Patents

Literature

32results about How to "Good density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively recycling valuable minerals in rare-earth tailings

InactiveCN103394408ATake advantage ofOptimized flotation collectionFlotationWet separationResource utilizationNiobium

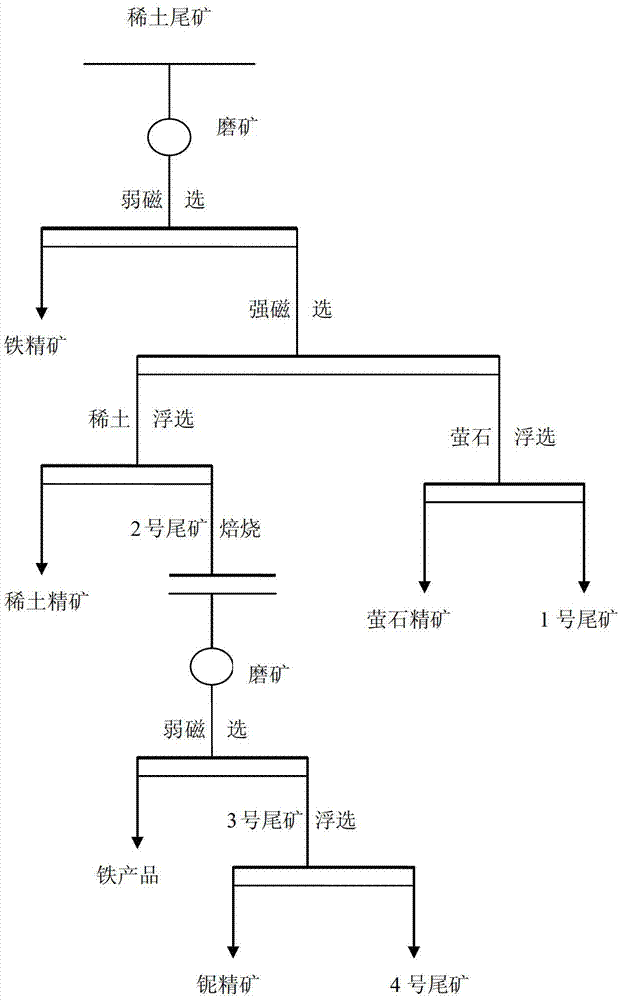

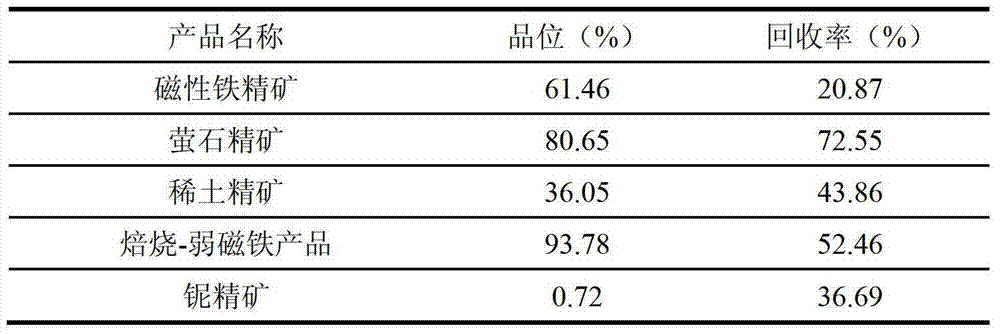

The invention relates to a method for comprehensively recycling valuable compositions of rare earth, iron, niobium and fluorite in rare-earth tailings, and belongs to the fields of comprehensive resource utilization technologies and mineral processing engineering. The rare earth, the iron, the niobium and the fluorite in the rare-earth tailings are efficiently and comprehensively recycled by the method including 'grinding the rare-earth tailings, performing low-intensity magnetic separation, performing high-intensity magnetic separation on weak-intensity magnetic tailings, performing flotation on high-intensity magnetic tailings to obtain fluorite in the high-intensity magnetic tailings, performing flotation separation on high-intensity magnetic concentrates to obtain rare earth, iron and niobium in the high-intensity magnetic concentrates, reducing and roasting base flows, performing low-intensity magnetic separation to obtain iron and niobium in the base flows and performing flotation on low-intensity magnetic tailings to obtain niobium in the low-intensity magnetic tailings according to characteristics that the rare-earth tailings contain the various valuable compositions. Compared with a method for singly recycling one or two valuable compositions, the method has the advantages that the purpose of comprehensively recycling the valuable compositions in the rare-earth tailings can be effectively achieved, secondary resources can be sufficiently utilized, and the method has excellent economical and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

