Patents

Literature

36results about How to "Reduced interfacial bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

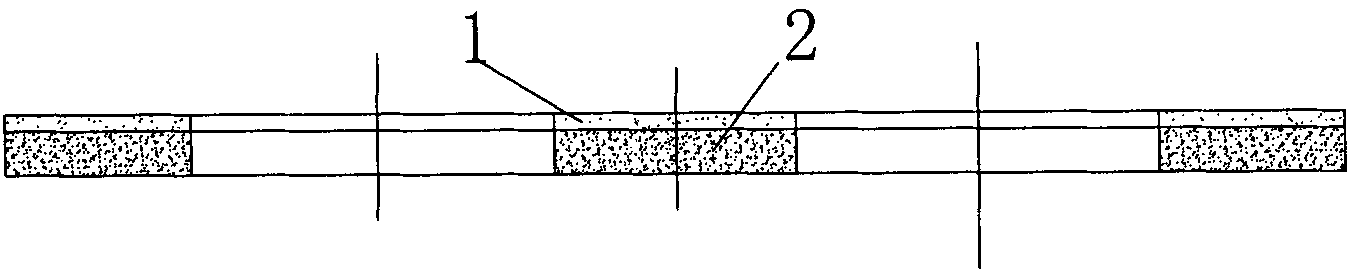

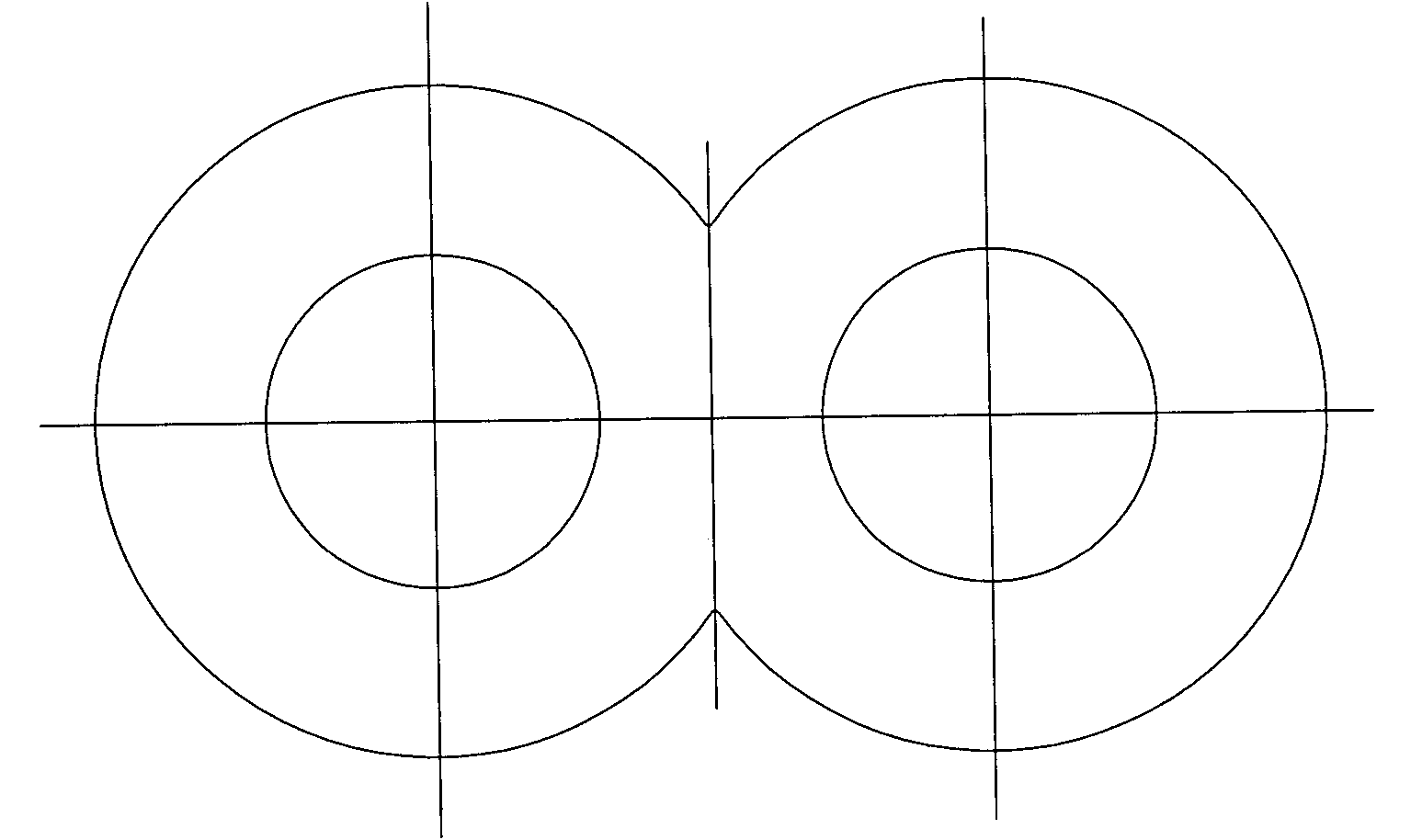

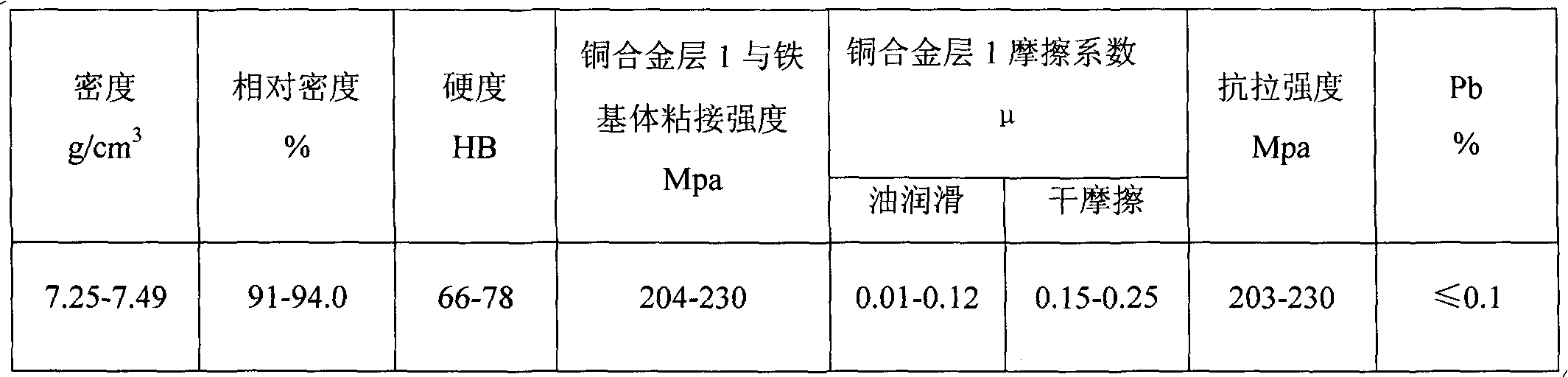

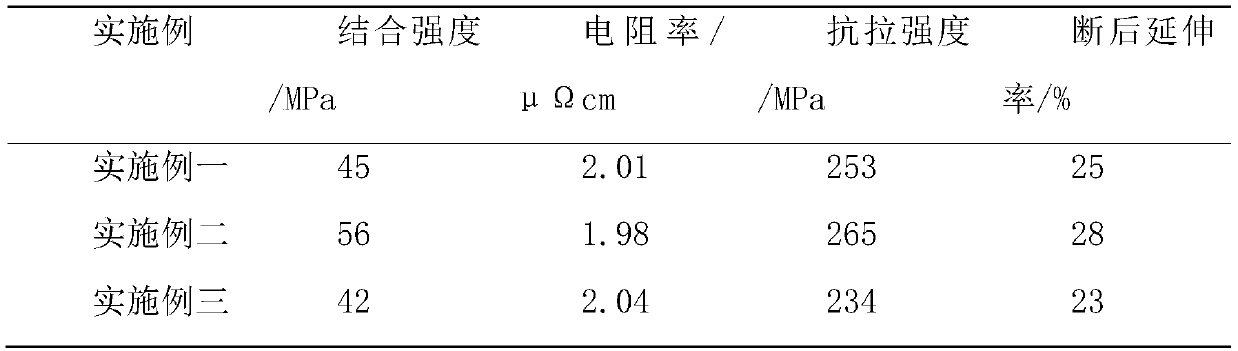

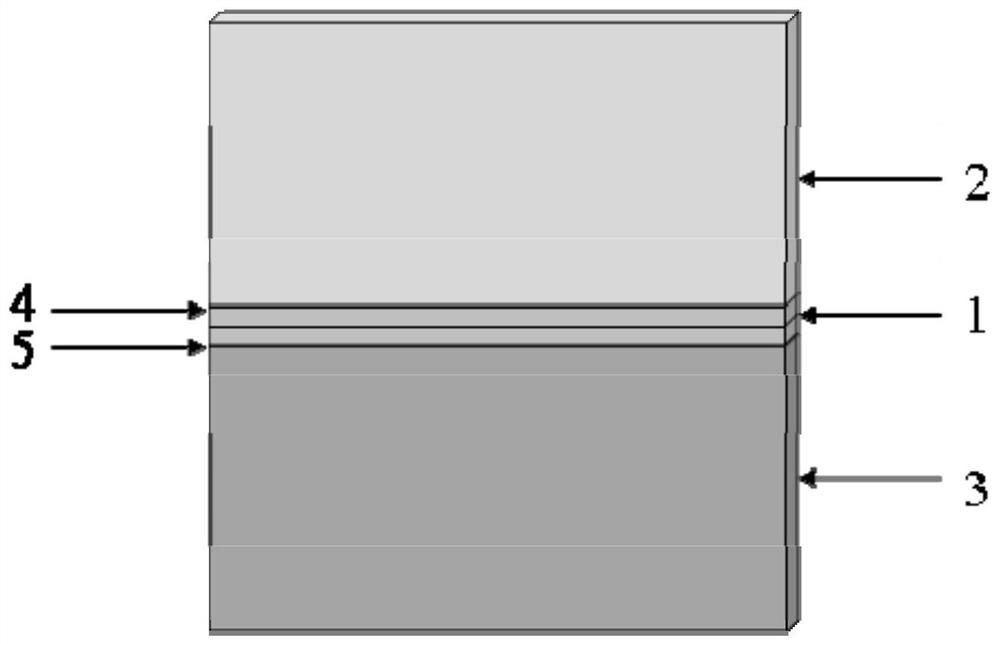

High strength self-lubricating iron-copper powder composite material and preparation method thereof

The invention relates to a high strength self-lubricating iron-copper powder composite material, a preparation method and application thereof. The composite material is characterized by comprising an iron alloy base body and a copper alloy base body as a surface layer, wherein the iron alloy base body contains Cu, C, Sn, Pb and Fe, and the copper alloy base body contains Ni, C, MoS2, Sn, Fe, Pb and Cu. The preparation method comprises the following steps of: respectively preparing copper alloy layer warm-pressing powder and iron alloy base body warm-pressing powder; filling the warm-pressing powder into a mould and then pressing once to form a green compact; sintering the green compact in the protection atmosphere; and shaping the sintered sintering compact in the mould so that the composite material is prepared. By the invention, the cost of parts can be greatly reduced on the basis of ensuring the use performance of the parts.

