Silver-nickel alloy powder and preparation method thereof and conductive slurry including silver-nickel alloy powder

A silver-nickel alloy and silver-nickel technology, which is applied to the field of silver-coated nickel alloy powder and its manufacturing, can solve the problems of high porosity of the powder surface coating and the non-dense coating, and achieve good compactness and improved performance. , the effect of good density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

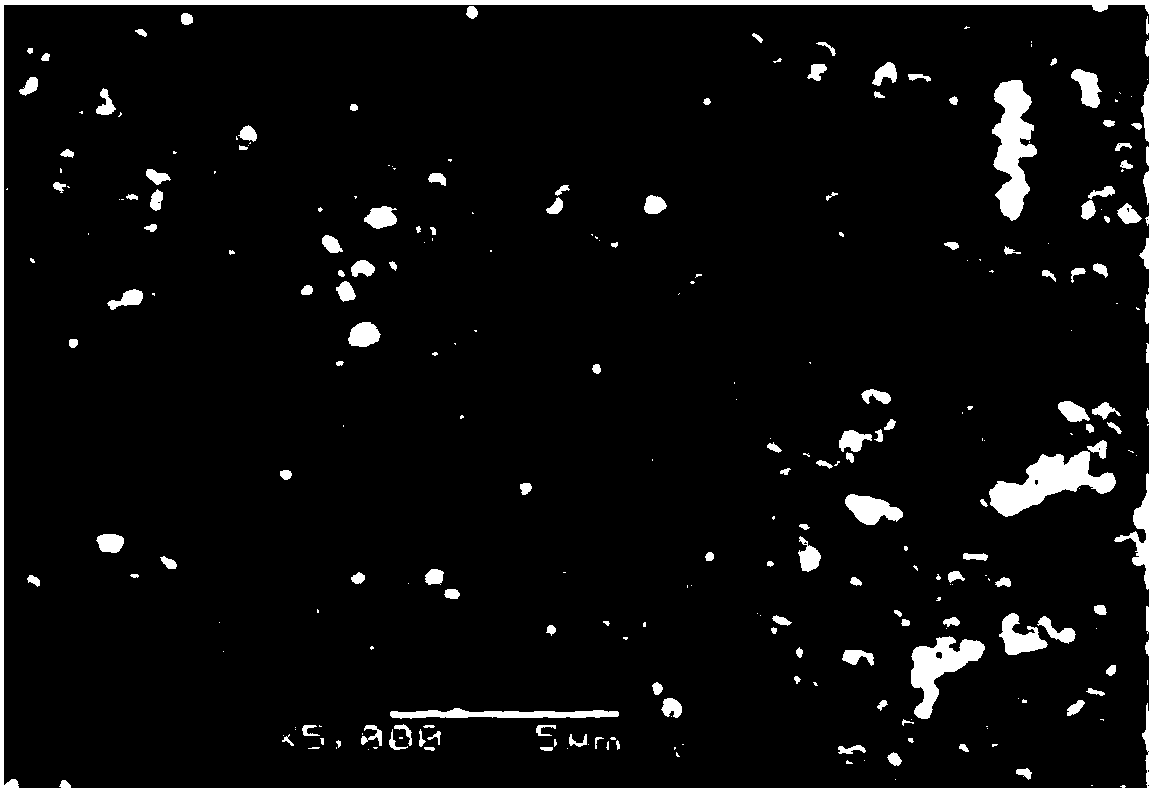

[0019] Take by weighing 300nm spherical nickel powder (Ningbo Guangbo Nano New Material Company produces) raw material 15.8g, add in the reactor, add mass concentration then and be 500ml of dilute sulfuric acid 5%, ultrasonic stirring 30min is to remove the oxide compound on the nickel powder core particle surface, Then filter and wash 3 times to obtain the nickel powder for use after pickling; Weigh 38g of glucose, 38g of triethylenetetramine and 11.3g of polyethylene glycol 400 and add it to 2000ml deionized water to form a complex solution, then add the nickel powder for use In the complexing agent solution and stirred evenly, it is called A solution;

[0020] Weigh 23.5g of silver nitrate and add it to 100ml of deionized solution to fully dissolve it, add concentrated ammonia water to adjust to a clear silver ammonium solution, then add it dropwise to the nickel powder complex solution at a rate of 5ml / min to form B solution;

[0021] Weigh 9.5g of ascorbic acid and add 19...