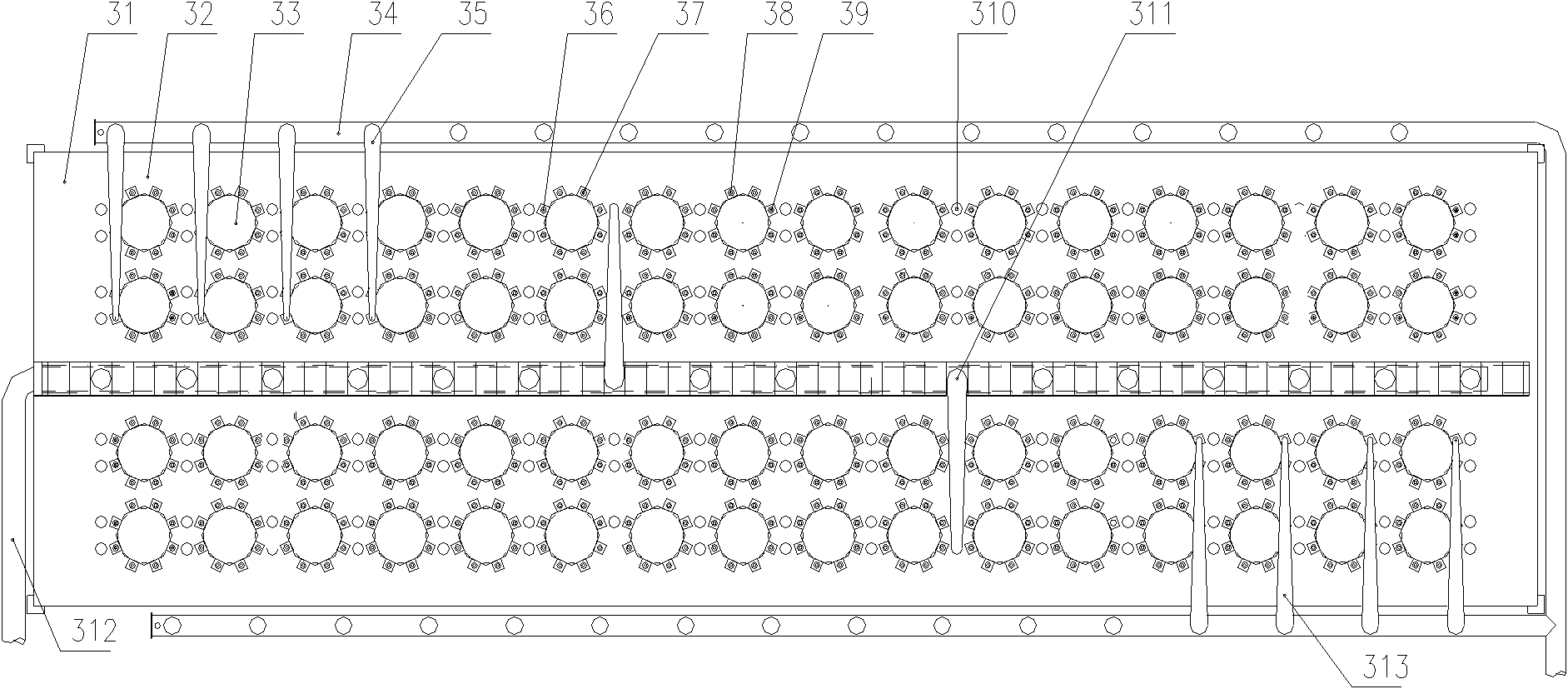

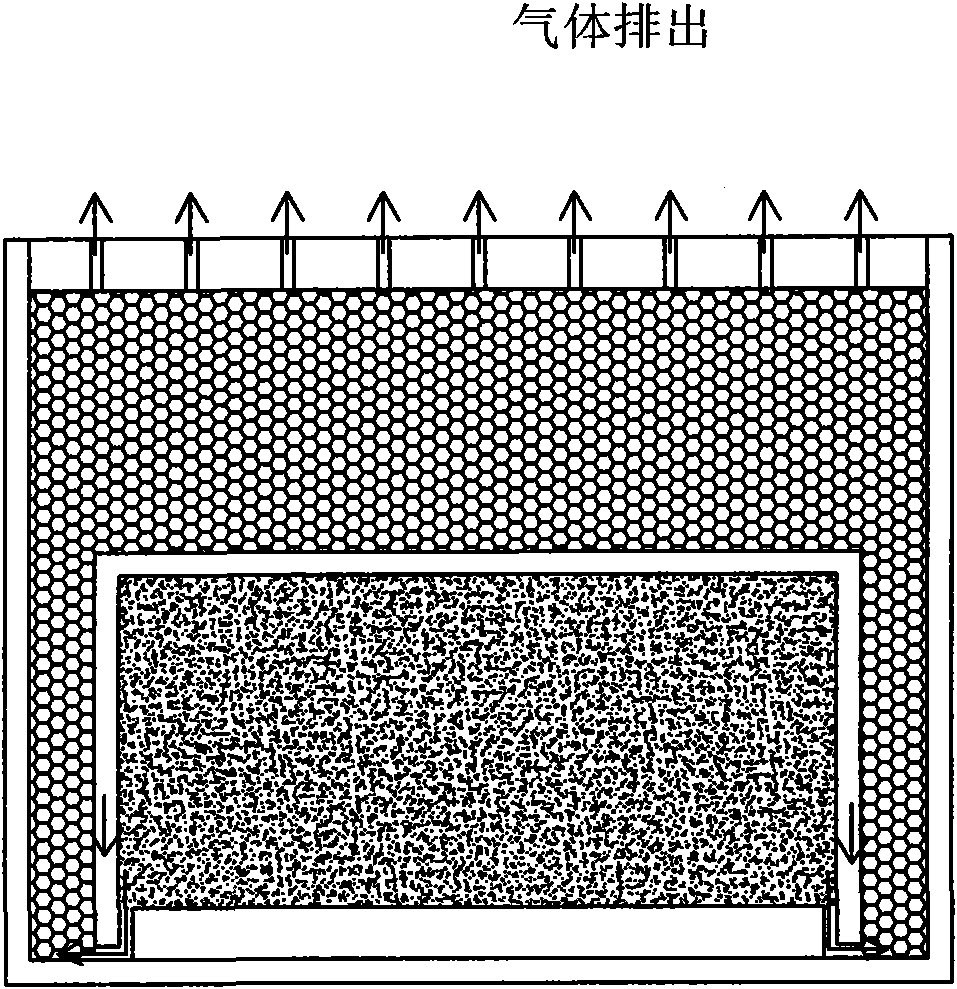

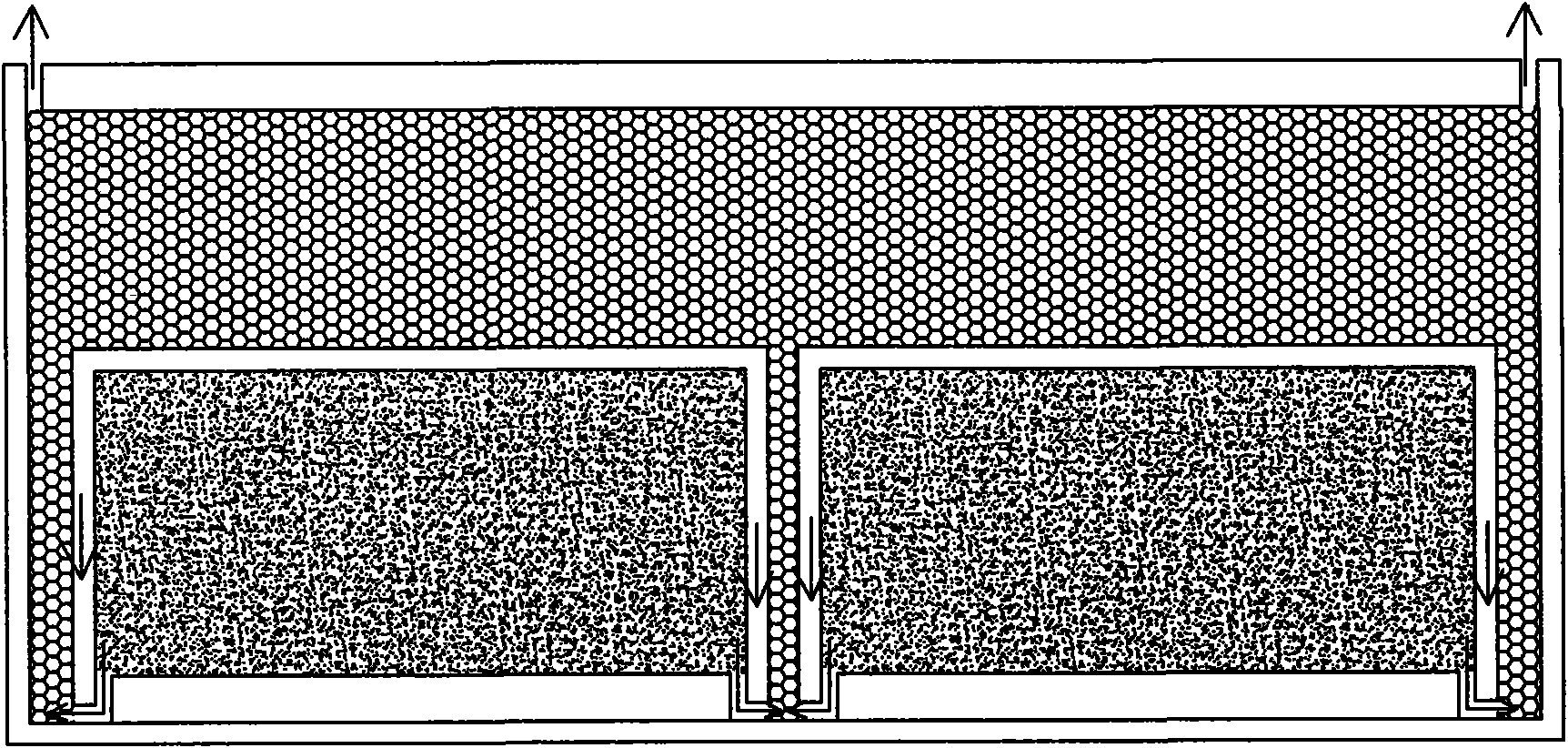

Apparatus and process for clarifying water efficiently

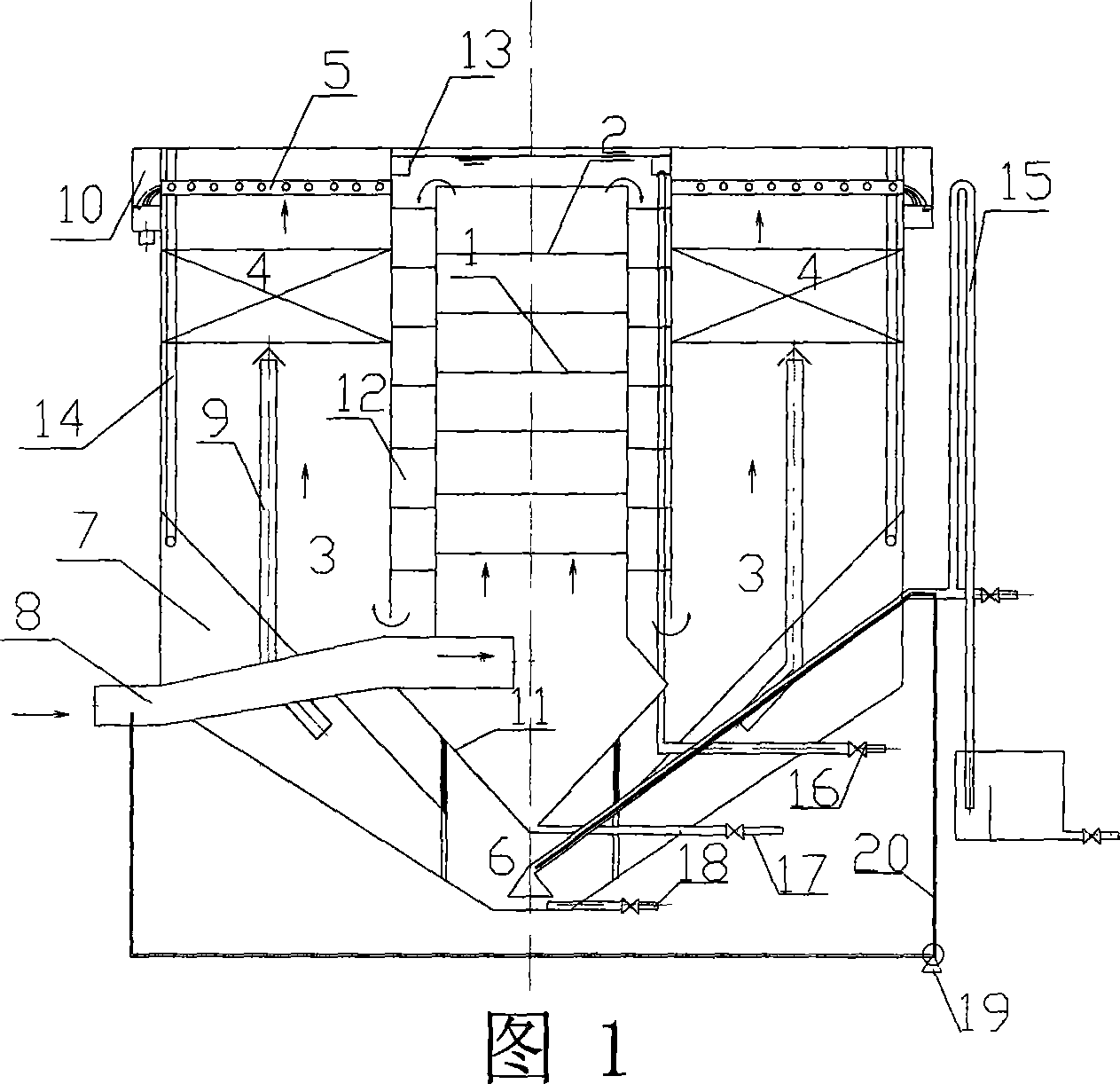

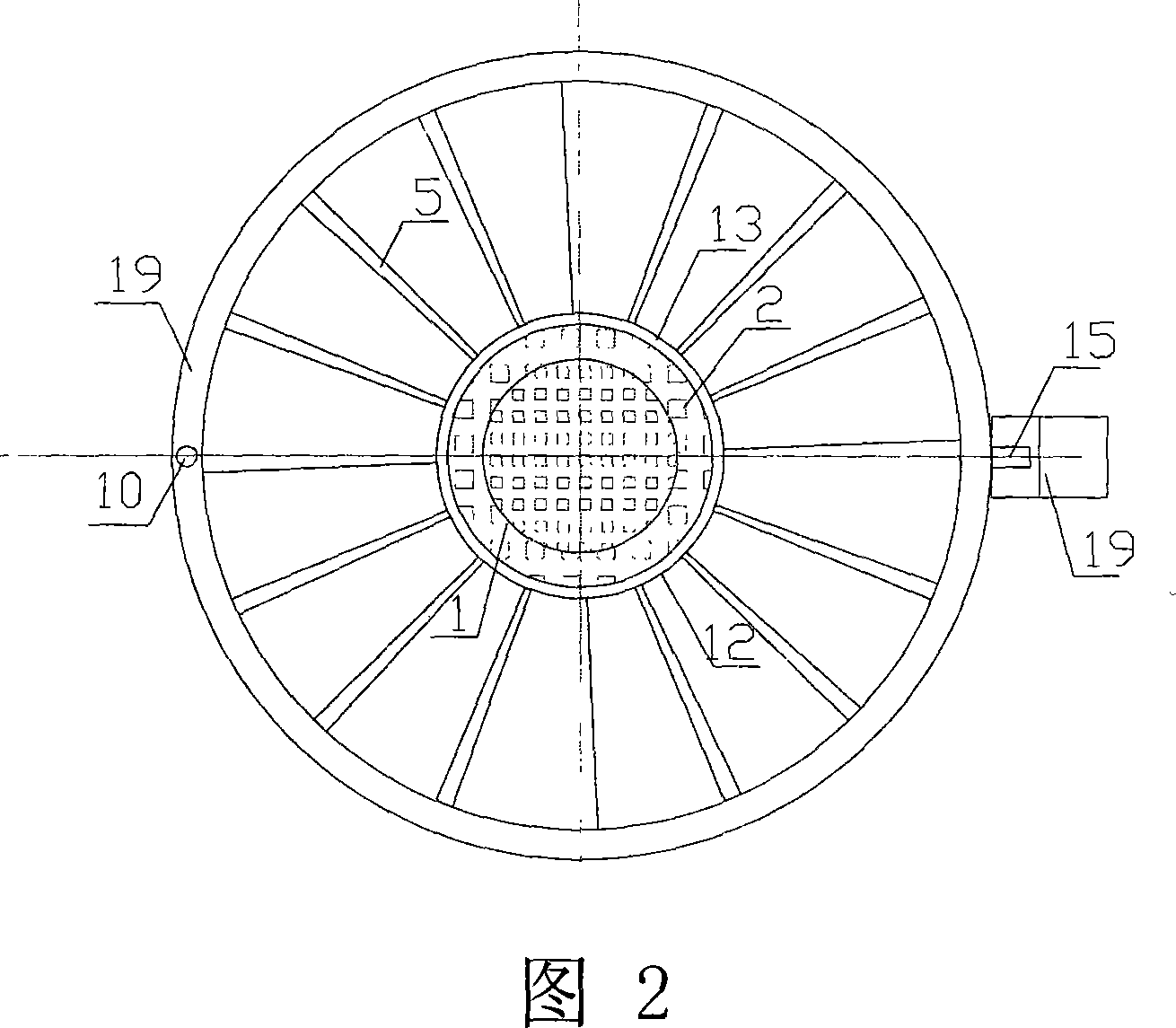

The invention is concerned with a kind of high efficiency water treatment equipment and technology belonging to water treatment field. The middle parts of the equipment are two flocculating rooms having mesh setting with disturbing flow, and the bottom of the flocculating room is precipitation tank. The suspending layer of active mud residue is out of the flocculating room and there is slanting pipe on top of it and concentrate room under it. The pipe excluding residue sets in the suspending layer of active mud residue, and the bottom of clean tank is filler to exclude residue, and there is siphon pipe connecting with the filler. There are grooves excluding residue at top of the flocculating room connecting with the pipe excluding residue and the siphon pipe connects with the residue reuse tank. The filler to exclude residue connects with a pump of reused residue. The equipment gathers the small air flotation, flocculating, active mud residue layer flocculating, and reused technology. Compared with traditional mixed and coagulate deposition technology, it saves 40 percent of field, reduces 10 percent of drug and enhances 15 percent disposal efficiency.

Owner:FUDAN UNIV +1

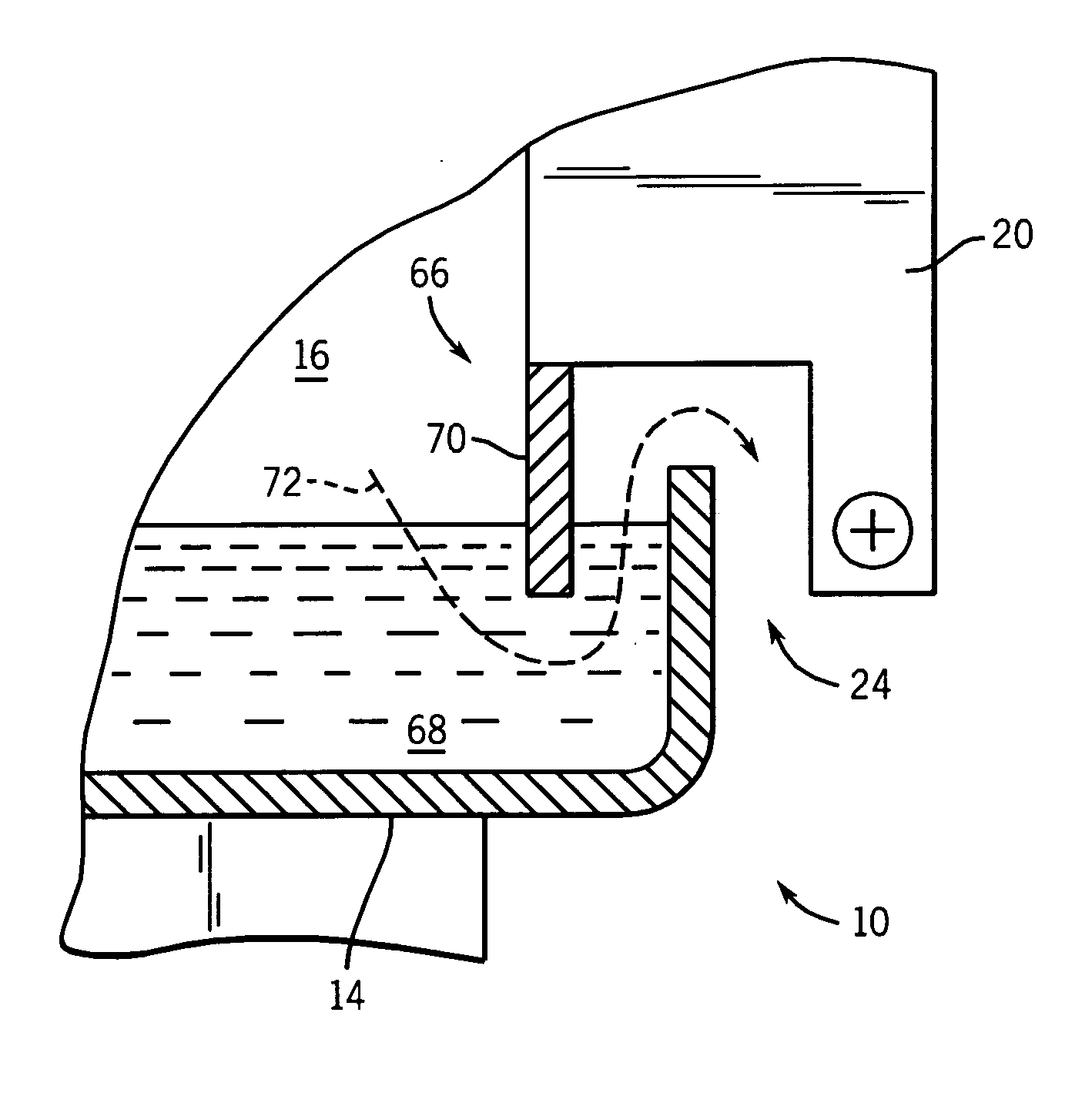

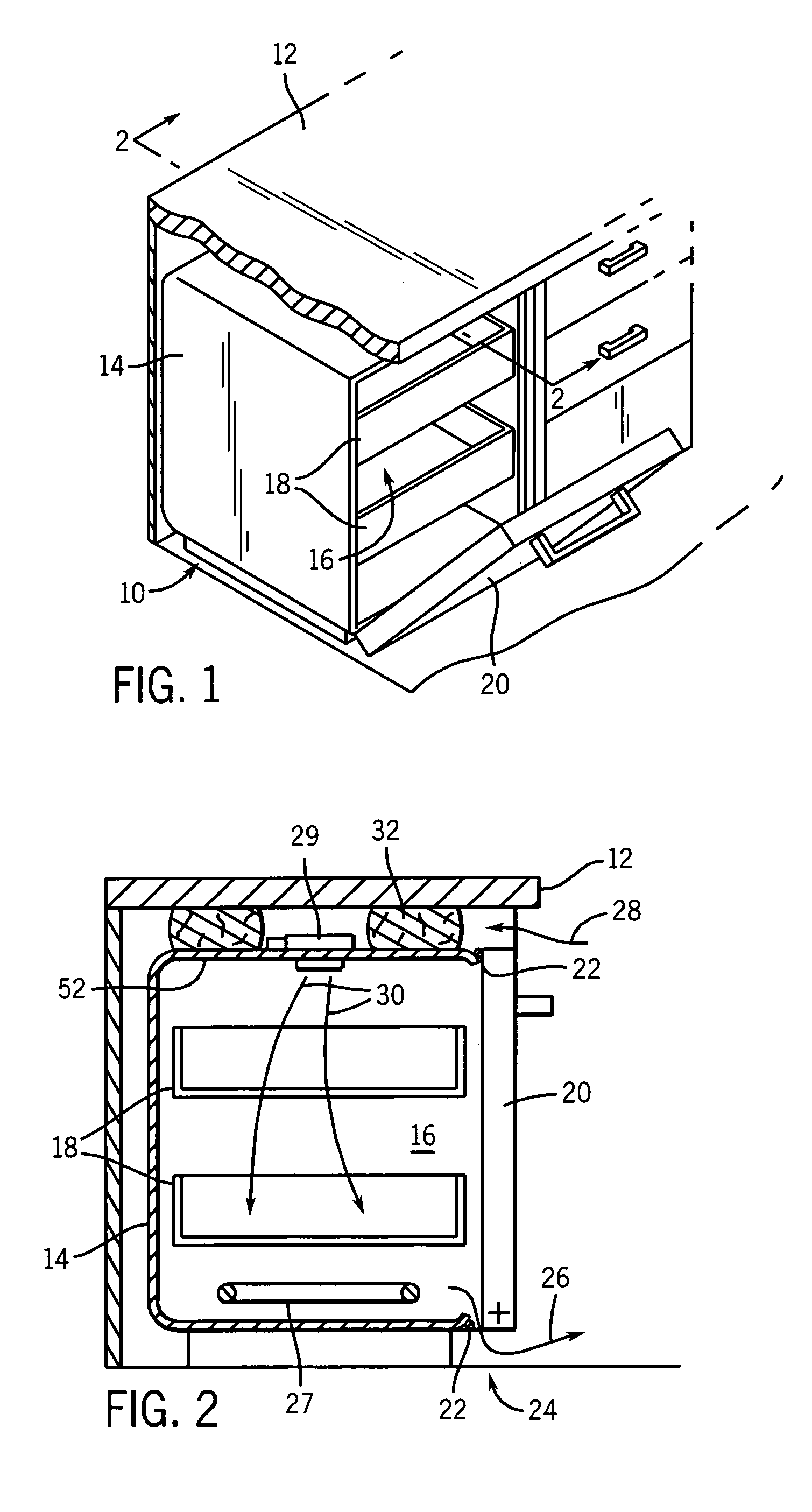

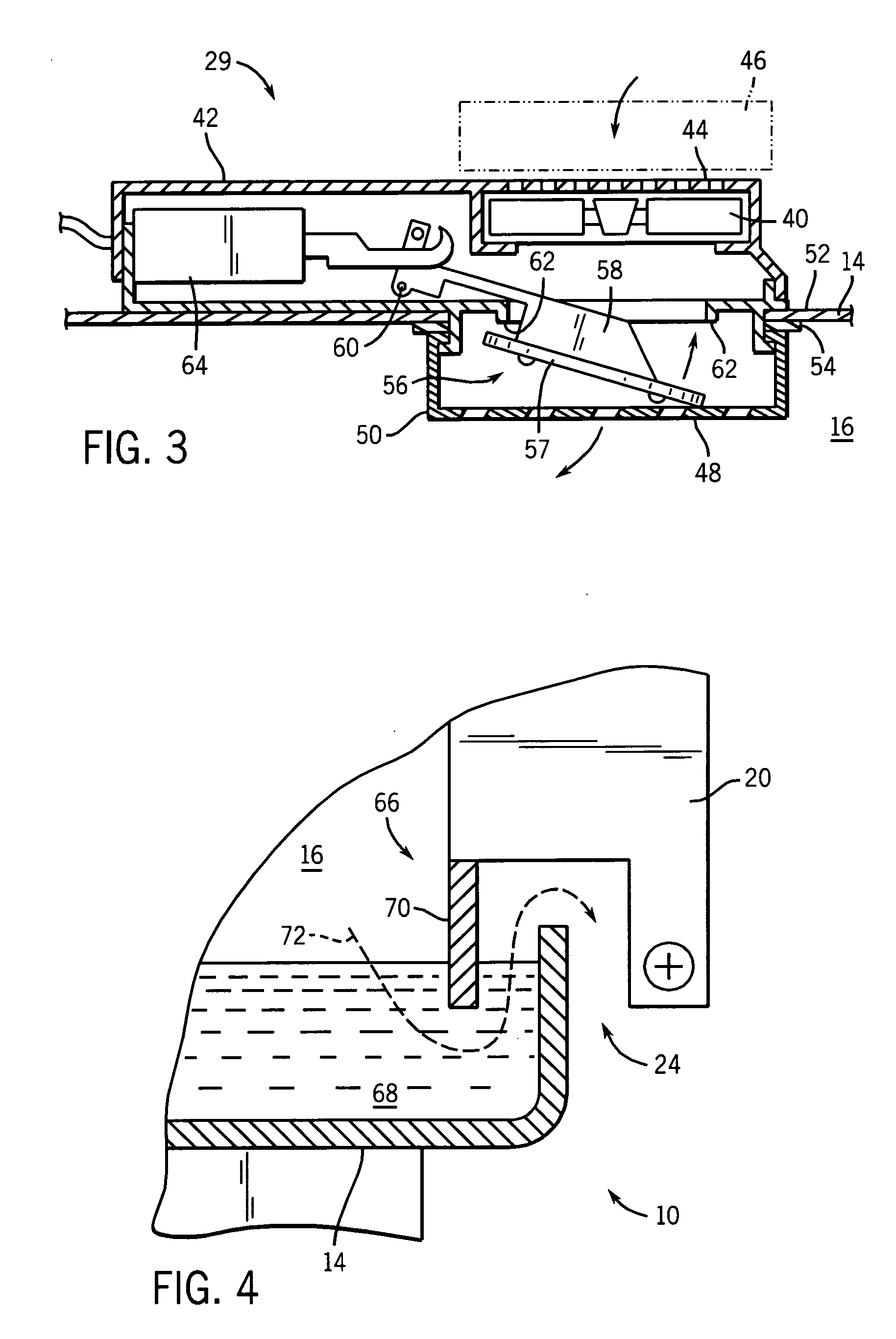

Dishwasher with counter-convection air flow

ActiveUS20060231122A1Low air flowGood densityHollow article cleaningTableware washing/rinsing machinesEngineeringForced-air

A dishwasher provides forced air flow in a counter-convectional direction so as to exhaust air out of a bottom portion of the washing volume in contrast to normal convective air flow.

