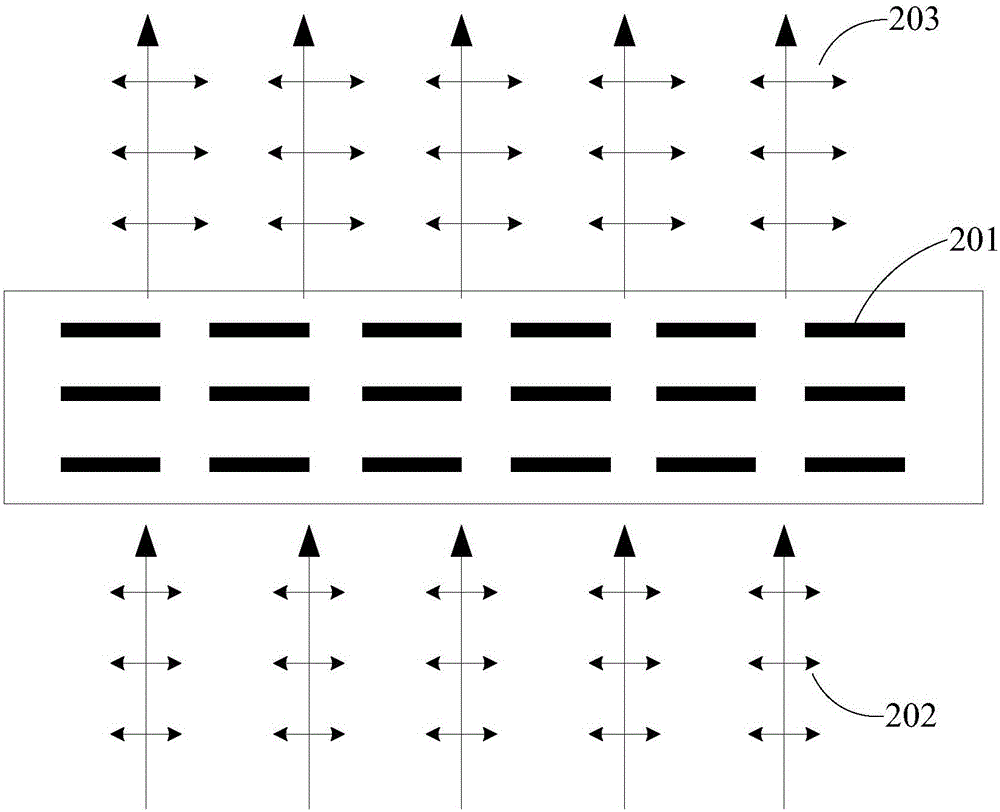

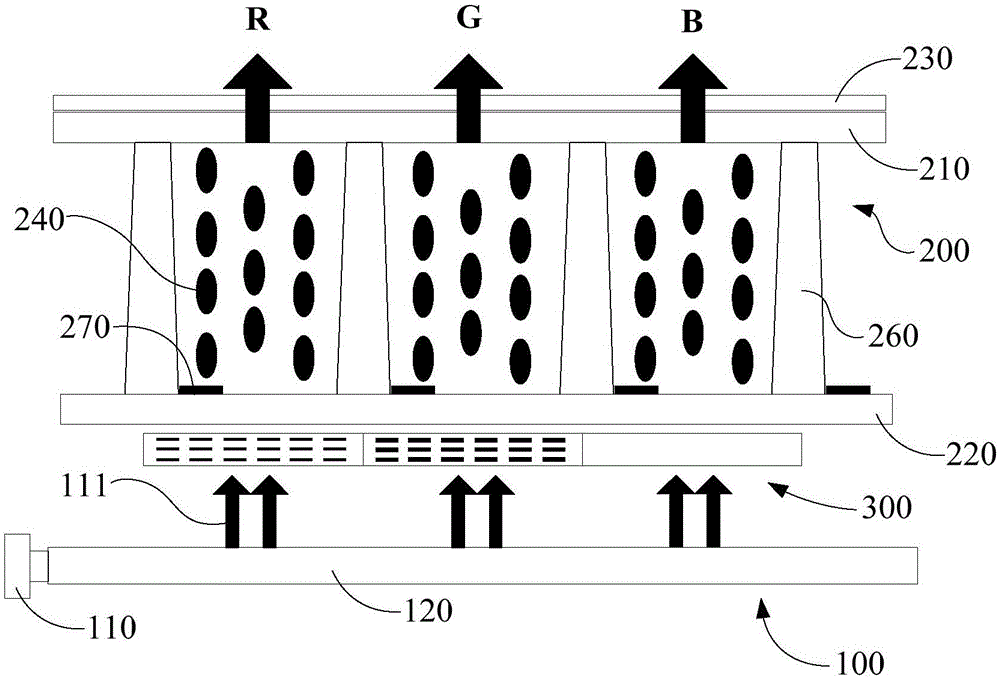

Liquid crystal display and liquid crystal display module thereof

The invention provides a liquid crystal display and a liquid crystal display module thereof. The liquid crystal display module comprises a backlight unit, a liquid crystal display panel and a quantum rod membrane arranged between the backlight unit and the liquid crystal display panel. The liquid crystal display panel comprises an upper substrate, a lower substrate and an upper polaroid. The portion between the upper substrate and the lower substrate is filled with liquid crystals. The upper polaroid is arranged on the outer side of the upper substrate, namely the light-emitting side of the liquid crystal display panel. The quantum rod membrane is specifically arranged between the lower substrate and the backlight unit. Due to the fact that a quantum rod capable of transmitting polarized light is adopted for the liquid crystal display module to replace a traditional color filter or a prism film assembly and a lower polaroid, the purposes of high color contrast, high colour saturation, low power consumption and the low cost of the liquid crystal display are achieved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Process for preparing a flexographic printing plate from a photopolymerizable element

InactiveUS20060160025A1High color contrastSufficient color contrastPhotosensitive materialsSemiconductor/solid-state device manufacturingLeuco dyeEngineering

This invention relates to a photosensitive element for use as a flexographic printing plate and a process for preparing the plate from the element. The photosensitive element has at least one photopolymerizable elastomeric layer that comprises a binder, a monomer, a photoinitiator, an onium salt, and a leuco dye. Upon exposure to actinic radiation, the onium salt and leuco dye react resulting in a change of color in polymerized portions of the photopolymerizable layer. The color change provides enhanced image color contrast in the photosensitive element.

Owner:DUPONT ELECTRONICS INC

Enhanced color contrast lens

InactiveUS20070171537A1Enhance color contrastAdvanced technologySpectales/gogglesMountingsViolet lightPhysics

A color contrast enhancing lens made from adhering two different lenses and a membrane together. It includes a color enhancing lens whose specific component will selectively absorb the yellow light in the visible spectrum, which enhances the user vision by enhancing the distinction between red and green. It also includes an ultraviolet blocking lens whose special compounds will absorb the majority of violet light and a part of blue light. It also includes a light polarization membrane whose special structure can reduce strong light. After the lens is formed by using adhesive, it can selectively absorb the yellow light in the visible spectrum, which enhances the user vision by enhancing the distinction between red and green. It can also absorb the majority of violet light and keep a low transmittance of blue light, thus reduced the retina injury caused by overexposure to blue light. It can also block the invisible ultraviolet and reduce strong light. So while the users' eyes are protected, they can also enjoy their view.

Owner:EASY POWER

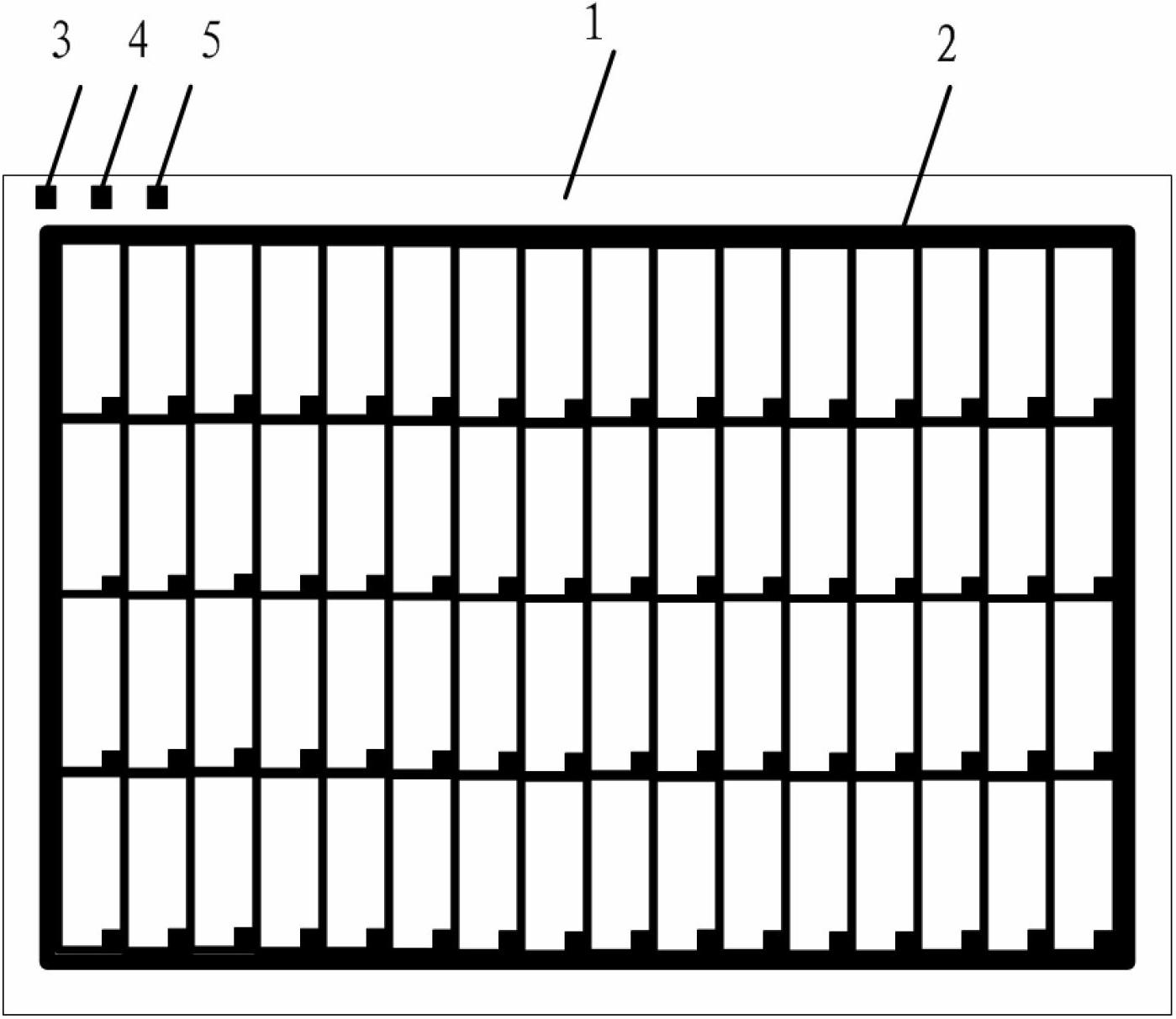

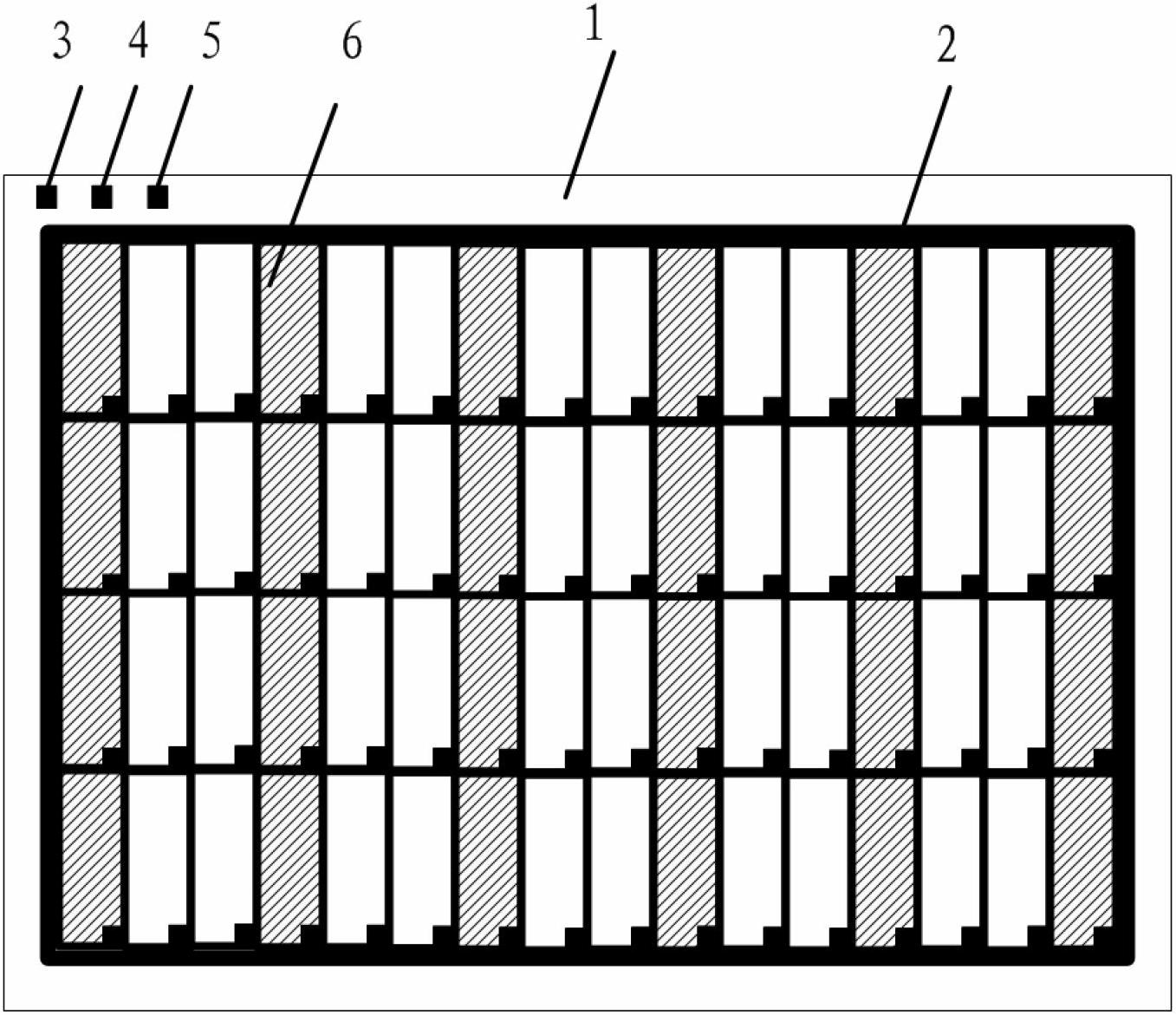

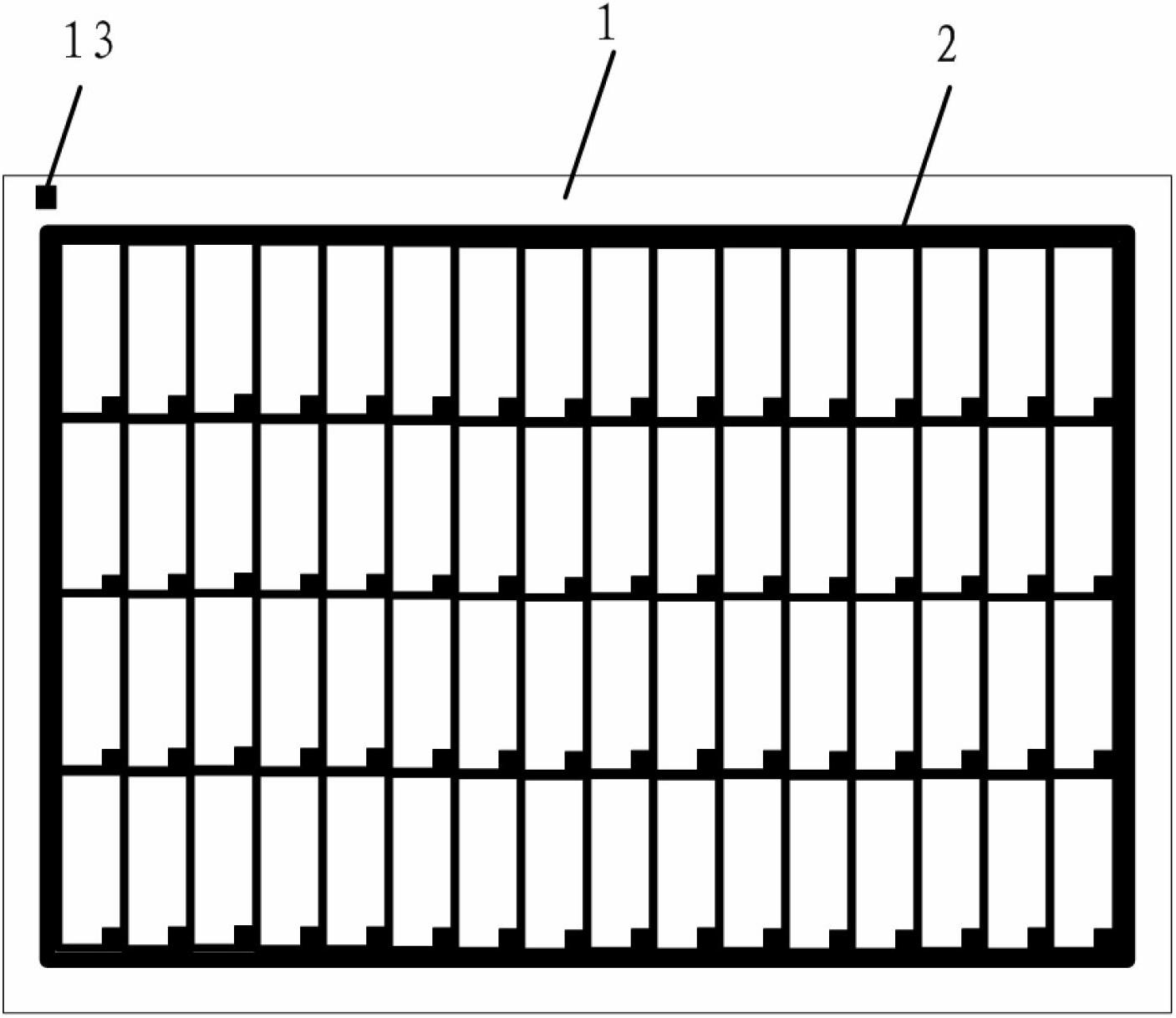

Color filter, manufacturing method thereof, liquid crystal panel and display device

ActiveCN102681251AEasy to identifyImprove yield rateOptical filtersNon-linear opticsDisplay deviceEngineering

The invention provides a manufacturing method of a color filter. The method comprises a step of forming a black matrix and a step of sequentially forming a first color filter layer, a second color filter layer and a third color filter layer, wherein the first color filter layer, the second color filter layer and the third color filter layer are formed in the black matrix respectively through a first color filter layer alignment mark, a second color filter layer alignment mark and a third color filter layer alignment mark; and in the step of forming the first color filter layer, the second color filter layer and the third color filter layer, the third color filter layer alignment mark is formed at the same time or after the first color filter layer is formed, and the first color filter layer alignment mark, the second color filter layer alignment mark and the third color filter layer alignment mark are not exactly same in color. According to manufacturing method of the color filter, the accuracy of alignment identification of exposure equipment in an exposure process in an exposure step is improved, and the occurrence of a phenomenon that the exposure equipment is difficult to acquire the third color filter layer alignment mark can be avoided, so that the production time is greatly saved, and the production cost is reduced.

Owner:BOE TECH GRP CO LTD +1

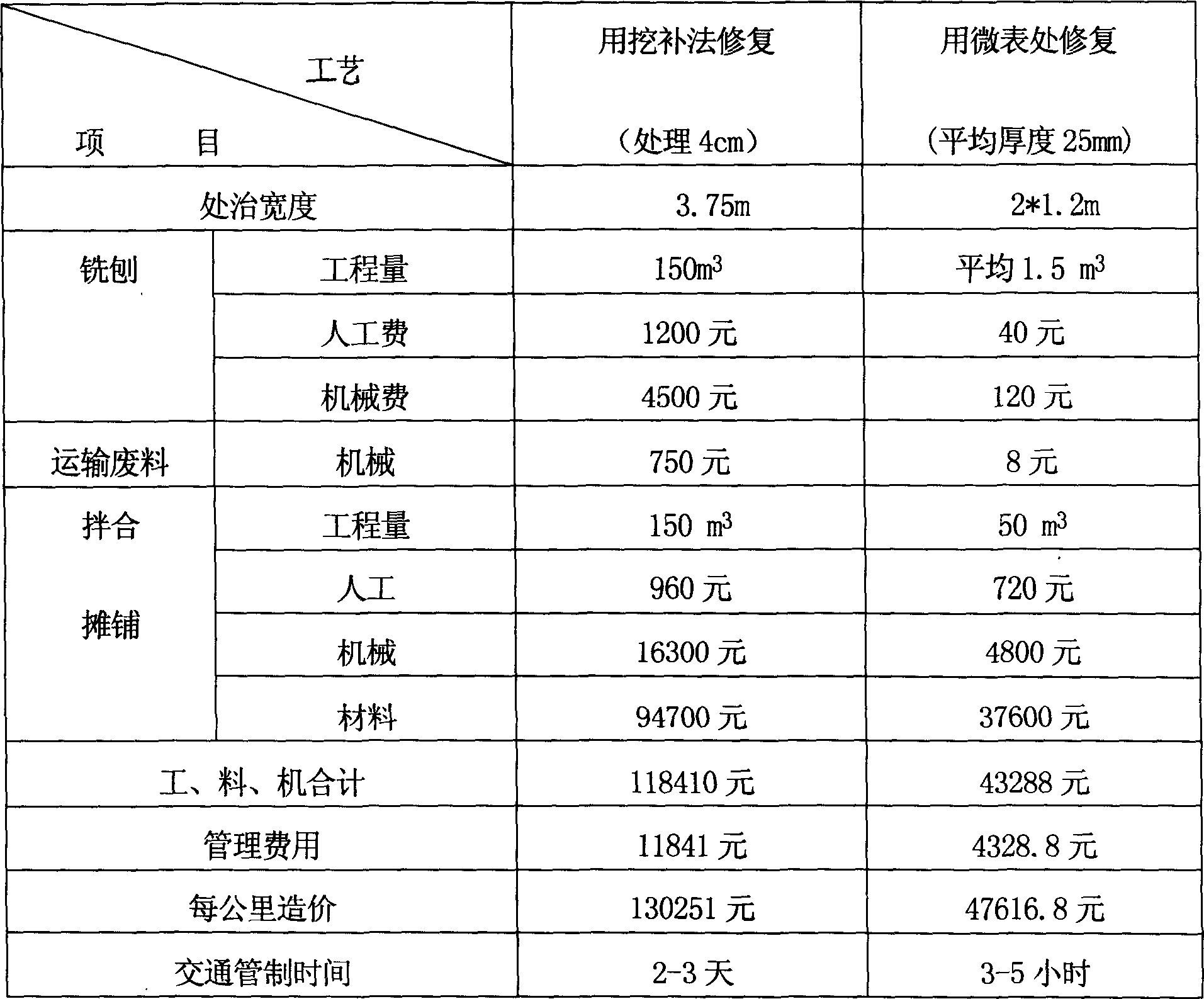

Reconditioning tracks on asphalt pavement by using thin paste mixture of modified emulsified asphalt and construction method thereof

InactiveCN1687526AImprove skid resistanceImprove flatnessIn situ pavingsRoads maintainenceMixed materialsRoad surface

This is a kind of restoring the tracks of the bitumen road surface with the modified emulsified bitumen watery slurry mixed materials and its job practice. Spread single layer modified emulsified bitumen watery slurry mixed materials on the bitumen road surface of 10 - 20 mm depth, and spread double layer modified emulsified bitumen watery slurry mixed materials on the bitumen road surface of 20 - 40 mm depth. The job practice of single layer modified emulsified bitumen watery slurry mixed materials is: close down the traffic, process the original road surface, lay samples, spread, appearance control, joint slots, initial maintenance and quality inspection. Other building steps of the lower layer job practice of the double layer modified emulsified bitumen watery slurry mixed materials are the same as that of single layer, except that the allocated proportion of the single layer modified emulsified bitumen watery slurry mixed materials is different and without quality inspection. The upper layer building steps are: spread, initial maintenance and quality inspection. It has such advantages as high abrading-resistant performance, thin structure layer, long using life, high building speed, fast molding, short building period, fast traffic opening, long building season, low resource waste, no deleterious gas euduction and so on.

