Electrochromic film as well as preparation method and application thereof

An electrochromic and thin-film technology, applied in nanotechnology, titanium oxide/hydroxide, optics, etc. for materials and surface science, can solve problems such as single color change, poor cycle stability, and low coloring efficiency, and achieve The effect of high optical contrast, good stability and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

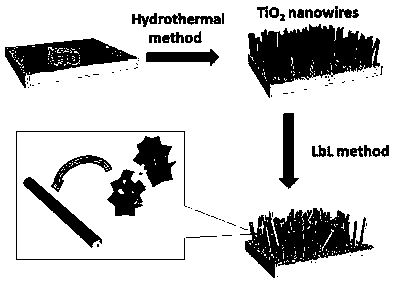

[0032] The invention provides a method for preparing an electrochromic thin film, comprising:

[0033] Soak the silane-modified titanium dioxide nanowire conductive substrate in the polyoxometalate solution and the PEI solution in sequence, and repeat the above immersion for 1 to 50 times to obtain the electrochromic film;

[0034] The polyoxometalate is K 17 [Ce(P 2 W 17 o 61 ) 2 ]·nH 2 O.

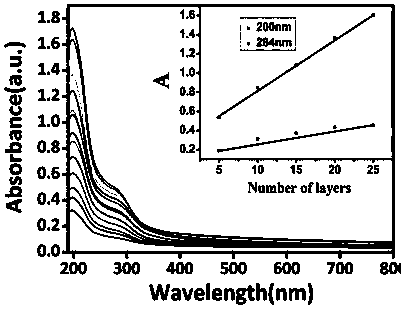

[0035] According to the present invention, the present invention repeatedly soaks the silane-modified titanium dioxide nanowire conductive substrate in the polyoxometalate solution and the PEI solution to obtain an electrochromic film; wherein, the polyoxometalate solution is preferably composed of The polyoxometalate is prepared by dissolving in a buffer solution; the buffer solution is an acetic acid-sodium acetate buffer solution; the concentration of the polyoxometalate in the polyoxometalate solution is preferably (2~10)×10 -3 mol / L, more preferably (3~8)×10 - 3 mol / L, most ...

Embodiment 1

[0045] Rare earth substituted polyoxometalates / TiO 2 Preparation of composite membrane

[0046] (1) TiO 2 Preparation of nanowires

[0047] Cut FTO into small pieces of 33mm×20mm, wash and set aside. Mix and stir 18ml of water, 18.5ml of hydrochloric acid, and 0.45ml of butyl titanate for 30 minutes to make a precursor solution; put the FTO conductive side down into the hydrothermal synthesis kettle, pour 6ml of the precursor solution into the reaction kettle, and tighten And heat in a constant temperature oven at 150°C for 4 hours, turn off the oven and take out the titanium dioxide nanowires, rinse with distilled water and then with absolute ethanol, and blow dry with a hair dryer. The fired NW is fired at 450° C. for 30 minutes and annealed to obtain a silane-modified titanium dioxide nanowire conductive substrate; the transmittance of the NW is measured, and 70% to 80% is qualified.

[0048] (2) Preparation of composite membrane

[0049] Prepared TiO 2 The nanowires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coloring efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com