Owner:ILLINOIS TOOL WORKS INC

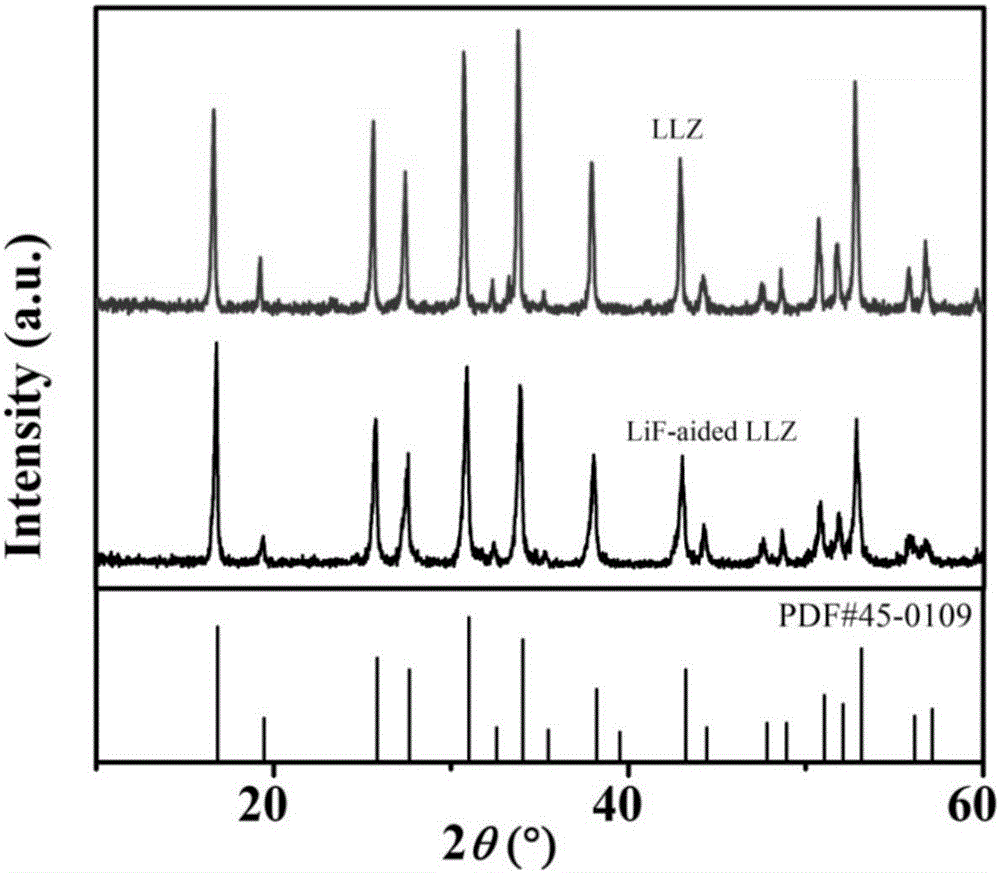

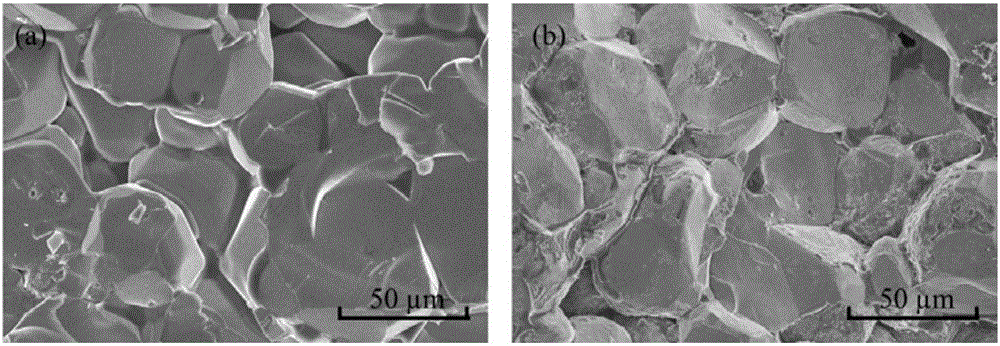

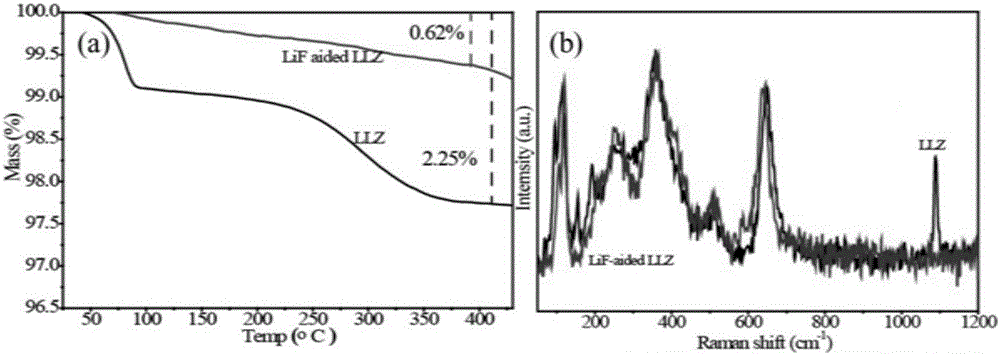

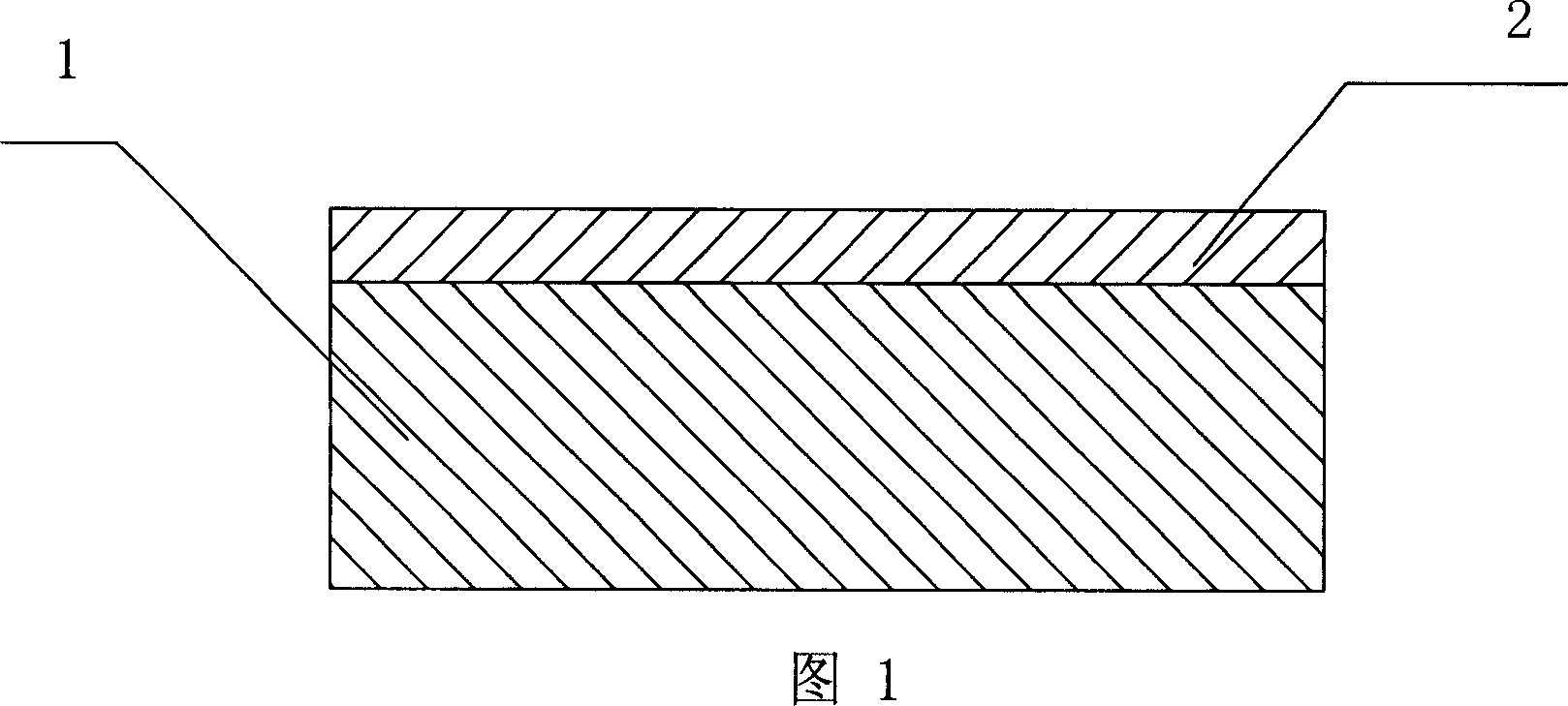

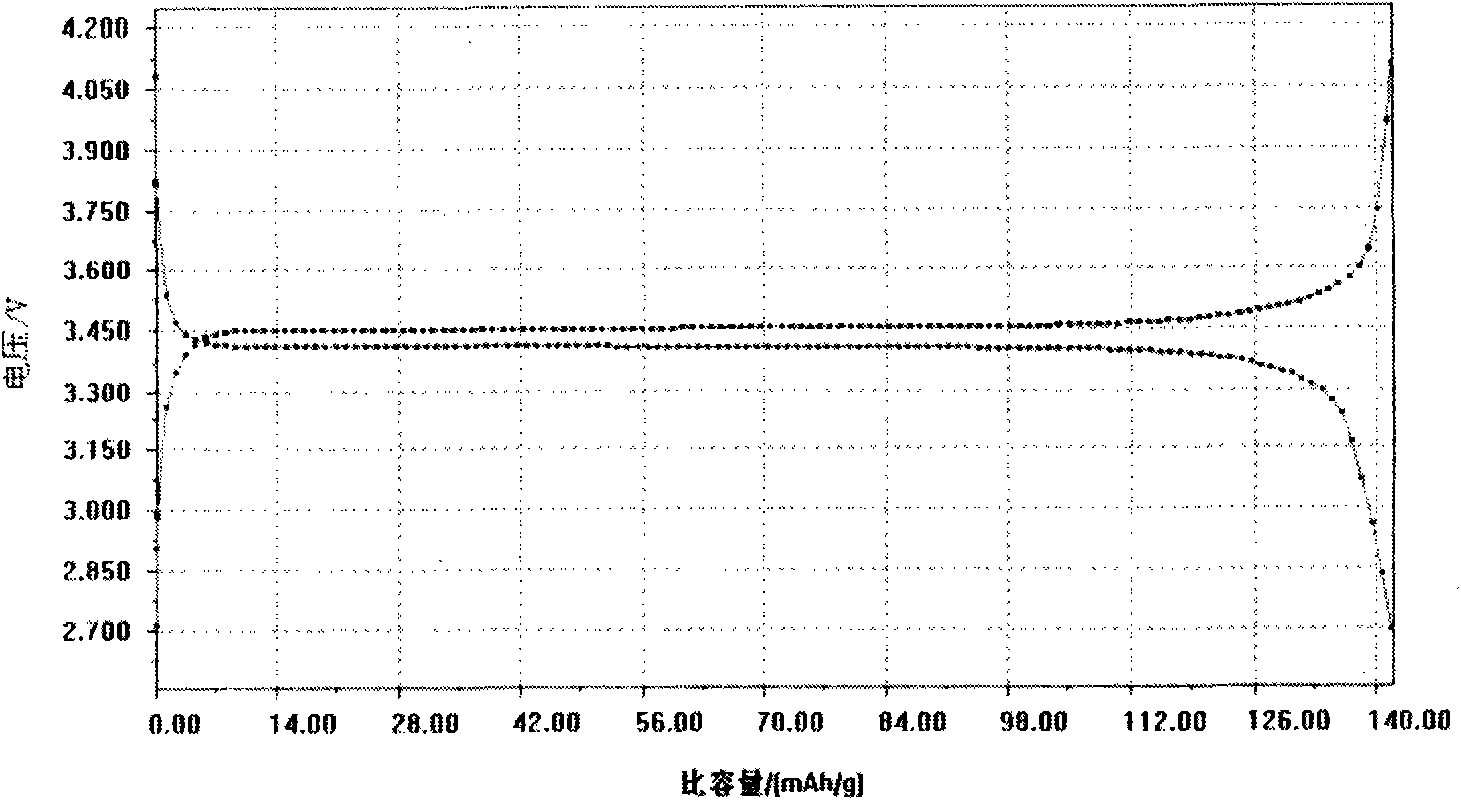

Solid electrolyte capable of lowering interface resistance on metal lithium electrode, and preparation method for solid electrolyte

ActiveCN106129466AReduce lossReduce time lossSecondary cellsElectrolyte immobilisation/gelificationSolid state electrolyteState of art

The invention relates to a solid electrolyte capable of lowering interface resistance on a metal lithium electrode, and a preparation method for the solid electrolyte. The preparation method comprises the steps of mixing lithium carbonate, lanthanum oxide and zirconium oxide, and uniformly grinding the mixture by a dry grinding method; then sintering the mixture in a muffle furnace, and grinding to obtain mother powder, and tabletting the mother powder; putting the tablet-shaped material into a crucible with a cover; then performing mother powder filling and sintering in the muffle furnace to obtain the compact ceramic sheet; and polishing the ceramic sheet until the surface of the ceramic sheet is smooth to obtain the solid electrolyte. Compared with the prior art, the electrolyte prepared by the method has the advantages of absence of impure phase on the surface, high relative density, low interface resistance on the metal lithium electrode, and the like.