Owner:西安高远公路养护技术有限公司

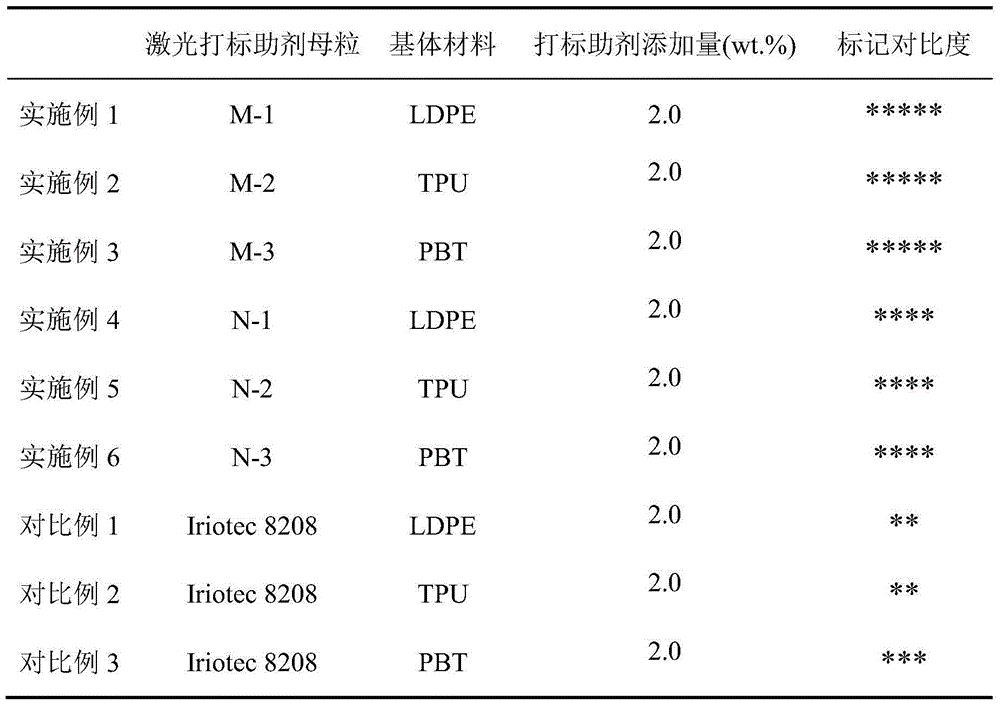

Color changing promoter composition as well as preparation method and application thereof

ActiveCN104610642AImprove product qualityImprove Chromatic Aberration ContrastPentaerythritolPhosphate

The invention discloses a color changing promoter composition. The color changing promoter composition is prepared from the following components in parts by weight: 5.0-40 parts of a mixture, 0.2-10.0 parts of a compatibilizer and 50.0-94.8 parts of a carrier polymer, wherein the mixture is prepared from the following components in parts by weight: 0.3-10.0 parts of metal powder, 60.0-75.0 parts of a metal oxide and 10.0-39.6 parts of a thermoplastic polymer. The novel color changing promoter composition is capable of greatly increasing the color difference contrast of a mark and a matrix material. Particularly, according to the color changing promoter composition disclosed by the invention, after adding dipentaerythritol phosphate, methyl ethyl zinc phosphinic acid and the like as accelerators, the color difference contrast is high. Meanwhile, the invention also provides a method of preparing the color changing promoter composition with simpleness, convenience, easiness in operation and good quality of products.

Owner:SICHUAN UNIV

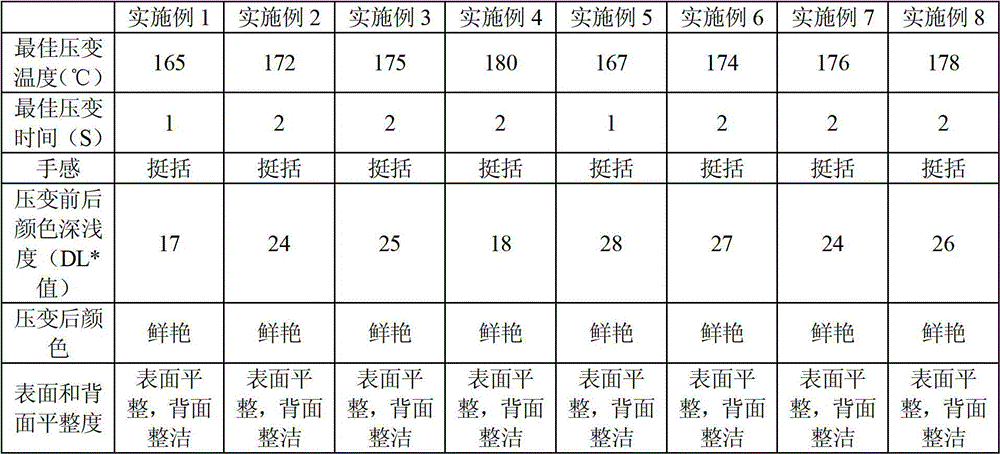

Manufacture method for PU embossed color-changing decoration leather

ActiveCN102747612AFeel crispFeel fullSynthetic resin layered productsLaminationThermal compressionSlurry

The invention provides a manufacture method for PU embossed color-changing decoration leather. According to the method, a layer of polyurethane work slurry prepared by using a wet method is coated onto a spunlaced non-woven fabric, and concrete steps of the method comprise: (a) preparing base cloth and unreeling and ironing the base cloth; (b) coating the polyurethane work slurry changeable at a pressure with a knife, wherein a formula for the work slurry comprises, by mass, 20 to 40 parts of high-modulus resin, 80 to 60 parts of low modulus resin, 90 to 200 parts of a solvent, 15 to 25 parts of a filling material, 3 to 15 parts of color paste, 0 to 4 parts of a microporous regulator, 0.1 to 1 part of an antifoaming agent and 0.1 to 1 part of a leveling agent; (c) carrying out solidification and rinsing; and (d) carrying out drying and reeling, wherein drying temperature is 120 to 155 DEG C. The prepared decoration leather has stiff and smooth touch, smooth surface and neat back; temperature for thermal changes of the decoration leather at a pressure is adjustable and is in a range of 165 to 180 DEG C; time for changes at a pressure is short; and the color of the decoration leather having undergone changes at a pressure is brilliant and full, presenting great contrast.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

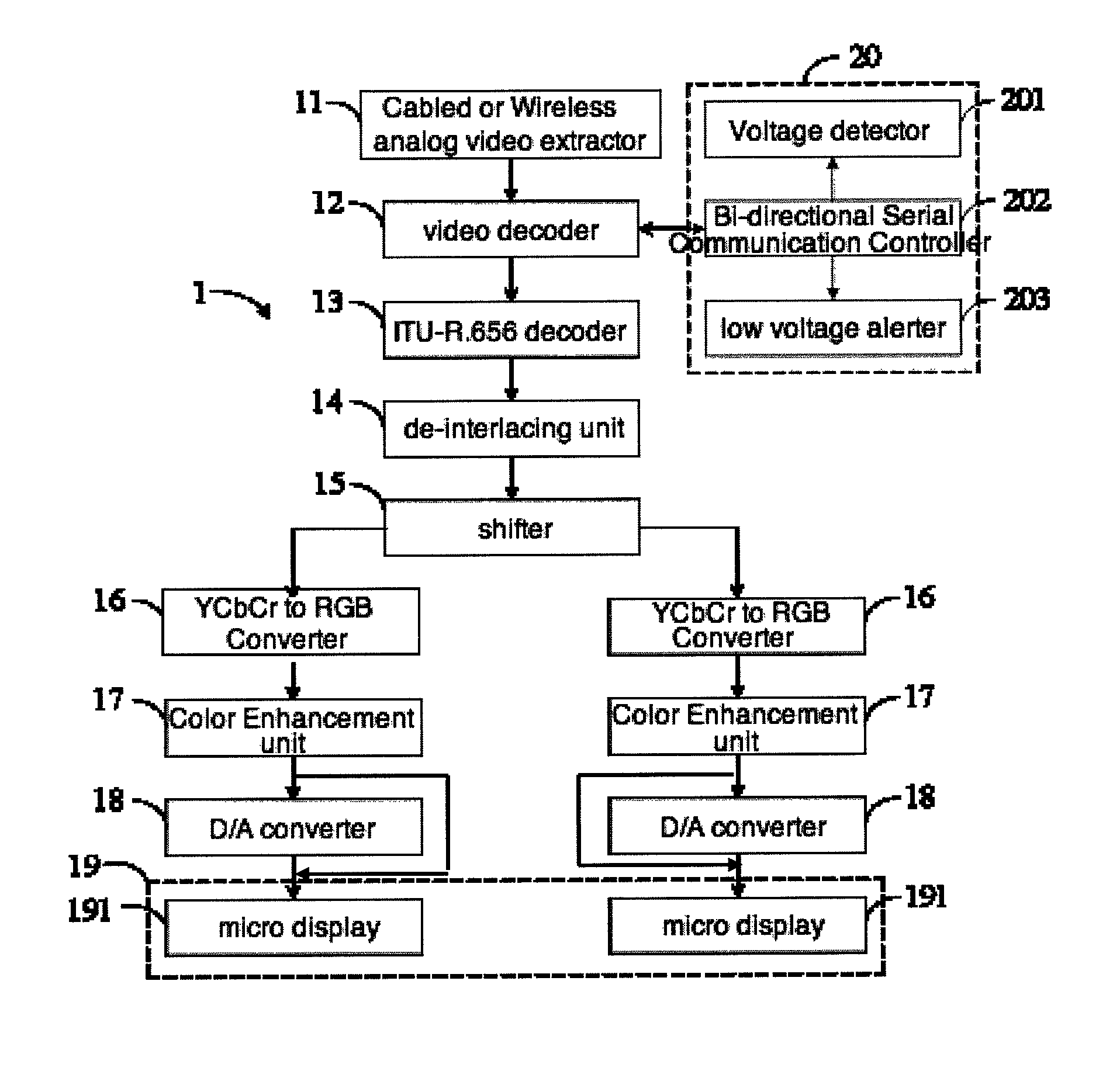

Head-mounted visual display device with stereo vision and its system

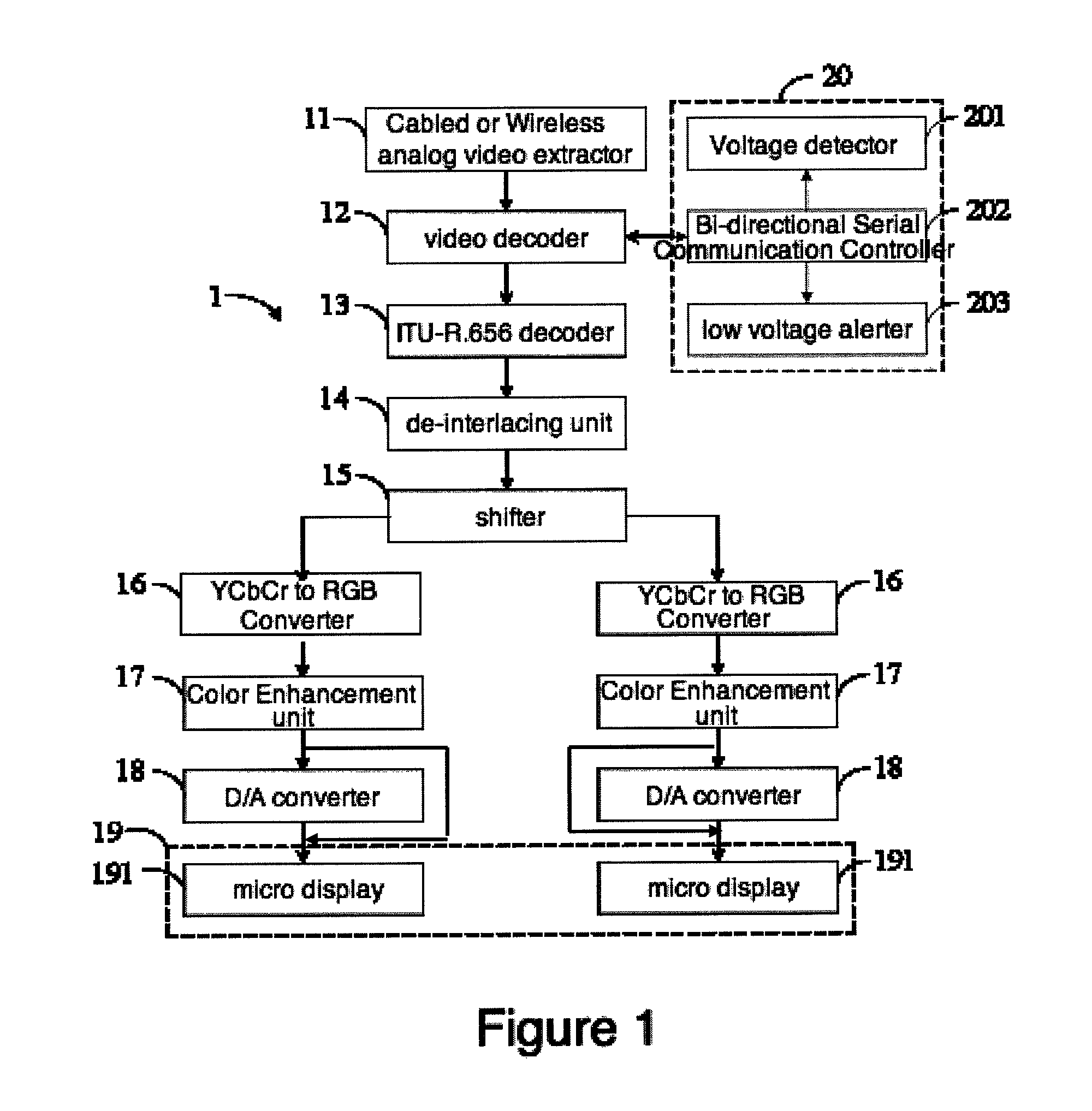

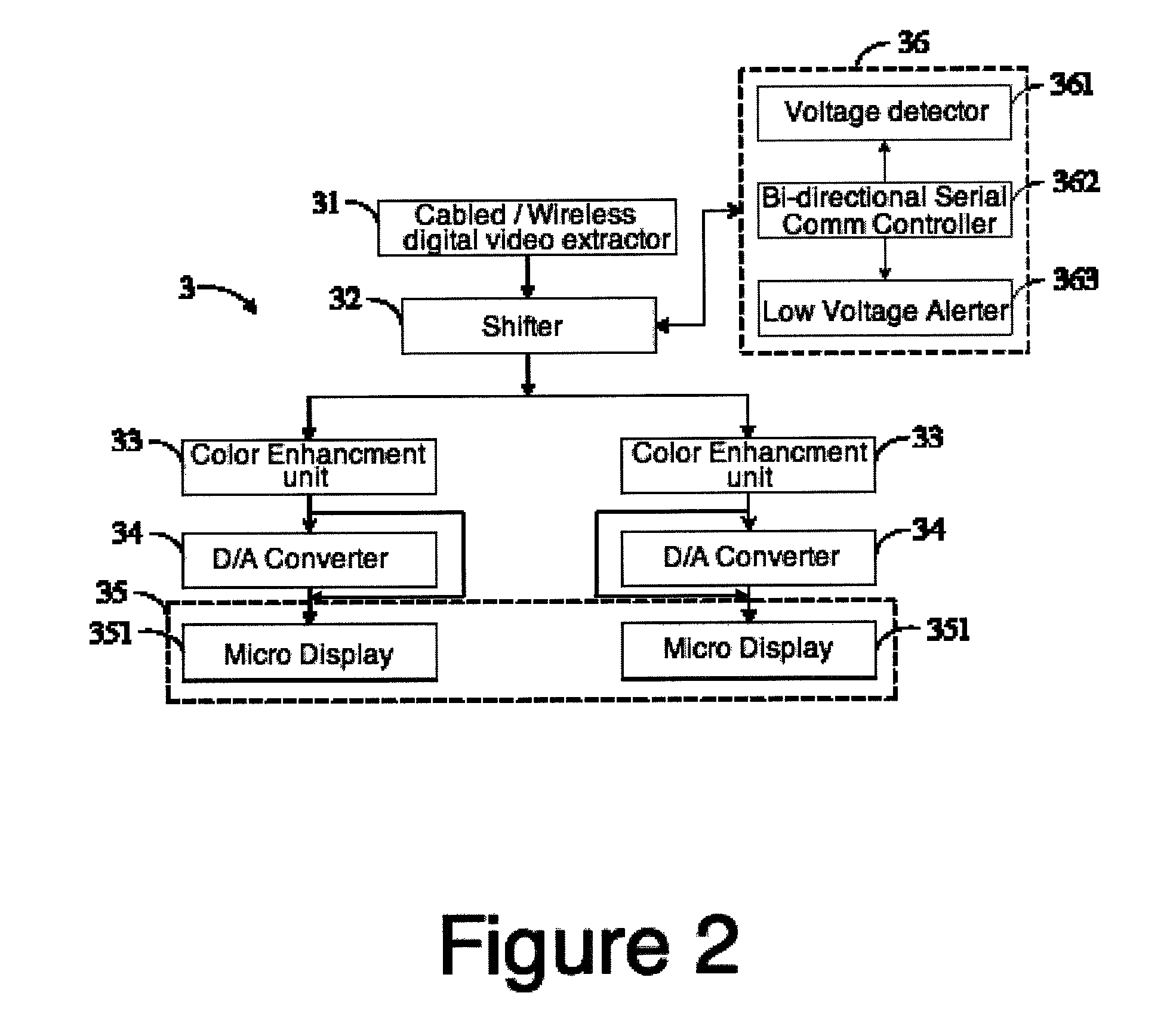

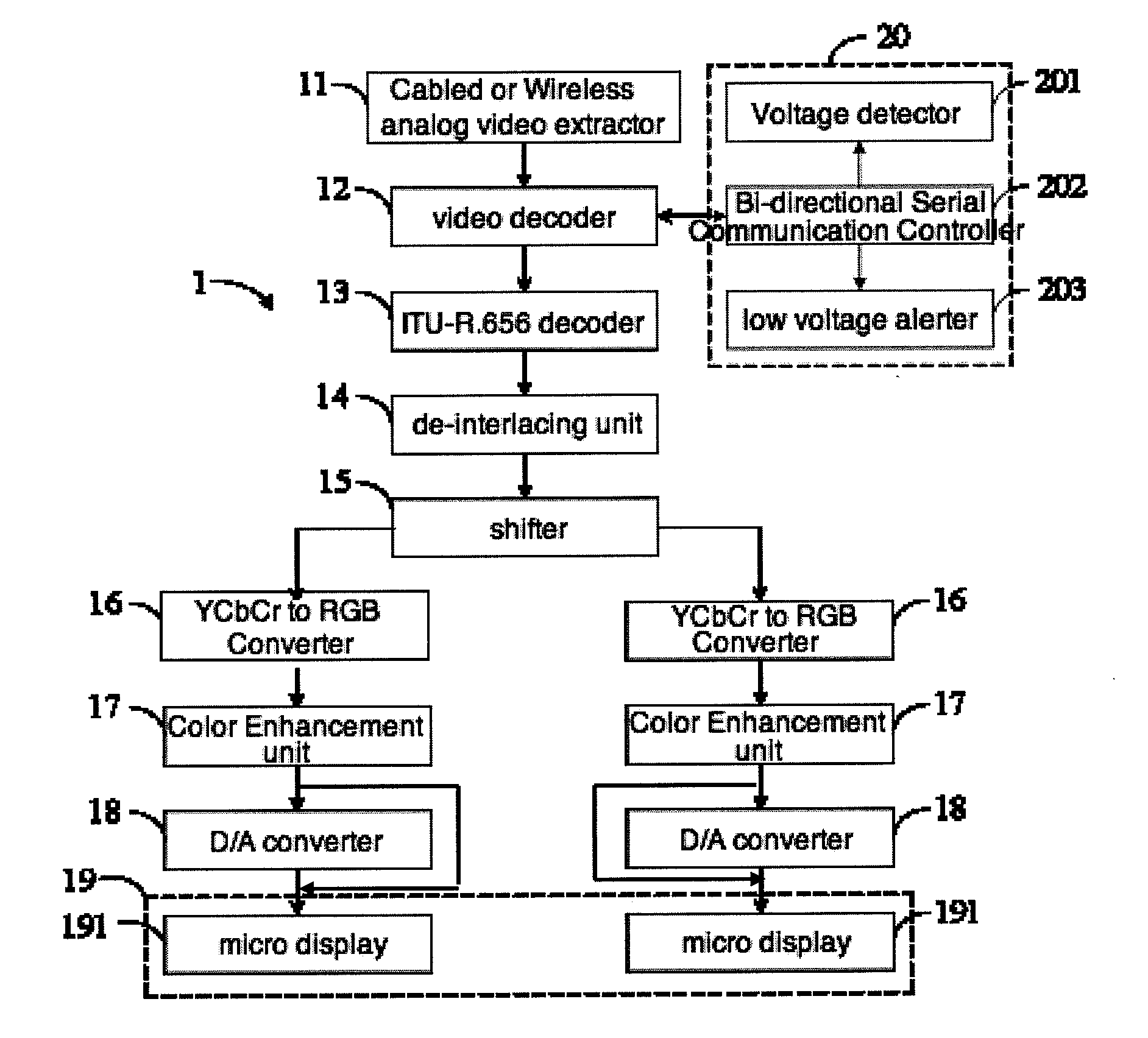

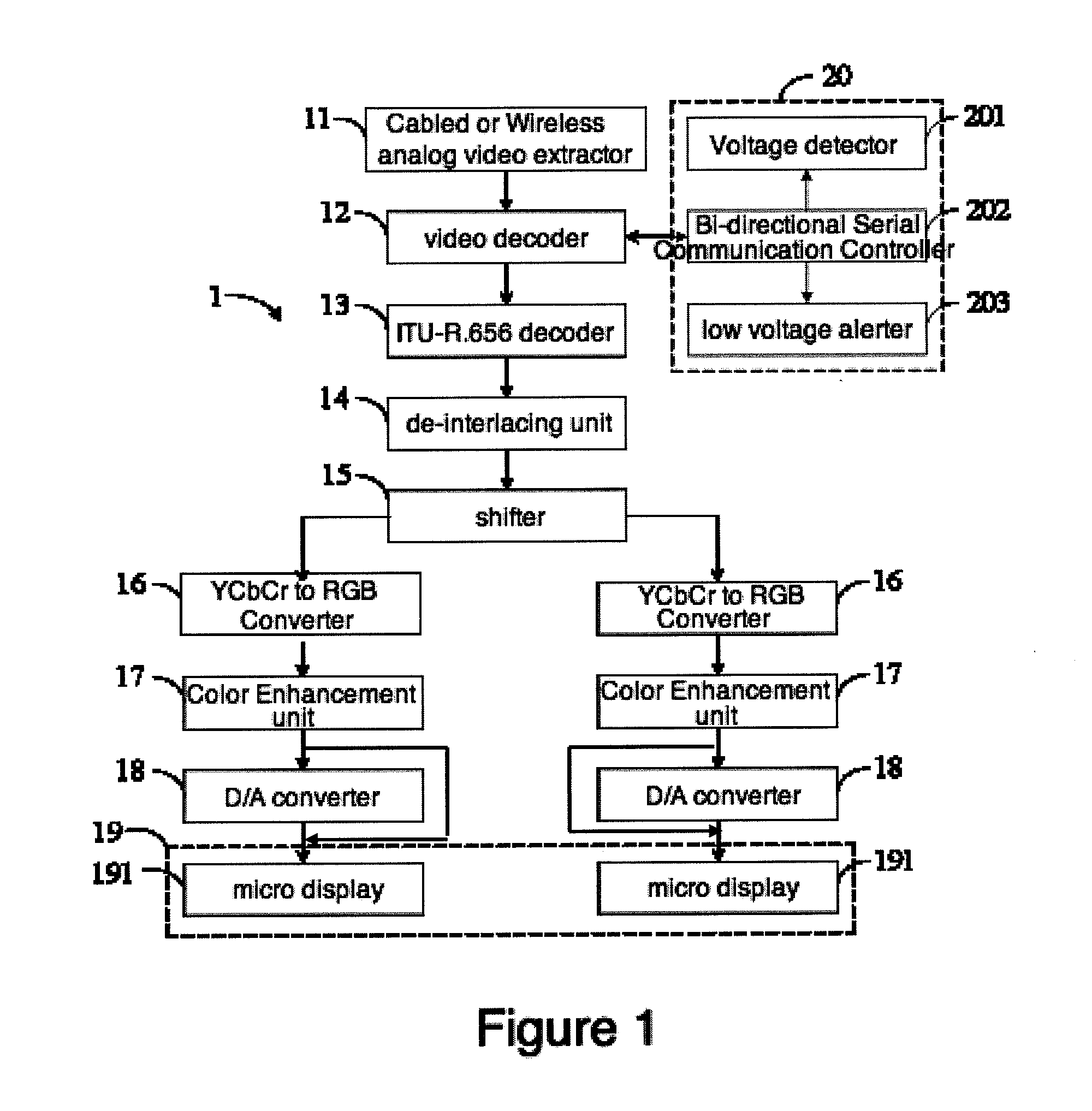

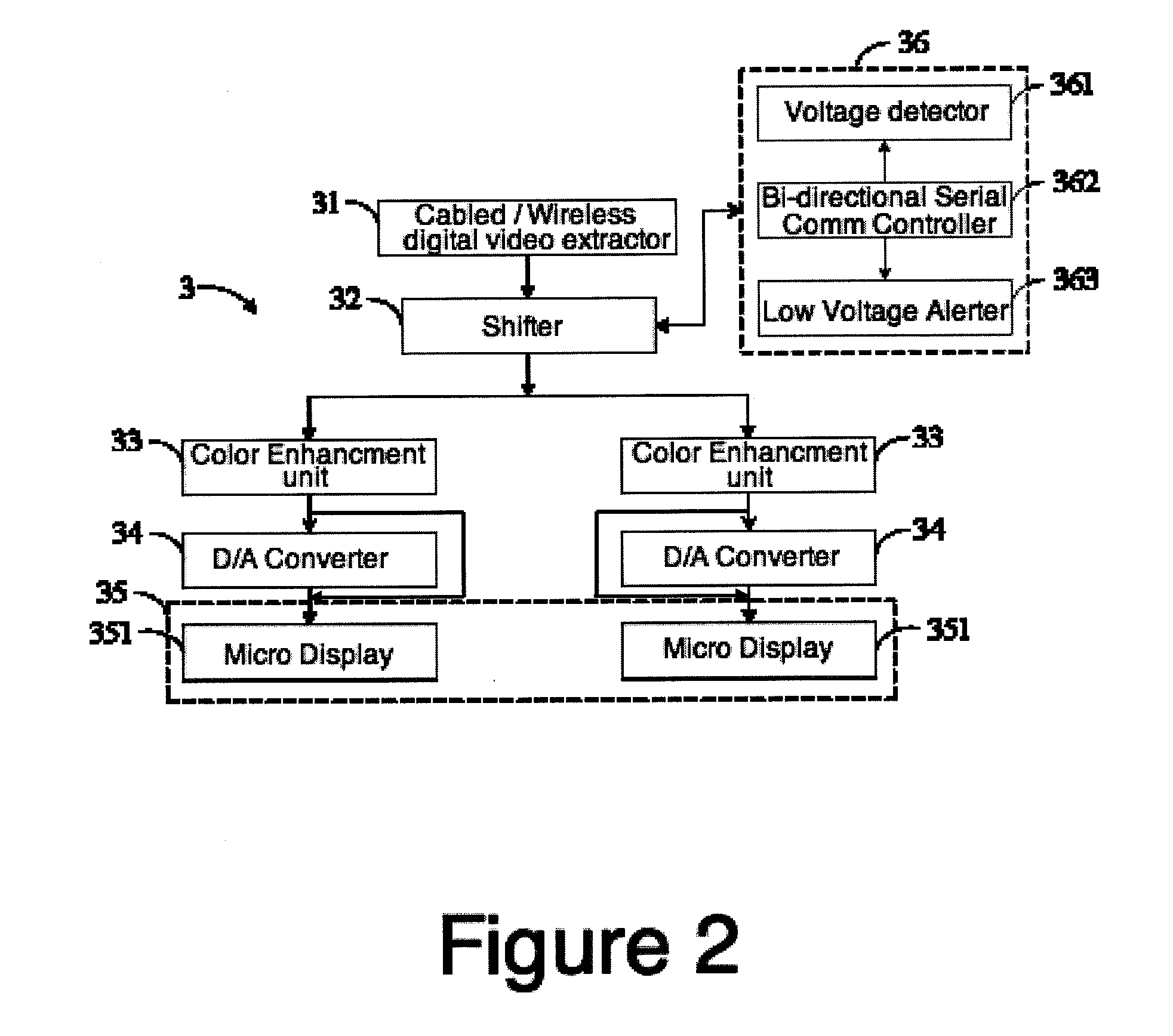

InactiveUS8350898B2Good colorHigh color contrastColor signal processing circuitsPicture reproducers using cathode ray tubesDigital videoDisplay device

A head-mounted visual display device for low-vision aid, which features 2 models, they are analog signal model and digital signal model. Said analog device contains at least an analog video extractor, a video decoder, an ITU-R.656 decoder, a de-interlacing unit, an image processor, two YCbCr to RGB converter, two color enhancement units, two video D / A converter, a head mounted display, a signal voltage controller and a wireless communication module. Said digital device consists of a digital video signal extractor / capturer, a RGB to YCbCr converter, an image processor, two YCbCr to RGB converter, two color enforcement units, a head-mounted display, a signal voltage controller and a wireless communication module.

