Hyperbranched polyether functionalized graphene/epoxy resin nano composite coating as well as preparation method and application thereof

A technology of hyperbranched polyether and epoxy resin, which is applied in the field of coatings, can solve problems such as poor dispersion, complicated preparation methods, and poor anticorrosion performance of epoxy resin, and achieve improved acid resistance, low corrosion rate, and effective impermeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

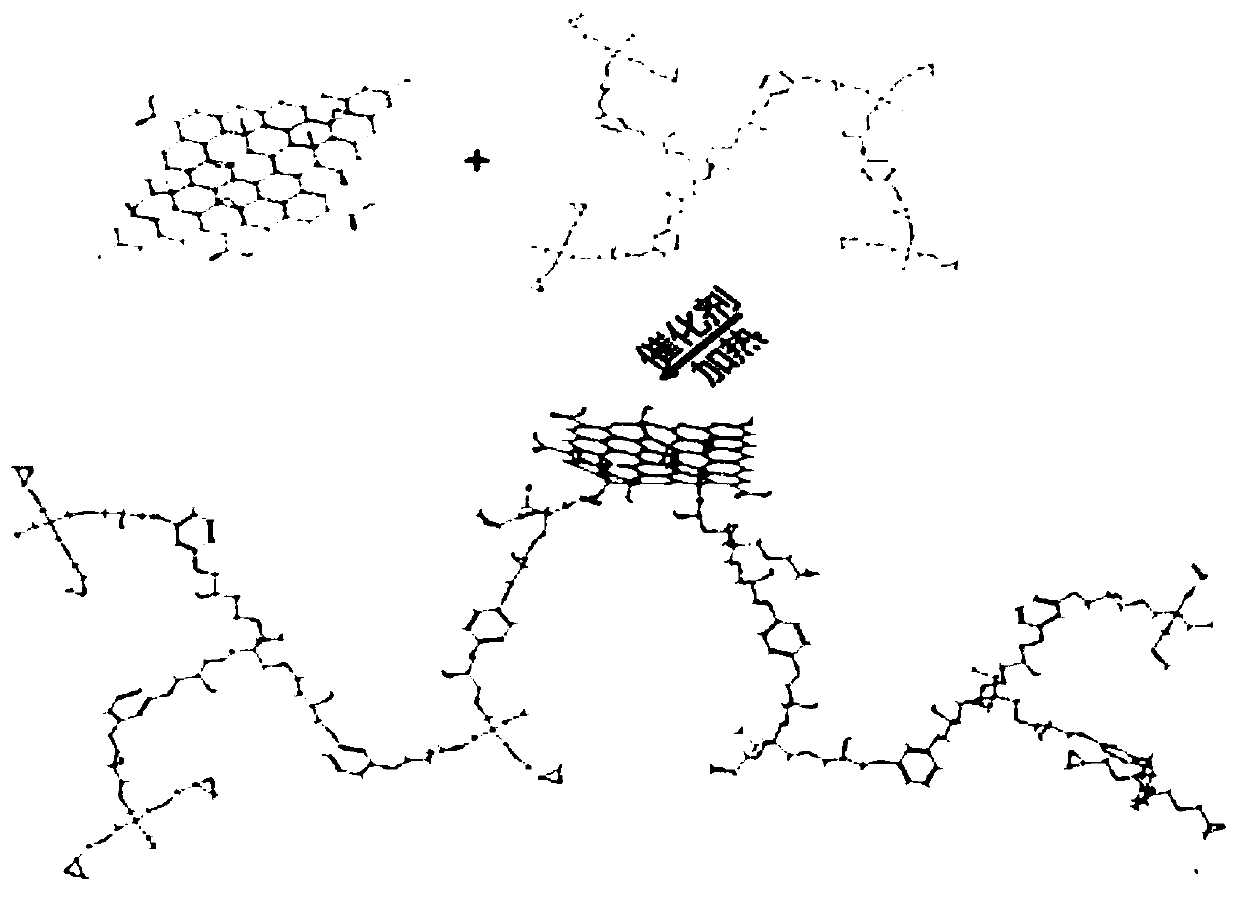

[0030] The preparation method of hyperbranched polyether functionalized graphene of the present invention is: at room temperature 25 ℃, 10.2mg graphene oxide and 1.019g EHBPE prepared by the above-mentioned method are added in 40mLDMF, and treat with ultrasonic (frequency is 5000Hz) 30 minutes , then add 0.05g tetrabutylammonium bromide, heat to 80°C under the condition of magnetic stirring speed of 300rpm, react for 10h, lower the reaction system to room temperature, wash with water, centrifuge and filter to obtain graphene oxide modified hyperbranched Polyether epoxy resin, hereinafter abbreviated as EHBPE-GO.