Owner:SHANGHAI JIAO TONG UNIV

Graphite crucible

The invention provides a graphite crucible and relates to a crucible. The graphite crucible has a size of Phi (1200-1500)mm, an inner diameter of Phi (960-1260)mm and a depth of (1750-1900)mm. The graphite crucible is acquired based on the following steps: adding accessories into a raw material of forged petroleum coke grains, thereby acquiring a mixture; crushing the mixture, adding the mixture into a mixing kneading pot and stirring; adding liquid pitch into the mixing kneading pot and wetting the petroleum coke grains with the pitch; after molding a crucible blank, putting the crucible blank into a crucible roaster for roasting, thereby acquiring a roasted crucible product; steeping the roasted crucible product, thereby acquiring a steeped crucible; and graphitizing the steeped crucible, thereby acquiring the graphite crucible. The graphite crucible is once formed and the surface thereof is directly extruded and rubbed by a grinding tool, so that the compactness of the graphite crucible is better and pores are few. The graphite crucible is subjected to twice high-pressure steeping, so that the surface of the graphite crucible is more compact, the liquid metal is difficult to immerse and the service life is long. A test proves that physicochemical indexes of the acquired graphite crucible are as follows: the volume density is more than 1.75g / cm<3> and the compression strength reaches 25MPa.

Owner:福建兴朝阳硅材料股份有限公司

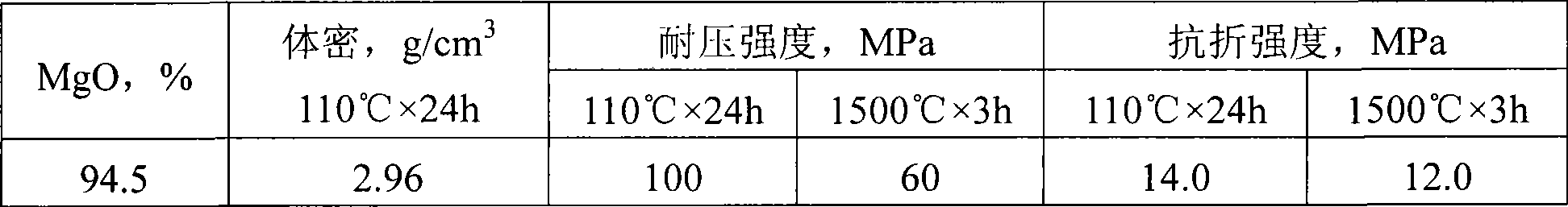

Magnesium oxide precast refractory material and construction method thereof

The invention discloses a precast magnesia refractory material, which is prepared by mixing and stirring the following component materials (100 percent by weight) uniformly: 59 to 72 percent of magnesia particles, 18 to 31 percent of magnesia powder, 0.5 to 6 percent of silica micropowder, 0.5 to 4 percent of aluminium micropowder, 0.05 to 0.3 percent of SHMP, 0.05 to 0.3 percent of STPP and 0.04 to 0.1 percent of organic fiber. The invention also discloses a construction method for the precast magnesia refractory material, which comprises the following steps of batching, stirring, vibrating, tapping, demoulding after final setting, and drying. The precast magnesia refractory material is high in magnesium and low in aluminum, and strong in slag resistance, has less pollution to liquid steel, and reaches or surpasses high aluminum-magnesia castable in bonding strength and thermal shock resistance.

Owner:ANHUI HEPURE CERAMIC

Calcium carbide dregs concrete pedestrian path brick and its preparing method

This invention relates to a calcium carbide slag concrete footpath brick and a process method, in which, the brick is composed of a lower layer of base material and an upper layer of face material, the face layer is composed of color cement 35-45, medium sand 55-65, in terms of weight and the base layer is composed of calcium carbide slag 5-15, cement 15-25, medium sand 15-20, gravels 30-40 and breeze 15-20 according to weight portions, and the process method includes: arranging materials, mixing them, molding and maintaining. The character of the bricks is as follows: 1, weight is reduced and transportation cost is reduced, 2, it is easy to be molded and not easy to generate cracks, 3, the strength and quality of footpath bricks are increased, 4, land is saved and pollution is reduced.

Owner:哈尔滨明日水泥制品有限公司

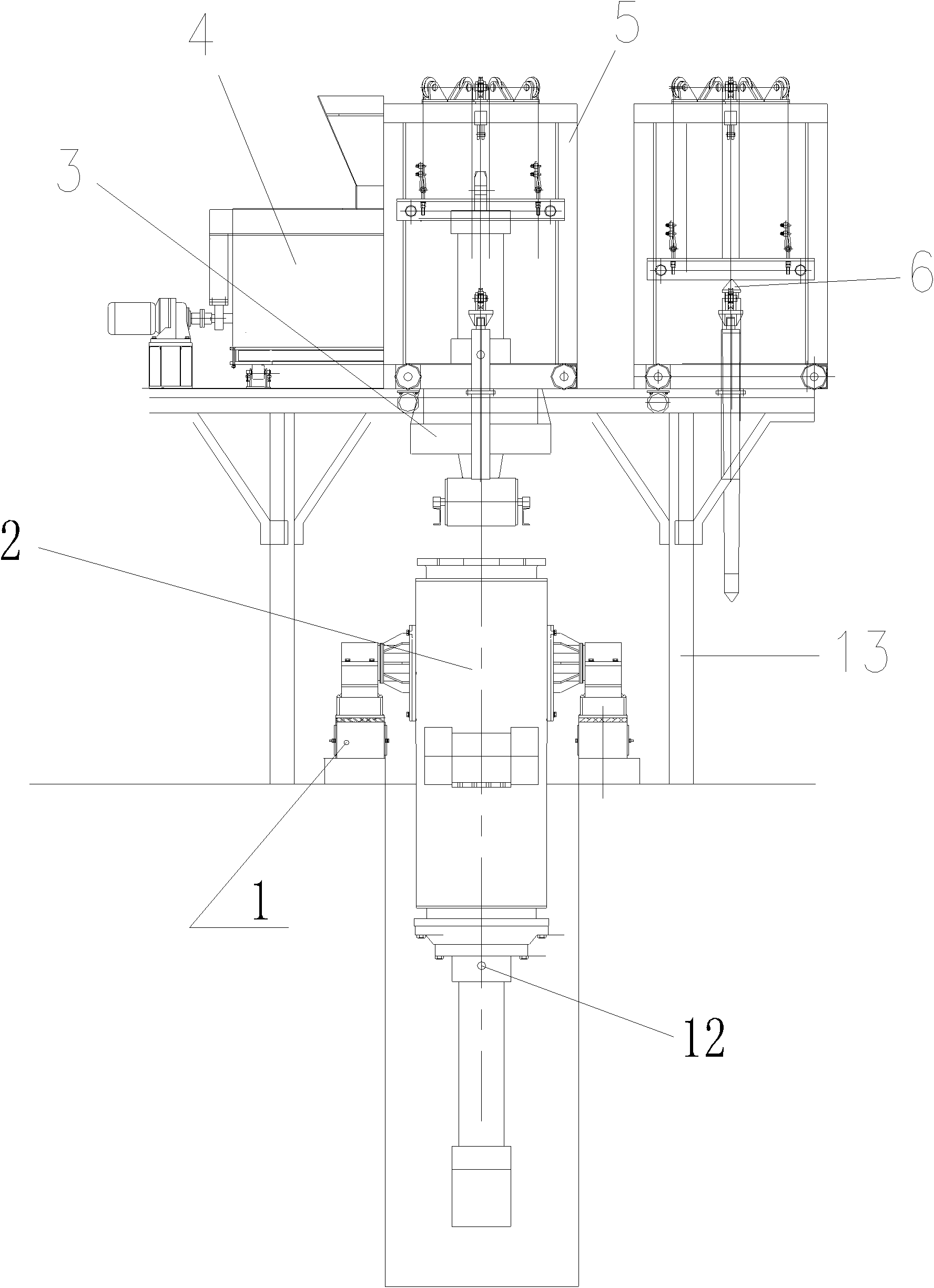

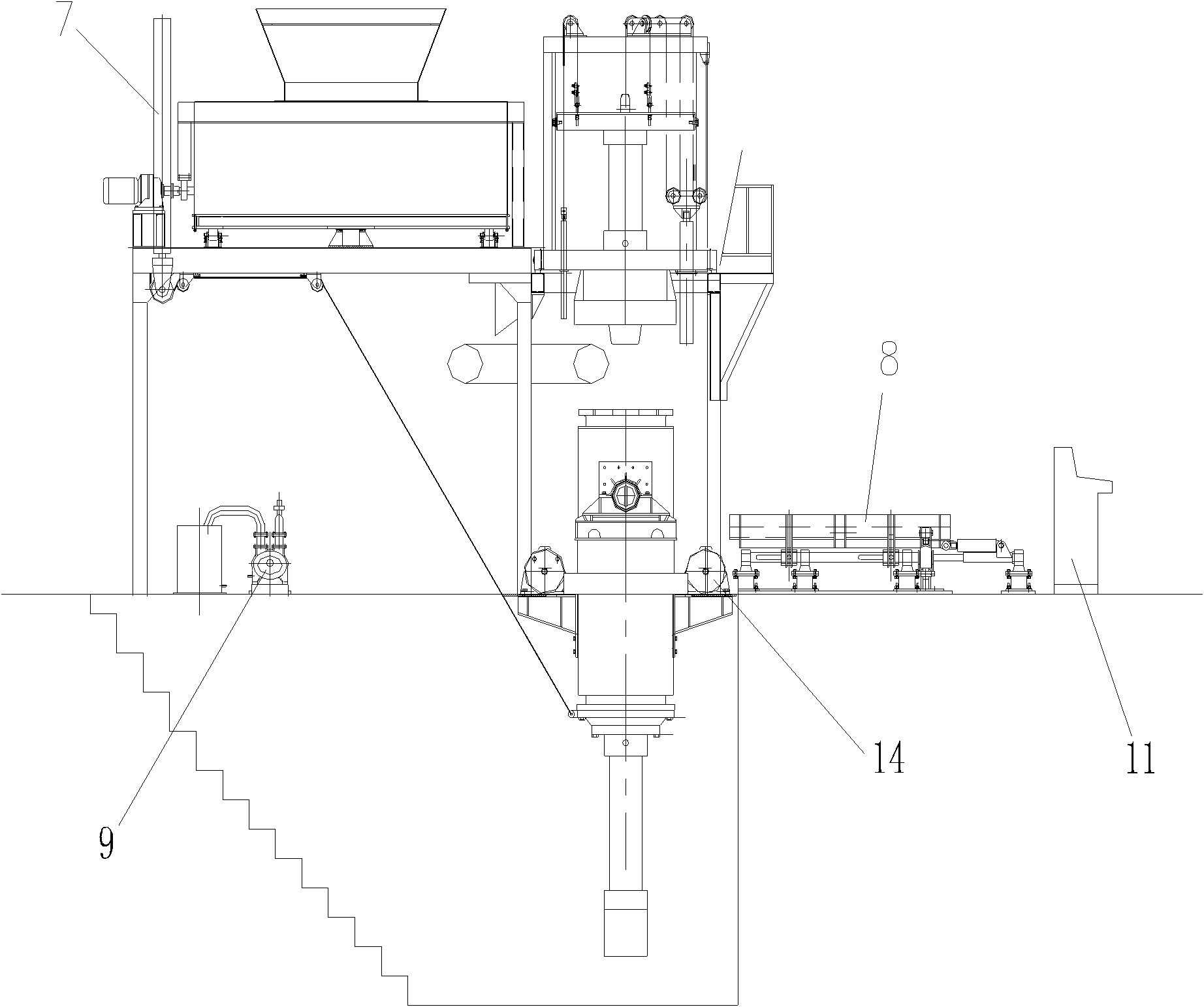

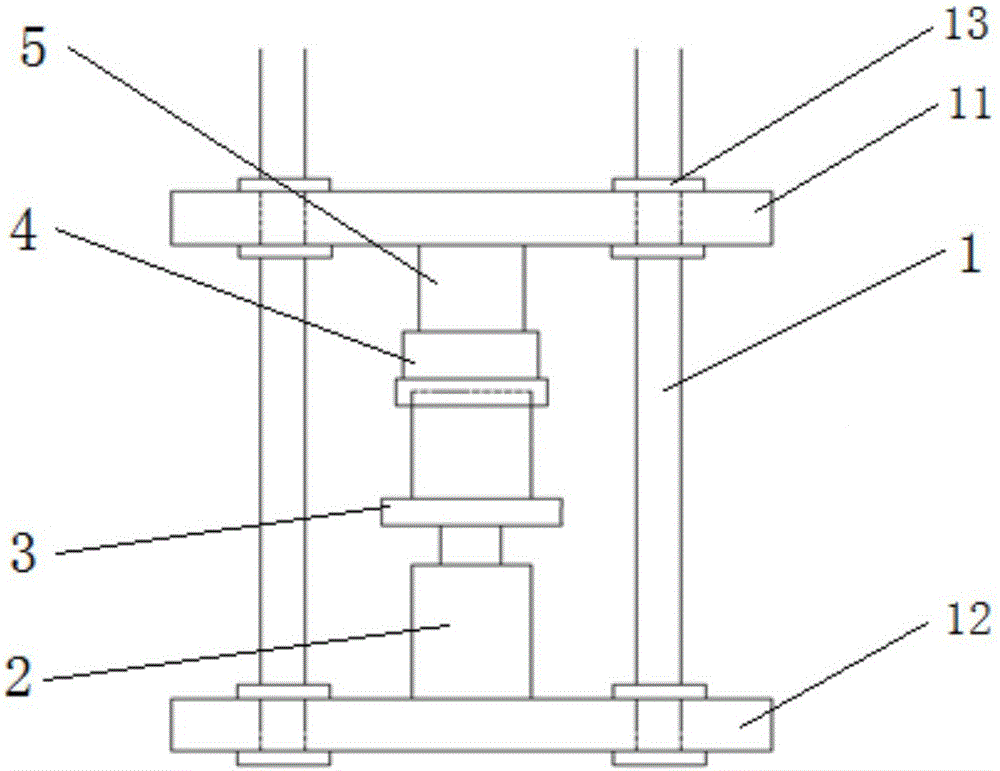

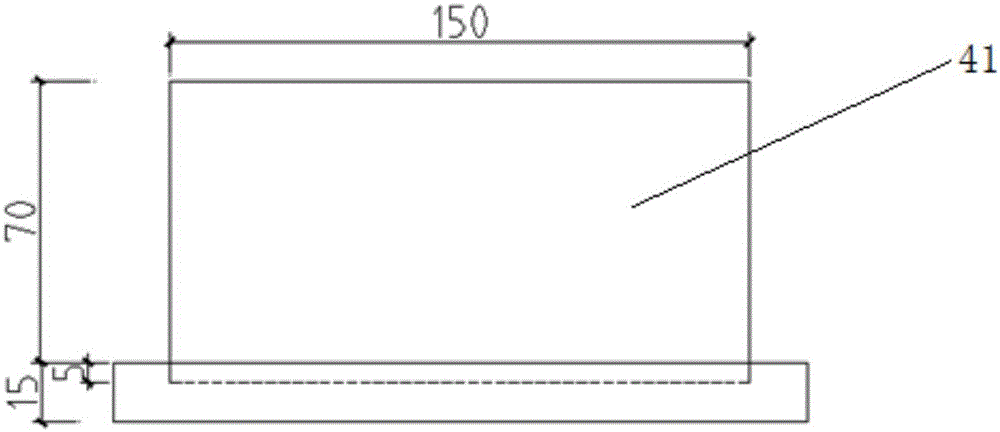

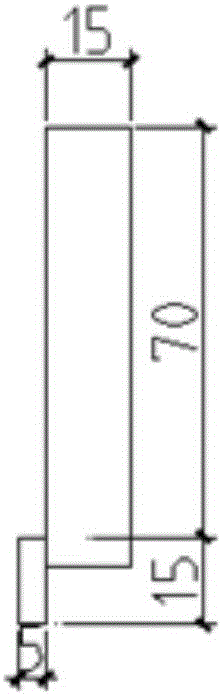

Sample preparation method and compaction device for immature soil base materials

ActiveCN105890961AStable compressive strengthGood densityPreparing sample for investigationDuctilityMaterials science

The invention discloses a sample preparation method and a compaction device for immature soil base materials. The method comprises the steps that the interior of a mold is coated with a lubricating oil layer, the immature soil base materials are put into the mold layer by layer, the immature soil base material layers in the mold are compacted through a jack every time one layer of immature soil base material is laid, and therefore a sample to be detected is obtained; the compaction speed of the jack is 0.5 mm / s, the compaction pressure of the jack is 18-19 K / N, and the compaction time of the jack is 3-5 min; the compaction device comprises a test bed, the test bed is sequentially provided with a first platform and a second platform in parallel in the horizontal direction from top to bottom, the second platform is coaxially provided with the jack, a gasket, the mold and a pressing column in sequence from bottom to top in the vertical direction, and the top end of the pressing column abuts against the first platform. Compared with a traditional hammer test, a press compaction test and a jack compaction test, the compressive strength of a test piece compacted by the jack is more stable than the compressive strength of a test piece compacted by the other two test methods, test piece overall deformation is good, and the test piece has good ductility when compacted.