Owner:NATIONAL YANG MING UNIVERSITY

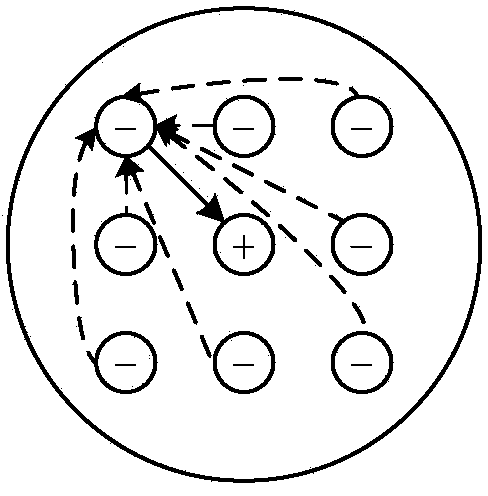

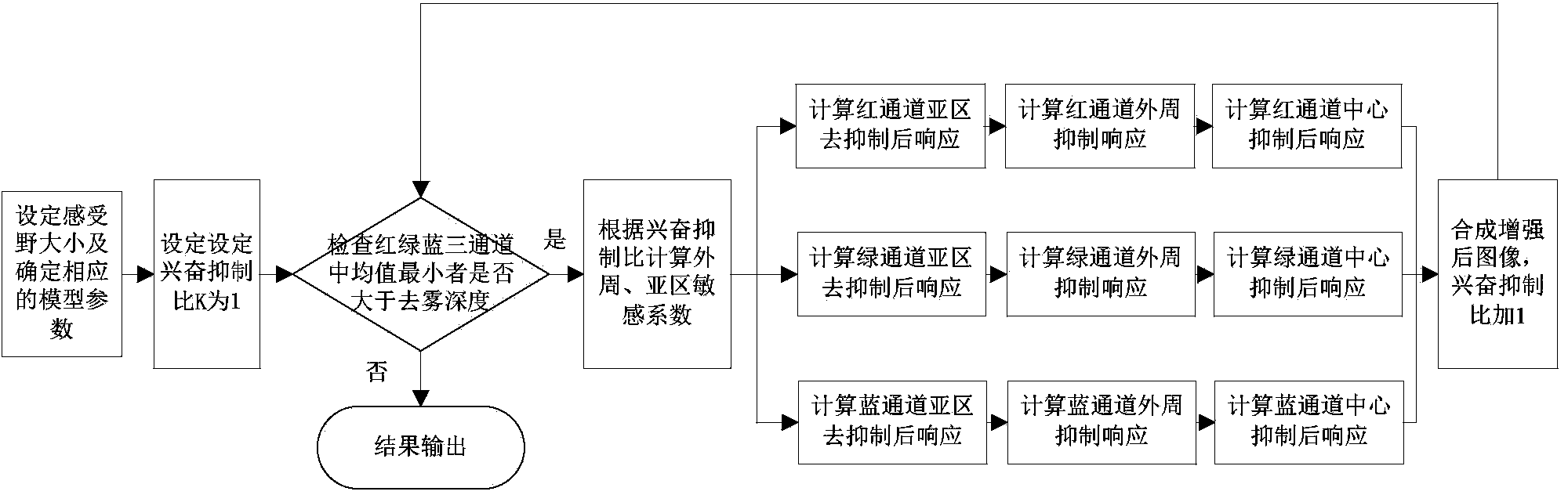

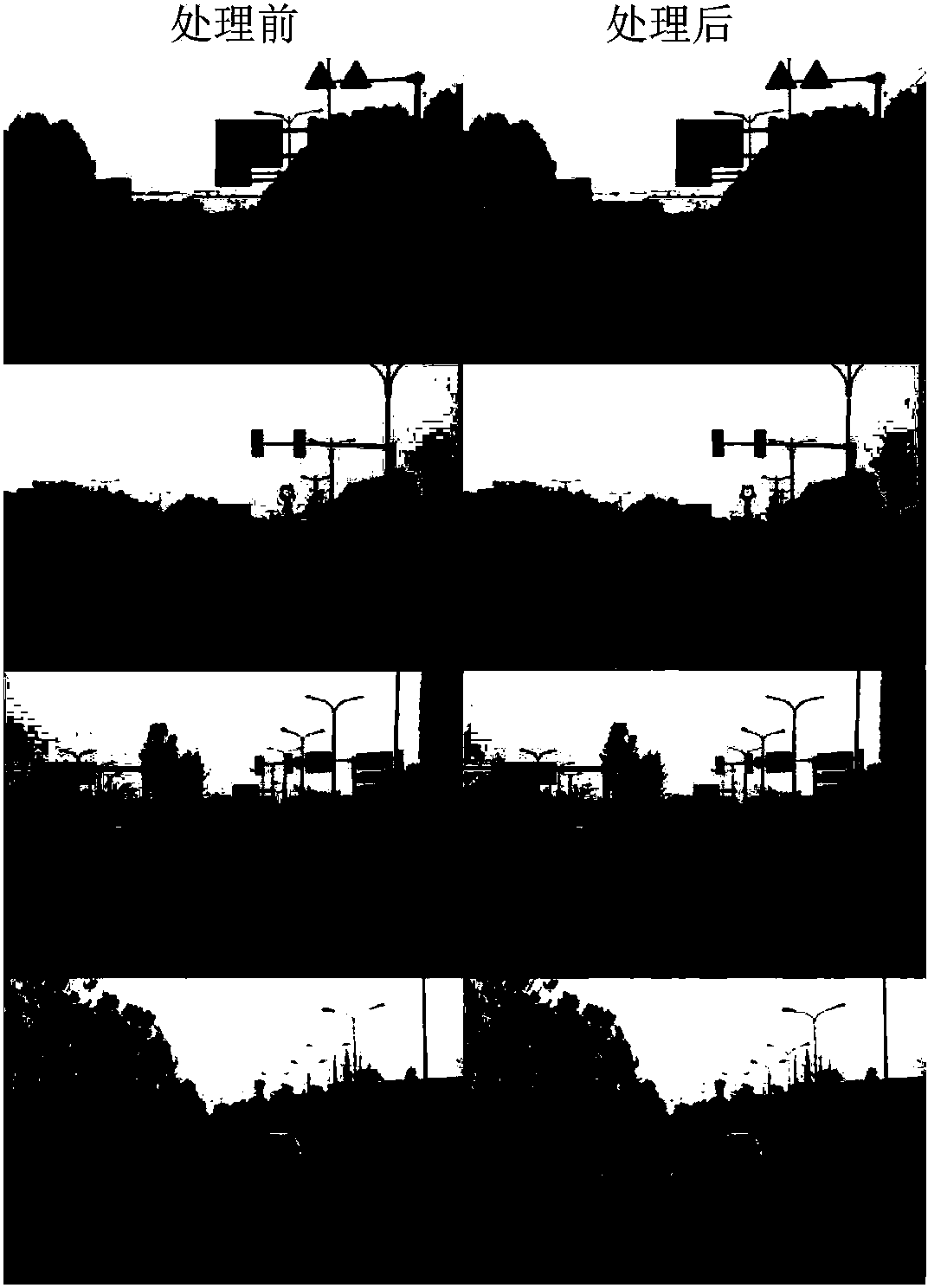

Image defogging method based on biological vision mechanism

ActiveCN103955900AImplement auto-enhancementHigh color contrastImage enhancementColor imageInhibitory effect

The invention discloses an image defogging method based on a biological vision mechanism. The diffusion illumination of a foggy image is removed through a non-classic receptive field single antagonism model and interaction of the inhibiting effect of the periphery under different sensitivity coefficients and the disinhibition effect of a subregion, the degree of color contrast of an original image is increased, and the foggy image can be automatically enhanced. A method conforming to the physiological property is provided, and the color defogging and enhancing of the single foggy color image are accurately and efficiency achieved while the detail features are reserved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

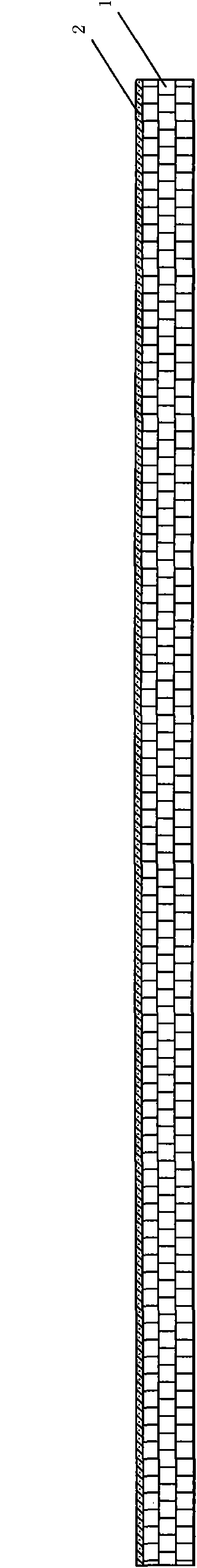

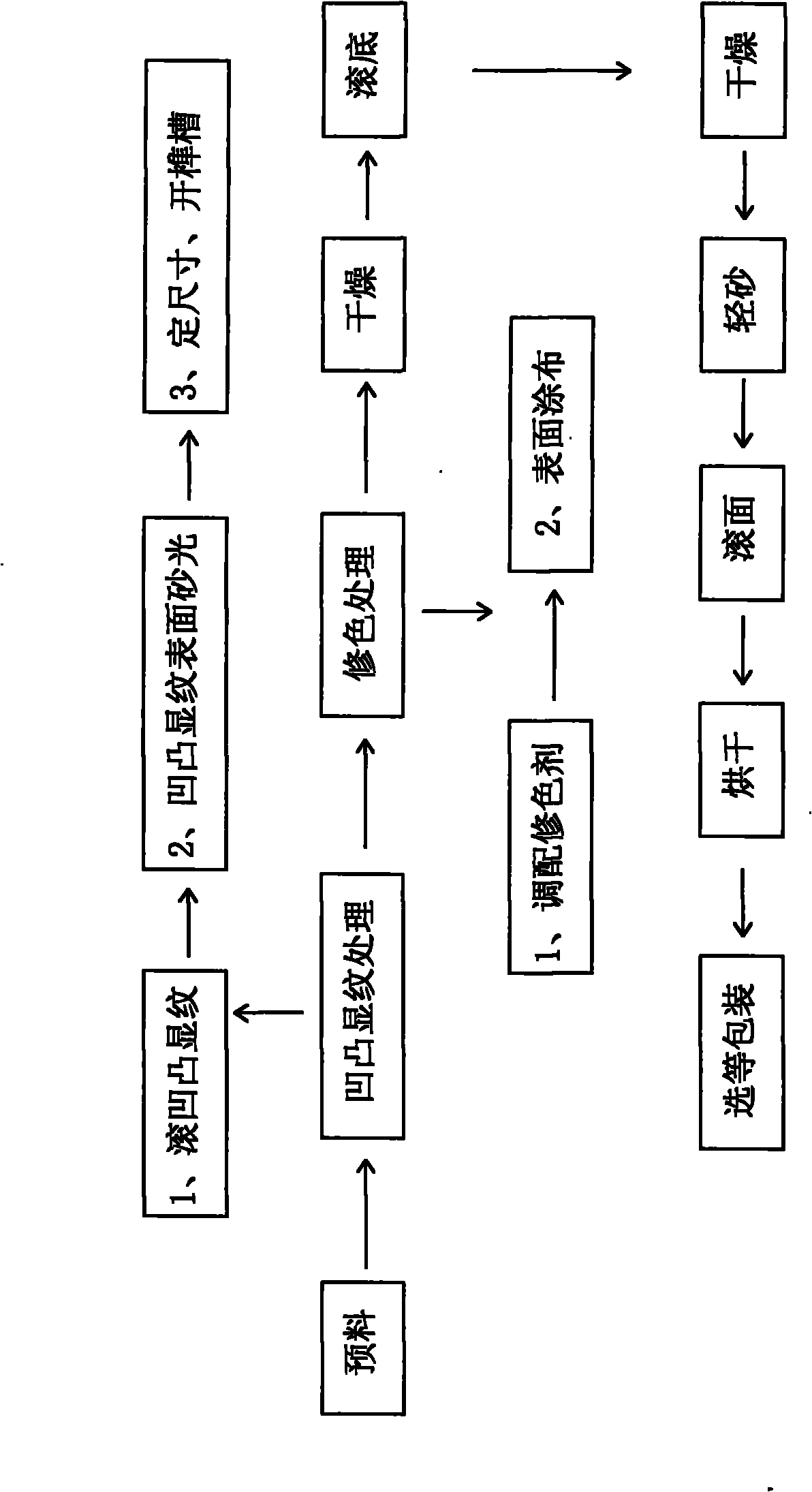

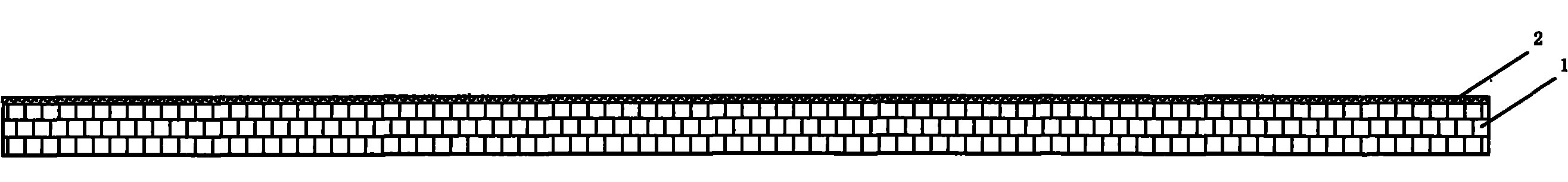

Concave-convex obvious texture solid floor and manufacturing method thereof

InactiveCN102080440AHigh color contrastRaise the gradeDecorative surface effectsWood working apparatusMaterials preparationSolid wood

The invention discloses a concave-convex obvious texture solid floor and a manufacturing method thereof. The concave-convex obvious texture solid floor comprises a substrate layer, wherein a pattern layer is deeply rolled on the surface of the substrate by engraving and rolling. The manufacturing method comprises the following steps: (1) material preparation; (2) concave-convex texture treatment; (3) color modifying treatment; (4) drying; (5) base pain rolling coating; (6) drying; (7) slightly sanding; (8) finish paint rolling coating; (9) drying; and (10) sorting and packaging. The manufacturing method is characterized in that: required concave-convex obvious texture patterns are directly rolled at high temperature on various substrates without texture and then color modification and base paint rolling coating are performed; the solid floor has the advantages of wide application, high compression speed, industrial standardization, rich color, diversified texture and the like; the concave-convex obvious texture floor has higher color contrast and three-dimensional sensor, and has higher economic and social values than other floors; and a low-quality wood material is used to produce the high-quality imitation floor, so the quality of the floor is improved, and a large amount of high-quality rare wood can be saved.

Owner:胡斌

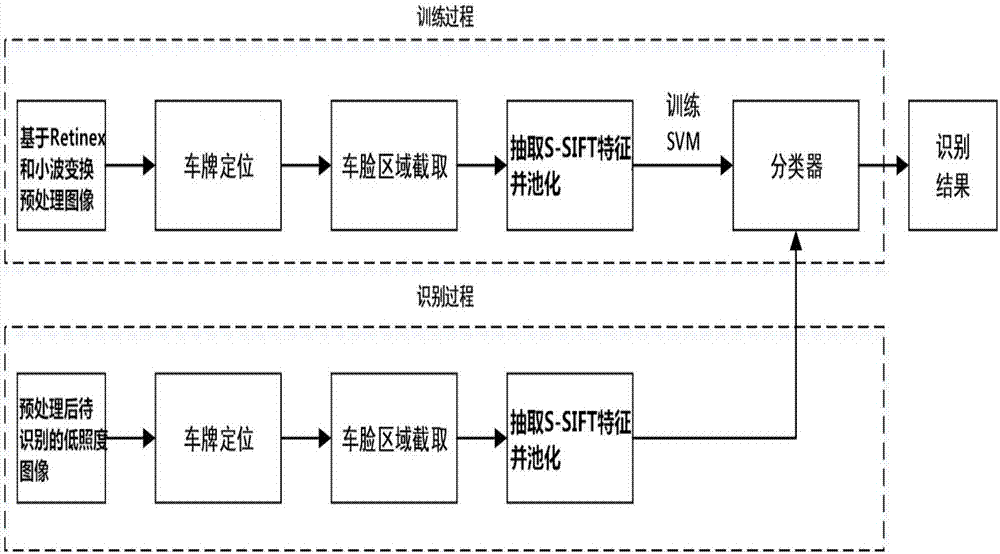

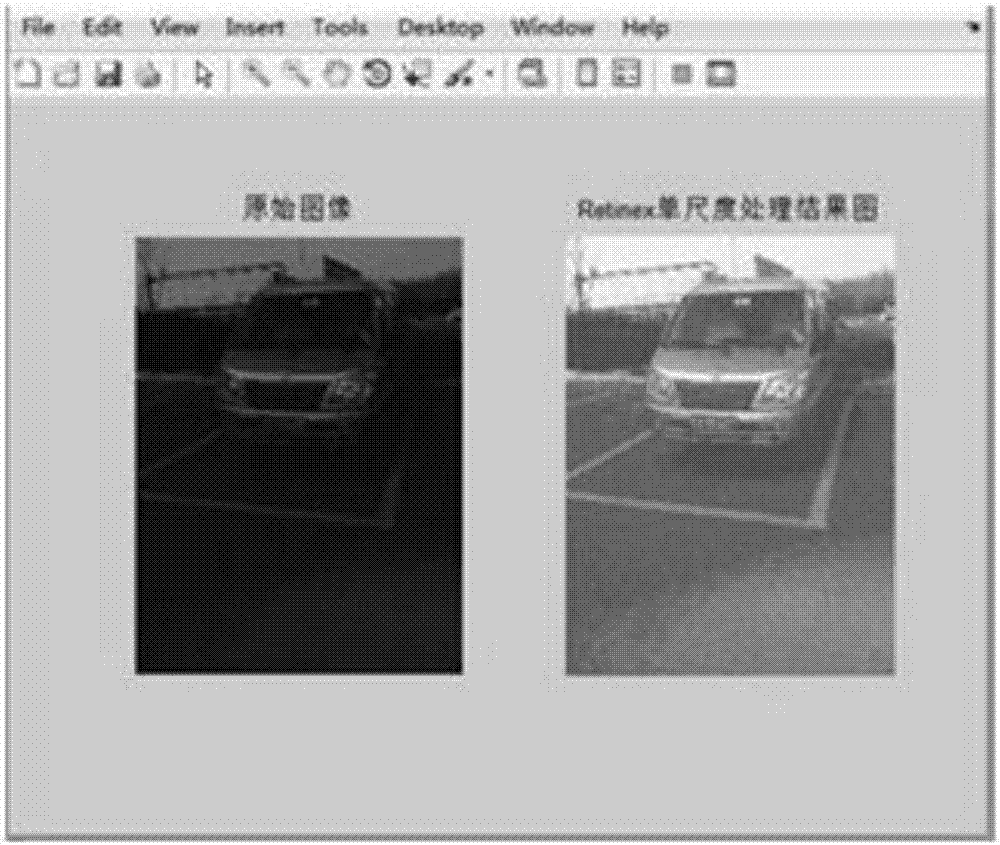

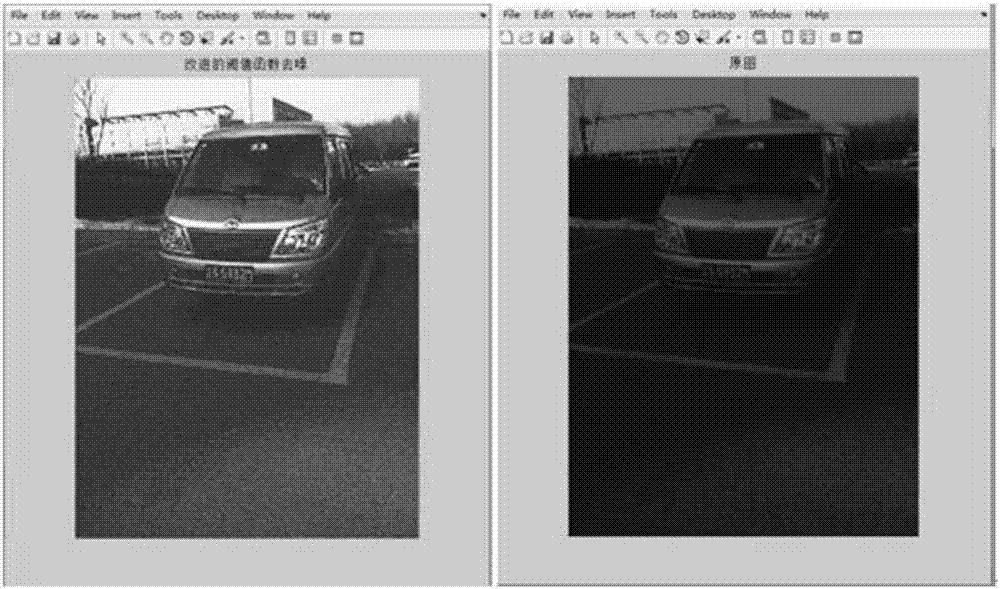

Low illumination model identification method based on Retinex and S-SIFT characteristic combination

InactiveCN107092876AMaintain color constancyHigh color contrastCharacter and pattern recognitionSelf adaptiveImage enhancement

The invention relates to the computer vision field and particularly relates to a model identification method under the low illumination environment based on Retinex and S-SIFT characteristic combination. The method comprises four steps that 1), low illumination image enhancement based on Retinex and wavelet adaptive threshold transformation is carried out; 2), license plate positioning is carried out; 3), interception of a vehicle face region including the model information is carried out; and 4), an S-SIFT characteristic model of model region images is established, and model identification is carried out in combination with an SVM trainer. The method is advantaged in that an embedded FPGA can be utilized for realization, the method is applied to a camera or a video camera which has a model identification function to output images in real time under the low illumination environment, system accuracy and reliability are effectively improved, and real-time demands can be satisfied.

Owner:HUNAN VISION SPLEND PHOTOELECTRIC TECH

Electrochromic device

This invention provides an electrochromic device which has superior coloration repeat properties, high light transmittance and small thickness. A film is provided comprising a first electrode and second electrode in the same plane, and an electrochromic region and electrolyte region laminated in this plane. The electrochromic region is provided on the second electrode, the electrolyte region is provided on the first electrode, and the boundary between the electrochromic region and electrolyte region lies in the planar direction of the film.