Owner:合肥波林新材料股份有限公司

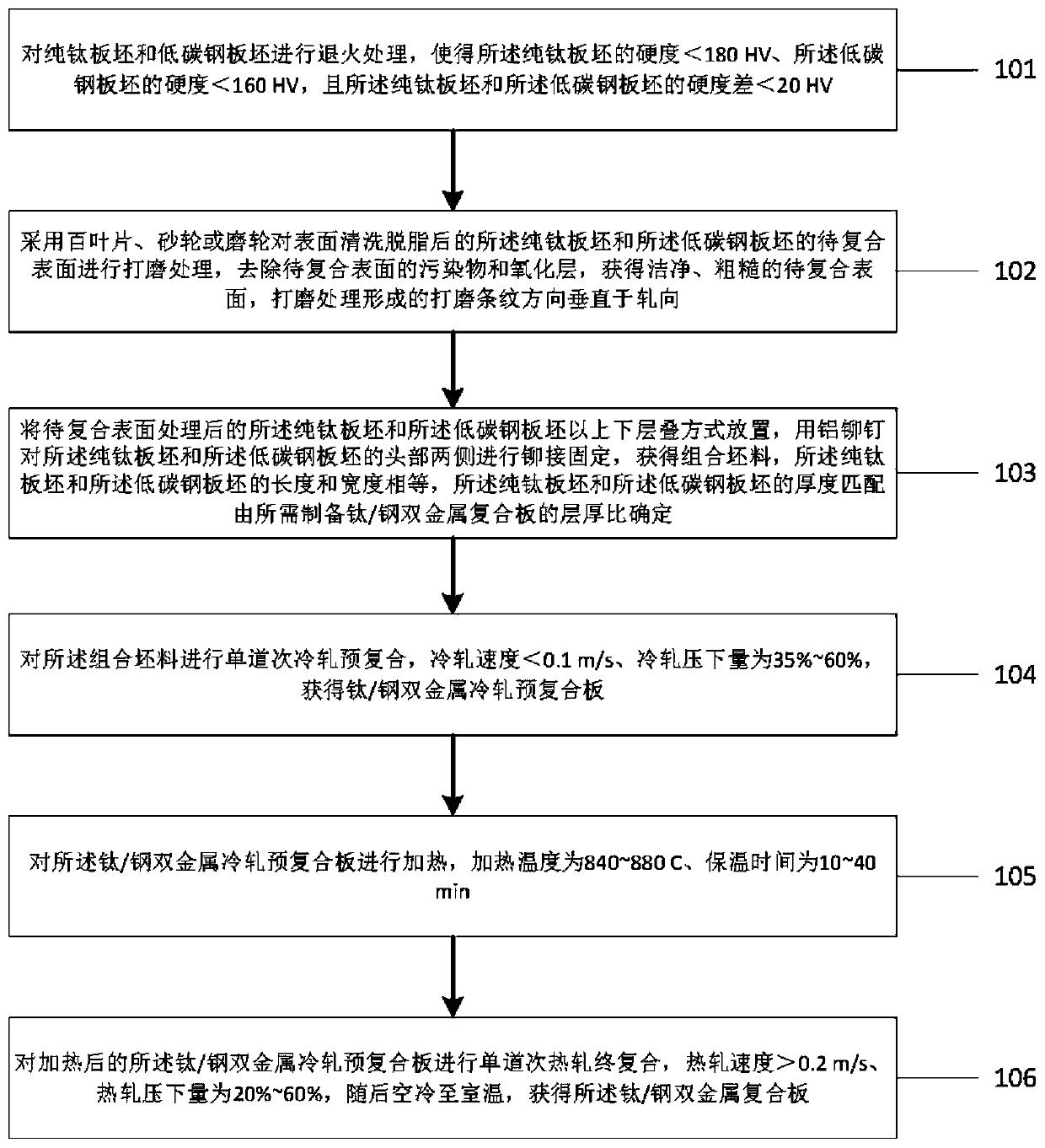

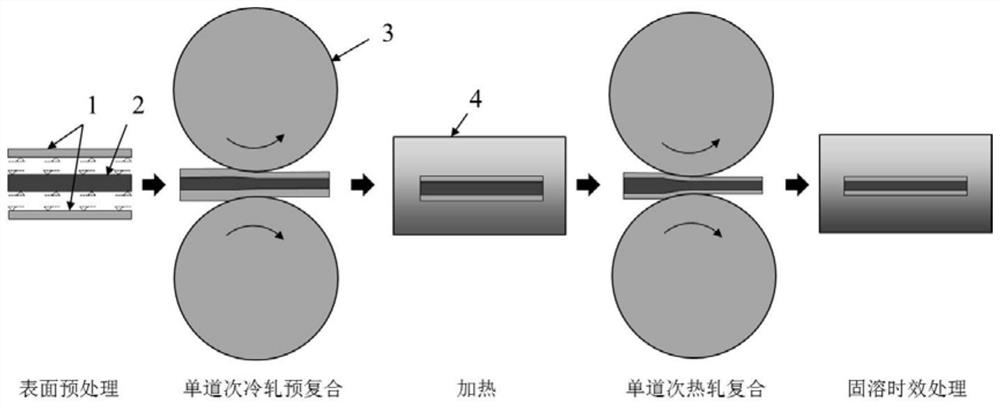

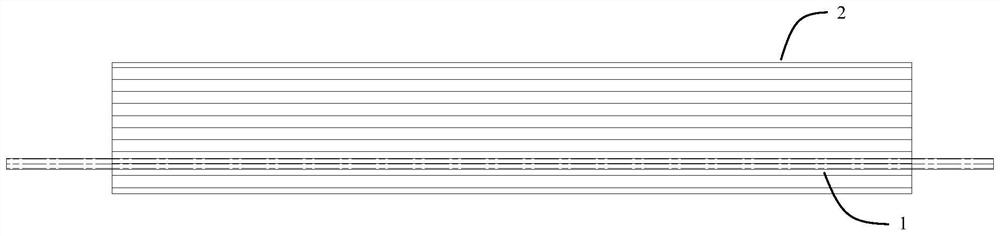

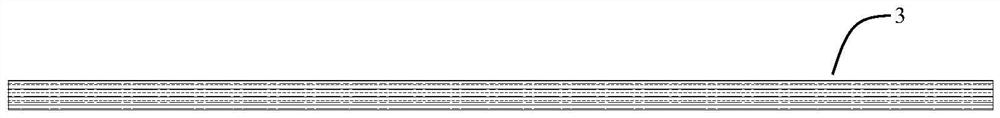

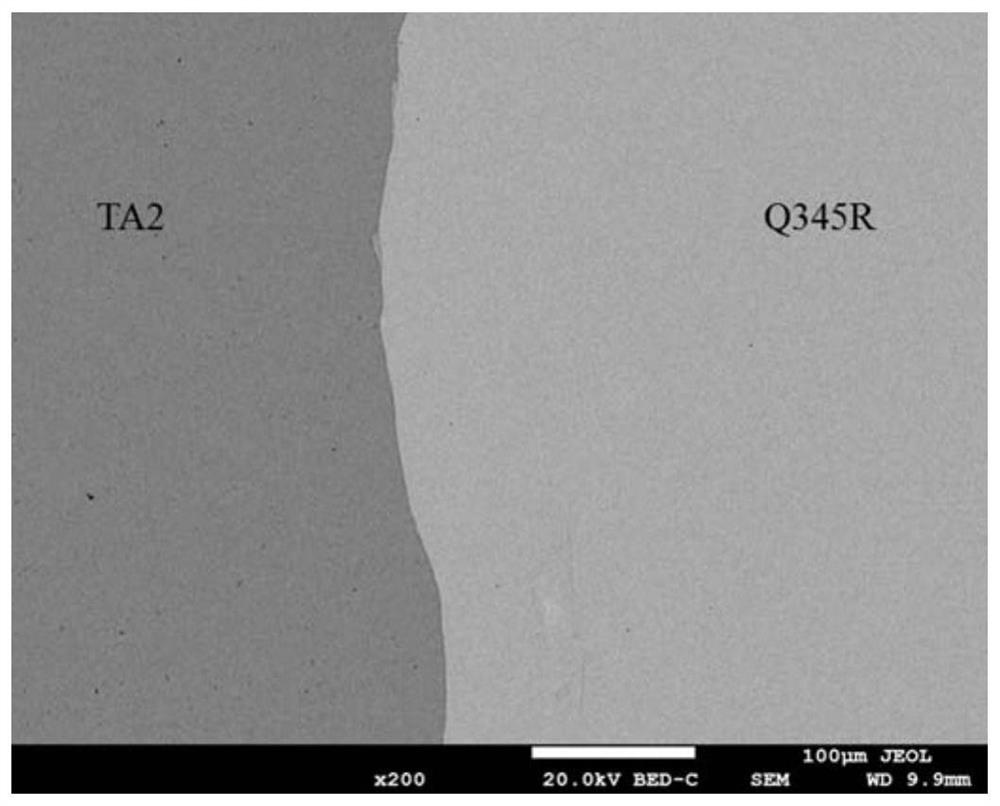

Preparation method of high-performance titanium/steel bimetallic composite plate

ActiveCN110665969AReduce the critical reductionImprove the bonding strength of the interfaceAuxillary arrangementsMetal rolling arrangementsCarbon steelTitanium