Owner:CHANGAN UNIV

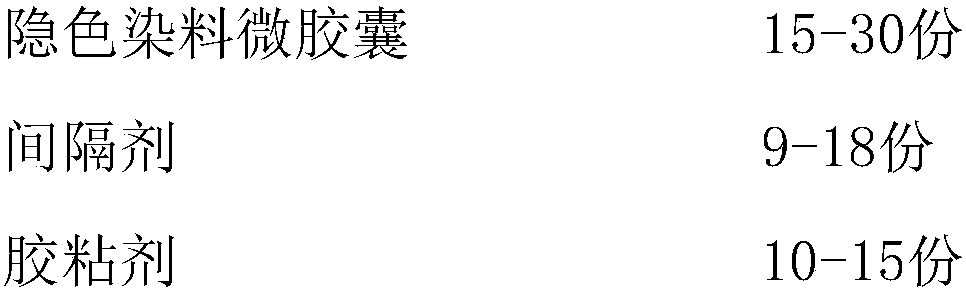

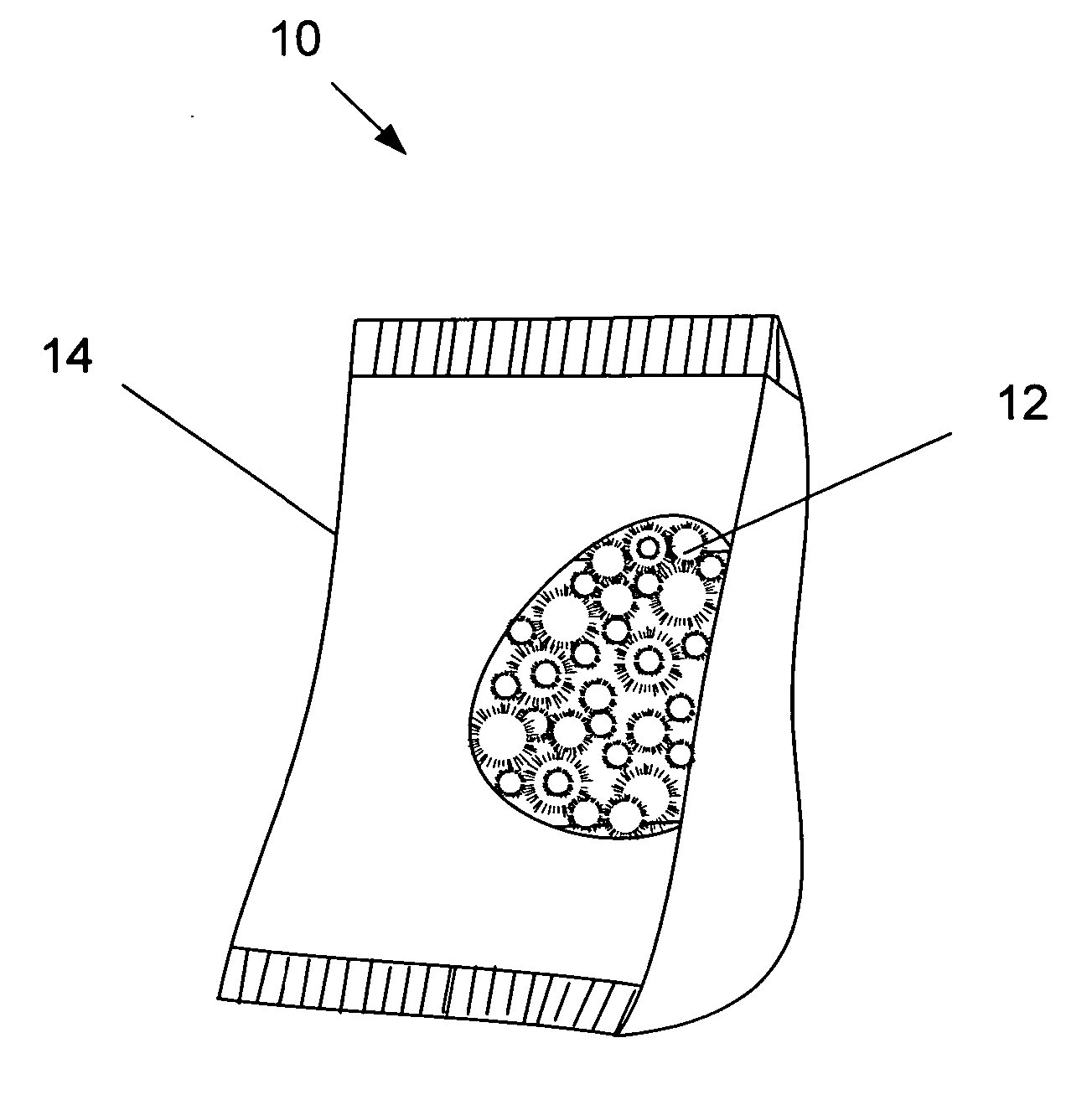

Pressure detecting paper and preparation method thereof

ActiveCN109374165ASmooth paperImprove stress resistanceForce measurement by measuring optical property variationTO-18Pulp and paper industry

The present invention relates to the technical field of display, in particular to a piece of pressure detecting paper and a preparation method thereof. The pressure detecting paper comprises a paper layer and a pressure sensitive color developing layer adhered to the paper layer. The pressure sensitive color developing layer is prepared by the following raw materials, by weight: 15 to 30 parts ofleuco dye microcapsules, 9 to 18 parts of spacing agents, 10 to 15 parts of adhesives, 15 to 30 parts of developer microcapsules, 1 to 3 parts of surfactants, and 30 to 45 parts of solvents. The pressure detecting paper has the flat paper surface and the smooth surface; the pressure sensitive color developing layer coated on the paper layer is not easy to fall and has good staining-resistant and yellowing-resistant performances; and the color displaying density and color development speed are good.

Owner:东莞市亚马电子有限公司

Insulation material

An improved insulation system. The improved insulation system includes: an insulation component further including an expansion ratio modifying agent, a compression package, wherein the packed insulation density is greater than the installed insulation density, and a secondary container for receiving the compression package.

Owner:U S GREENFIBER

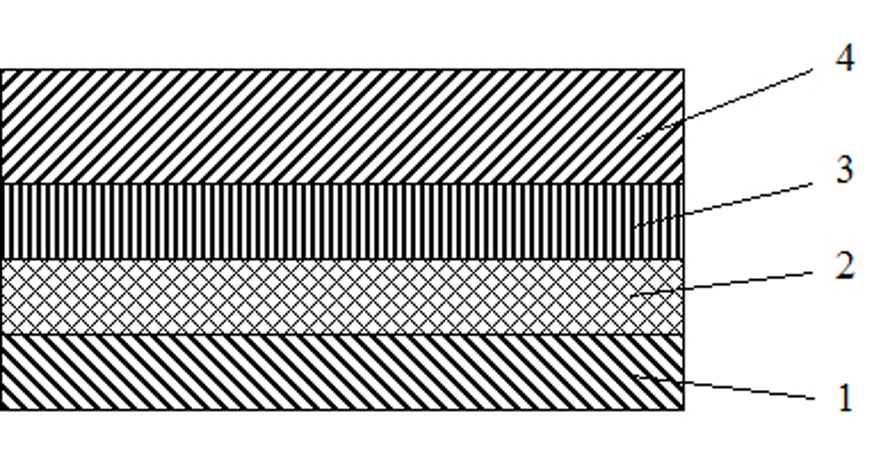

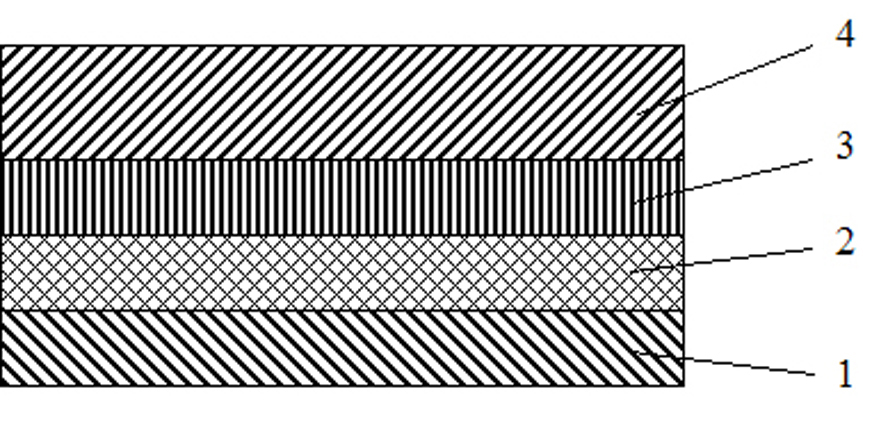

Bearing bush with vacuum sputtering film and production method thereof

ActiveCN101922513AGood densityImprove fatigue strengthVacuum evaporation coatingSputtering coatingMetallic NickelCopper

The invention discloses a bearing bush with a vacuum sputtering film and a production method thereof. The bearing bush with the vacuum sputtering film comprises a steel backing layer, a substrate layer, a nickel grid layer and an antifriction layer which are successively arranged. The bearing bush with a vacuum sputtering film is characterized in that the antifriction layer is composed of Cu-Sn alloy; the Cu-Sn alloy has the component proportion in percentage by weight: 5-7% of Sn and the balance of Cu. The method for producing the bearing bush with the vacuum sputtering film is as follows: bearing bush inner circle adopts vacuum sputtering to deposit one layer of lead-free material Cu-Sn alloy antifriction layer. The alloy film bearing bush of the invention has the advantages of good consistency, high fatigue resistance, favorable abrasive resistance and environment protection.