Owner:HITACHI LTD

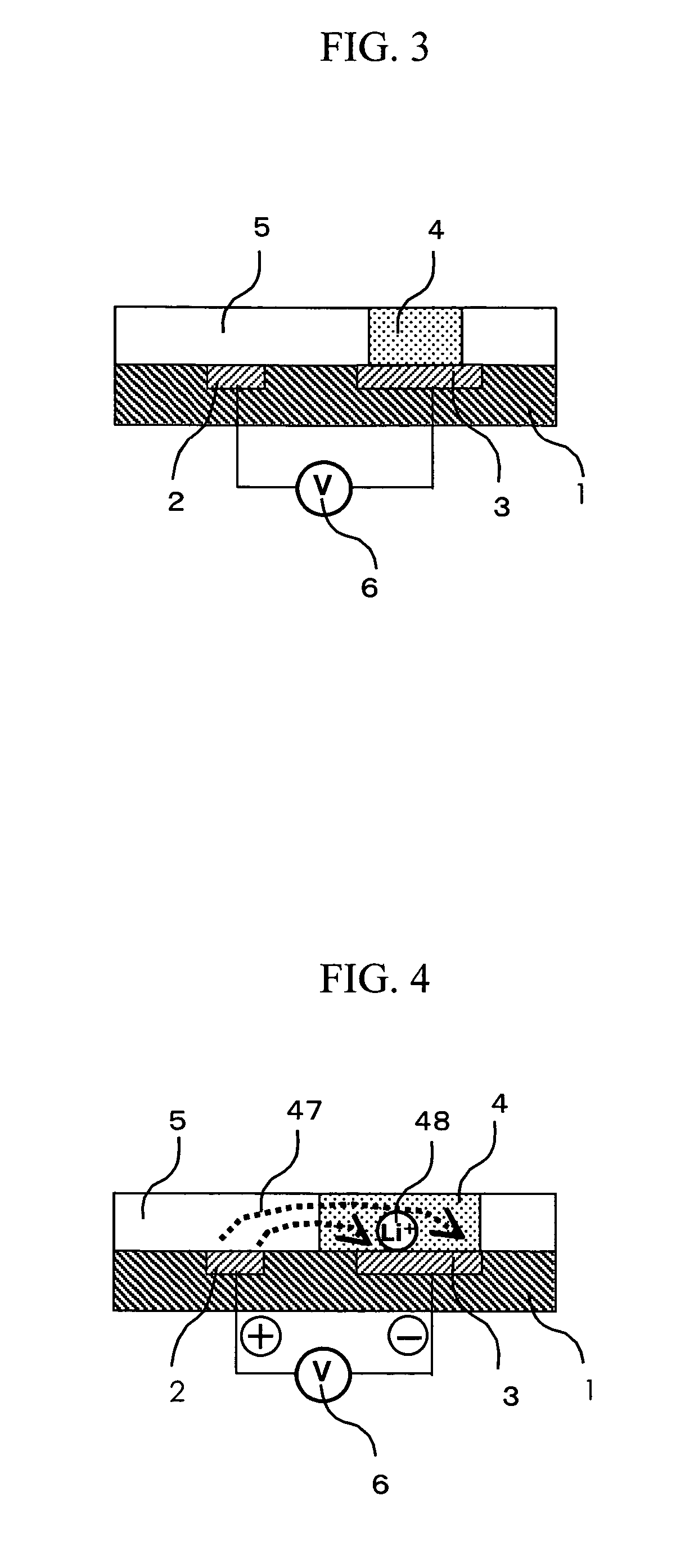

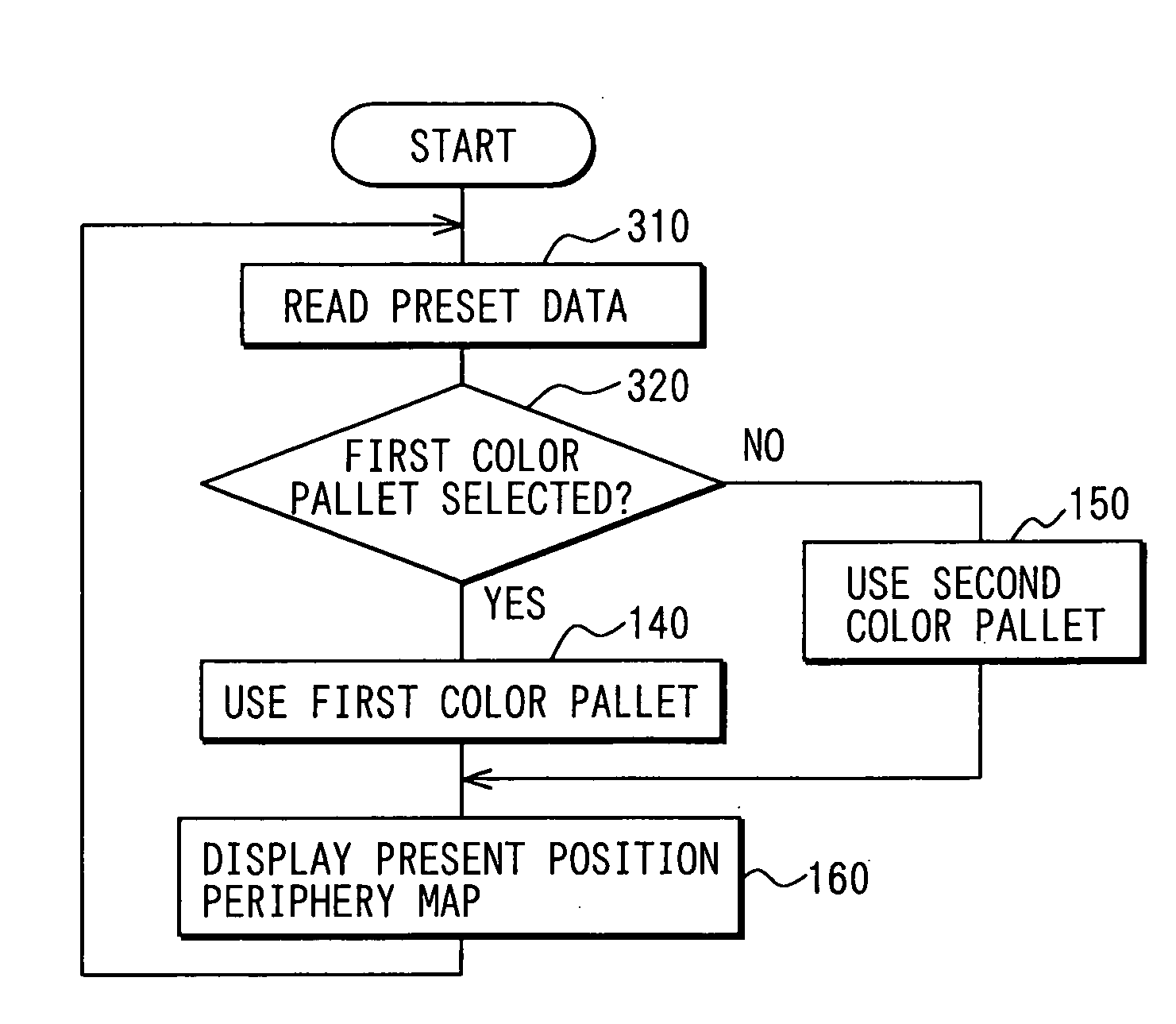

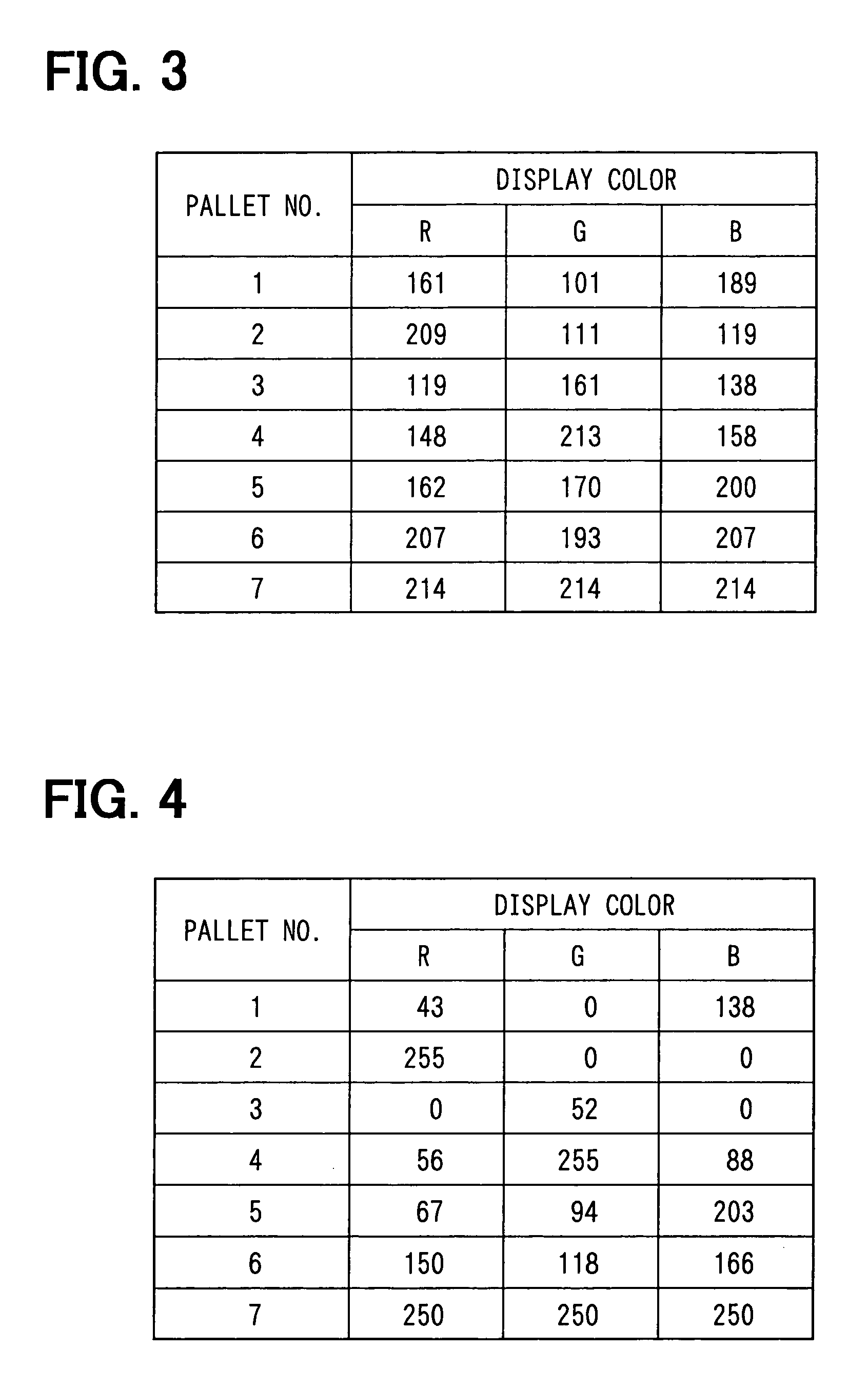

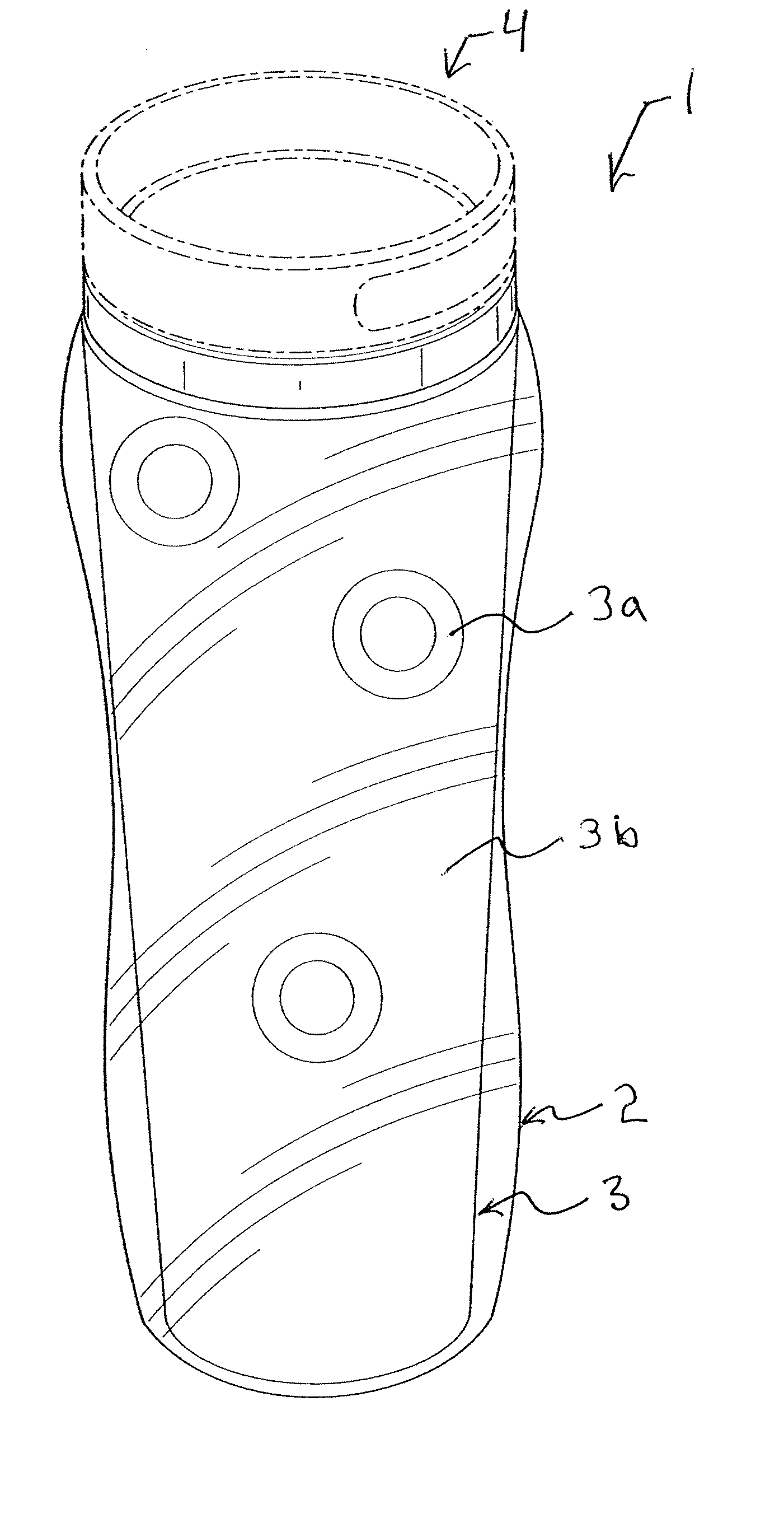

Map display device and method for operating thereof

InactiveUS20050190197A1Increase color contrastEasily identifiableInstruments for road network navigationRoad vehicles traffic controlMarine navigationDisplay device

A car navigation device displays a map by using display colors included in a first color pallet when the speed of a vehicle traveling is lower than a predetermined value and displays the map by using display colors included in a second color pallet having a group of display colors of contrasts higher than those of the group of display colors of the first color pallet when the speed of the vehicle traveling is greater than the predetermined value.

