Method for preparing SiC ceramic-based composite material from spongy silicon carbide nanofiber preform

A nanofiber and composite material technology, which is applied in the field of silicon carbide composite material preparation, can solve the problems of difficult control of the interface between SiCnf and matrix, small volume content of SiCnf, and difficulty in fully reflecting the mechanical properties of SiC, so as to achieve superior toughness and excellent performance. Good mechanical properties and good density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

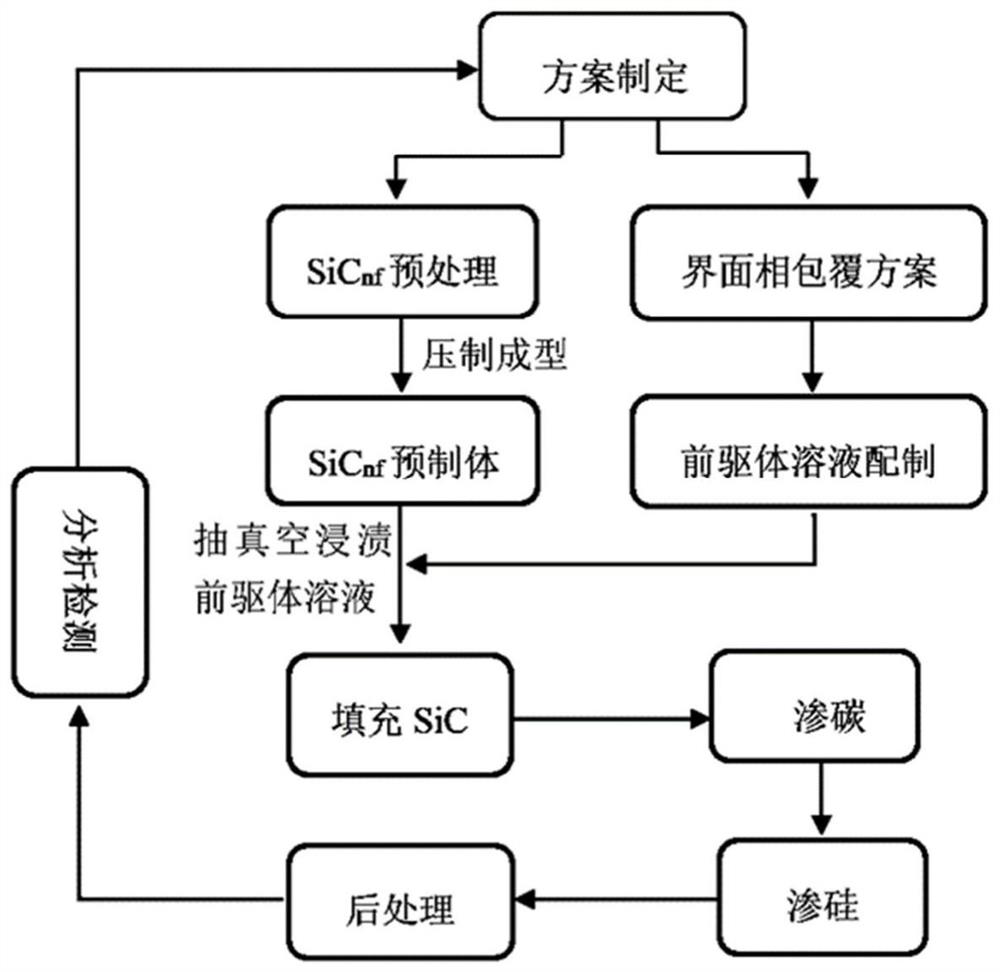

Method used

Image

Examples

Embodiment 1

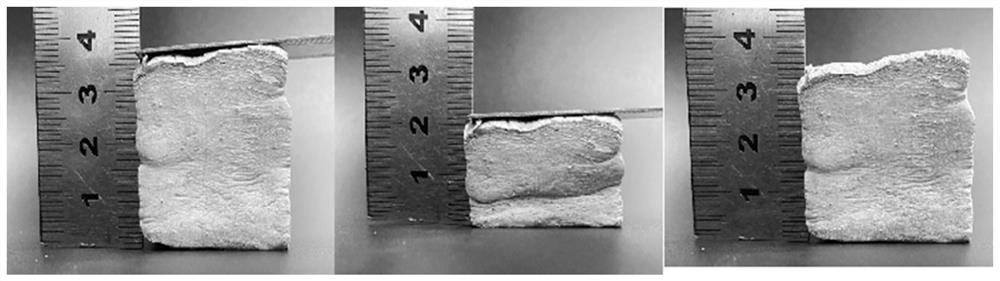

[0053] a. Put about 5g of spongy SiCnf material into a glass tube with an inner diameter of 5cm, use a Si sheet with the same diameter as the inner diameter of the glass tube to lay on the SiCnf material, and apply an external force after inserting a stick into the glass tube. Both ends of the glass tube are open, one end is placed on the table, and the other end is inserted into a stick, and an external force is applied along the axis of the glass tube to compress the sponge-like SiCnf material. The specific implementation is as Figure 4 shown.

[0054] b. impregnate the pre-compressed body obtained in step a with 16%wt phenolic resin solution, take it out of the glass tube after the solution is completely soaked, dry it in an oven at 70°C until it is half dry, put it into a mold, and use oil The SiC nanofiber column was pressed under a pressure of 30MPa by a press-type powder tablet press, and the holding time was 20min. After the pressing is completed, put it together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com