Owner:GUANGZHOU ANDA AUTOMOBILE PARTS

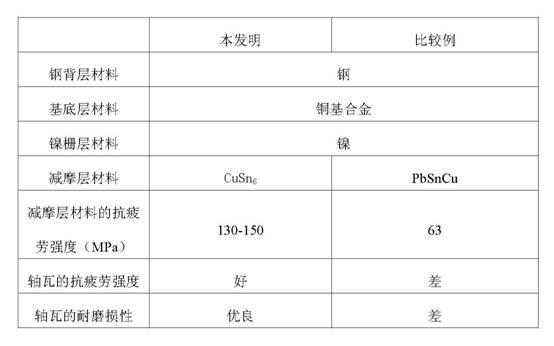

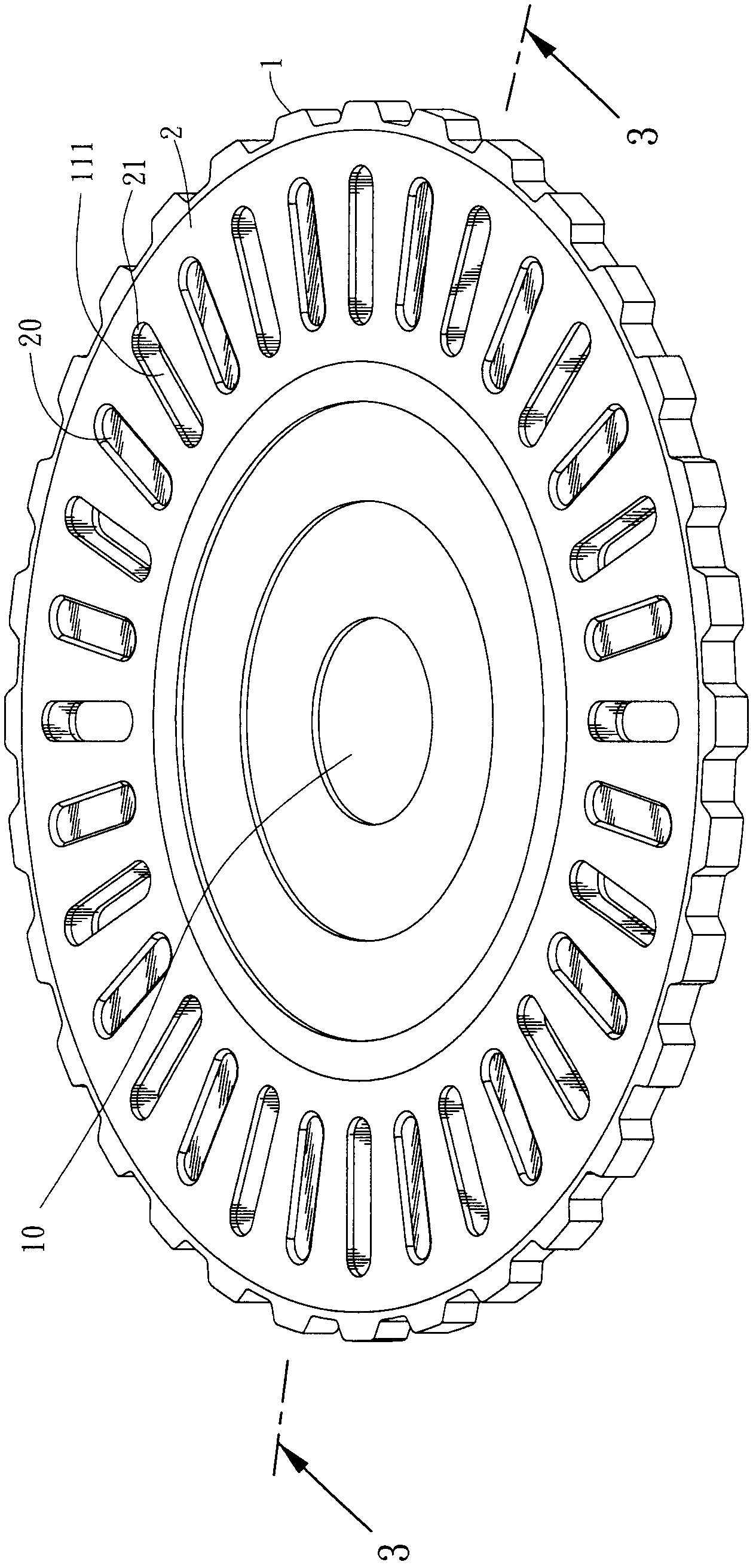

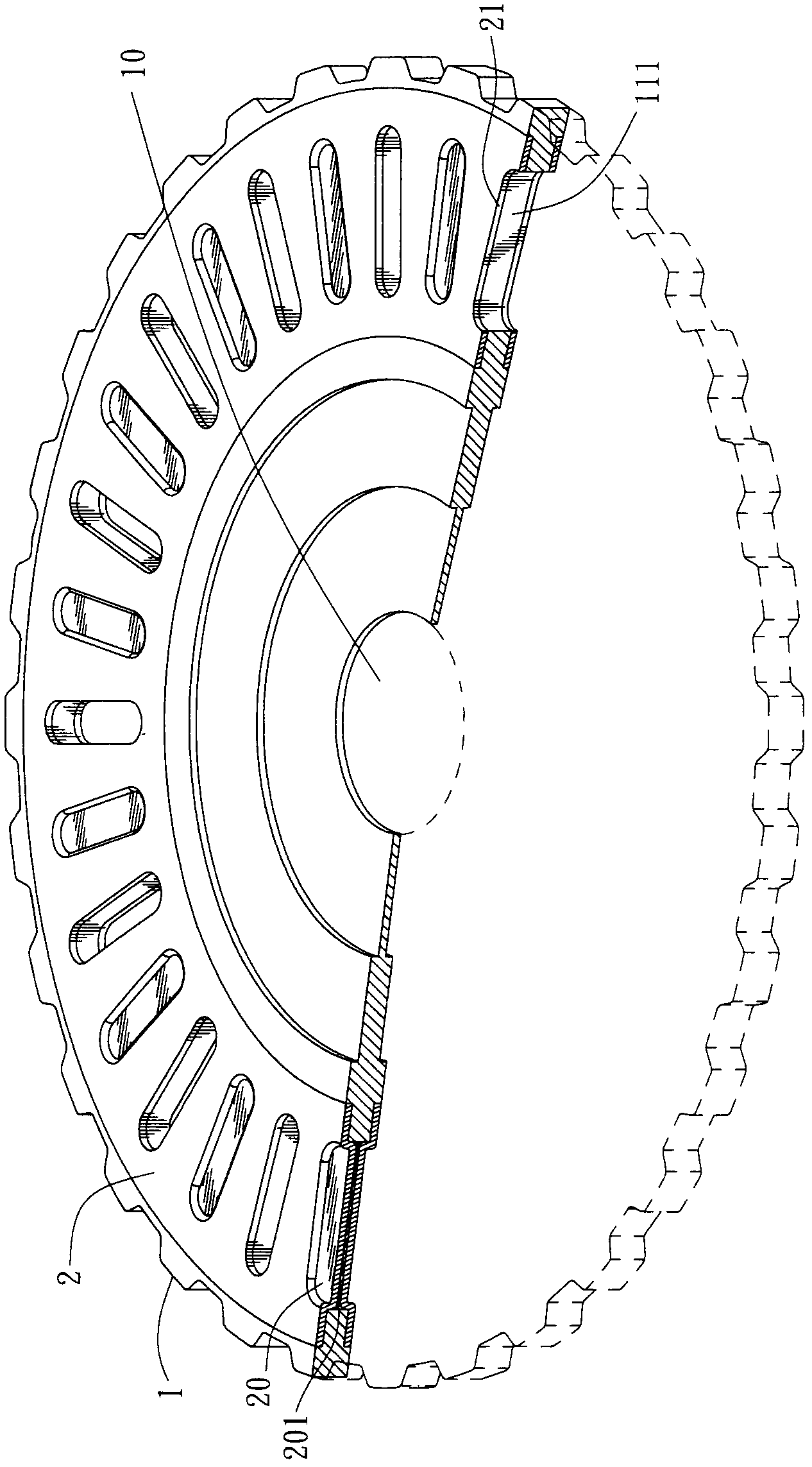

Wear-resistant disk

The invention discloses a wear-resistant disk. The wear-resistant disk comprises a carrying disk which is used for assembling a wheel hub and made of a light metal material; a plurality of annular holes are annularly formed in the carrying disk; two circular annular wear resistance frames are arranged on two sides of the carrying disk respectively to provide a wear resistance effect; both wear resistance frames are made of irony metal; a plurality of notches are annularly formed in the outer sides of both wear resistance frames; on the inner side of each wear resistance frame, a protruded surface is formed on the inner wall of each notch; the notches of both wear resistance frames are flush with the annular holes of the carrying disk, the protruded surface of each notch is embedded into each annular hole from two sides of the carrying disk; and the two relative protruded surfaces are combined correspondingly in the annular holes of the two wear resistance rings to ensure that the carrying disk and the two wear resistance frames are integrated, and the shearing force which is produced by a brake is transmitted to the carrying disk by the wear resistance frames. The wear-resistant disk has the advantages of light weight, wear resistance and high structural strength and density, and reduces production cost.

Owner:ASHIMA LTD

Method for producing lithium iron phosphate

The invention discloses a method for producing lithium iron phosphate without inert atmosphere protection, aiming at realizing the aim of reducing the manufacturing cost of positive material of a lithium iron phosphate battery. The method comprises the steps: the prepared precursor material is put into a semi-enclosed box body and pressed to be compact to exhaust the air in the precursor material; a high temperature resistant plate which is higher than the box body is arranged, and a gap is left between the high temperature resistant plate and the box body; then, the semi-enclosed box body and the high temperature resistant plate are arranged inside another semi-enclosed box body in a inverted way, and a carbon dust layer is filled into the box body; the high temperature resistant plate provided with the slim holes is laid on carbon dust or the gap is left between the high temperature resistant plate and the box body; the obtained semi-enclosed box body that is provided with the precursor and the carbon dust is firstly vacuumized and then filled with non-oxidizing gas for replacing the air in the precursor and the carbon dust; the box body is placed into a calcination device and heated from the room temperature to be 600-800 DEG C at the speed of 5-20 DEG C / min; after that, the temperature is maintained for 6-24h for calcination, and then the product is cooled to be the room temperature along with a furnace.

Owner:YUNNAN NENGTOU HUILONG TECH

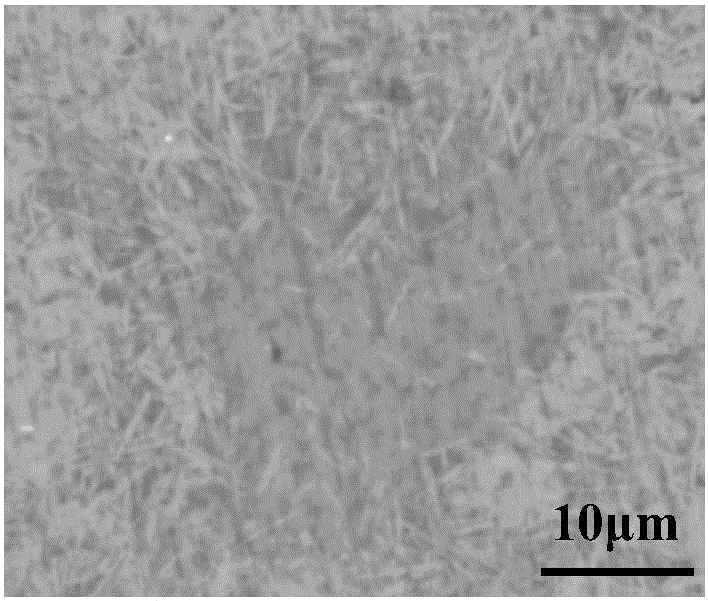

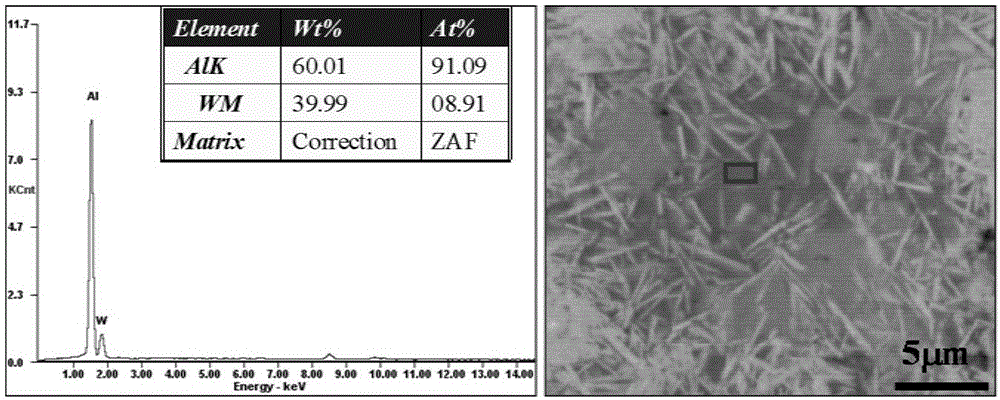

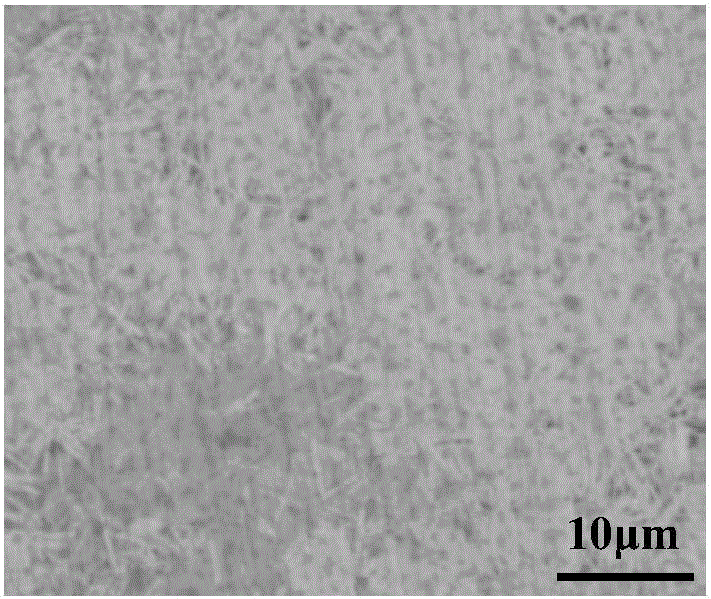

Surface modification method of tungsten and aluminum composite material

ActiveCN106756668AGood densityImprove wear and corrosion resistanceIncreasing energy efficiencyAluminum compositesTungsten

The invention belongs to the technical field of surface heat treatment and particularly relates to a surface modification method of a tungsten and aluminum composite material. The tungsten and aluminum composite material is subjected to surface heat treatment through a high-frequency induction heating furnace, a compound protection layer between tungsten and aluminum alloy is formed on the surface of the material, the protection layer is good in density, and obvious holes or cracks do not exist. By means of the modification method, wear resistance and corrosion resistance of the surface of the tungsten and aluminum composite material are improved, and application of the tungsten and aluminum composite material to a complex environment can be met.

Owner:GRIMAT ENG INST CO LTD

Formaldehyde-removing multifunctional wall putty powder and preparation method thereof

InactiveCN107474621AEnhance the body's resistanceGood densityFilling pastesCalcium carbonateIndoor air

Owner:厦门东顺涂料有限公司

Precision casting molding process

InactiveCN106807889AGood densityThe overall specification is consistentFoundry mouldsFoundry coresWaxPosition error

The invention discloses a precision casting molding process. The molding process steps are as follows: (1) put the wax material into a mixer, heat it to 45-48°C, and stir it into a paste; Insert the two die sleeve holes of the flexible mold sleeve into the flexible mold sleeve, and place the three in the mold cavity of the metal mold, and then make them close the upper and lower molds; (3) put the paste wax Inject into the mold at a pressure of 3.5 atmospheres, respectively pour the wax mold of the casting body and the wax mold of the sprue, and cool at room temperature for 30-60 minutes; (4) Open the upper and lower molds of the metal mold, and place the two The metal column mold is pulled out, the wax mold of the casting body and the gate part are removed from the mold, and then placed in a water pool to cool to 22-27°C, and taken out for later use; (5) The wax mold of the casting body made in step (4) is trimmed, Then, the sprue wax pattern and the casting body wax pattern are bonded together with a hot knife at 150° C. to obtain a casting wax pattern. The technological process is simple and easy to operate, the casting has good compactness, and the overall specification is consistent, the size is stable, the shape and position error is small, and the yield is high.

Owner:赵敏

Lithium zirconate ceramic ball tritium breeding material and preparation method thereof

The invention belongs to the technical field of nuclear energy and particularly relates to a lithium zirconate ceramic ball tritium breeding material and a preparation method thereof. According to the preparation method disclosed by the invention, an isostatic pressing method is adopted for preparing ceramic balls, and the density is higher than those prepared by rotational molding, wet process dehydration molding and wet process ZrO2 addition molding. The ceramic balls prepared by other methods are molded under the situation that external pressure does not exist, and the degree of compaction of components is lower than that of the isostatic pressing method. Simultaneously, the structure can release carbon dioxide during the sintering process, and the density of the balls is lower; and however, in the preparation method disclosed by the invention, powder is firstly prepared and can realize full reaction and release the carbon dioxide, and when the sintering of the ceramic balls is performed in the second step, the released carbon dioxide is very little, and the density of the prepared lithium zirconate ceramic balls is higher. In addition, if the density of the ceramic balls needs to be improved continuously, the pressure for isostatic pressing can be improved, and then the density of the obtained ceramic balls can be increased.

Owner:TSINGHUA UNIV

Refining flux for magnesium-lithium alloy and preparation method thereof

The invention provides a refining flux for a magnesium-lithium alloy and a preparation method thereof. The flux is prepared from, by mass, 20-50% of potassium chloride (KCl), 15-40% of potassium fluoride (KF), 20-40% of potassium bromide (KBr), 5-15% of lithium chloride (LiCl), 5-10% of lithium fluoride (LiF) and 1-3% of a carbonate foaming agent. The carbonate foaming agent comprises one or more of lithium carbonate and potassium carbonate. According to the flux, the proportion of all the components is optimized, the flux has the good melting point, viscosity and wettability, meanwhile, in the using process, the foaming agent is heated to generate inert gases, the part of the impurities can be brought out to the surface of melt in the bubble floating process, so that the dosage of the flux is reduced, the flux is not prone to being mixed into alloy liquid, separation from the melt is facilitated, and the ingot casting quality is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