Owner:DENSO CORP

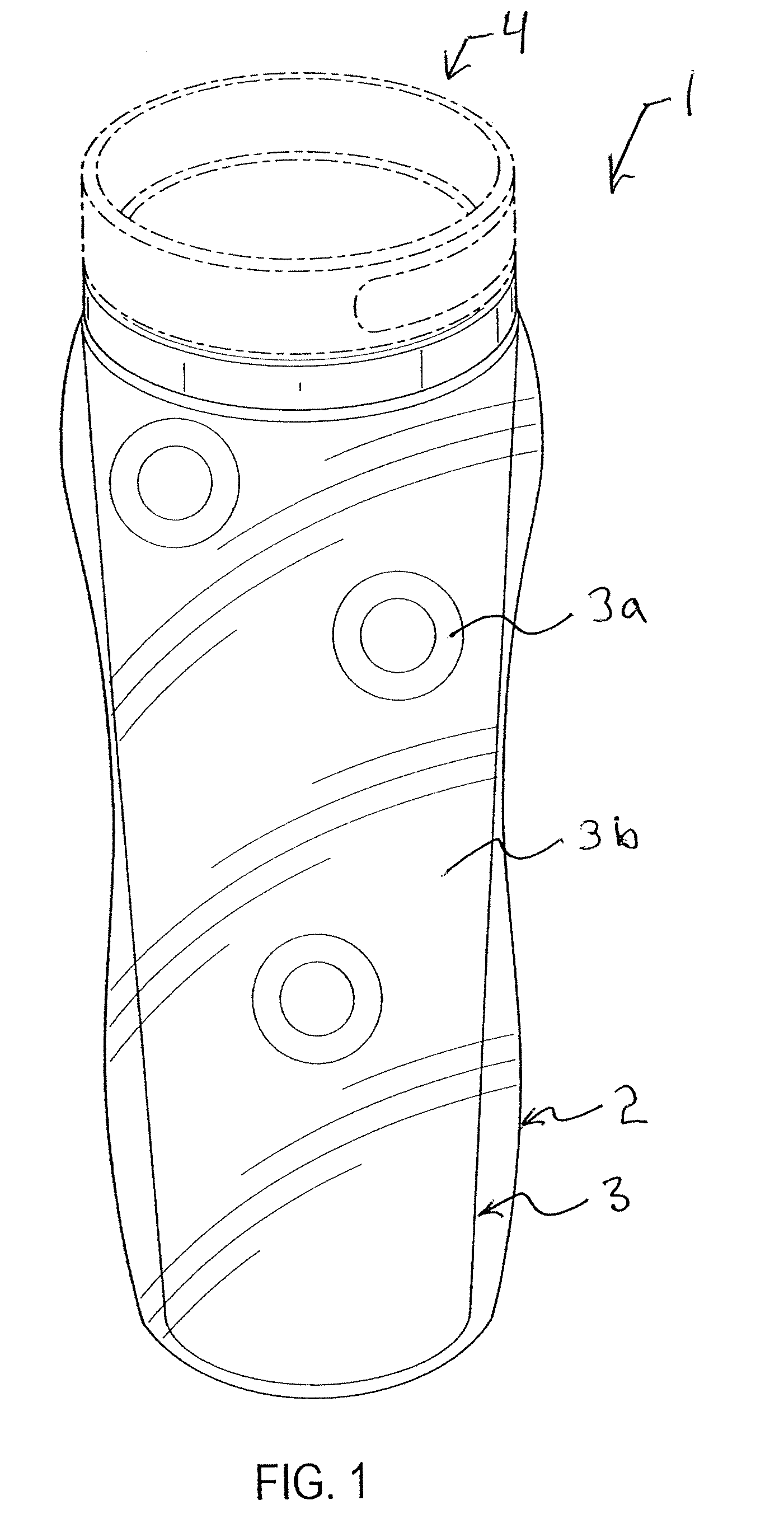

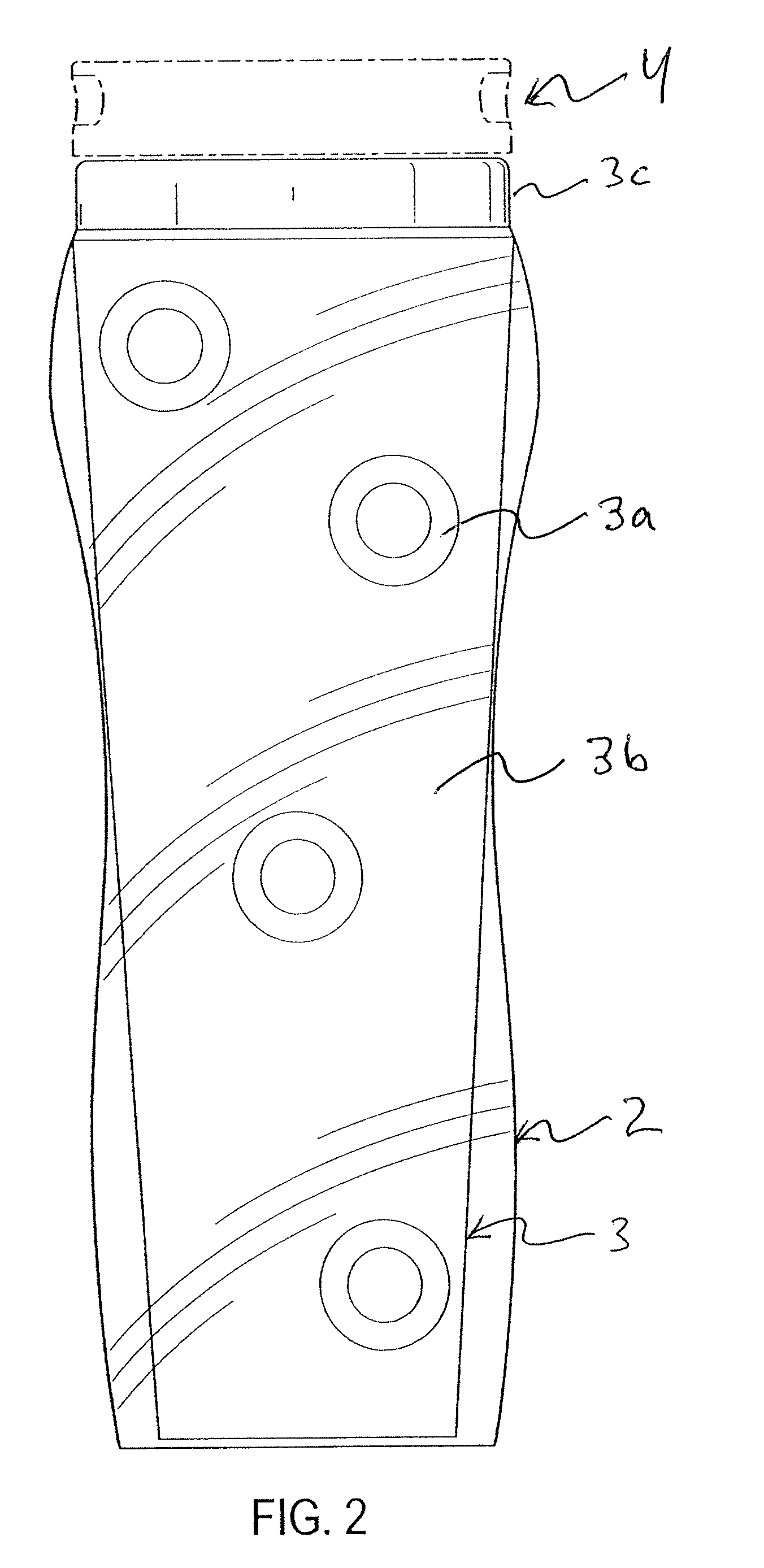

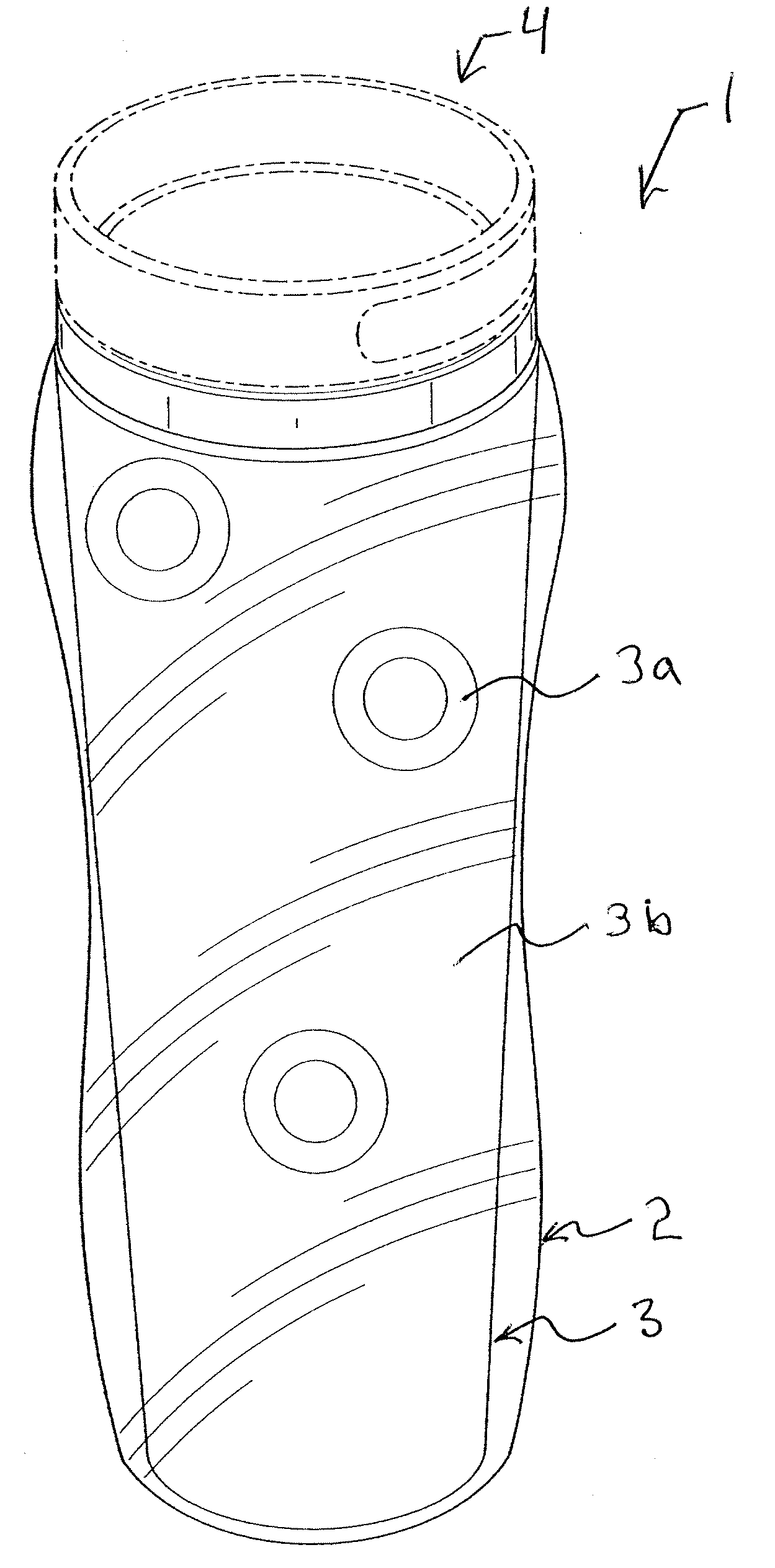

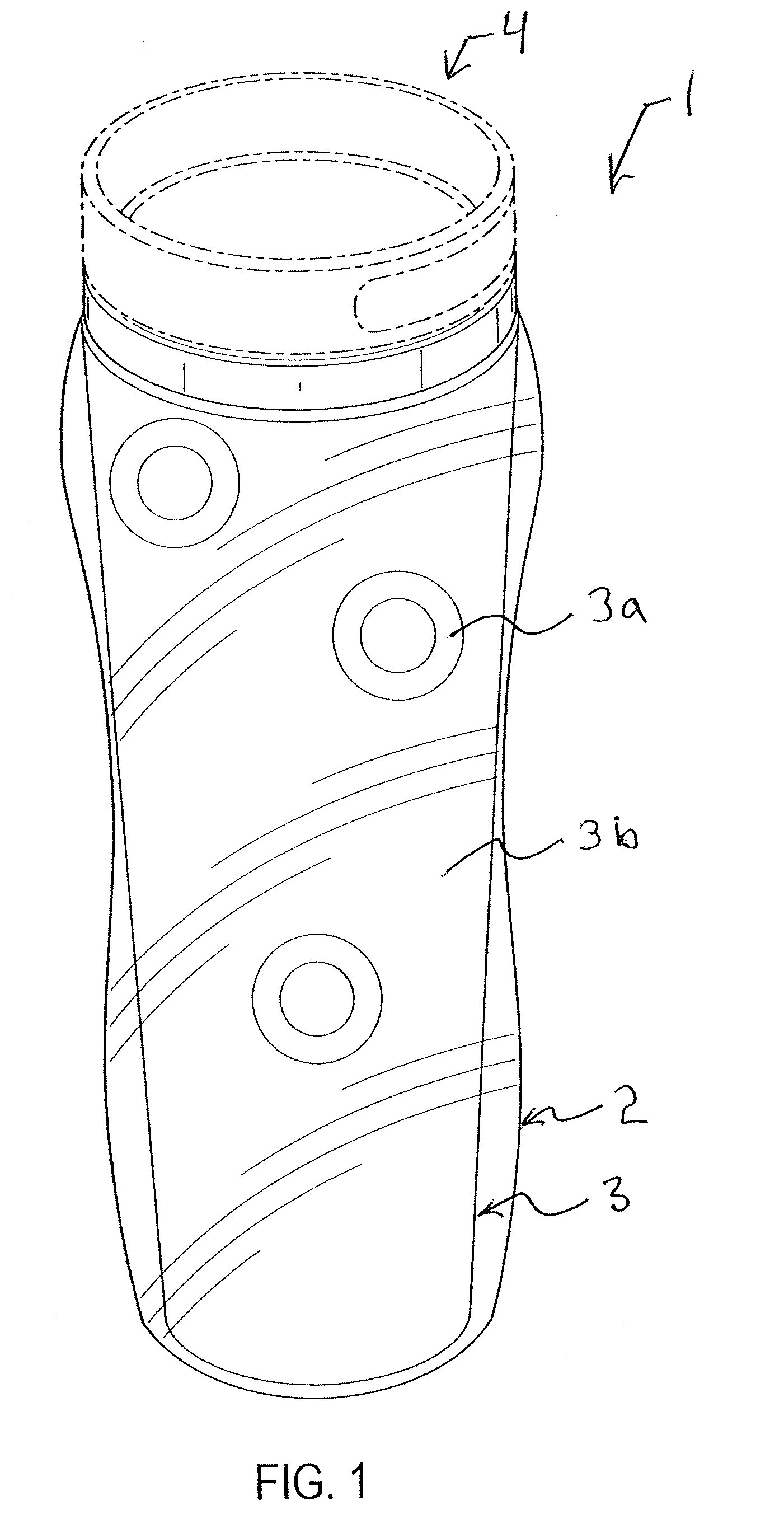

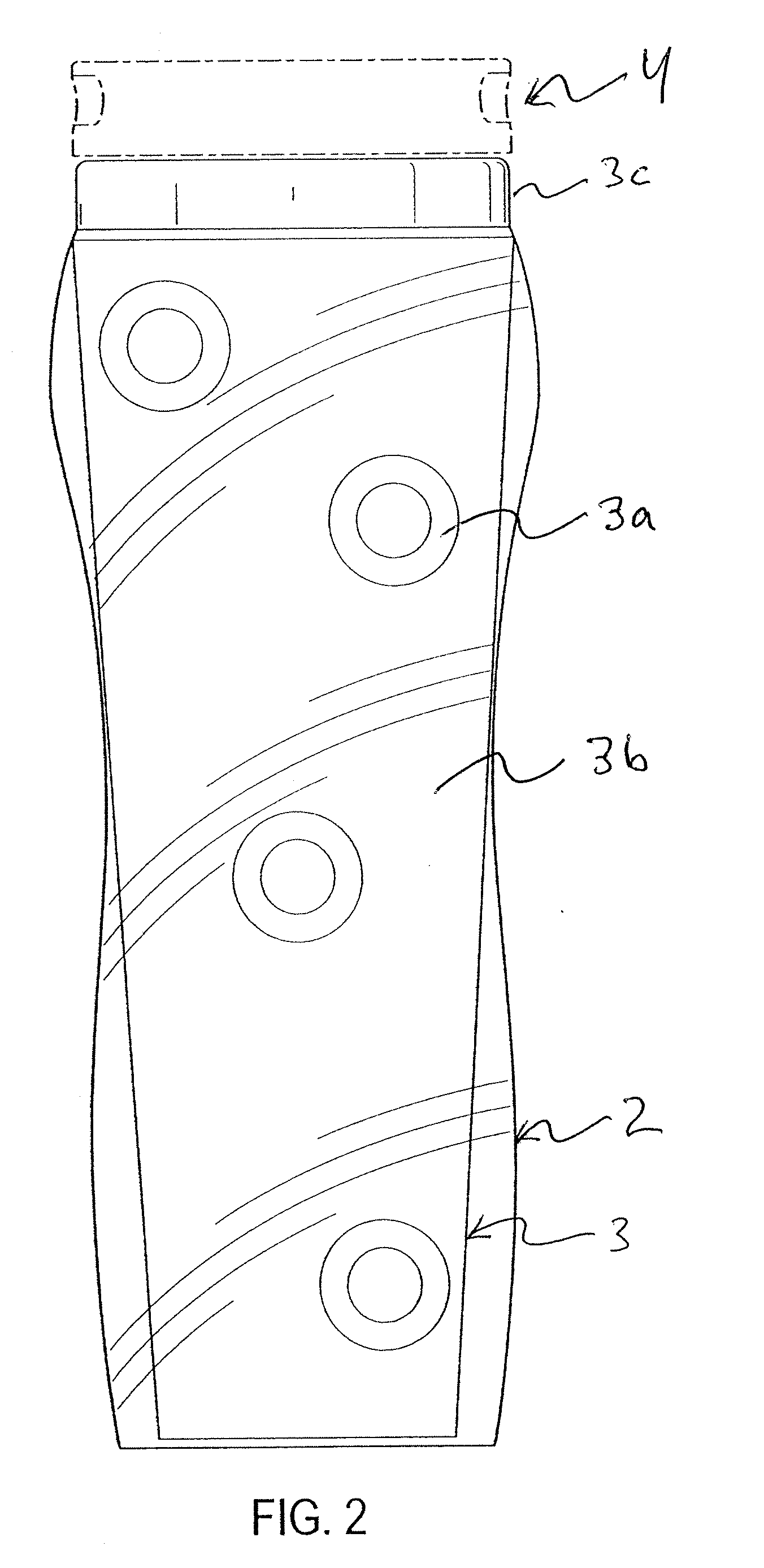

Dual-wall container with heat activated and/or temperature-change activated color changing capability

ActiveUS7556425B2High color contrastTemperature measurement in household appliancesThermometers using physical/chemical changesChange colorEngineering

Dual-wall container includes an outer wall that is at least one of at least partially substantially transparent and at least partially substantially translucent, an inner wall adapted to contain a substance, at least one symbol arranged an outer surface of the inner wall, and at least one of a coating of a thermochromatic composition arranged on the outer surface of the inner wall, a thermochromatic composition layer arranged on the outer surface of the inner wall, and a thermochromatic composition arranged on an outer surface of at least the at least one symbol. The thermochromatic composition is structured and arranged to change color when the inner wall experiences or senses a temperature change. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:ROBERT GORDON INDS

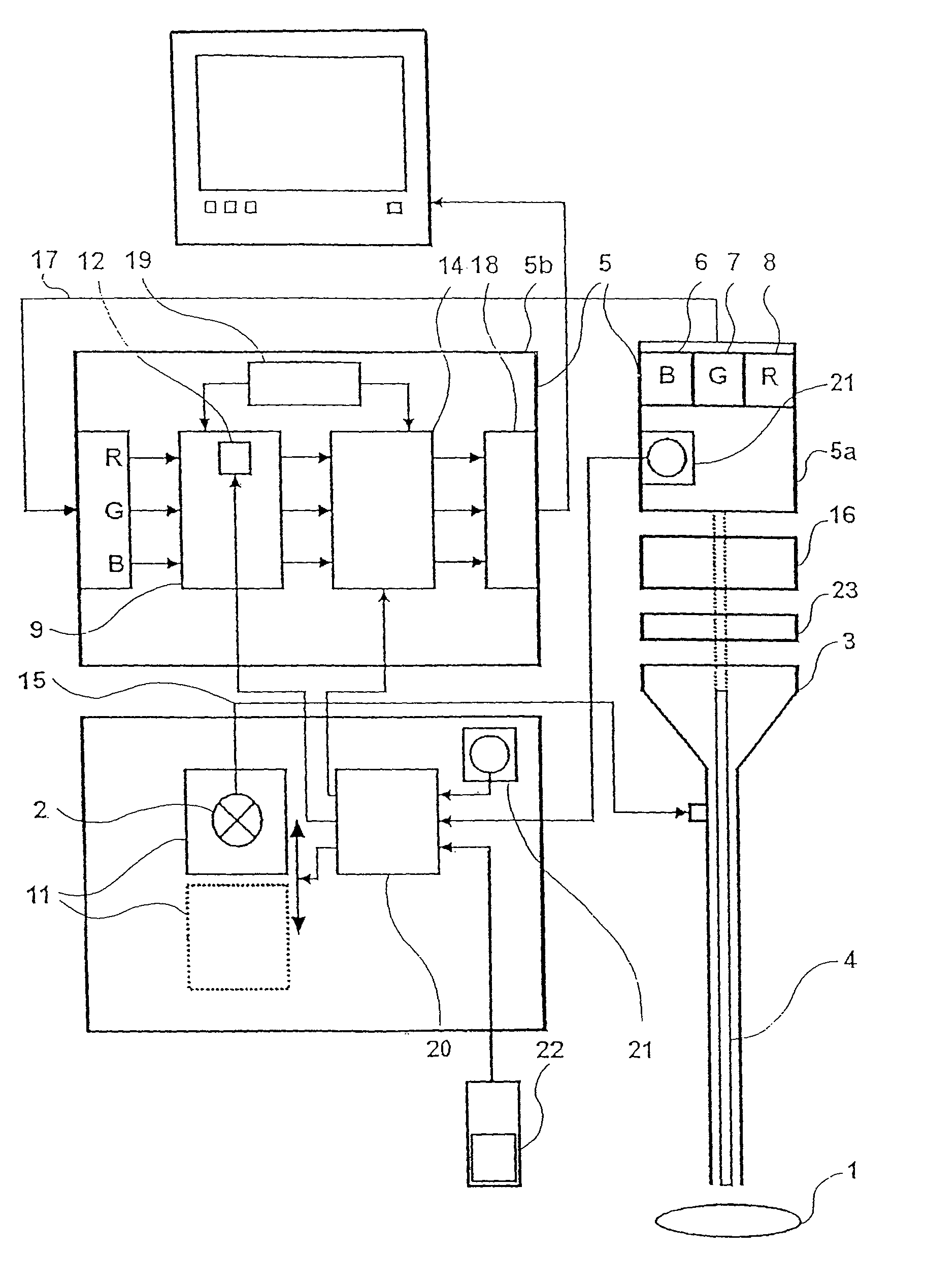

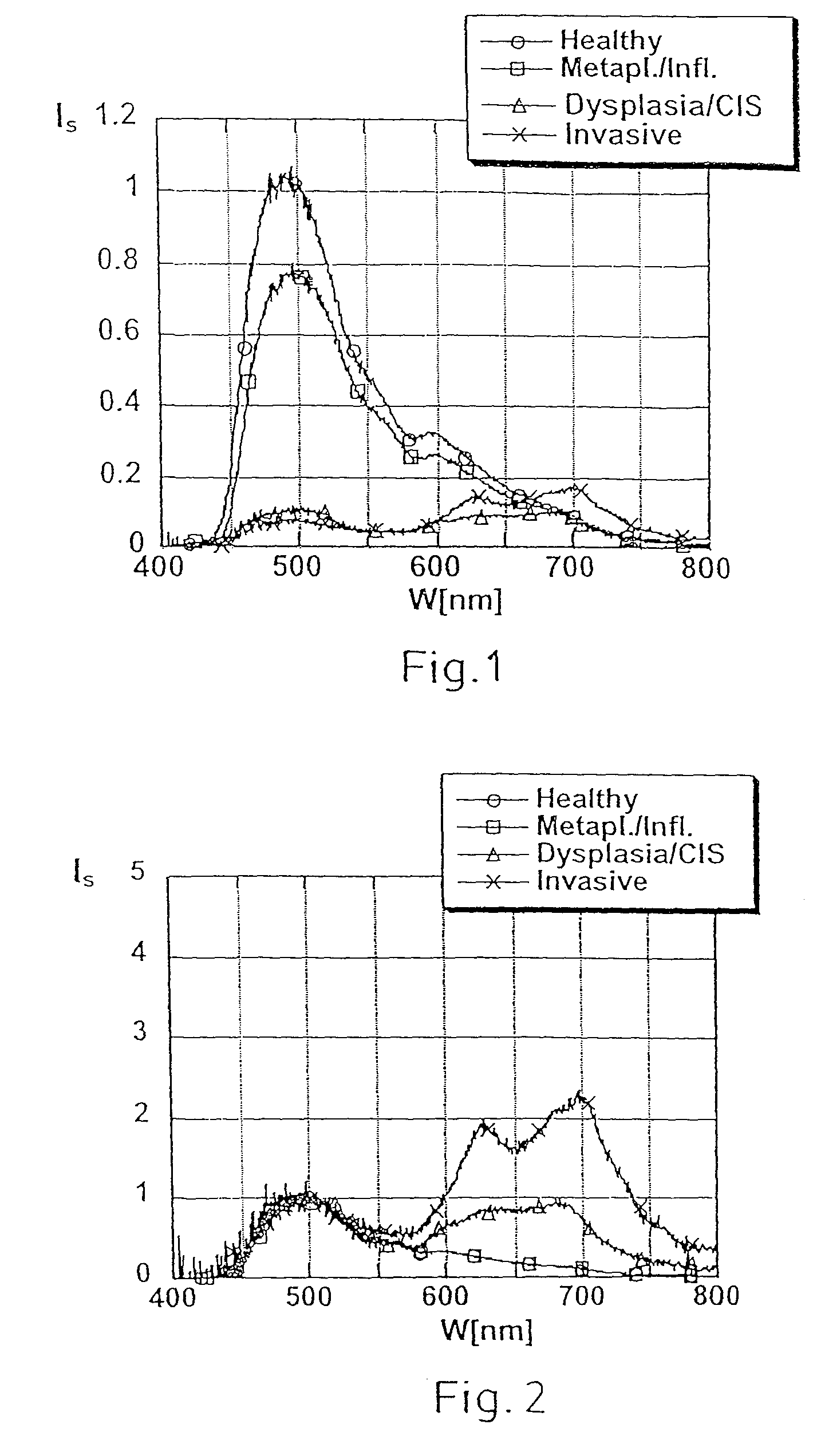

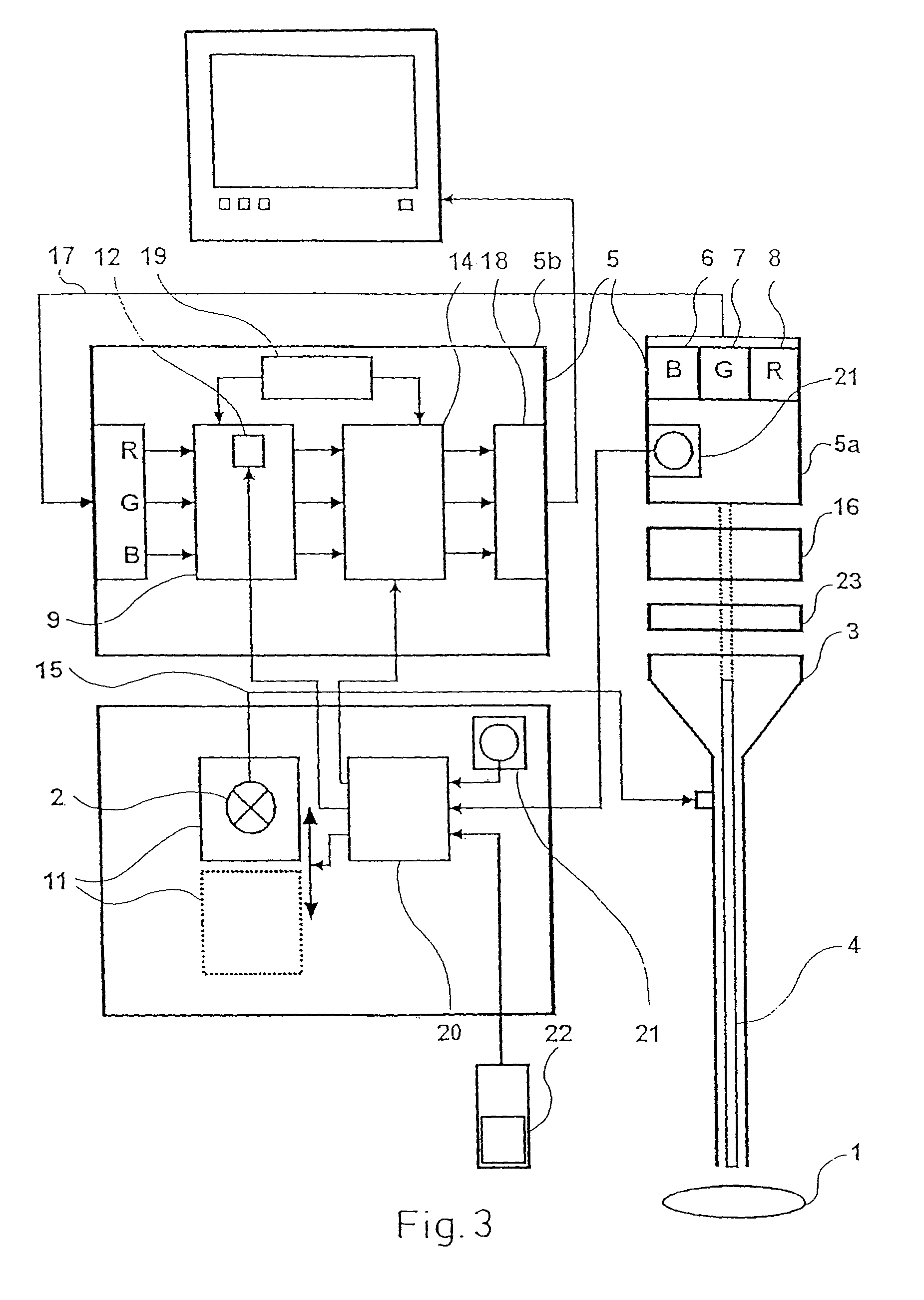

Device for the picture-providing diagnosis of tissue using one of at least two diagnosis modes

InactiveUS8019405B2High color contrastPromote differentiationBronchoscopesLaryngoscopesRed fluorescenceWhite light

A device for picture-providing diagnosis of tissue is selectively operated in a picture-providing white light diagnosis mode and a picture providing auto-fluorescence mode. A color camera having red, green, and blue sensors provides a monitor which picture signals. A light source emits fluorescence excitation light and additionally emits so much red light that the red light remitted by the tissue dominates the red fluorescence light in the picture providing auto-fluorescence mode. The signal from the red sensor of the camera is damped so that normal time appears green and pre-malignant and early malignant tissue appears red.