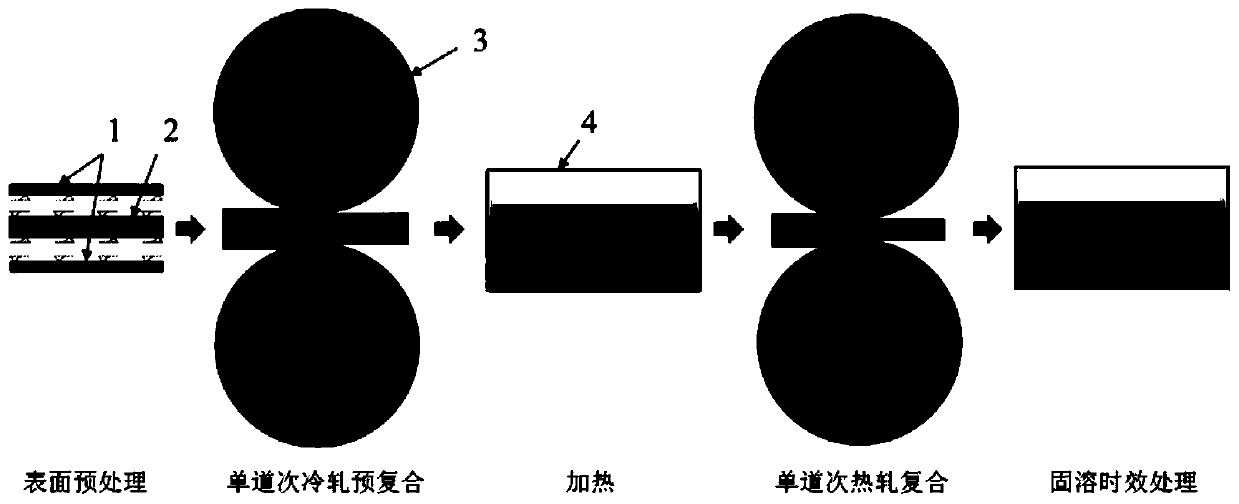

The invention discloses a preparation method of a high-performance titanium / steel bimetallic composite plate, and belongs to the technical field of preparation of bimetallic composite plates. A pure titanium slab and a low-carbon steel slab are subjected to annealing treatment, the hardness of the slabs is reduced, and the hardness of the pure titanium slab and the hardness of the low-carbon steelslab are close; then the to-be-composited surfaces of the slabs are cleaned, degreased and ground, wherein the grinding stripe direction is perpendicular to the rolling direction; then the pure titanium slab and the low-carbon steel slab are stacked to obtain a combined slab, the head of the combined slab is riveted, the combined slab is subjected to single-pass cold rolling pre-compounding, andthen heating is carried out; and finally, single-pass hot rolling final compounding is carried out, and the high-performance titanium / steel bimetallic composite plate is obtained. The method is low inequipment requirement, short in process flow, high in production efficiency and low in production cost. The interface bonding strength of the prepared titanium / steel bimetallic composite plate is larger than 230 MPa, the area bonding rate is 100%, and the method is particularly suitable for preparation of high-performance thin titanium / steel bimetallic composite plates or thin-titanium-layer titanium / steel bimetallic composite plates.