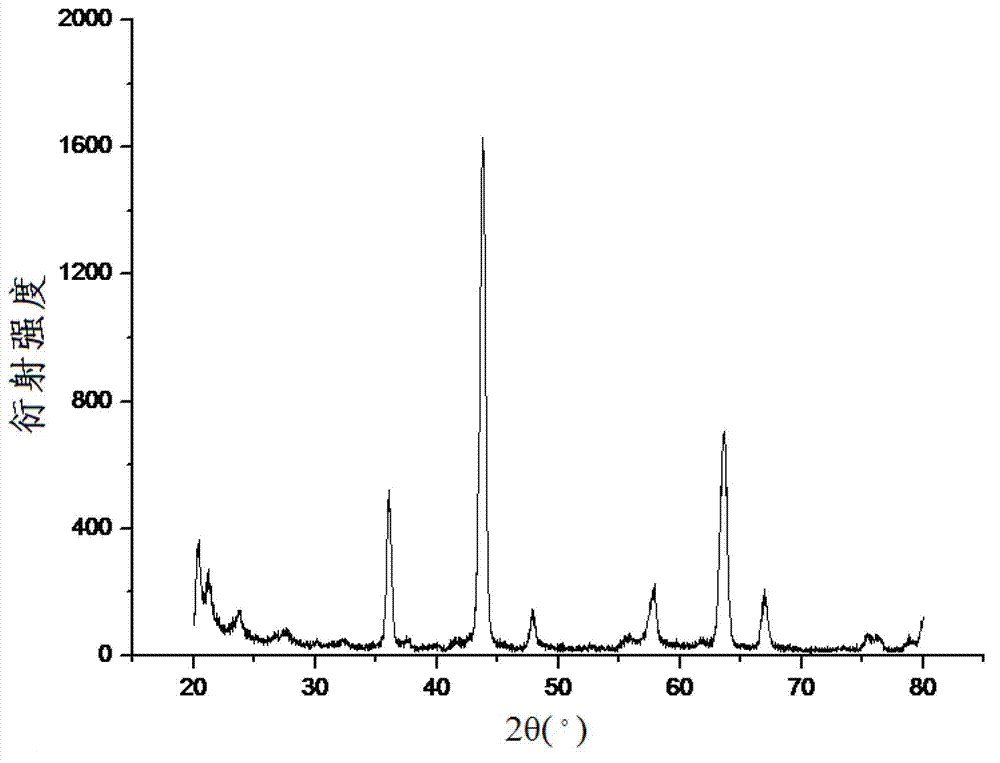

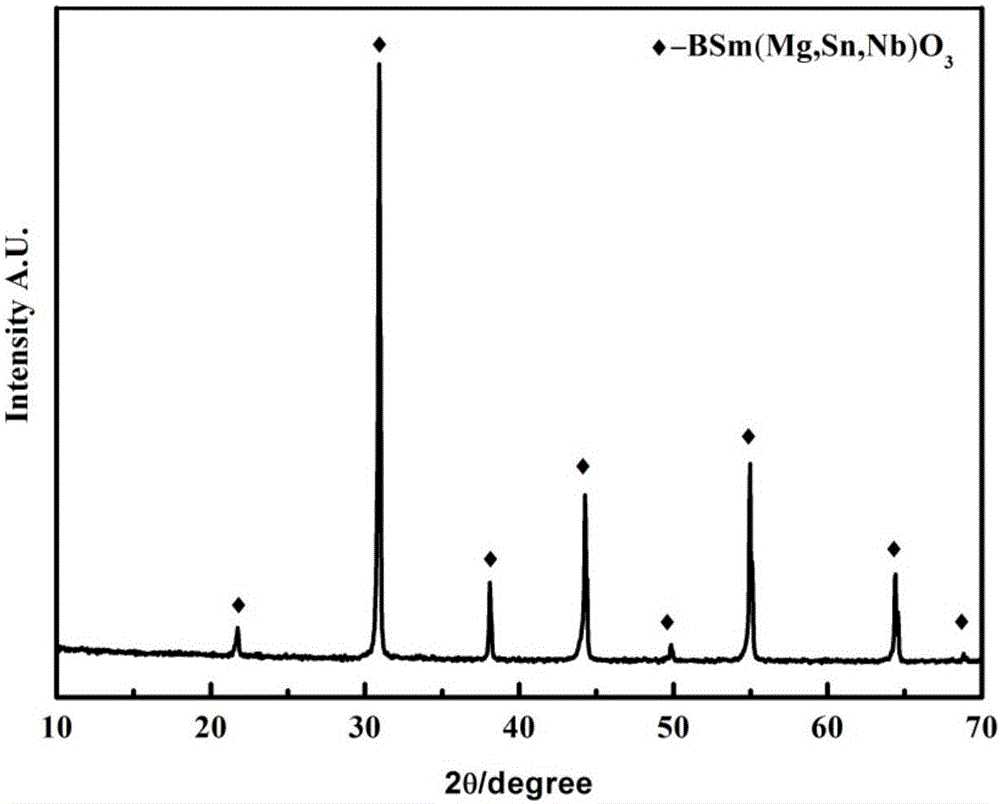

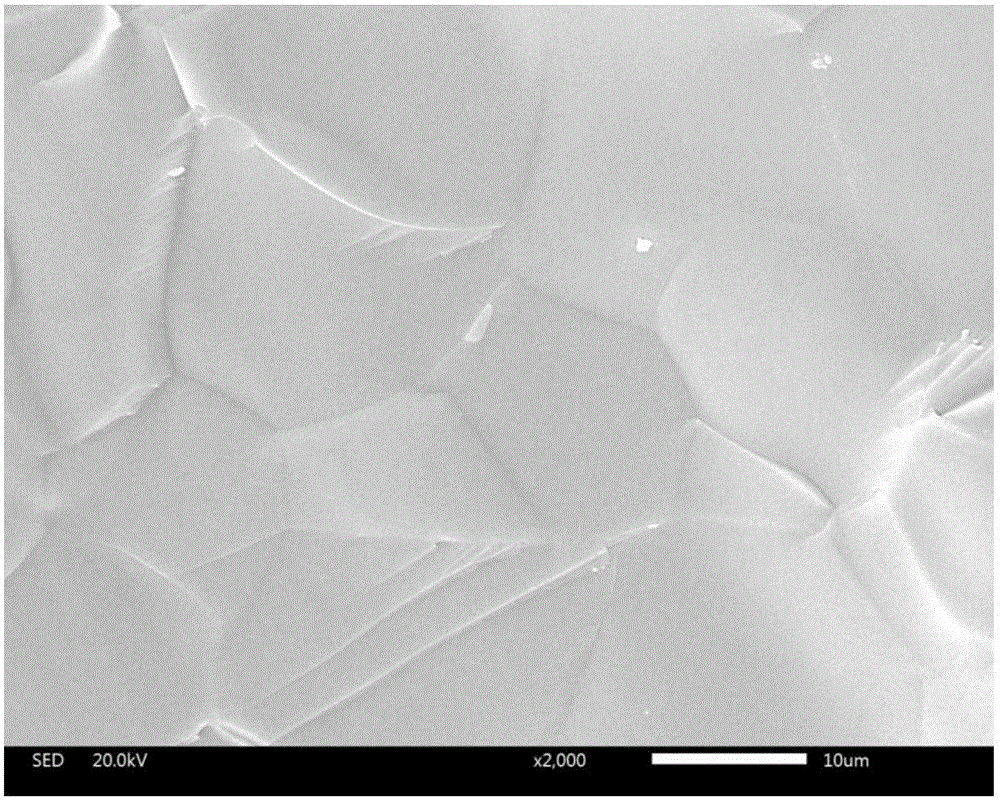

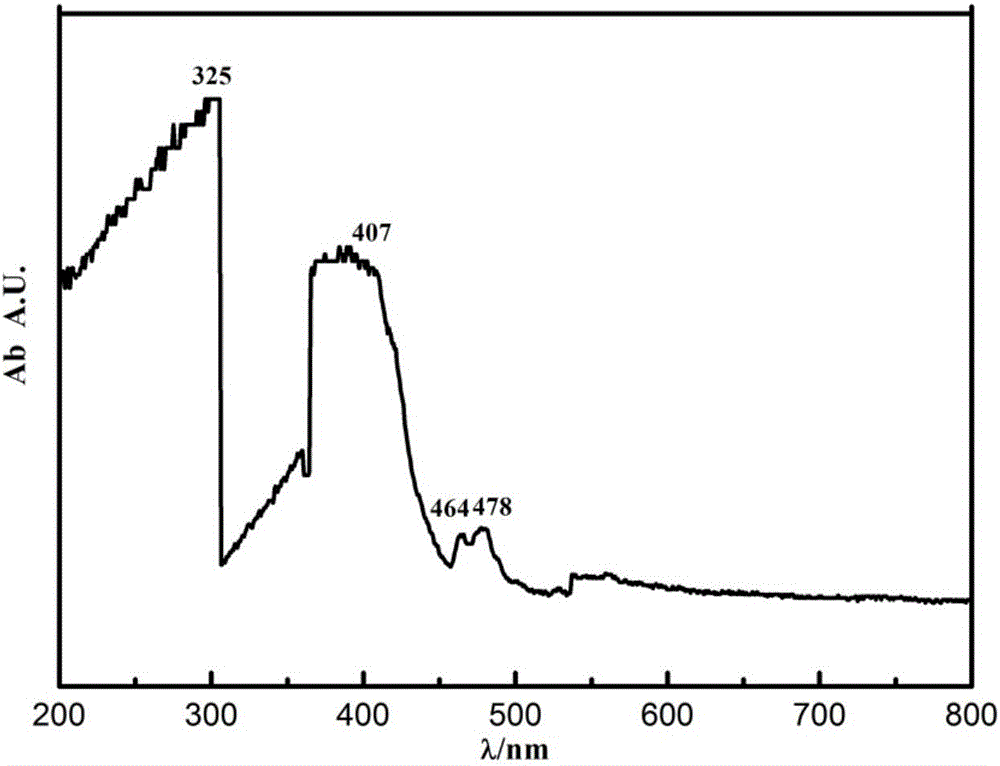

Barium magnesium niobate light-emitting ceramics and preparation method thereof

The invention relates to barium magnesium niobate light-emitting ceramics and a preparation method thereof.The formula of the barium magnesium niobate light-emitting ceramics is Ba(1-x)Smx(Sn0.1Mg0.3Mg0.3Nb0.6)O3, wherein 0.005< / =x< / =0.03.The preparation method includes the steps of firstly, performing ball milling on a barium-source compound, a samarium-source compound, a magnesium-source compound, a tin-source compound and a niobium-source compound according to the weight requirements of the formula, then sintering under 1300-1350 DEG C to obtain products, and performing secondary ball milling on the products to obtain ceramic powder; secondly, adding a polyvinyl alcohol aqueous solution into the ceramic powder for pelleting, aging, crushing to obtain ceramic particles, forming the ceramic particles to obtain ceramic bodies, and preparing the ceramic bodies into even-pressure ceramic bodies through isostatic cool pressing; thirdly, sintering the even-pressure ceramic bodies under oxygen atmosphere after the even-pressure ceramic bodies discharge glue, cooling along with a furnace, and coarsely polishing and finely polishing to obtain the barium magnesium niobate light-emitting ceramics, wherein sintering temperature is 1500-1600 DEG C, and the temperature is kept for 48-60 hours.The barium magnesium niobate light-emitting ceramics have the advantages that the crystal boundary of the ceramics has no impurity phases, and the ceramics are good in compactness, even in grain size, high in chemical stability, and good in physical performances such as compressive strength; the ceramics have evident absorption peak in the visible light range, the quenching concentration can reach 2%mol, and high light-emitting intensity is achieved.

Owner:WUHAN UNIV OF TECH

Composite sawdust-based biomass particles of waste cotton clothes and preparation method of particles

The invention discloses composite sawdust-based biomass particles of waste cotton clothes. On one hand, sawdust is subjected to carbonization treatment and then modified, therefore, the toughness and the density of inorganic carbon particles are improved, the combustion heat value of sawdust carbon residues is increased, volatile components in the combustion process are decreased, and the sulphur content of exhaust gas is low; on the other hand, rice straw, sweet potato vines and sorghum stalks are subjected to fermentation treatment, therefore, the structural layer of the raw materials is changed to form the compact tissue structure, high-content organic matter is generated, and components of the organic matter are increased; the materials are continuously subjected to fermentation treatment by adding modified dolomite and the waste cotton clothes, then combustibles in the organic matter raw materials are increased, and lastly the materials are subjected to extrusion forming by being compatible with other effective auxiliaries. In this way, the prepared biomass particles have the advantages of being low in cost, good in toughness, long in service life, resistant to sun, not prone to corruption and the like.

Owner:TONGLING XINGMAO AGRI PROFESSIONAL COOP

Decorating plate brick producing process

The production process of a decoration board brick sprays a layer of epoxide resin varnish evenly on the surface, then a layer of laser powder fleck on the surface, sweeping and pressing the surface with the laser powder evenly attached on the glass brick, resting until drying of the varnish, spraying bottom paint on the laser powder fleck and baking in 150 degree for 30-60 minutes, cooling, net printing the bottom color paint with plastic rubber till its natural drying or baking it to dryness. It is cheap in cost, good in luster, straightness, transparency and intensity with strong cubic effect, free from erosion with long durability.

Owner:潘文建

Silver-nickel alloy powder and preparation method thereof and conductive slurry including silver-nickel alloy powder

InactiveCN108296478AGood densityImprove performanceTransportation and packagingMetal-working apparatusIonSilver particles

The invention discloses silver-nickel alloy powder. The particle size of nickel particles ranges from 0.1 micrometer to 5.0 micrometers, and silver accounts for 0% to 60% of the total weight of silverparticles and the nickel particles. A method for preparing the silver-nickel alloy powder comprises the steps that a reducing agent I is used firstly, the silver particles are primarily separated outon the surfaces of the nickel particles, and therefore a precursor is prepared; and then the precursor is in full contact with a dispersing agent, a complexing agent, the silver particles and a reducing agent II of the silver particles in deionized water, and therefore silver is further replaced and separated out on the surface of the precursor. A silver coating layer on the surfaces of the silver particles and the nickel particles prepared through the method is high in density and has fewer holes, and therefore surface oxidization of the nickel particles and resistance reduction of the silver-nickel alloy powder can be controlled well, it is guaranteed that the conductive performance of the silver-nickel alloy powder after long-time storage is still good, and the silver-nickel alloy powder can be applied to conductive slurry.

Owner:宁波广新纳米材料有限公司

Method for preparing water-resistant anti-spalling printer paper coating material

InactiveCN106868939ANot easy to fall offImprove performanceWater-repelling agents additionDuplicating/marking methodsCross-linkChemical Linkage

The invention discloses a preparation method of a water-resistant and anti-shedding printing paper coating, which belongs to the technical field of printing paper coatings. The invention provides a method of extracting wood tar from pine wood, mixing spider silk and tea leaves for enzymolysis, then mixing and fermenting the enzymolysis solution, nano-montmorillonite and wood tar, and finally adding coupling A method for preparing printing paper coatings with additives and surfactants. In the present invention, spider silk protein is used as the adhesive matrix of the coating, and the number of lipophilic ester groups in the adhesive matrix is increased after wood tar modification, so that the coating not only improves water resistance, but also increases the absorption of ink, and then By adding nano-montmorillonite, the ink-absorbing ability and weather resistance of the coating are enhanced, and it is not easy to change color. Finally, a large number of active groups produced during the microbial fermentation process can form chemical bonds with the active groups on the surface of the paper base and form a network crosslink. structure, thereby solving the problem of paint falling off easily, and has broad application prospects.

Owner:仇颖莹

Diatom plate and production technology

The invention discloses a diatom plate and a technology. The diatom plate is prepared from the following raw materials in parts by weight: 32 parts of PVC resin, 6.47 parts of heavy calcium carbonate,38 parts of diatomaceous earth, 0.3 part of traditional Chinese medicine root powder, 10 parts of reclaimed materials, 5 parts of crocalite, 0.25 part of nano calcium carbonate, 1.93 parts of a stabilizer, 4.28 parts of a conditioning agent, 0.15 part of polyethylene wax, 0.39 part of G-60, 0.59 part of a foaming agent, 0.17 part of zinc stearate and 0.47 part of oxidized polyethlene wax.