[0031] The reaction process is as figure 1 shown.

[0032] Carry out Fourier transform infrared spectrum test to the prepared EHBPE-GO, the result is in 1750cm -1 There is a carbonyl peak on the surface of graphene oxide at 2960cm -1 ~2880cm -1 Attributable to the aliphatic - C-H stretching vibration peak, 1231cm -1 and 1100cm -1 belong to Ph-O-C and C-O-C stre...

Embodiment 2

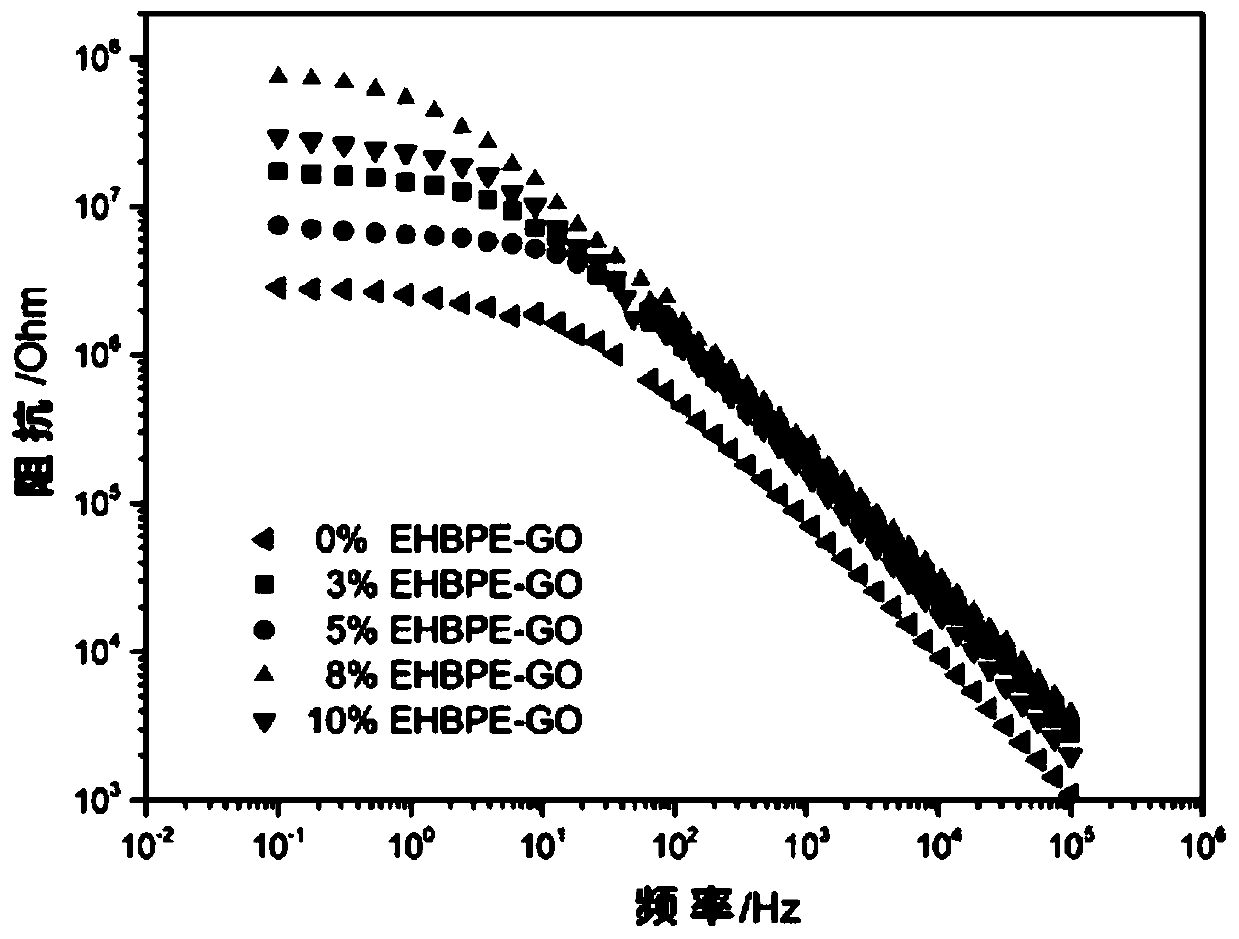

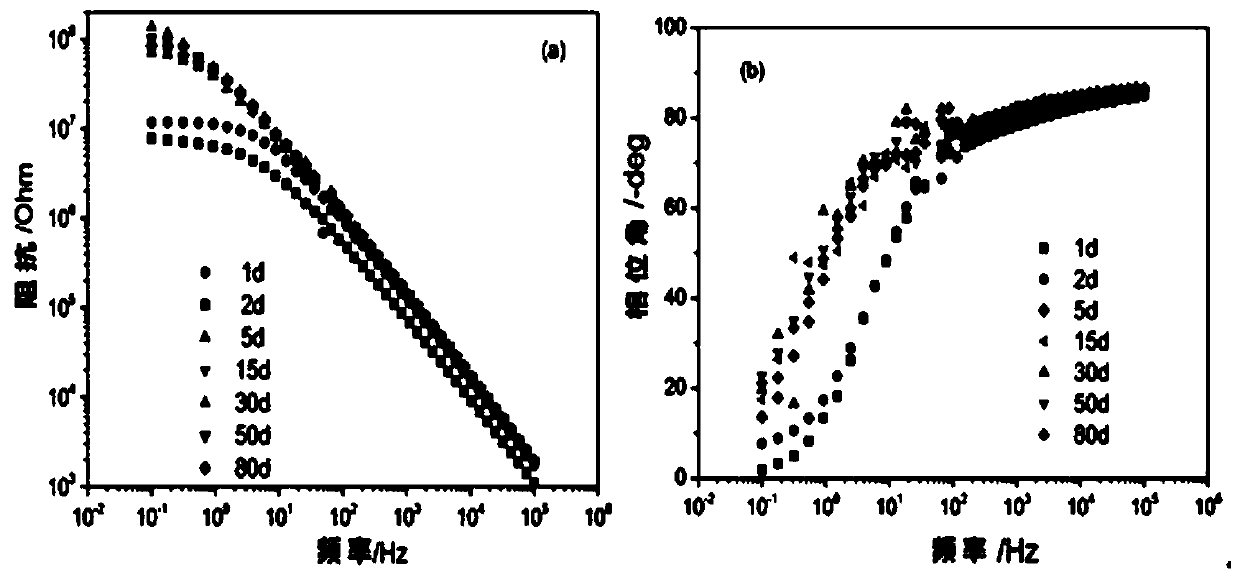

[0034] A kind of hyperbranched polyether functionalized graphene / epoxy resin nanocomposite coating, is made up of A component and B component, and described A component comprises following components by weight: mixed resin 33.4 parts, antirust pigment: molybdenum 6 parts of zinc acid and 8 parts of zinc phosphate, inorganic pigment: 20 parts of ferric oxide, mineral powder: 4.8 parts of mica and 7.8 parts of talcum powder, organic solvent: xylene and methyl ethyl ketone mixed in a volume ratio of 7:3 for 20 share,

[0035] The B component is 43.6 parts of epoxy resin curing agent LITE3000;

[0036] The mixed resin is composed of hyperbranched polyether functionalized graphene and bisphenol A type epoxy resin prepared in Example 1, and the weight of the hyperbranched polyether functionalized graphene accounts for about 10% of the bisphenol A type ring. 3% of the oxygen resin weight, i.e. 1 part of hyperbranched polyether functionalized graphene, 32.4 parts of bisphenol A type ...

Embodiment 3

[0038] The hyperbranched polyether functionalized graphene / epoxy resin nanocomposite coating of the present embodiment is the same as that of embodiment 2, the difference is that the weight of the hyperbranched polyether functionalized graphene accounts for about 5% of the oxygen resin weight, that is, 1.6 parts of hyperbranched polyether functionalized graphene, and 31.8 parts of bisphenol A epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com