Owner:UNIV OF SCI & TECH BEIJING +1

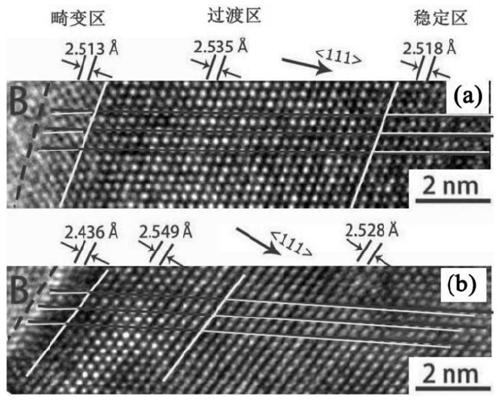

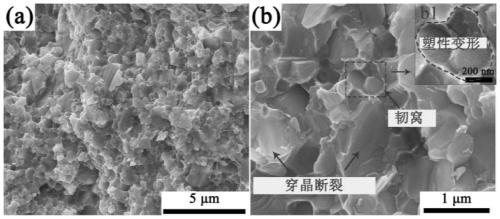

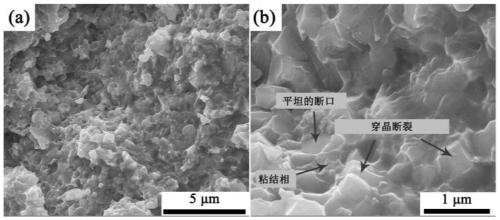

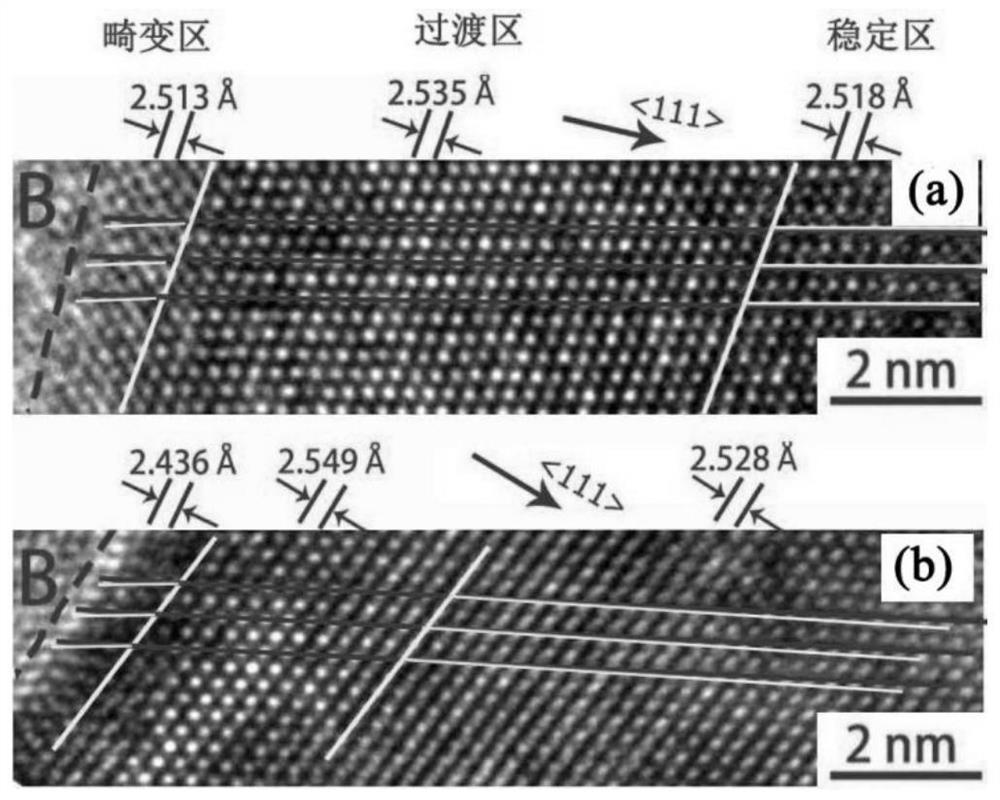

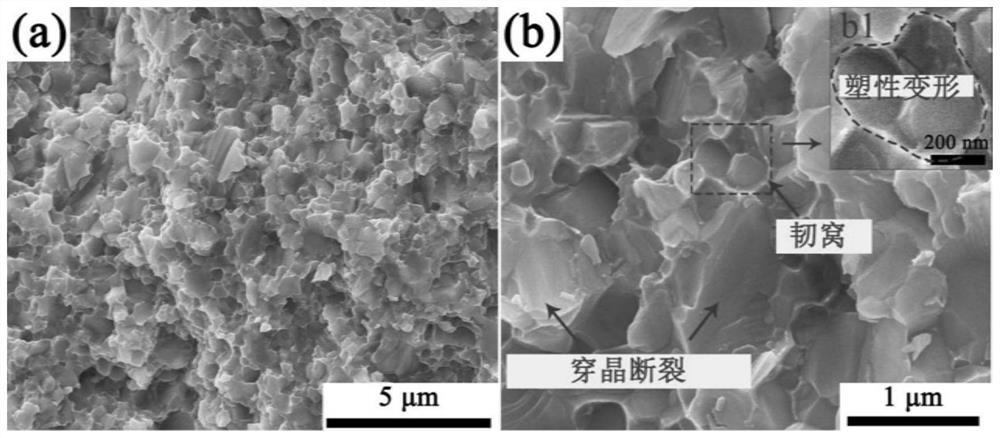

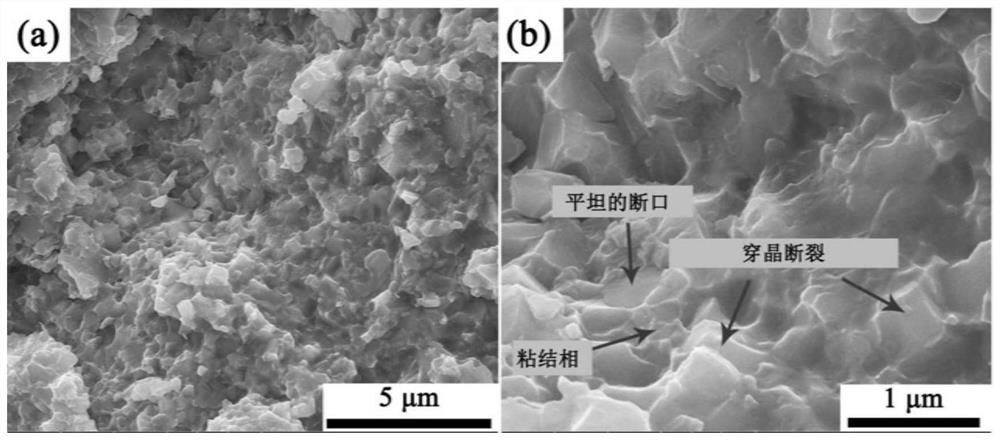

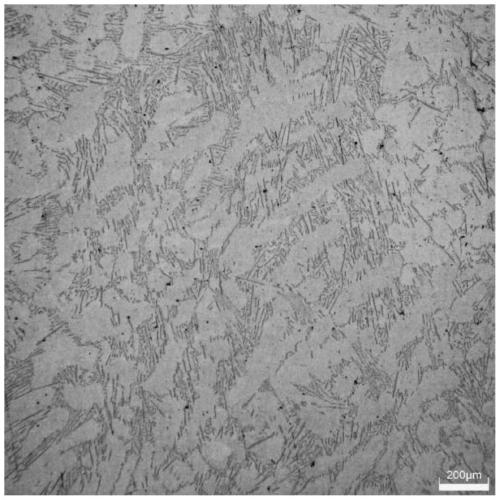

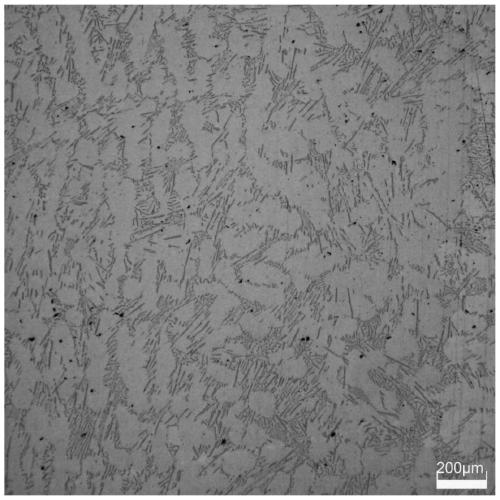

Manufacturing method of high-strength and high-toughness Ti (C, N) based metal ceramic

ActiveCN110358960AReduce defectsInhibit denitrification behaviorTransportation and packagingMetal-working apparatusLattice mismatchVanadium carbide

The invention discloses a manufacturing method of a high-strength and high-toughness Ti (C, N) based metal ceramic. The manufacturing method comprises the steps of firstly, adding vanadium carbide andexcessive carbon into raw materials so as to reduce lattice parameters of a ring phase and carbon rich in a binding phase in the metal ceramic; introducing nitrogen in the solid phase sintering stagefor partial pressure to reduce the nitrogen loss of the Ti (C, N) based metal ceramic; and meanwhile, after the metal ceramic is sintered in a high-temperature liquid phase, cooling the metal ceramicto a freezing point (1,300-1,380 DEG C) and keeping the temperature for extra 1-3 hours so as to make the crystal lattice of the outer ring phase complete and the change of the crystal lattice parameters small. By means of the manufacturing method, the lattice mismatch of the outer ring phase and a metal interface of the Ti (C, N) based metal ceramic is less, and the interface bonding strength ofthe ceramic and the binding phase is higher; and the reduction of the lattice mismatch in the outer ring phase promotes the transformation of the fracture mode from intergranular fracture to transgranular fracture, and dimples are generated in situ near the fracture of the ceramic, and therefore the strength and toughness of the metal ceramic are effectively improved. The manufactured metal ceramic can be widely applied to the fields of bearing materials, cutting tools, die materials and the like.