Owner:潘立明

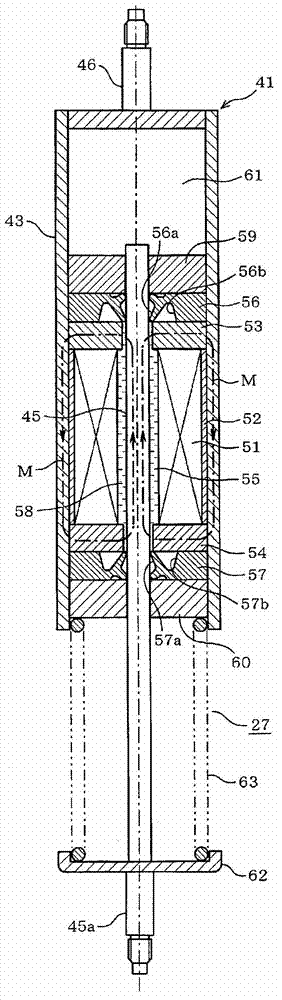

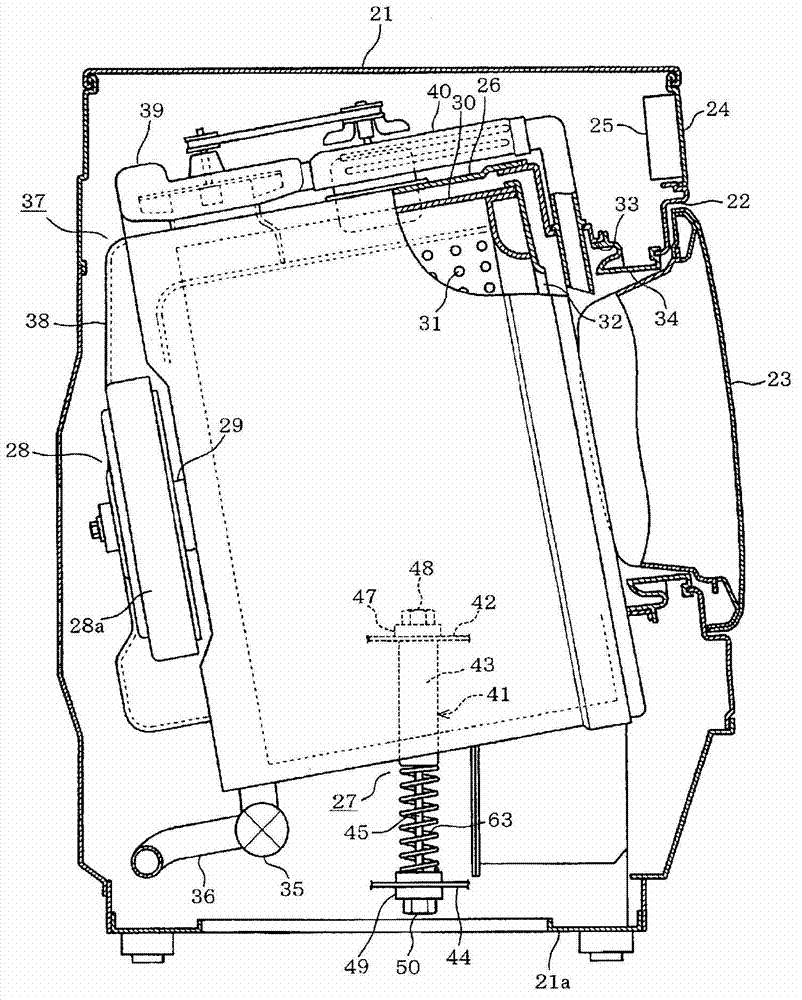

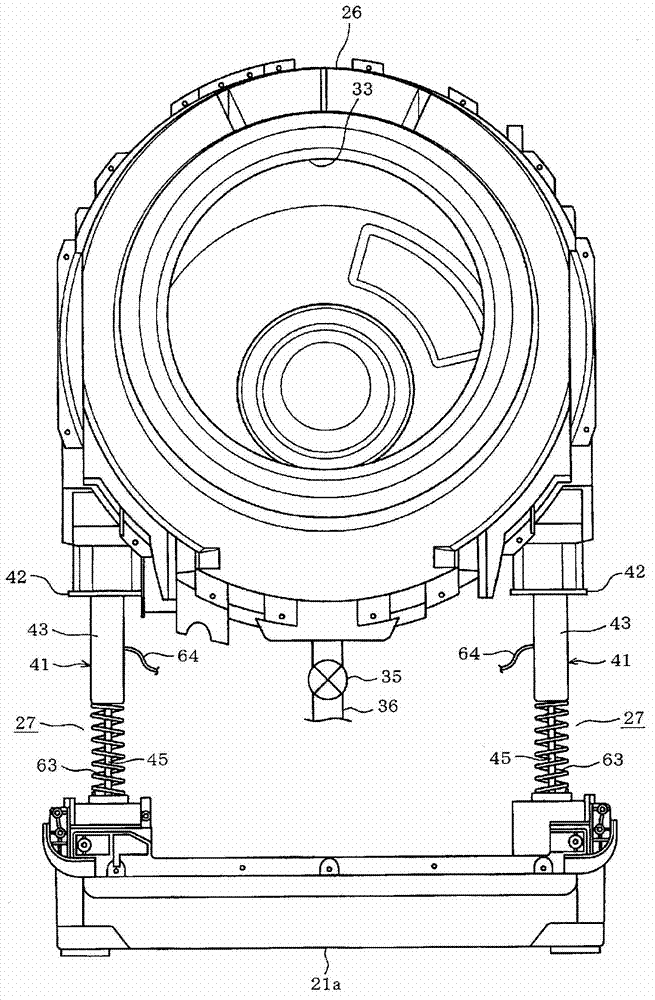

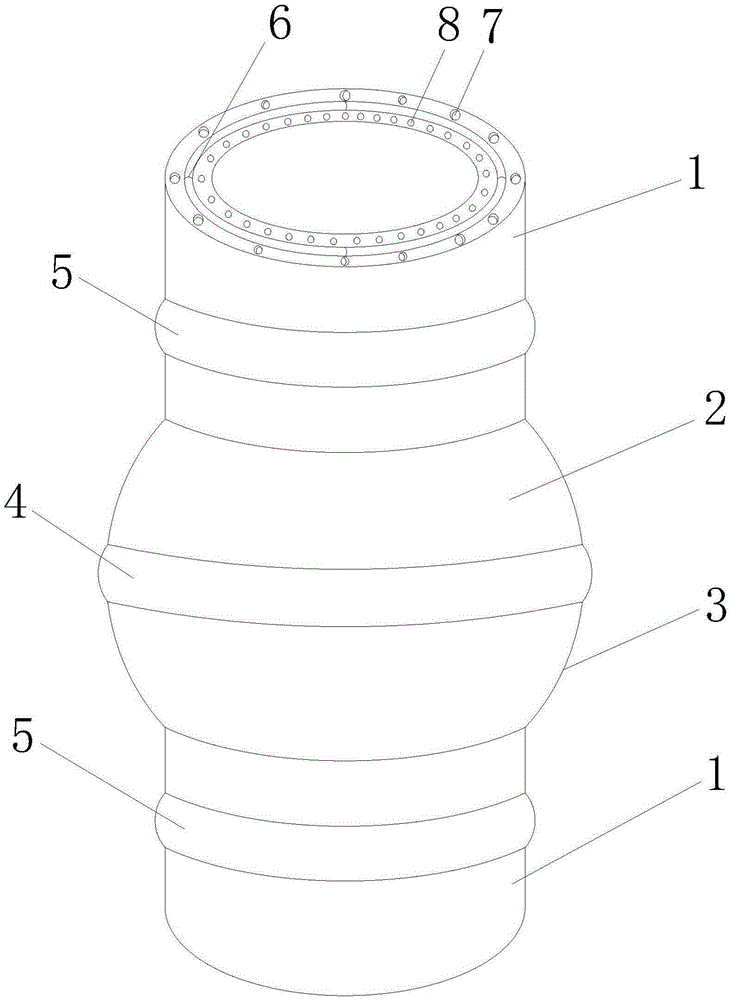

Damper, washing machine, and washer/dryer

ActiveCN102770594AGood densityGuaranteed DensityEngine sealsLinear bearingsEngineeringFrictional resistance

Disclosed is a damper that obtains damping force through friction resistance resulting from the viscosity of a magnetic viscous fluid, and that is positioned on the outsides in the axial direction of a lower yoke and an upper yoke, a seal being disposed on one side (bottom) thereof and a seal being also disposed on the other side (top) thereof. As a result, the magnetic viscous fluid is sealed in both outer ends in the axial direction of a section that is filled with the magnetic viscous fluid, and the leakage thereof can be prevented. Also, as air is not led into the section that is filled with the magnetic viscous fluid, it is possible to favorably maintain the density of the magnetic viscous fluid in said section that is filled with the magnetic viscous fluid, and it is possible to prevent the occurrence of a decrease in damping force.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

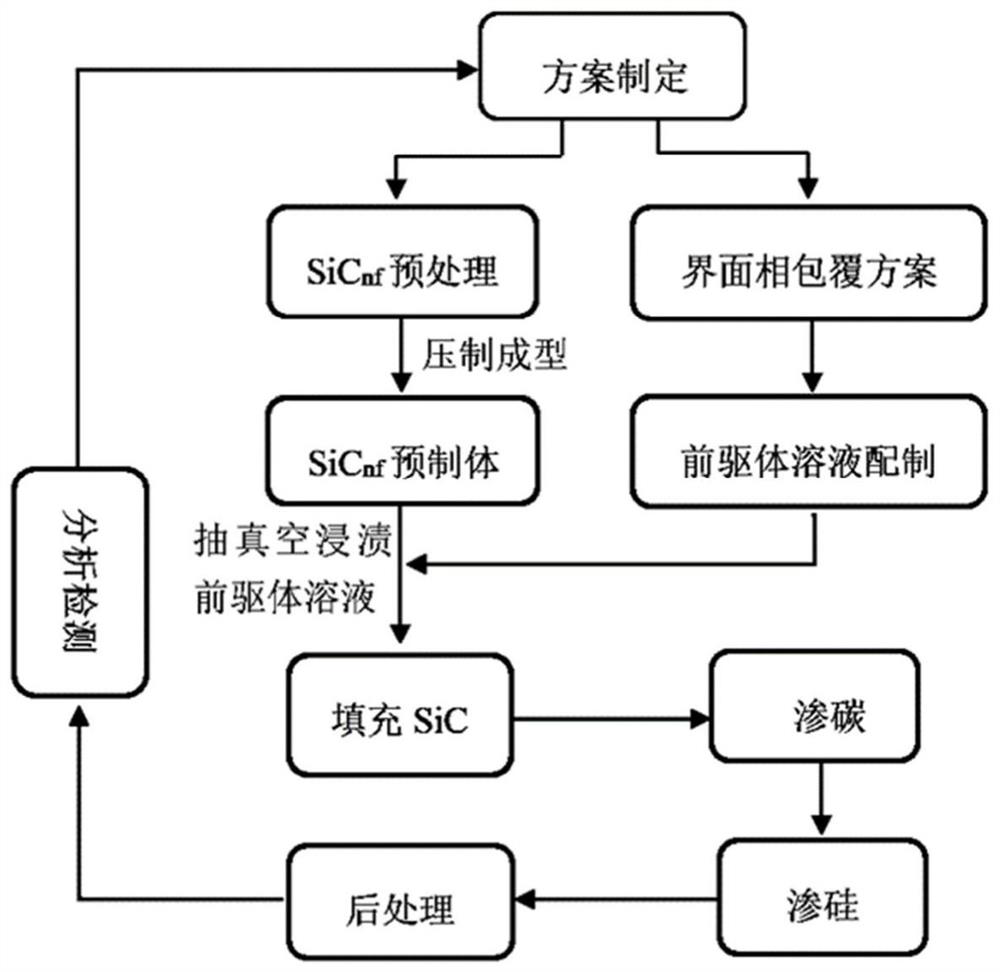

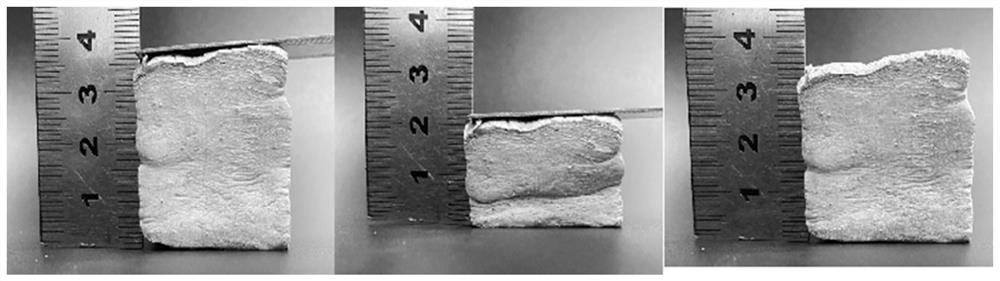

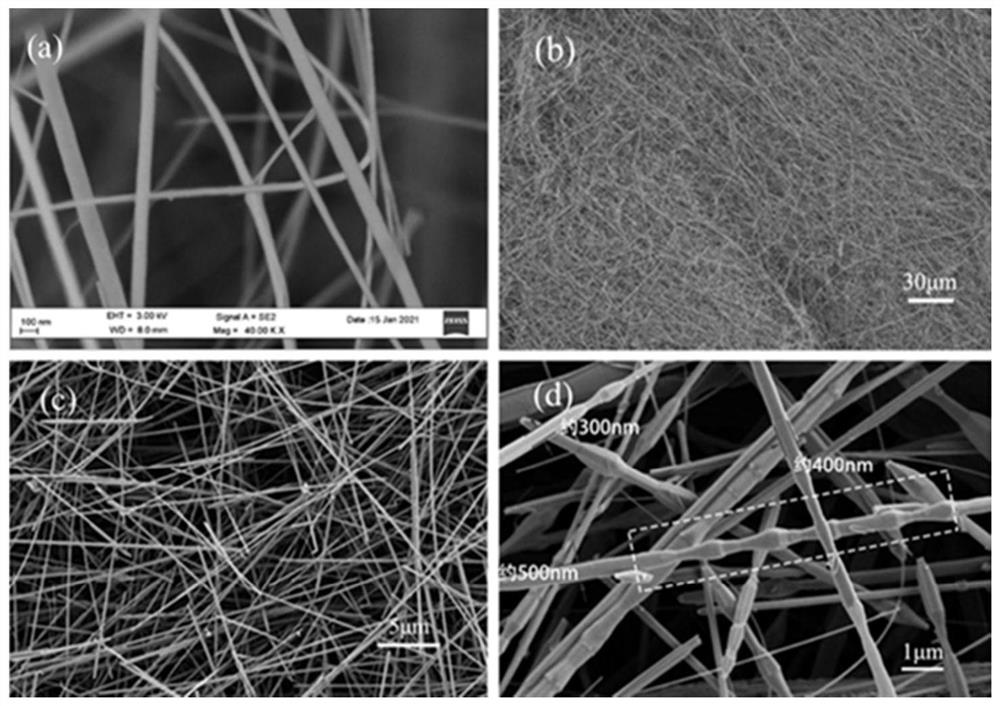

Method for preparing SiC ceramic-based composite material from spongy silicon carbide nanofiber preform

The invention discloses a method for preparing a SiC ceramic-based composite material from a spongy silicon carbide nanofiber preform. The method comprises: filling a glass tube with a spongy SiCnf material, and pre-compressing the spongy SiCnf material by external force to obtain a pre-compressed body; soaking the pre-compressed body in a low-concentration phenolic resin solution, taking out the pre-compressed body after soaking, drying the pre-compressed body to be half-dry, putting the pre-compressed body into a mold, carrying out pressing, drying, cracking, and repeating for multiple times; carrying out vacuum impregnation with a PCS solution, taking out the product, carrying out drying and cracking, and repeating for multiple times; after completely cooling, carrying out vacuum impregnation with a high-concentration phenolic resin solution, carrying out drying and cracking, and repeating for multiple times; and placing the above in a crucible, uniformly covering the surface with Si powder, and then firing. According to the invention, the characteristics of high strength, wear resistance, corrosion resistance and the like of SiC ceramic are retained, and the composite material also has the advantages of low density, high toughness and stable high-temperature performance, so that preparation of the SiCnf / SiC composite material with high volume fraction, high compact network structure, low porosity and low residual silicon is realized, and the composite material has excellent mechanical properties of a SiCnf reinforcement.

Owner:ZHEJIANG SCI-TECH UNIV

Inner shock absorption framework

InactiveCN105422728AImprove stabilityEnhance tooth engagementNon-rotating vibration suppressionEngineeringRadian

The invention discloses an inner shock absorption framework which comprises cylinder parts arranged symmetrically at the two ends and a middle jar part. The outer surface of the middle jar part is of a convex cambered face structure. The radian of the convex cambered face is designed to be 60 degrees. A first protrusion is machined on the middle jar part and designed of a cambered face structure. The radian of the cambered face of the first protrusion is designed to be 120 degrees. Second protrusions are machined on the cylinder parts arranged symmetrically at the two ends and each designed of a cambered face structure. The radian of the cambered face of each second protrusion is designed to be 60 degrees. Third protrusions are machined on the end faces of the cylinder parts and each designed of a cambered face structure. The radian of the cambered face of each third protrusion is designed to be 120 degrees. The inner shock absorption framework is good in stability, the shock absorption and resistant performance is achieved, the sealing performance is excellent, the use effect is greatly improved, and the service life is greatly prolonged.

Owner:ANHUI DINGYUAN METAL PROD CO LTD

High strength bamboo-wood composite board assembly method

InactiveCN106493800AHigh compressive strengthGood densityWood veneer joiningHigh intensityMaterials science

The invention discloses a high strength bamboo-wood composite board assembly method. The high strength bamboo-wood composite board assembly method is characterized in that 2 to 8 gum dipping thin bamboo curtains are stacked between an upper wood veneer and a lower wood veneer, and a gum dipping thick bamboo curtain is placed in the middle portion of the 2 to 8 gum dipping thin bamboo curtains. A bamboo-wood composite board manufactured according to the method is high in compressive strength and good in compactness; and the method is mainly used for manufacturing building templates and platform floors.

Owner:HUNAN ZHONGNAN SHENJIAN BAMBOO WOOD CO LTD

Buffer composite packaging paper and preparation method thereof

The invention discloses buffer composite packaging paper and a preparation method thereof. The buffer composite packaging paper is prepared from, by weight, 6-18 parts of mineral fiber, 3-9 parts of a modified foaming agent, 60-90 parts of talcum powder, 10-15 parts of a high molecular polymer, 5-10 parts of a dispersing agent and 10-20 parts of a moisture-proof agent.. The modified foaming agent coats the mineral short fibers, the modified foaming agent prepared from carbonate modified by the titanate coupling agent has a better foaming effect in use, initiated bubbles are smaller and denser, and the buffering and damping effects of the packaging paper are guaranteed.

Owner:马鞍山高思贸易有限公司

Method for mixing nitrogen element in gate silicon oxide layer and process for manufacturing gate silicon oxide layer structure

InactiveCN101964305AGood mass densityGood densitySemiconductor/solid-state device manufacturingSemiconductor devicesMetallurgyNitrogen

The invention provides a method for mixing a nitrogen element in a gate silicon oxide layer, which comprises the following steps of: introducing N2 and O2 in a gas flow ratio of 1:3 in a main oxidation process or an annealing process for forming the gate silicon oxide layer; and forming a silicon oxynitride layer on the formed silicon oxide layer so that the nitrogen element is diffused to the gate silicon oxide layer. In the method for mixing the nitrogen element in the gate silicon oxide layer, N2O is substituted by adopting mixed atmosphere of the N2 and the O2 in a specific ratio, so that the nitrogen element can be mixed into the gate silicon oxide layer effectively in a high-temperature furnace which is not provided with an independent N2O supply system. Compared with the annealing process performed merely in inert gases, the annealing process performed under the process condition of the specific mixed atmosphere has the low heat budget value, and the quality and compactness of the gate silicon oxide layer formed by oxidizing while annealing are excellent.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com