Owner:RICHARD WOLF GMBH

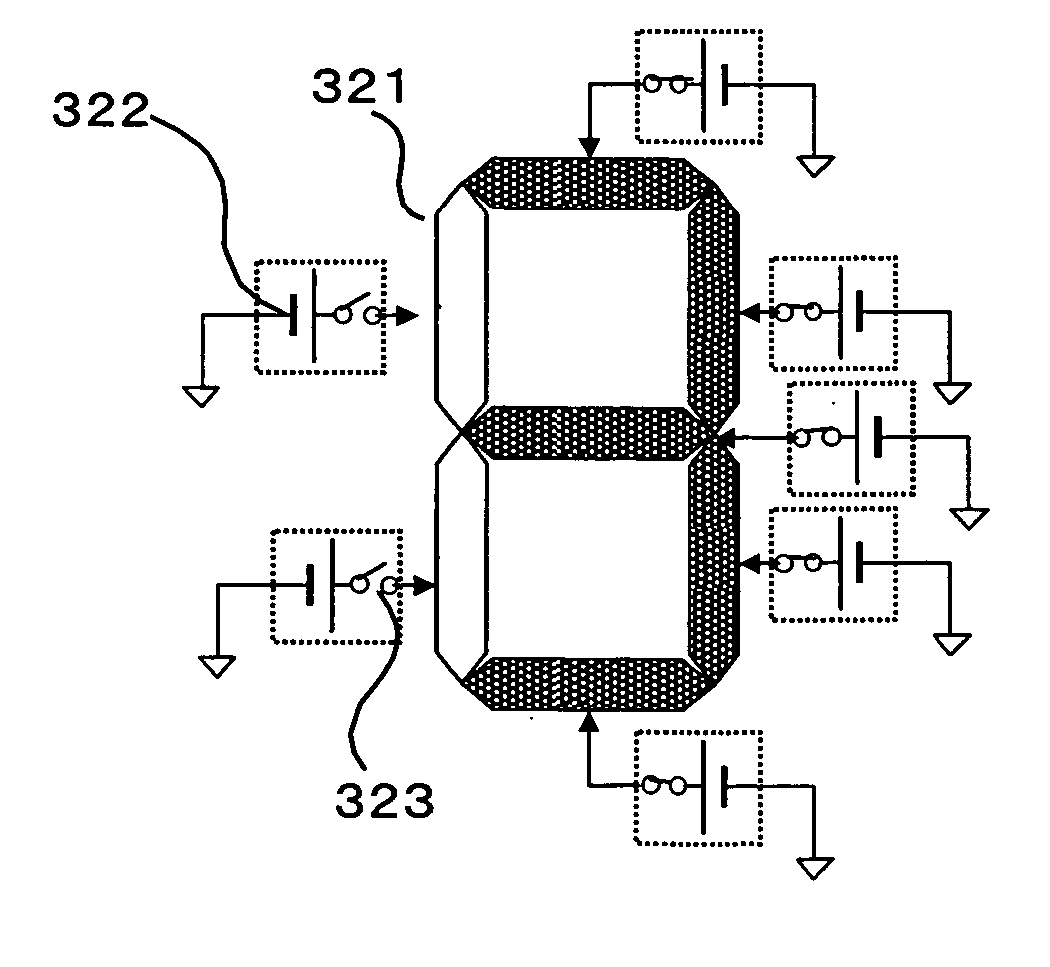

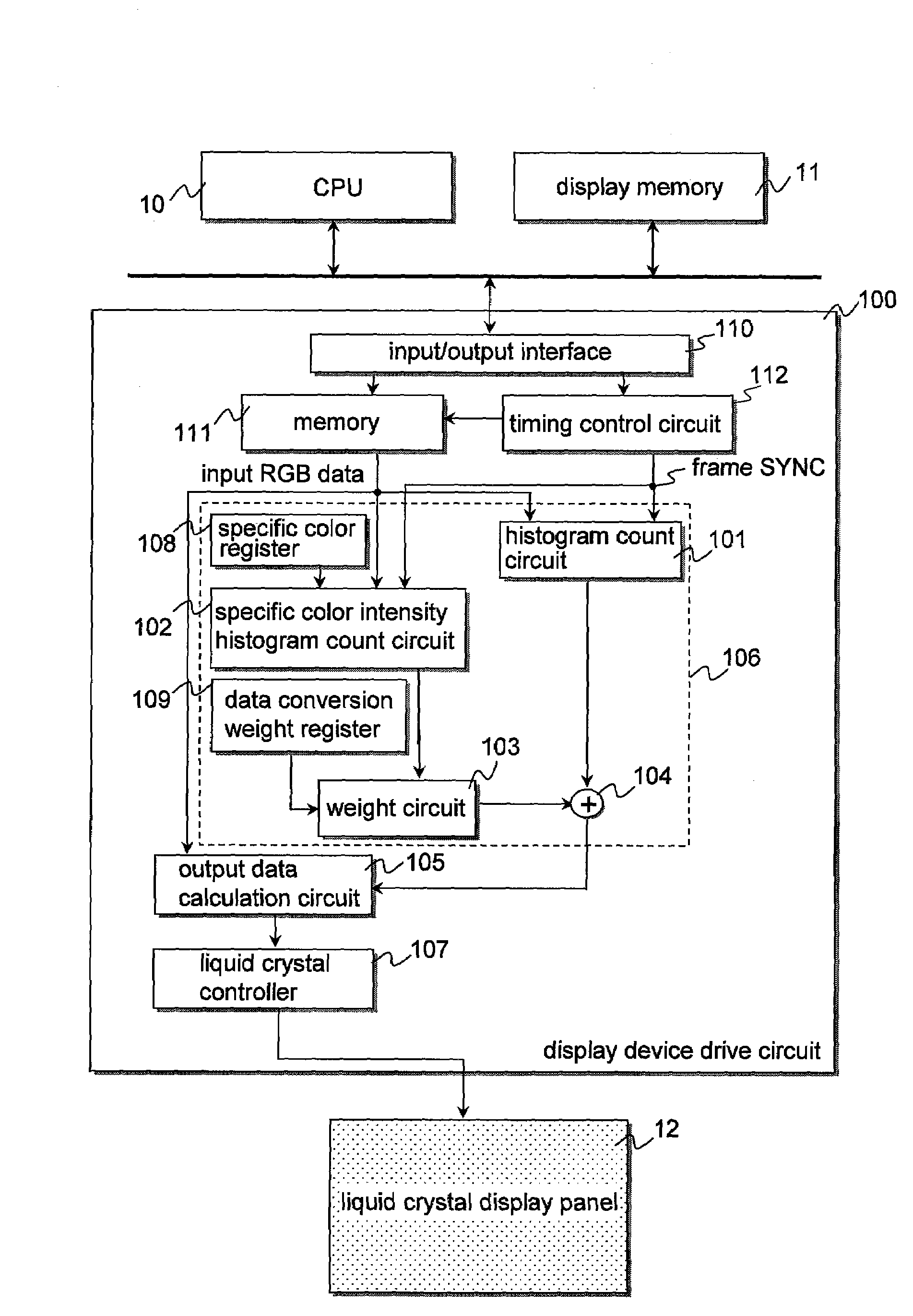

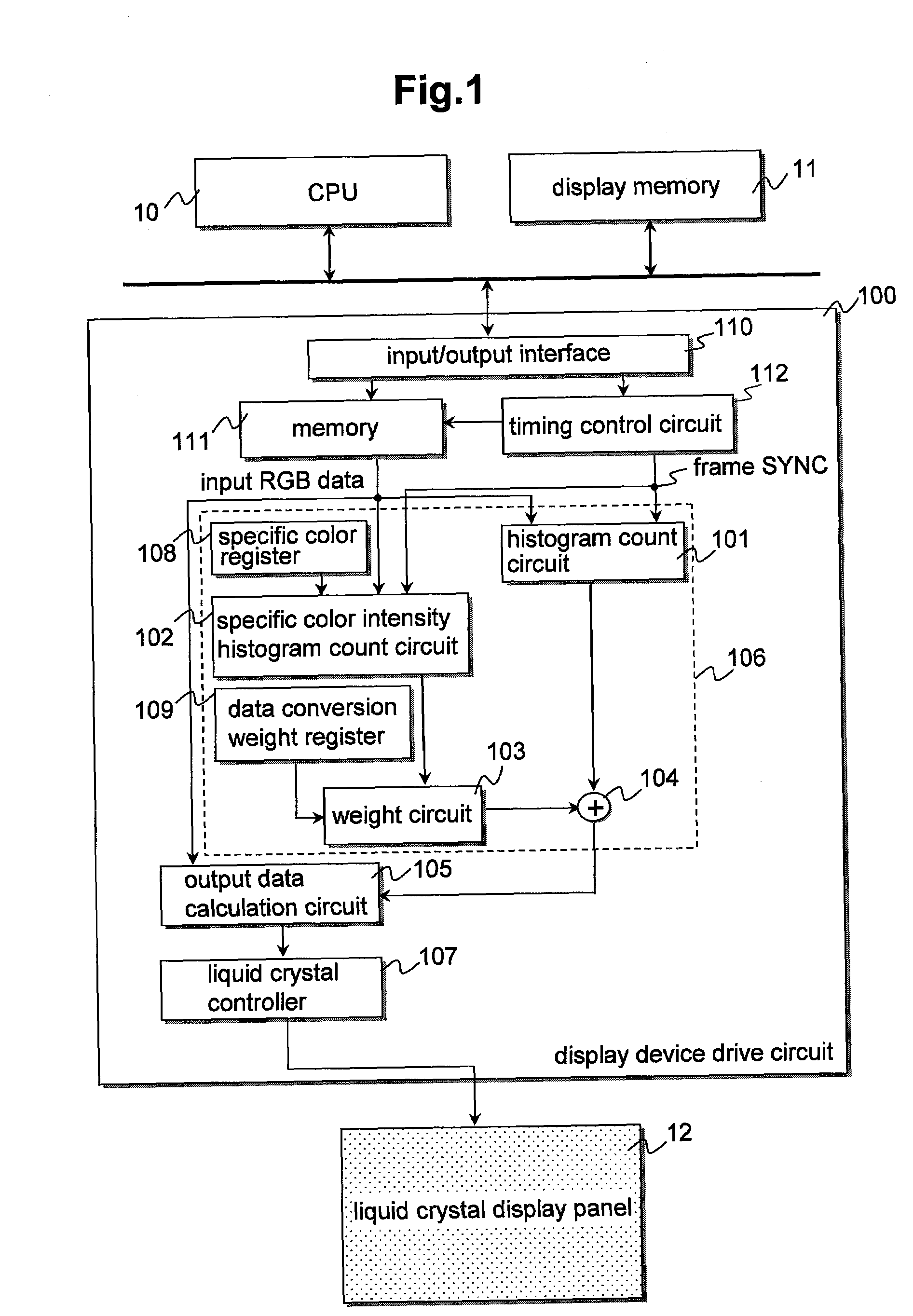

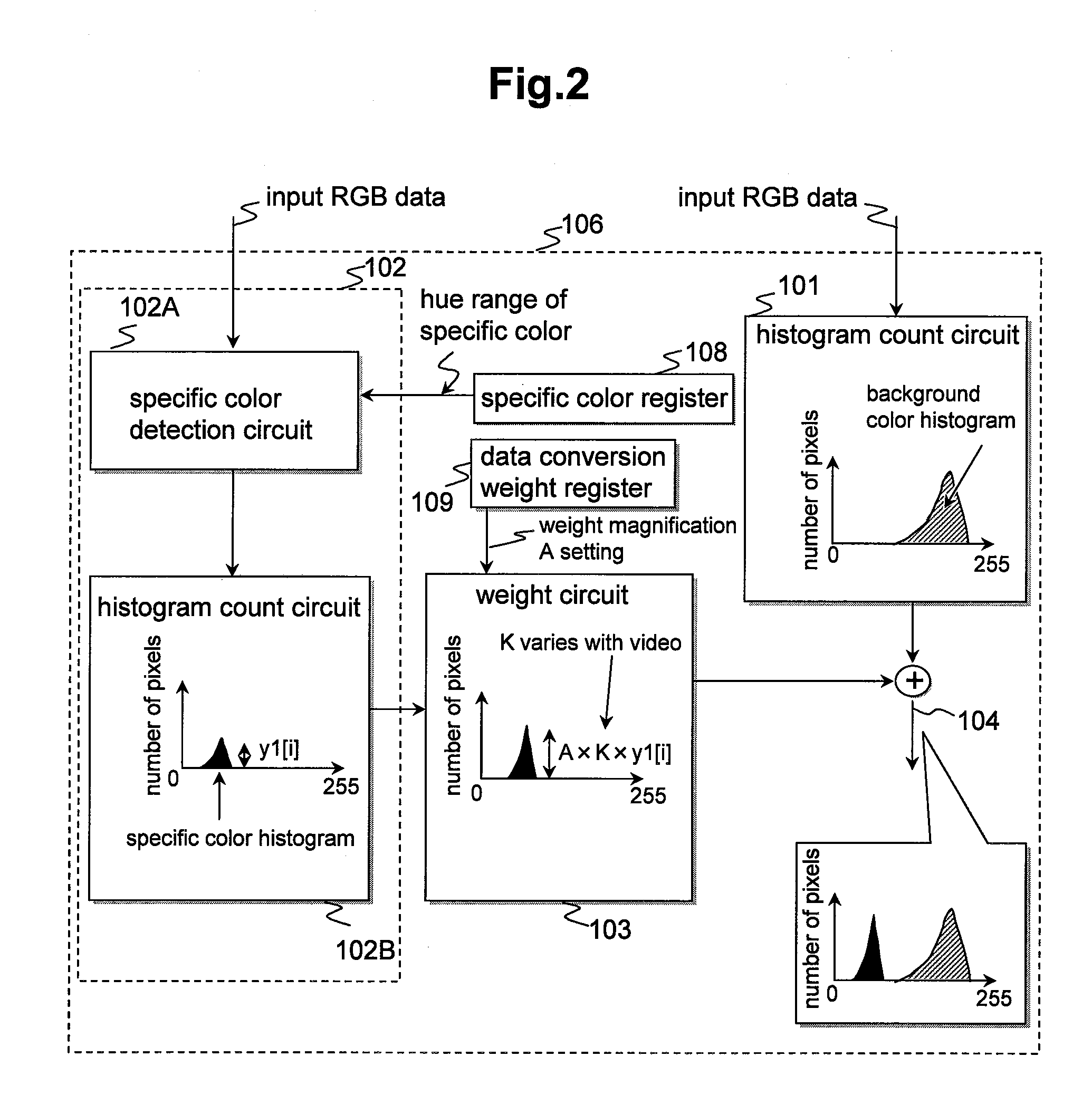

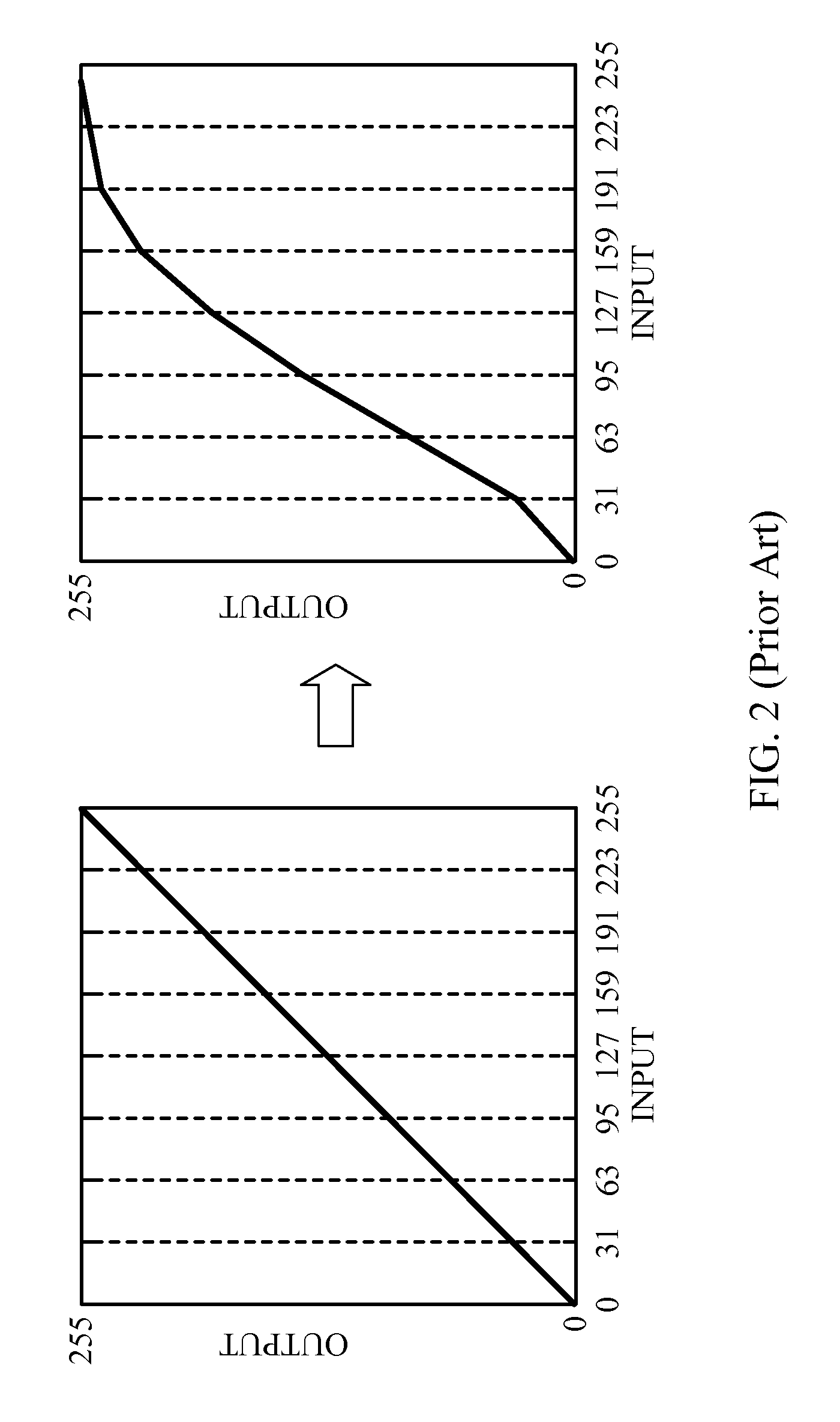

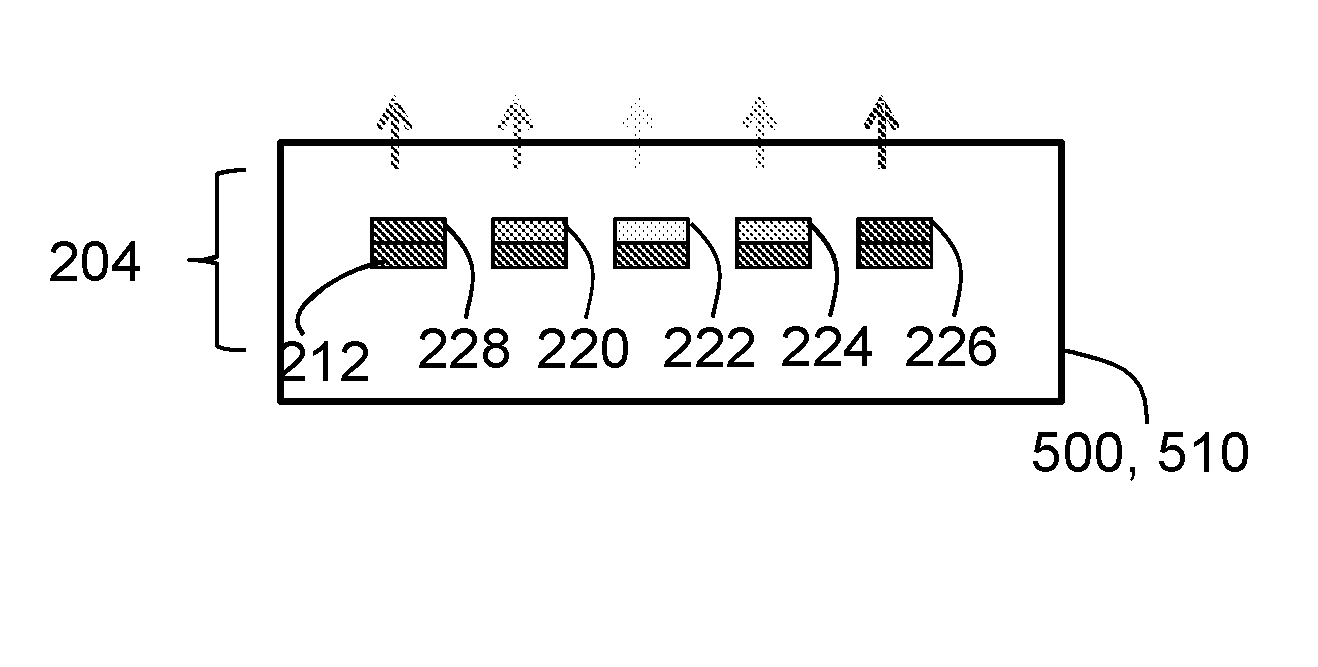

Liquid crystal driving device

InactiveUS20090303264A1Reduce intensityIncrease display contrastCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayHigh intensity

A liquid crystal driving device includes a liquid crystal controller and specific color expansion circuits. The liquid crystal controller generates a liquid crystal drive signal to be supplied to a liquid crystal display panel in response to display data. The specific color expansion circuits generate an image output signal from a low-intensity image input signal corresponding to a specific color by intensifying a gradation using a specified factor. The specific color expansion circuits generate an image output signal from a high-intensity image input signal corresponding to a specific color by intensifying a gradation using another small factor. The image output signal is appropriately intensified by the specific color expansion circuits and is supplied as display data to the liquid crystal controller.

Owner:RENESAS ELECTRONICS CORP

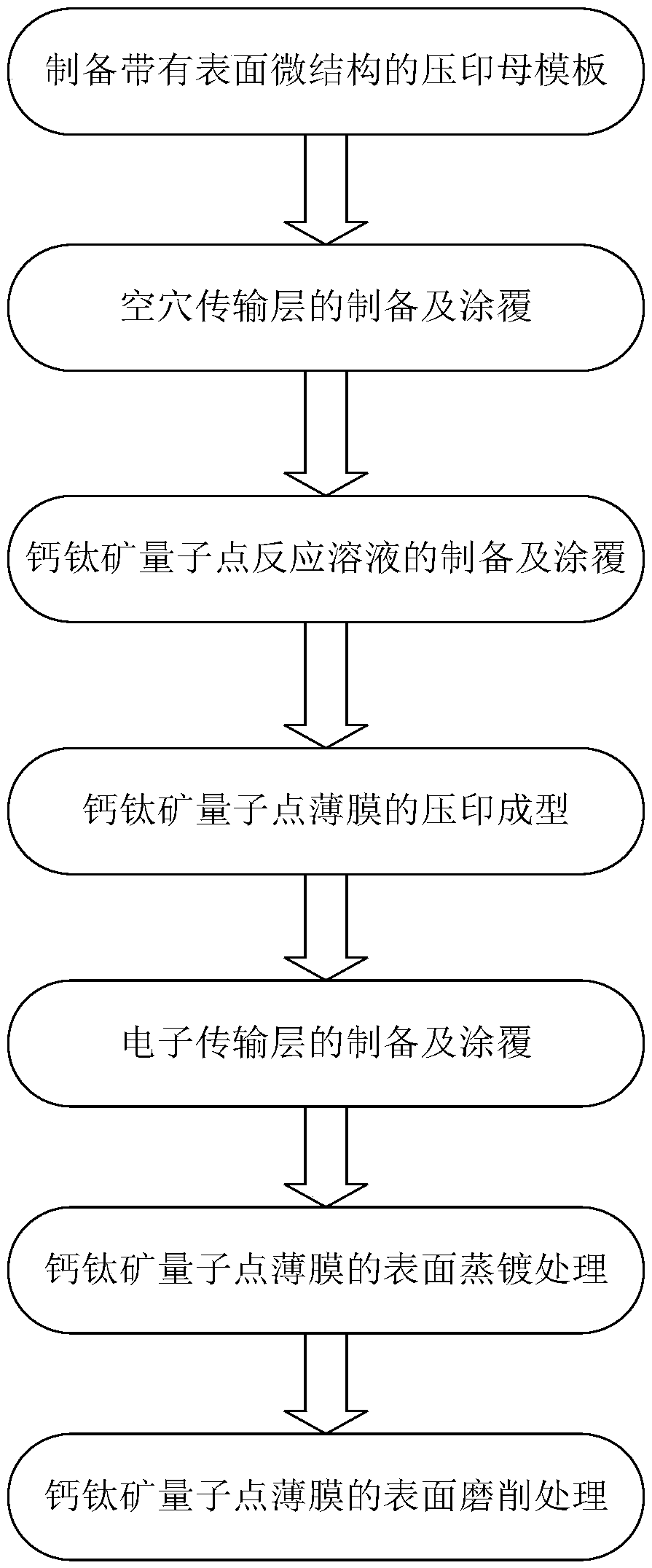

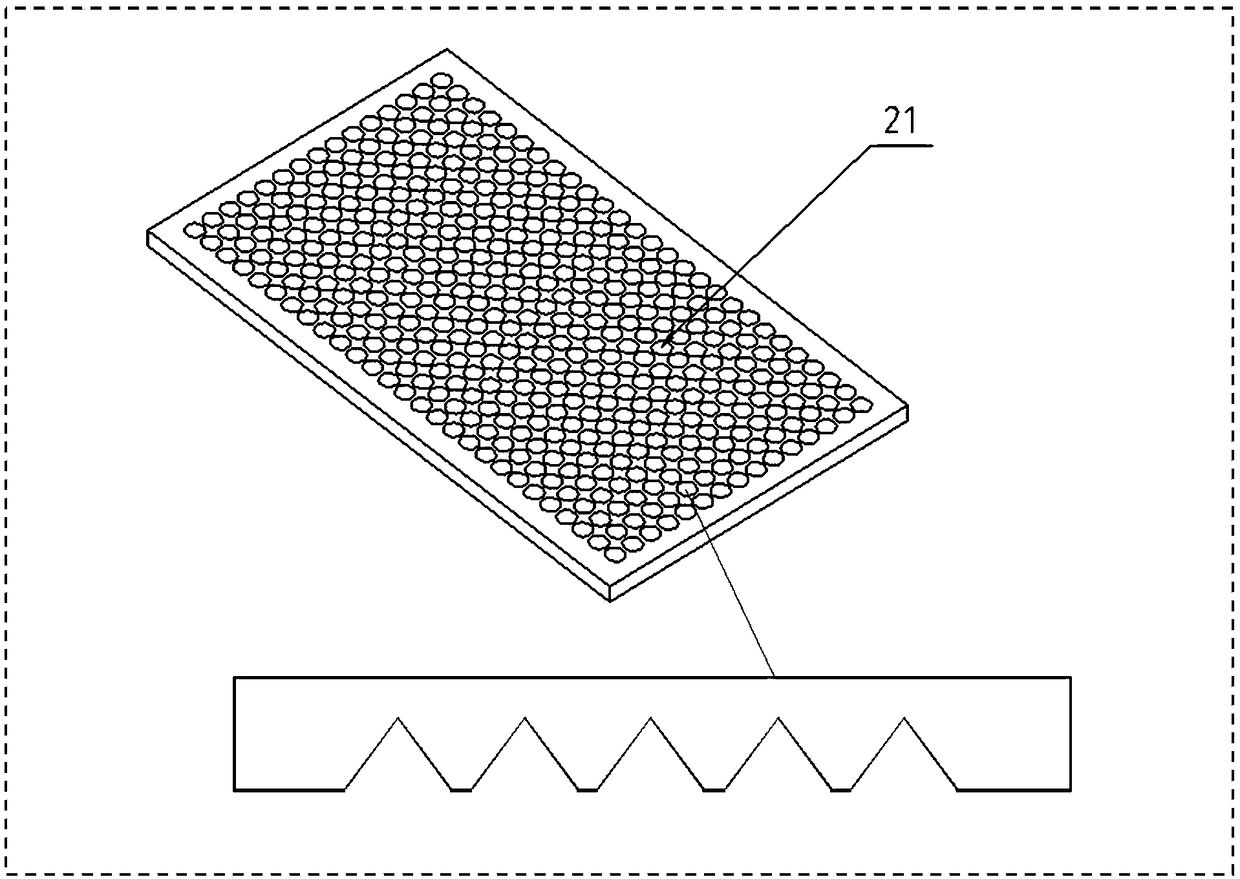

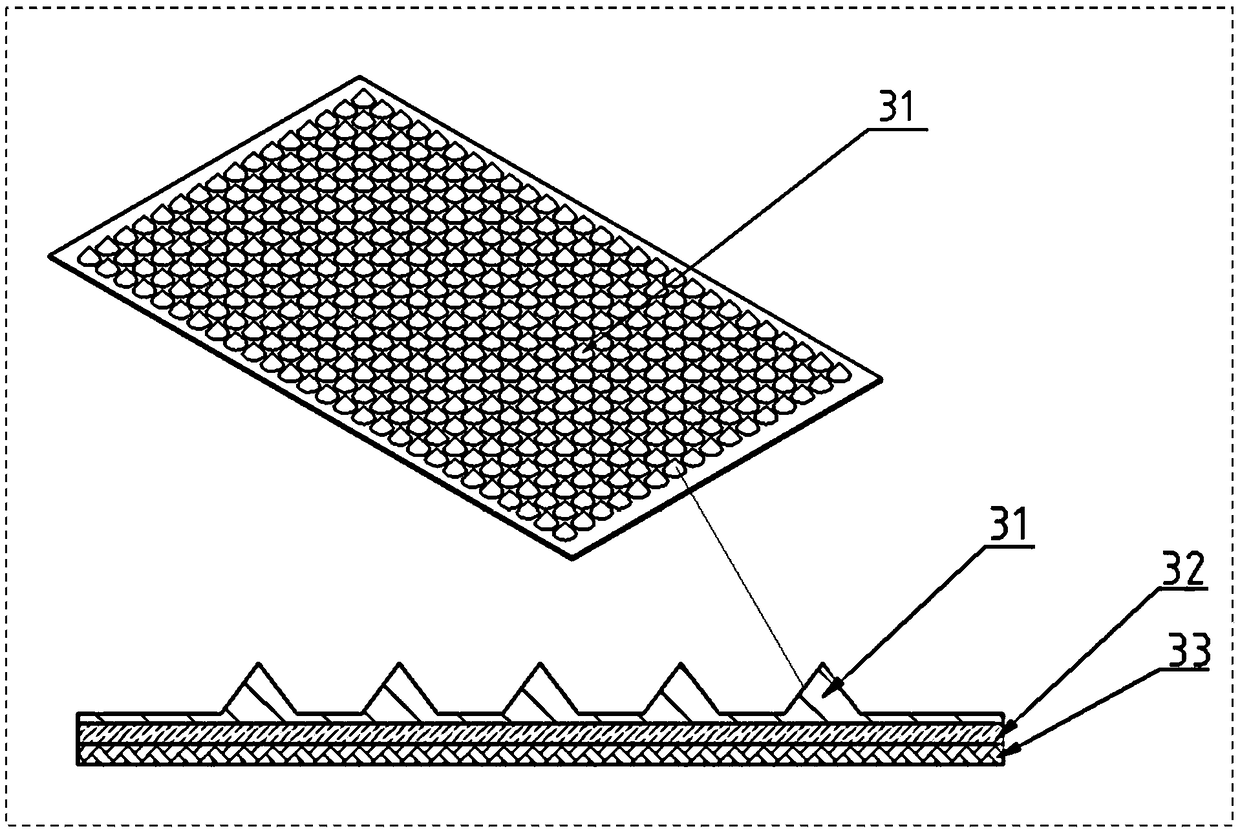

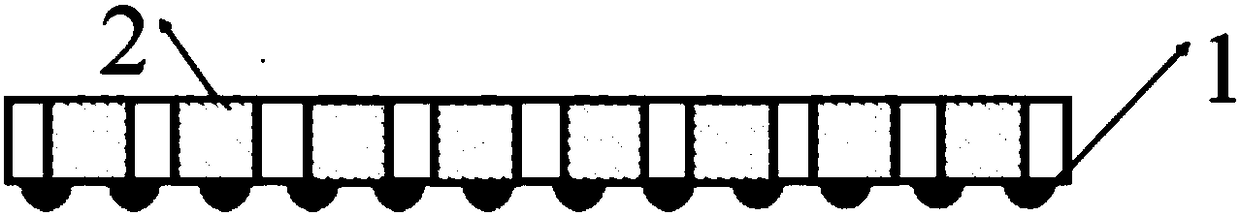

Preparation method of conductive and light transmittance perovskite quantum dot thin film