Owner:CENT SOUTH UNIV

High-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material and manufacture method thereof

ActiveCN110665968AHigh strengthImprove plasticityTemperature control deviceFurnace typesLaminated compositesCorrosion resistant

The invention discloses a high-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material and a manufacture method thereof, and belongs to the technical field of aluminumalloy laminated composite materials. The high-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material is composed of a 1-series or 3-series aluminum alloy multi-layermaterial and a 6-sereis aluminum alloy base layer material. Annealing treatment is conducted on the aluminum alloy multi-layer material and the aluminum alloy base layer material; washing degreasingand polishing treatment are conducted on to-be-composited surfaces, wherein the polishing stripe direction is perpendicular to the rolling direction; then, a combined blank material is obtained through laminating; single-pass cold rolling pre-compositing, heating and single-pass hot rolling compositing are sequentially conducted on the combined blank material subjected to head riveting; and finally, the high-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material with strong alloy combination adopted for the interface is obtained through solid solution-aging treatment. The high-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material and the manufacture method are low in device requirement, simple in process flow, short in period, high in production efficiency, low in energy consumption and low in cost, and the manufactured aluminum alloy laminated composite material has high strength, high plasticity and excellent anti-corrosion performance at the same time.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing concrete preservative

The invention discloses a method for preparing a concrete preservative and belongs to the technical field of building materials. The method includes: performing mixed enzymolysis on vegetable protein,endopeptidase and water and inactivating the enzyme to obtain an enzymatic hydrolysate; heating, stirring and mixing a modified sodium alginate solution, the enzymatic hydrolysate and a calcium nitrate solution to prepare pretreated enzymatic hydrolysate; stirring and mixing the pretreated enzymatic hydrolysate, a modifying additive, activated chitosan, plant essential oil, a preservative component, modified sepiolite and modified fibers to prepare the concrete preservative. The concrete preservative makes concrete to have excellent mechanical property and durability and can reduce the slumploss of the concrete and improve workability of the concrete, so that the concrete preservative has extensive application range.

