Light guide plate with quantum dot diaphragm array and quantum dot site and application of light guide plate

A technology of quantum dot film and light guide plate, applied in the field of light guide plate, can solve the problems of poor color gamut stability and brightness stability, white light color decay, etc., achieves small water and oxygen barrier limit, reduces color decay, and improves normal service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

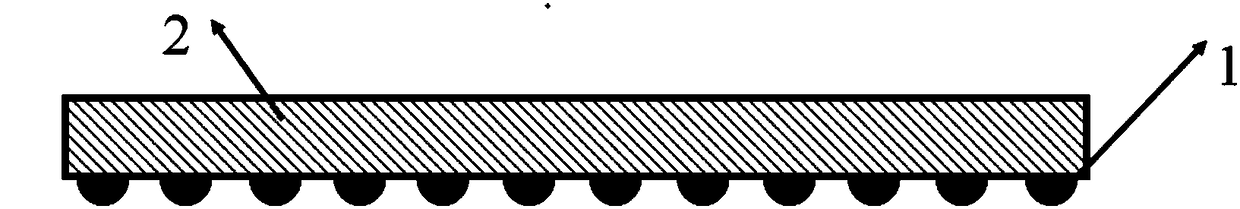

[0074] 1. Preparation of light guide plate printed with quantum dots

[0075] Weigh the amino silicone oil dispersion containing 15g of red cadmium selenide, 20g of the green cadmium selenide amino silicone oil dispersion, and 100g of printing ink, and mechanically stir the mixed solution for 3 hours, and let stand to obtain the quantum dot mixed slurry. The mass ratio of the above raw materials is 0.15:0.2:1 to achieve white balance. The above-mentioned mixed quantum dot mixed slurry is printed on the lower surface of the light guide plate by screen printing to prepare a light guide plate printed with quantum dot screen dots. In the quantum dot network, the content of red quantum dots is 2.25%, and the content of green quantum dots is 3%.

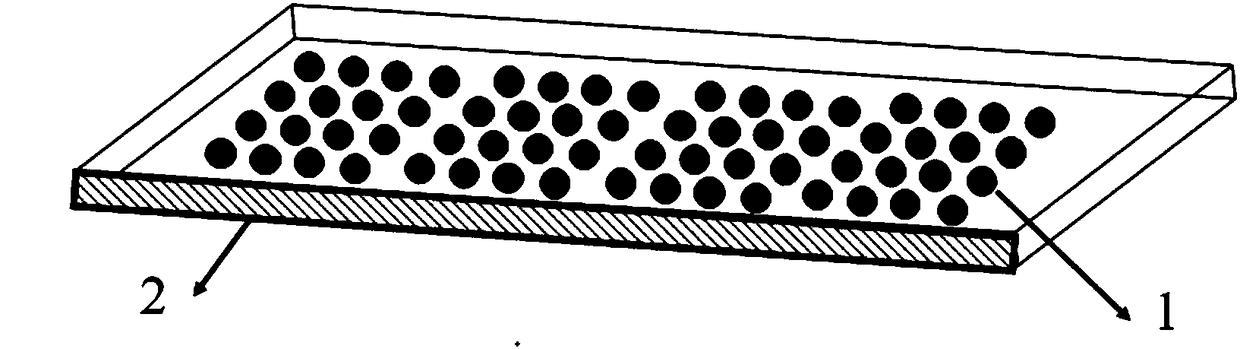

[0076] 2. Preparation of one-dimensional quantum dot membrane

[0077] Weighing 90g solid content is 40% titanium dioxide isobornyl acrylate (IBOA) dispersion liquid, after stirring and mixing on the shaker, join the amino silicone oil d...

Embodiment 2

[0084] 1. Preparation of light guide plate printed with quantum dots

[0085] Weigh the mixture containing 10g red cadmium selenide amino silicone oil dispersion, 30g green cadmium selenide amino silicone oil dispersion, and 100g ink, stir it mechanically for 3 hours, and let it stand to obtain the quantum dot mixed slurry. The mass ratio of the above raw materials is 0.1:0.3:1 to achieve white balance. The above-mentioned mixed quantum dot mixed slurry is printed on the lower surface of the light guide plate by screen printing to prepare a light guide plate printed with quantum dot screen dots. In the quantum dot network, the content of red quantum dots is 2.25%, and the content of green quantum dots is 3%.

[0086] 2. Preparation of zero-dimensional quantum dot membrane

[0087]Weigh 90g of the titanium dioxide IBOA dispersion with a solid content of 40%, stir and mix evenly on a shaker, add to the amino silicone oil dispersion containing 30g red cadmium selenide, 40g gree...

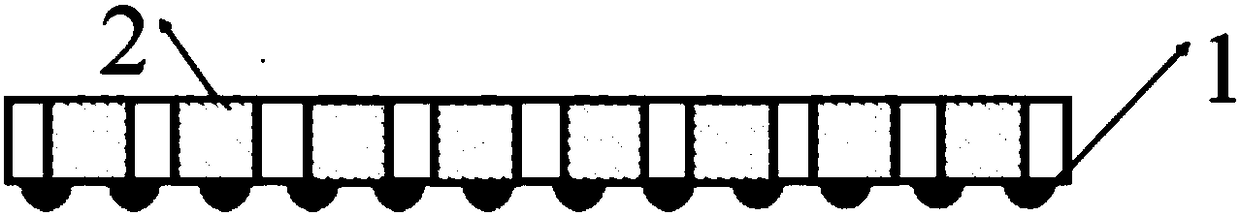

Embodiment 3

[0094] Quantum dot network point and one-dimensional quantum dot film array provided as embodiment 1, wherein the amino silicone oil dispersion liquid of red cadmium selenide used in network point, the amino silicone oil dispersion liquid of green cadmium selenide and printing ink are 1: 1:15; the mass ratio of titanium dioxide IBOA dispersion, red quantum dot amino silicone oil dispersion, green quantum dot amino silicone oil dispersion, and acrylate UV-curable glue used in the one-dimensional quantum dot film is 1.5:3:3:100. In the quantum dot network, the content of red quantum dots is 1%, and the content of green quantum dots is 1%. The content of inorganic particles in the quantum dot glue layer is 6%, the content of red quantum dots is 0.45%, and the content of green quantum dots is 0.45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com