PendingCN109301093AHigh color contrastImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotTransmittance

The present invention discloses a preparation method of a conductive and light transmittance perovskite quantum dot thin film. The method comprises the steps of: preparation of a cavity plate with a surface array microstructure; preparation and coating of a hole transport layer; preparation and coating of a quantum dot reaction solution; imprinting of a quantum dot thin film; preparation and coating of an electron transfer layer; surface evaporation processing of the quantum dot thin film; and surface grinding processing of the quantum dot thin film. The preparation method of the conductive and light transmittance perovskite quantum dot thin film employs surface processing such as imprinting and metal evaporation to achieve preparation of the conductive thin film, employs surface grindingto achieve the light transmittance performance of the thin film; and the thin film can be light-transmitted and conductive, and the preparation method is high in efficiency, accurate in precision andlow in manufacturing low and is suitable for large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

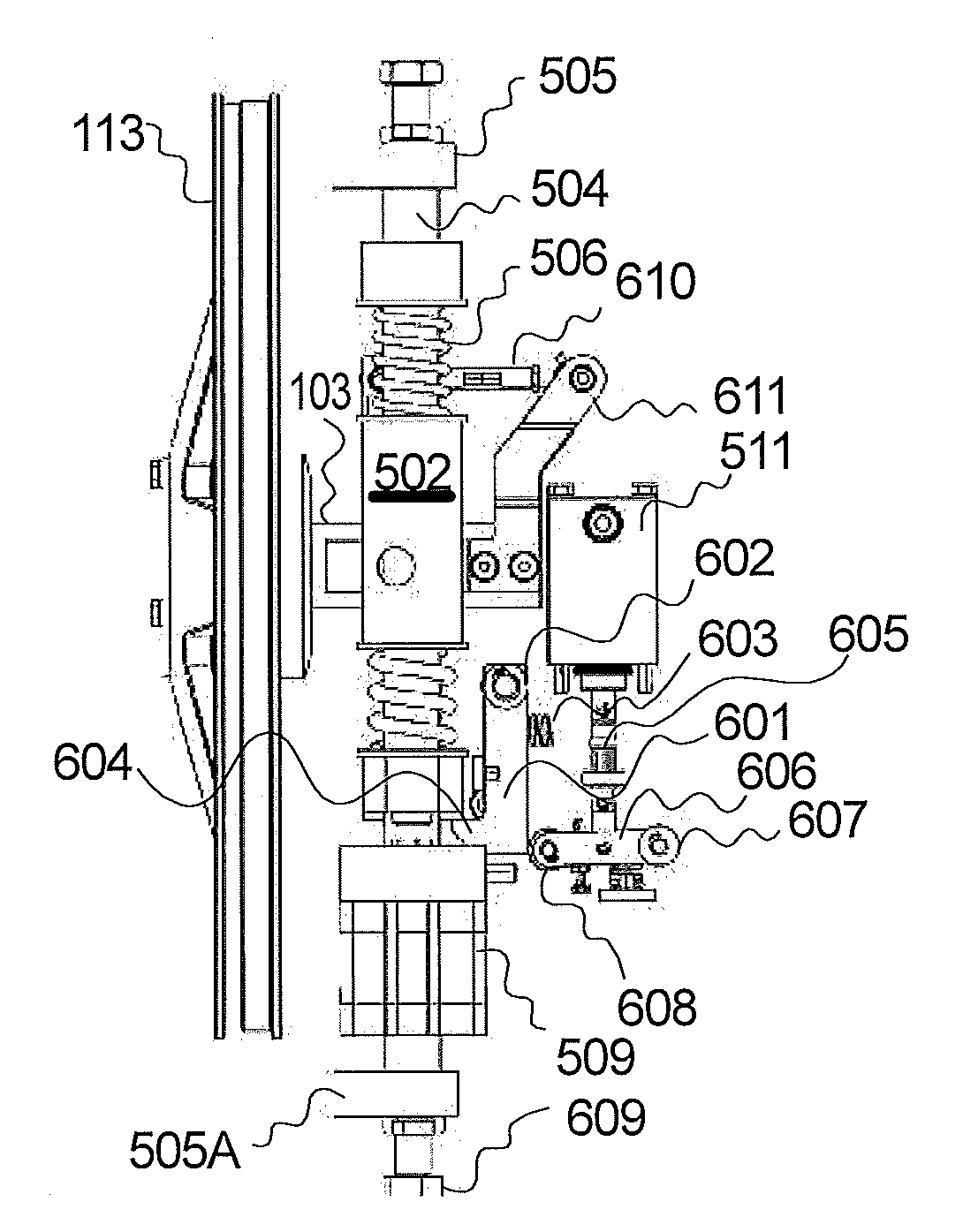

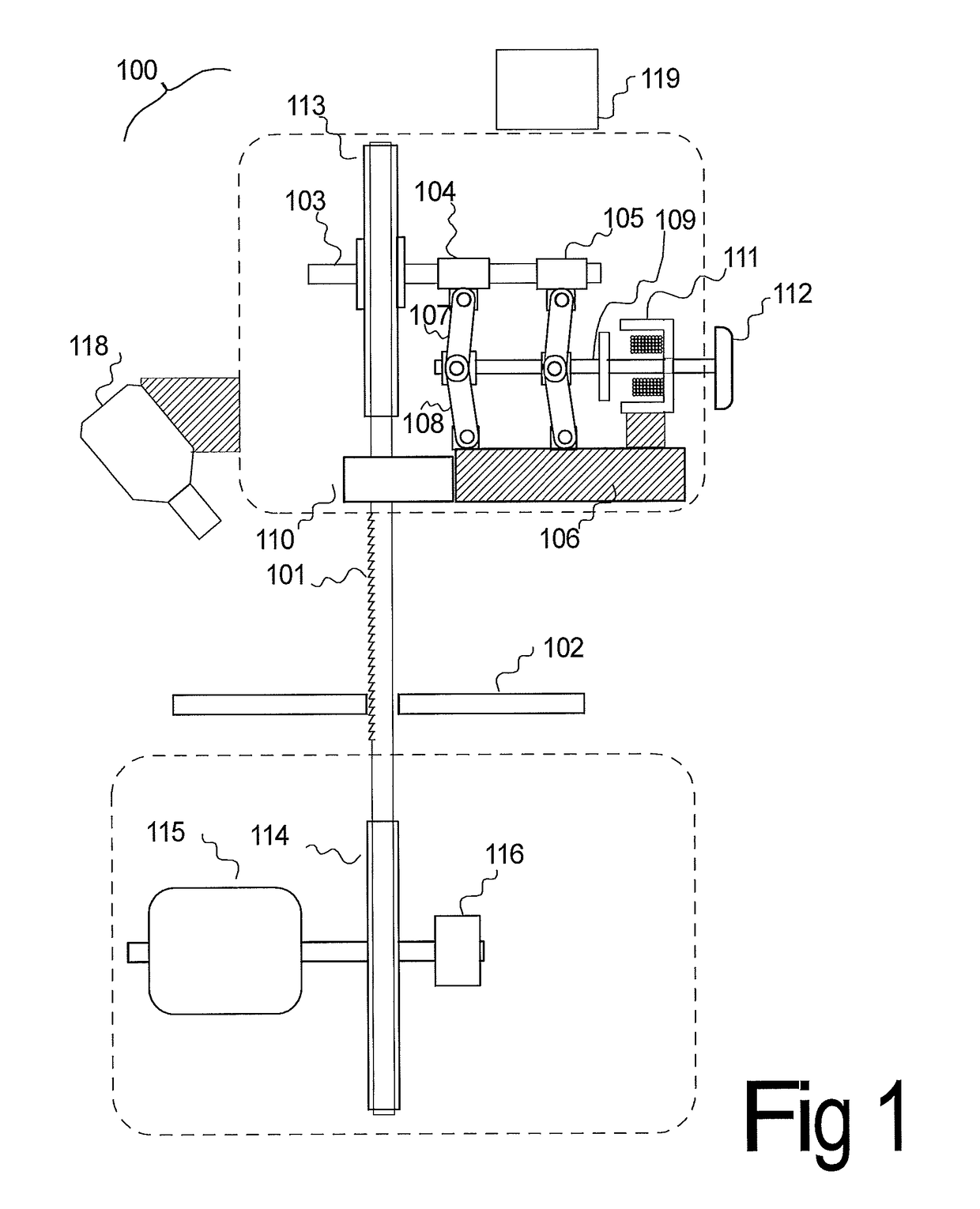

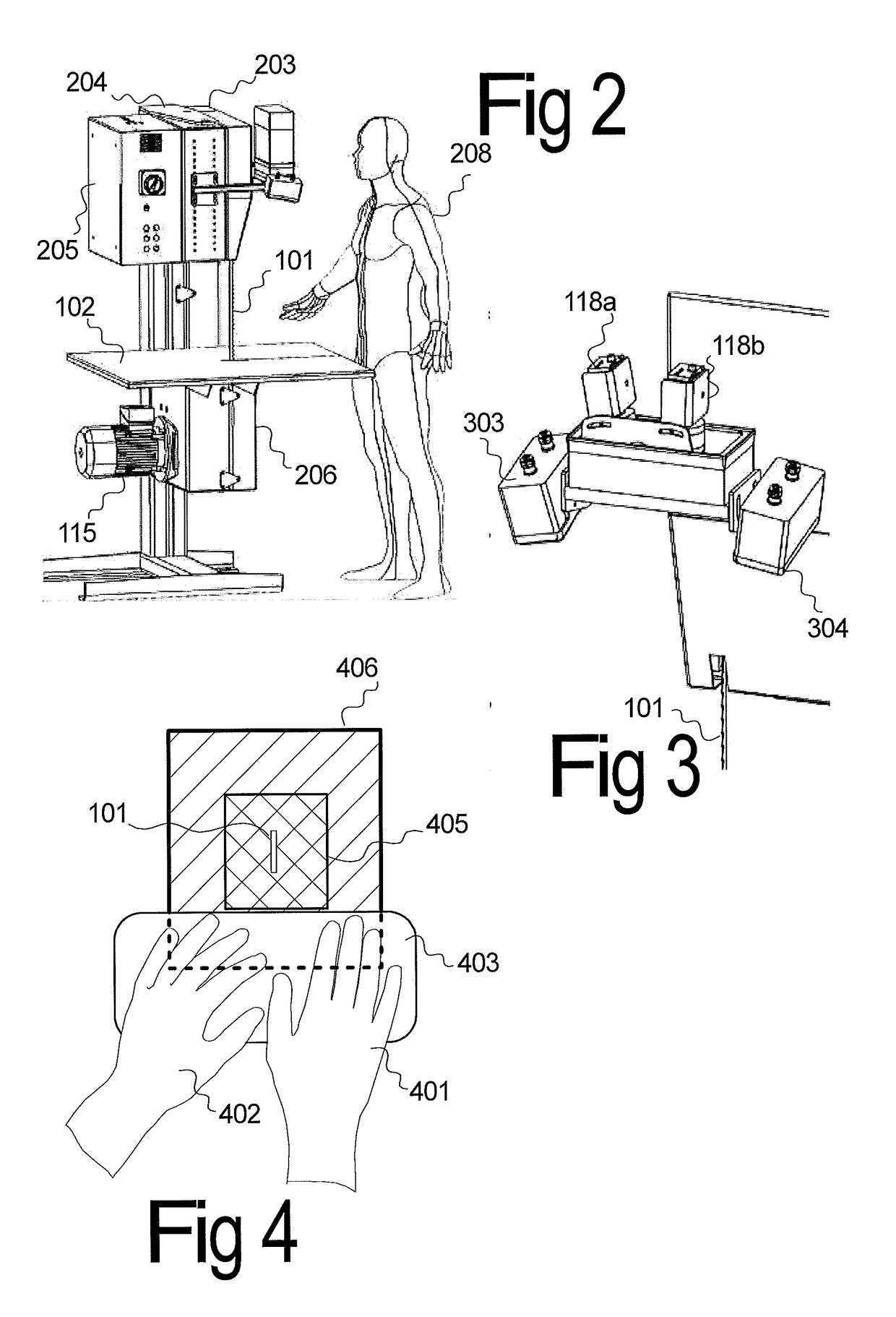

Productivity enhancement for band saw

ActiveUS20170252939A1Ensure reliabilityHigh color contrastEngineering safety devicesCircular sawsProduction rateMachine vision

Machine vision apparatus tracks a distinctive object in relation to a hazardous location on a work surface of a modified band saw in two, three, or four (3-D+T) dimensions, and calculates whether to send an “immediate shut-down signal” to the band saw. Cameras and an image processor are mounted on the band saw. The signal causes an integrated blade-arresting or stopping mechanism to immediately shift the idler wheel, removing blade tension and disconnecting the blade which is then braked to a complete, safe stop before an approaching blue-gloved hand can touch the blade.

Owner:KANDO INNOVATION LTD

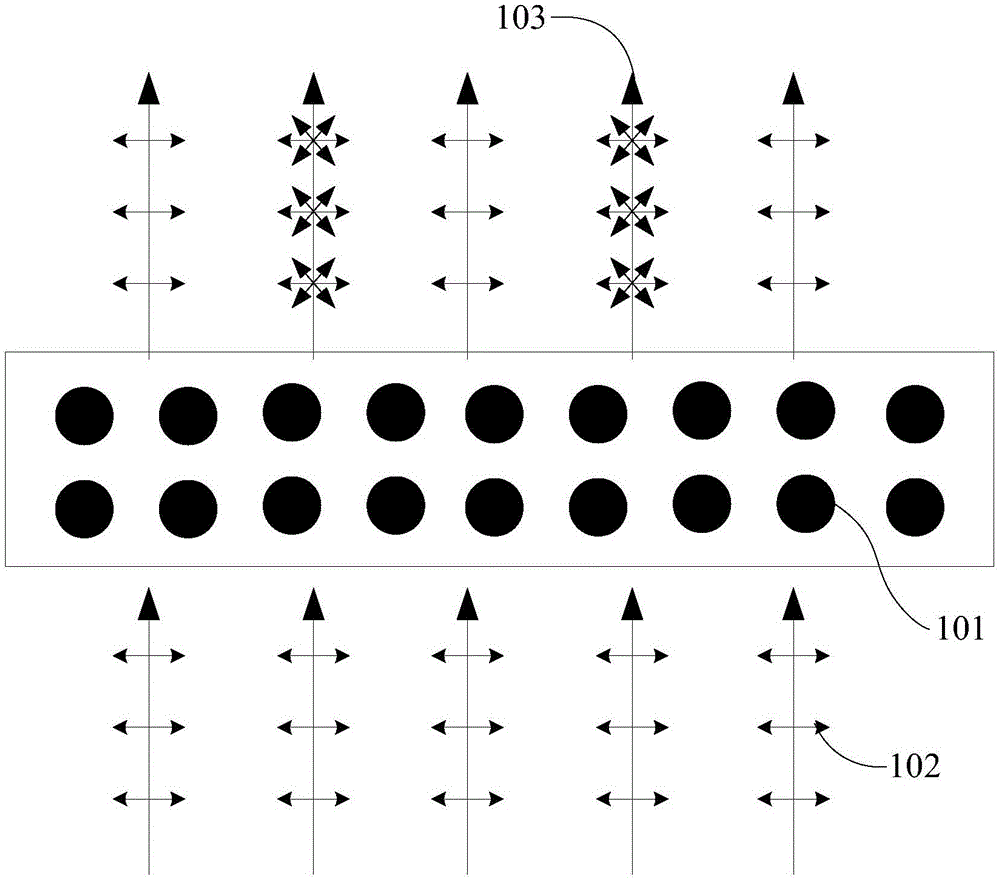

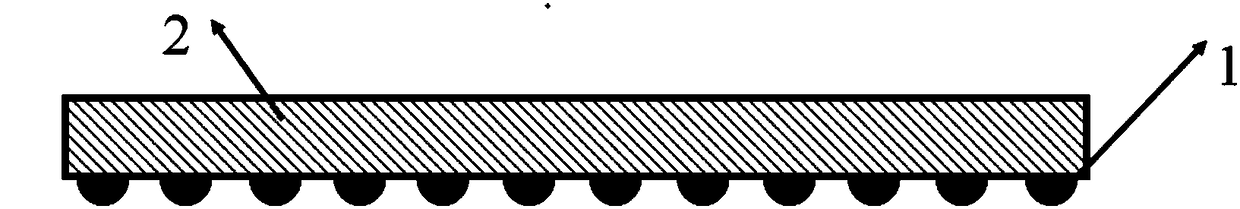

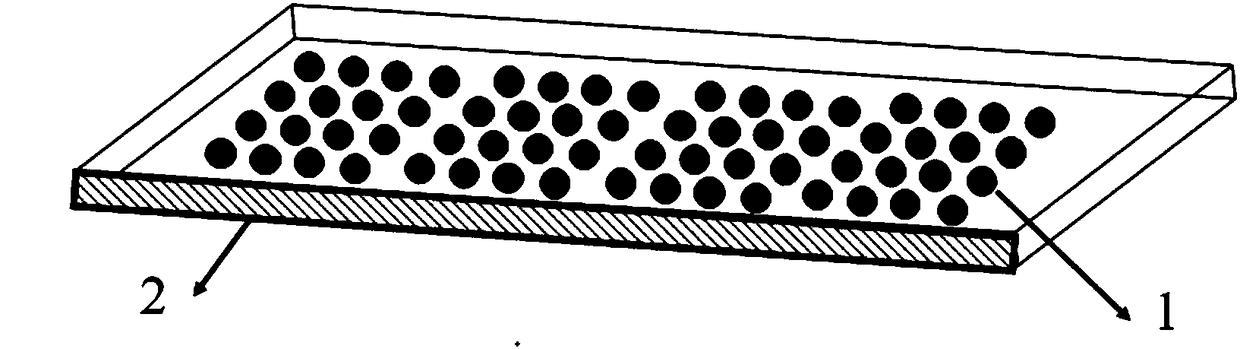

Light guide plate with quantum dot diaphragm array and quantum dot site and application of light guide plate

ActiveCN108072930AReduce dosageReduce restrictionsPlanar/plate-like light guidesNon-linear opticsGamutLight guide

The invention belongs to the field of backlight display, and particularly relates to a light guide plate with a quantum dot diaphragm array and a quantum dot site and application of the light guide plate. In order to solve the problem that an existing display device is very poor in color gamut stability and brightness stability, the light guide plate with the quantum dot diaphragm array and the quantum dot site and application of the light guide plate are provided. At least one quantum dot diaphragm is stuck on the light-in surface of the light guide plate, the quantum dot site is printed on the opposite face of the light-out surface of the light guide plate, and the quantum dot site includes red quantum dots and green quantum dots. The light guide plate is applied to a display device, andthe display device is good in color gamut stability and brightness stability.

Owner:NINGBO EXCITON TECH

Underwater image comprehensive enhancement method for target recognition

ActiveCN111161170AHigh color contrastImprove color saturationImage enhancementWater resource assessmentColor saturationImage contrast

The invention relates to an underwater image comprehensive enhancement method for target recognition, which comprises the following steps of: performing red channel color compensation on an underwaterdegraded image, and eliminating contrast reduction caused by forward scattering of the compensated underwater color image by adopting color cast correction. Meanwhile, in order to meet the application requirements of underwater target detection, gamma correction is carried out on the brightness, saturation and hue of an HSV color space, and the problem of blurring caused by dark overall images and backward scattering is solved by adopting single-channel defogging, so that better image contrast and color saturation are obtained, and meanwhile, the definition of details is effectively improved.The method has the advantages that as proved by subjective and objective experiments on various types of underwater images, compared with the conventional underwater image restoration and enhancementalgorithm, the algorithm provided by the invention can effectively improve the color saturation and definition of the underwater images, is wider in application range, and enables a subsequent targetdetection task to obtain higher accuracy.