Embodiment 2

[0024] Silver-nickel alloy powder was obtained by performing the same process as in Example 1 except that the particle size of the nickel particles was changed to 600 nm.

Embodiment 3

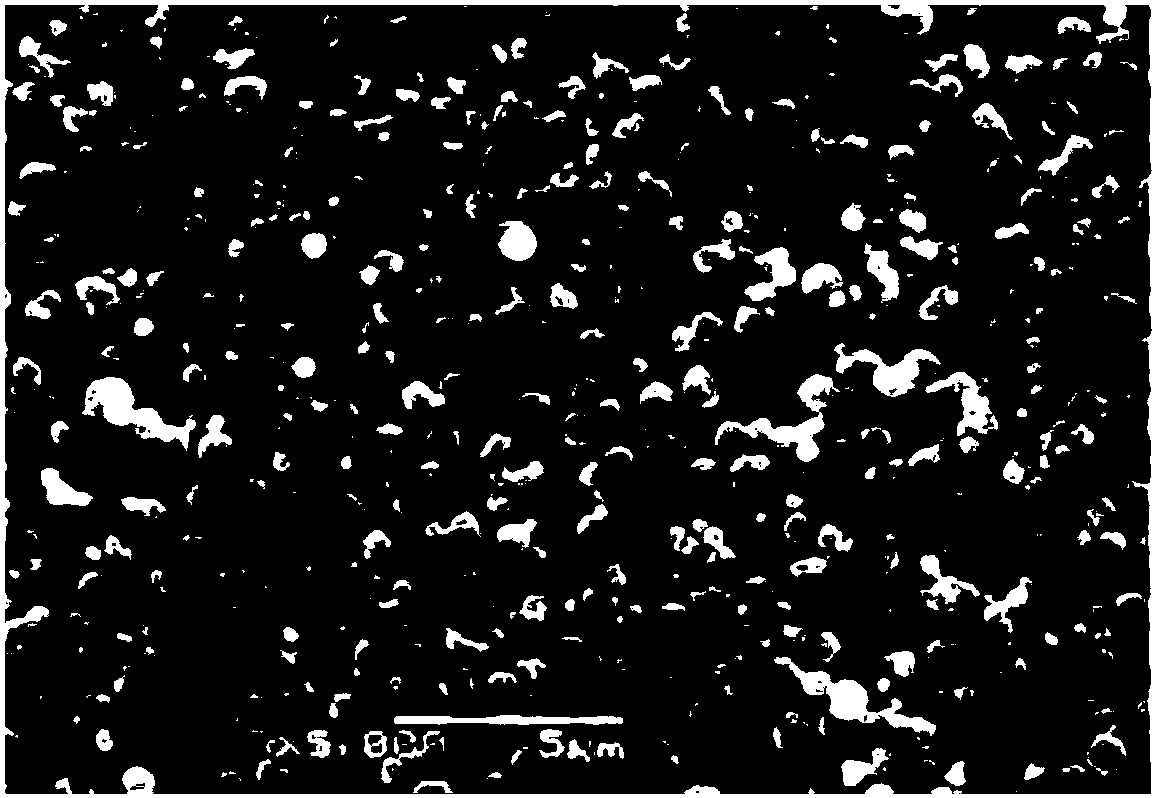

[0026] Silver-nickel alloy powder was obtained by performing the same process as in Example 1 except that the particle size of the nickel particles was changed to 1000 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com