Owner:JIANGSU UNIV OF SCI & TECH +1

Dual- wall container with heat activated and/or temperature-change activated color changing capability

ActiveUS20080084915A1Increase color contrastHigh color contrastThermometer detailsTemperature measurement in household appliancesEngineeringDouble walled

Dual-wall container includes an outer wall that is at least one of at least partially substantially transparent and at least partially substantially translucent, an inner wall adapted to contain a substance, at least one symbol arranged an outer surface of the inner wall, and at least one of a coating of a thermochromatic composition arranged on the outer surface of the inner wall, a thermochromatic composition layer arranged on the outer surface of the inner wall, and a thermochromatic composition arranged on an outer surface of at least the at least one symbol. The thermochromatic composition is structured and arranged to change color when the inner wall experiences or senses a temperature change. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:ROBERT GORDON INDS

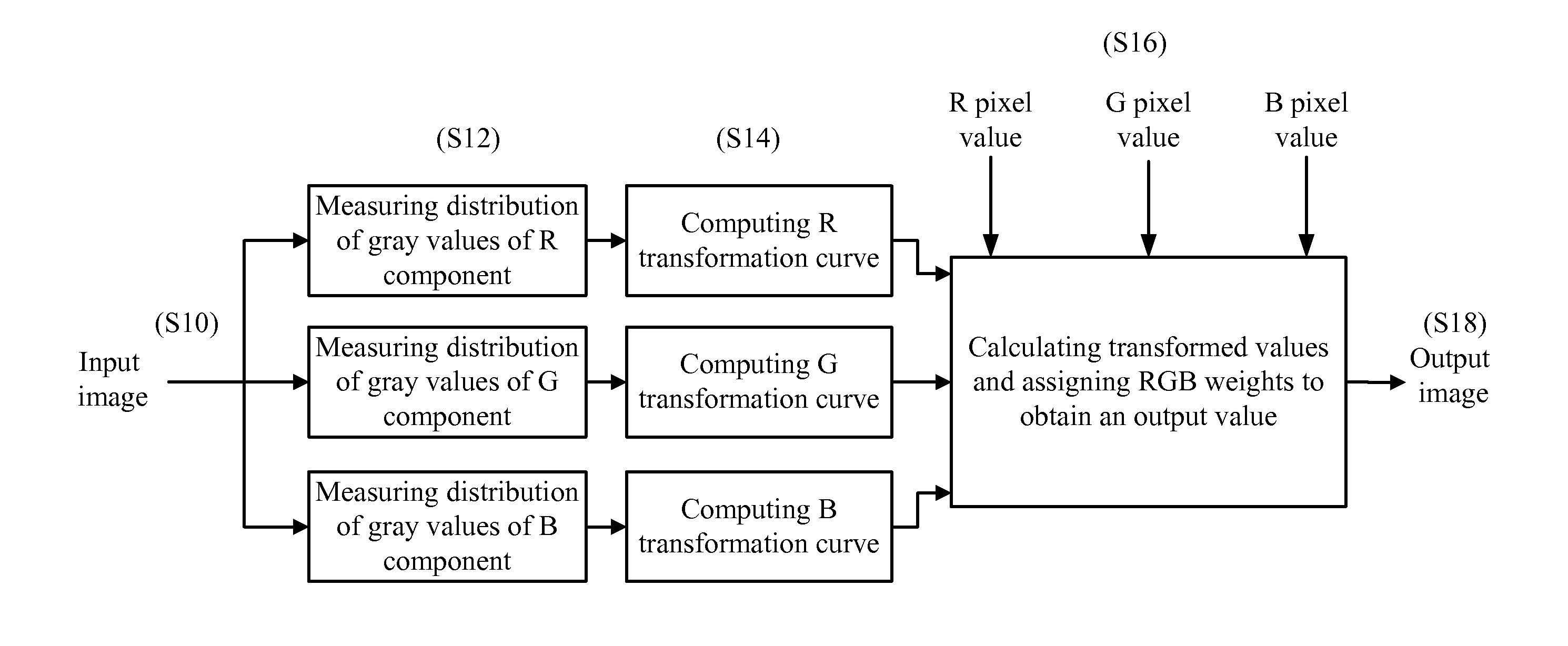

Method for enhancing contrast of color image displayed on display system and image processing system utilizing the same

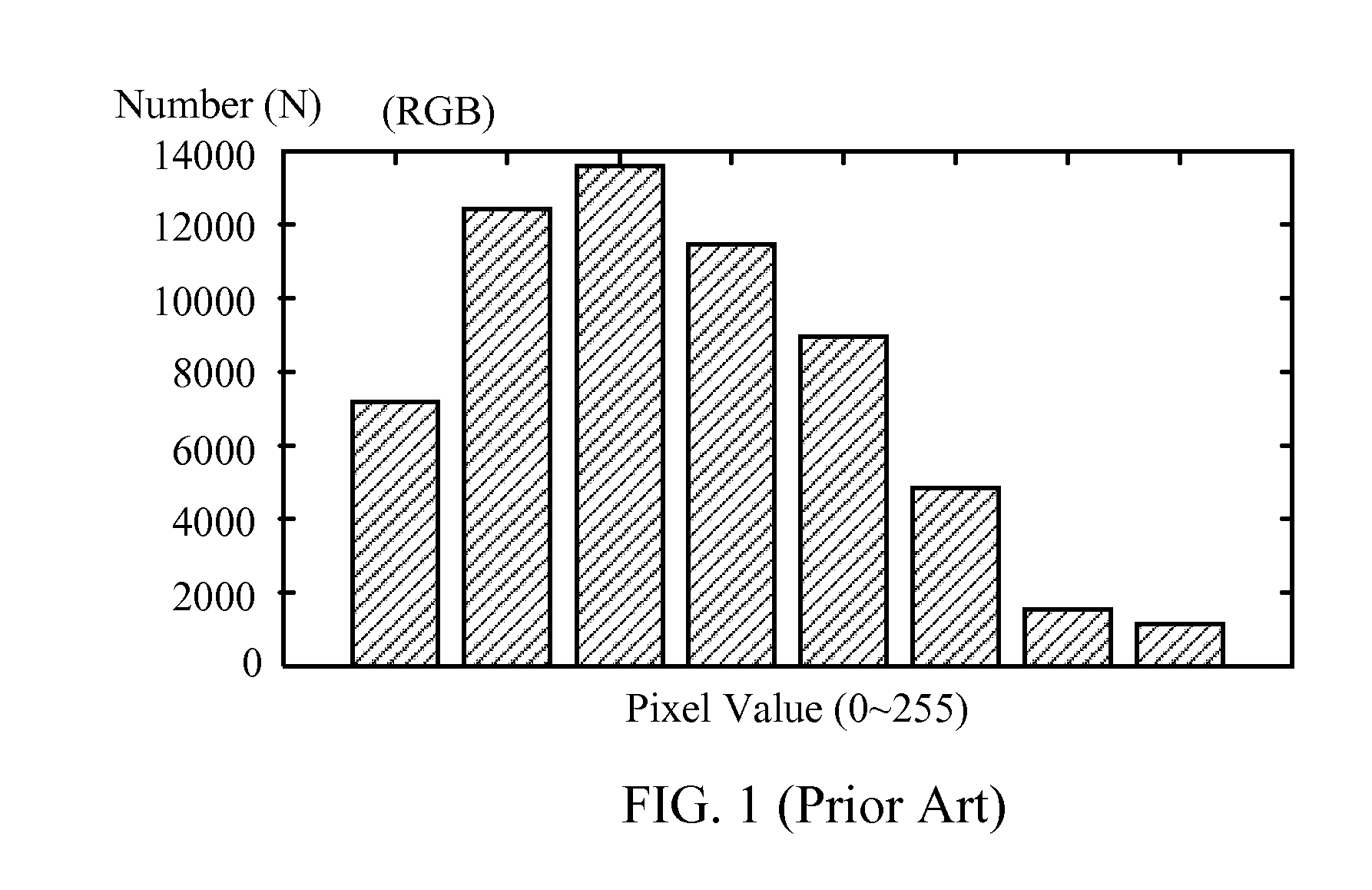

InactiveUS20140125688A1Effectively maintain color distributionImprove image contrastCathode-ray tube indicatorsColor imageImaging processing

The present invention provides a method for enhancing contrast of a color image displayed on a display system and an image processing system utilizing the same. In the present invention, the gray values of R, G, and B components of one color image are separately counted during processing the image. When calculating the corresponding output values for the gray values of R, G, and B components in each pixel, they are adapted to ratios between the gray values of R, G, and B components. Therefore, the present invention can effectively maintain the color distribution for a considerable degree and greatly enhance the image contrast.

Owner:CHUNGHWA PICTURE TUBES LTD

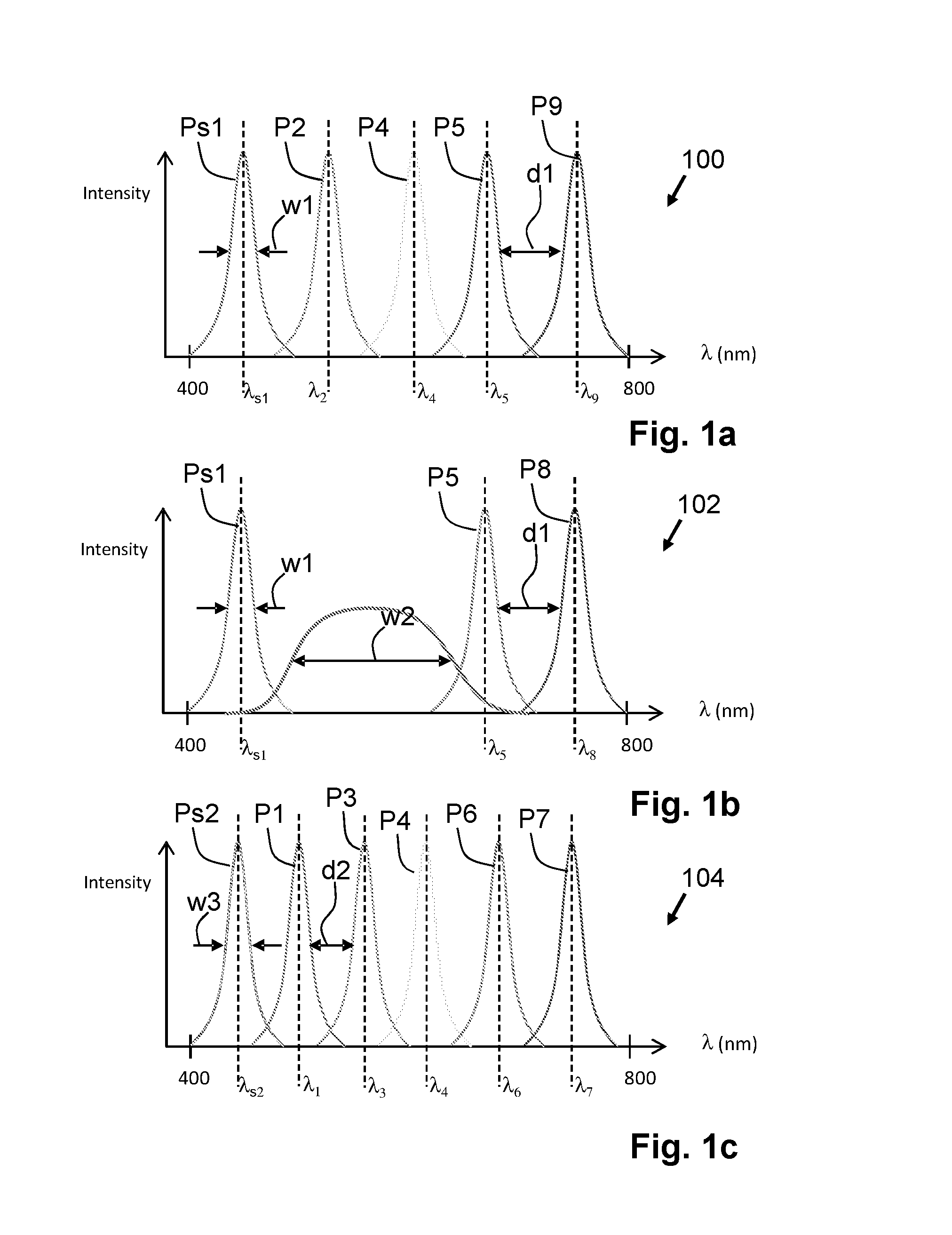

Light source, luminaire and surgical illumination unit

ActiveUS20150362151A1High color contrastMechanical apparatusPoint-like light sourceLength waveColor contrast

The Invention provides a light source, a luminaire and a surgical illumination unit in which two narrow-band light emitters both emit light in a narrow spectral peak having a full-width-half-maximum equal to or smaller than 40 nanometers. Both of the narrow-band light emitters have a different central emission wavelength within a blue color-range, within a green color range or within a red color-range. At least one of the two narrow-band light emitters comprises a luminescent material for generating the narrow spectral peak. The light source is further configured such that a distance between the narrow spectral peaks of the two narrow-band light emitters prevents overlap of the narrow spectral peaks. Due to the individual narrow spectral peaks, a color contrast within one of the color-ranges is significantly enhanced.

Owner:SIGNIFY HLDG BV

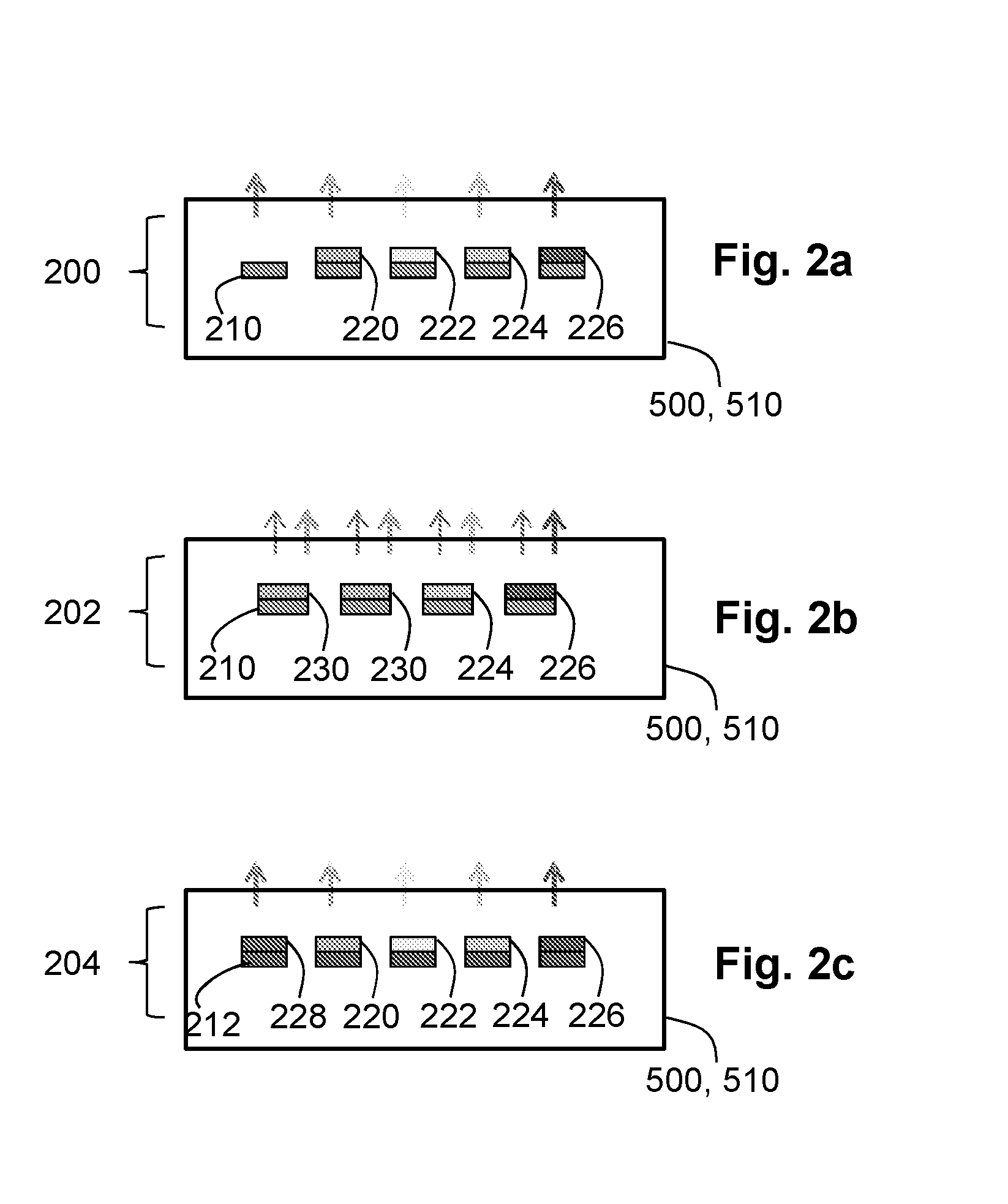

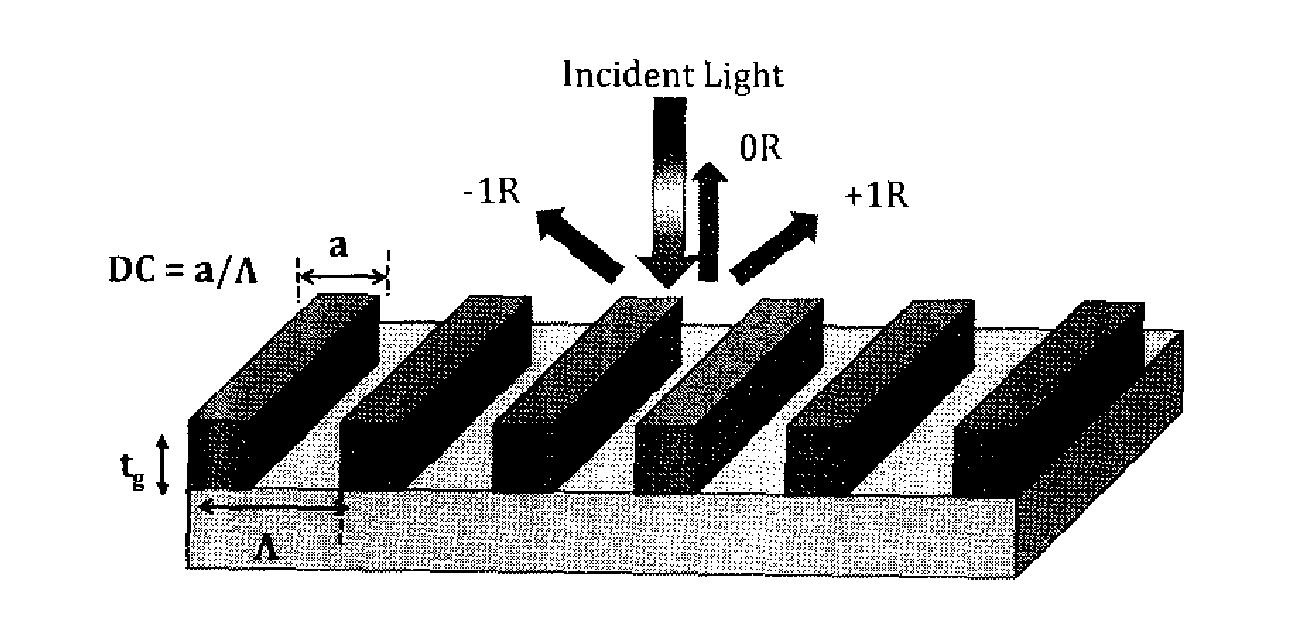

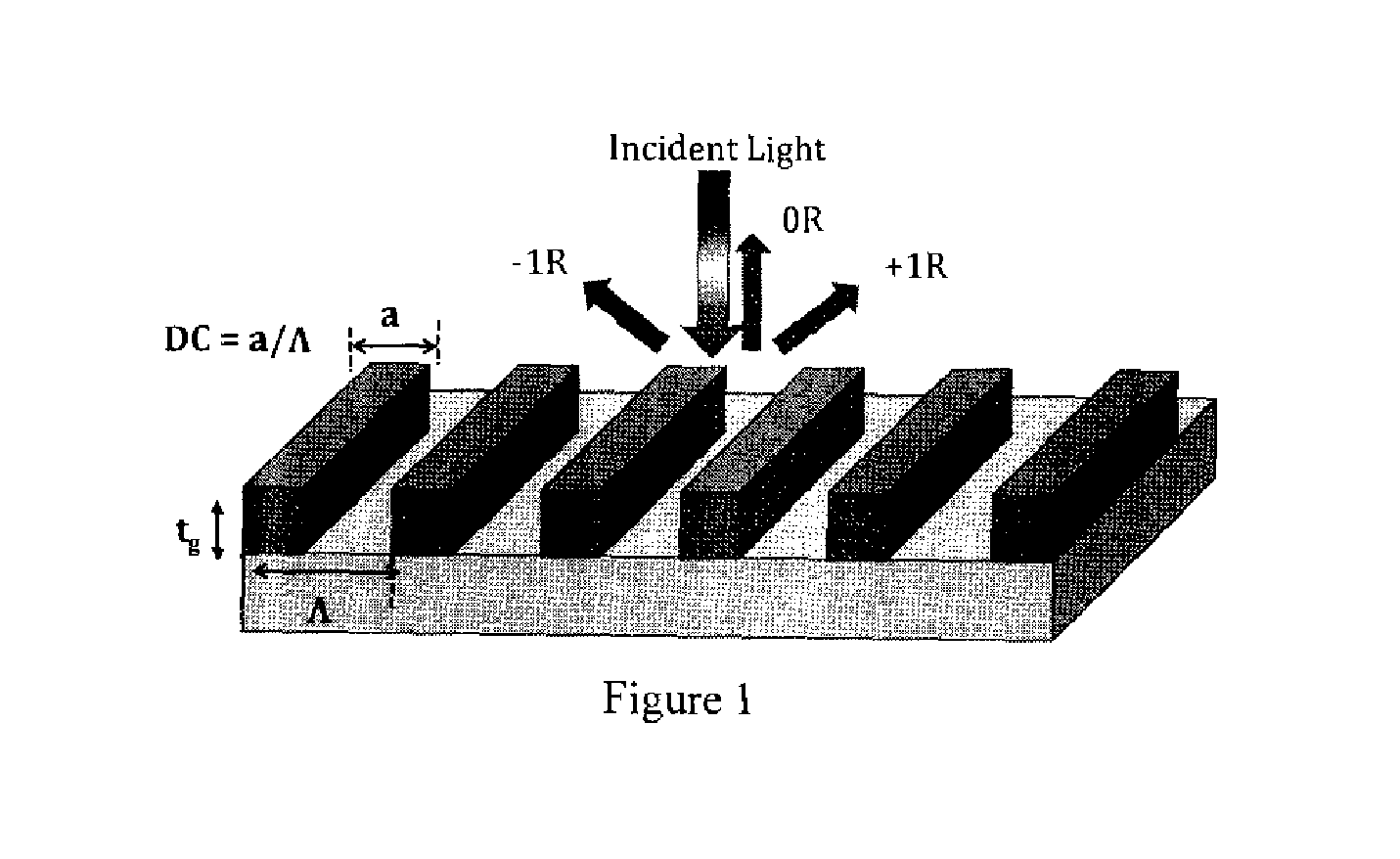

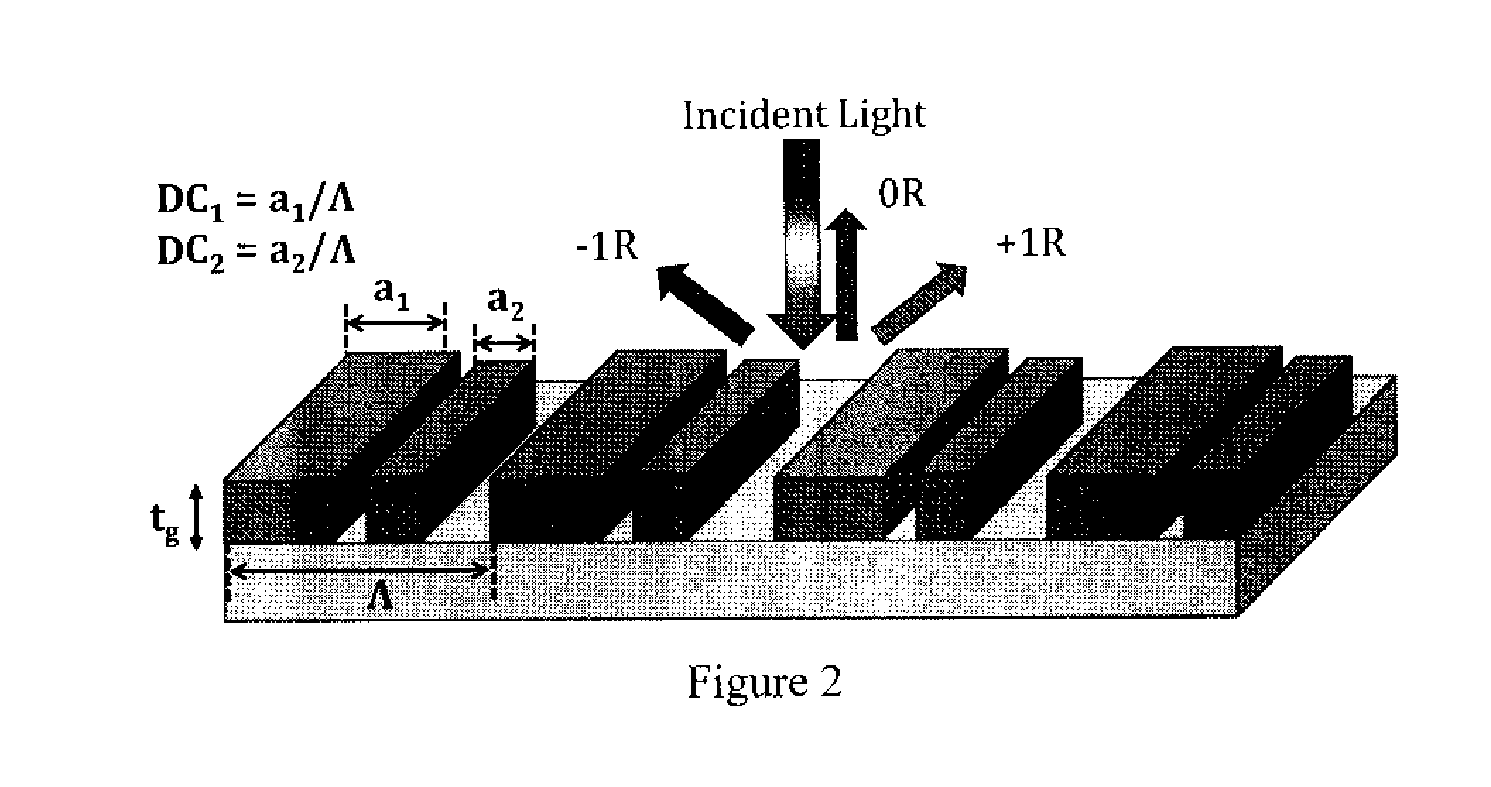

Method to design a security feature on the substrate of security documents using sub wavelength grating

Method of designing a security thread in security documents with better color contrast at any viewing angle is claimed. The invention discloses designing of security thread in security documents like bank notes using subwavelength gratings with period and thickness less than the wavelength of light. The sub wavelength gratings preferably asymmetric are designed such that the Oth order reflections are of longer wavelength (red) and the higher order reflections (diffracted orders) are of shorter wavelengths (blue / green). The security thread so designed gives better color contrast unlike the rainbow colors of prior art thus allowing better and easier distinction of authentic documents.

Owner:COUNCIL OF SCI & IND RES

Head-mounted visual display device with stereo vision and its system

InactiveUS20110134319A1Increase brightnessImprove clarityColor signal processing circuitsPicture reproducers using cathode ray tubesDigital videoDisplay device

A head-mounted visual display device for low-vision aid, which features 2 models, they are analog signal model and digital signal model. Said analog device contains at least an analog video extractor, a video decoder, an ITU-R.656 decoder, a de-interlacing unit, an image processor, two YCbCr to RGB converter, two color enhancement units, two video D / A converter, a head mounted display, a signal voltage controller and a wireless communication module. Said digital device consists of a digital video signal extractor / capturer, a RGB to YCbCr converter, an image processor, two YCbCr to RGB converter, two color enforcement units, a head-mounted display, a signal voltage controller and a wireless communication module.

Owner:NATIONAL YANG MING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com