Owner:常州市玉宇化工有限公司

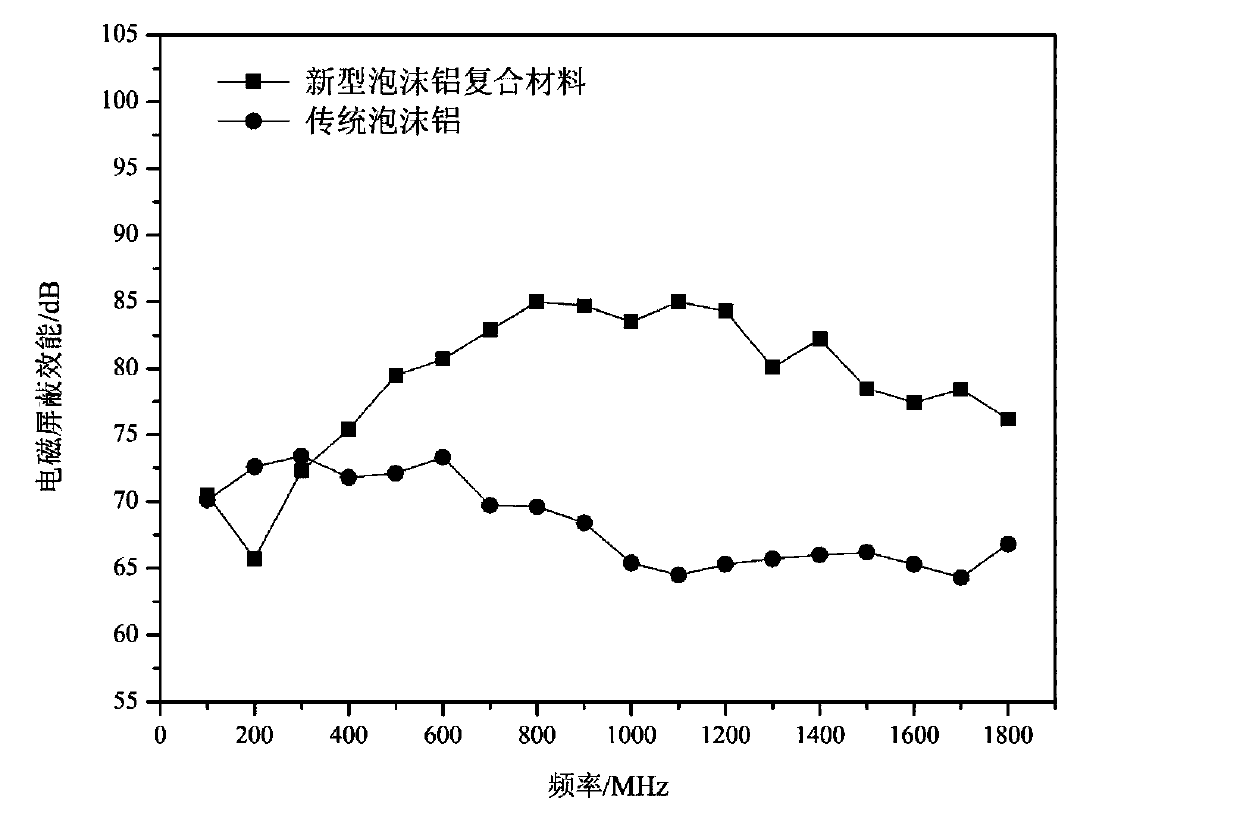

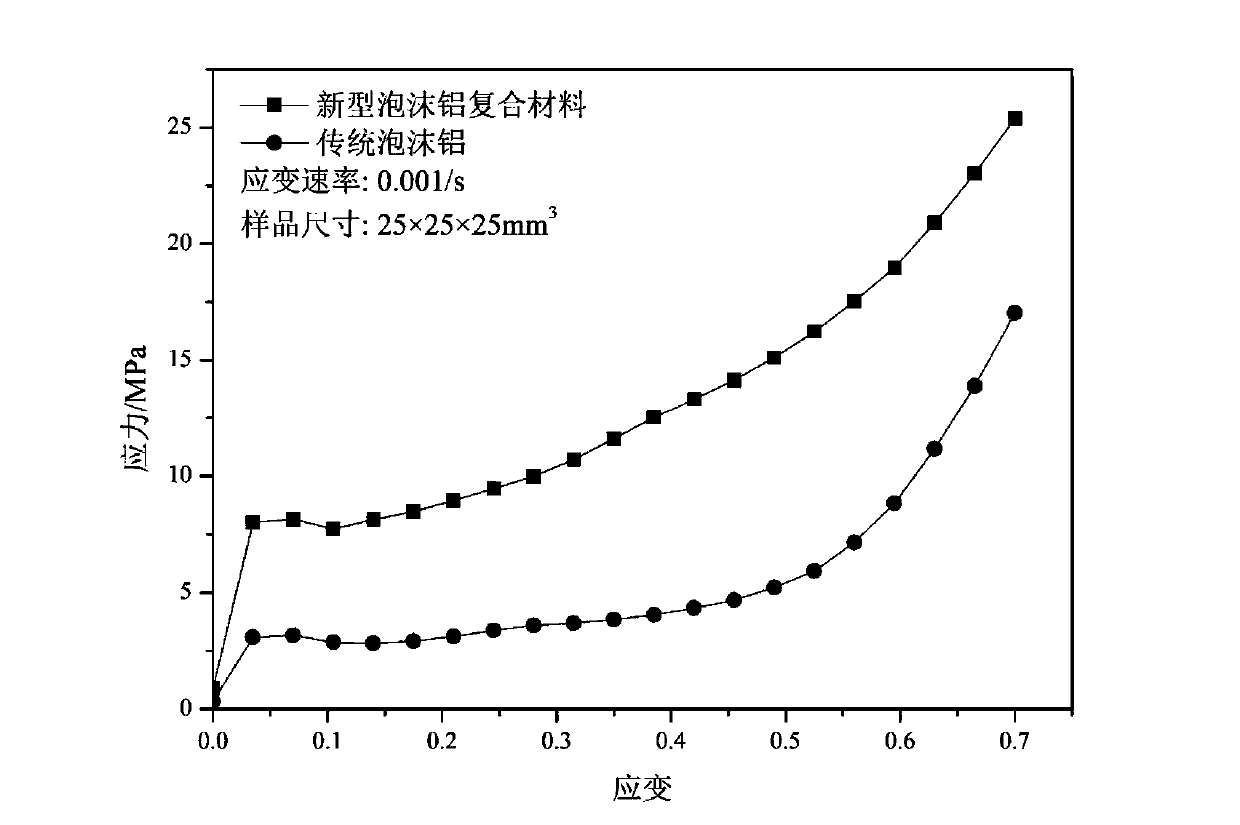

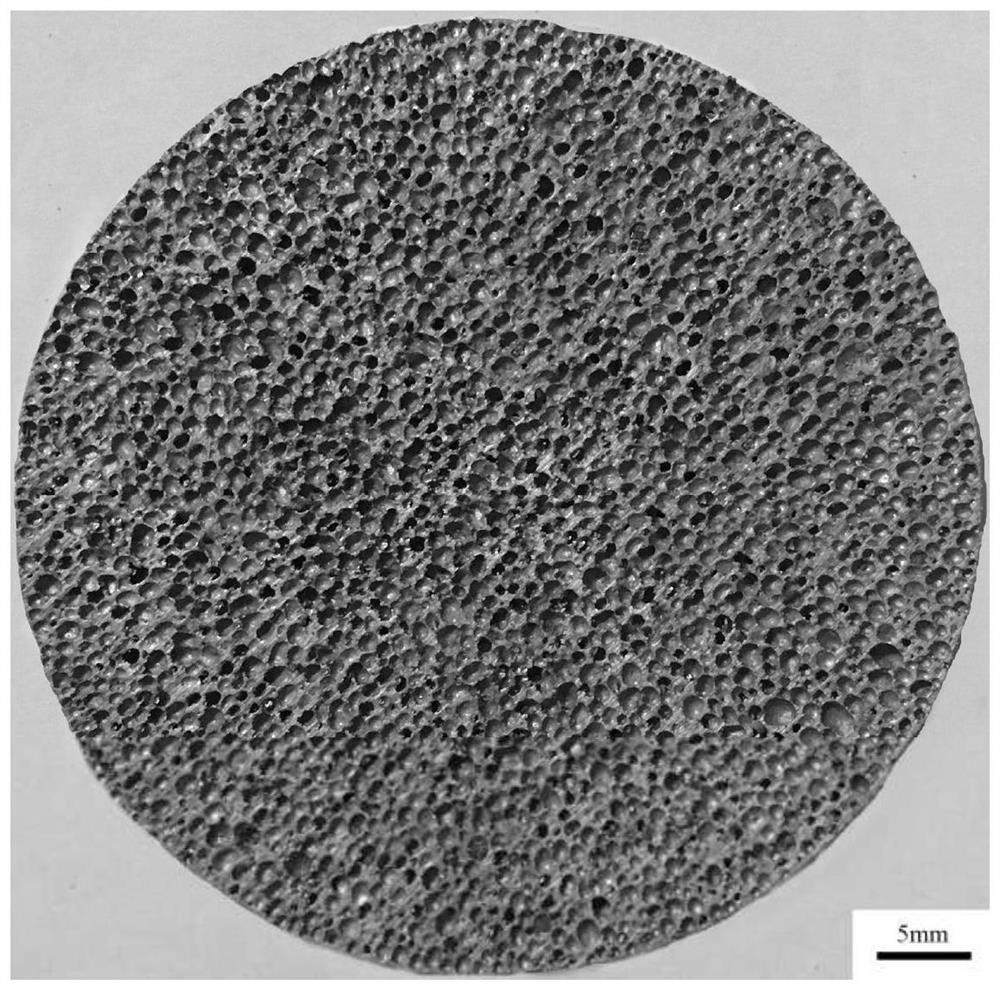

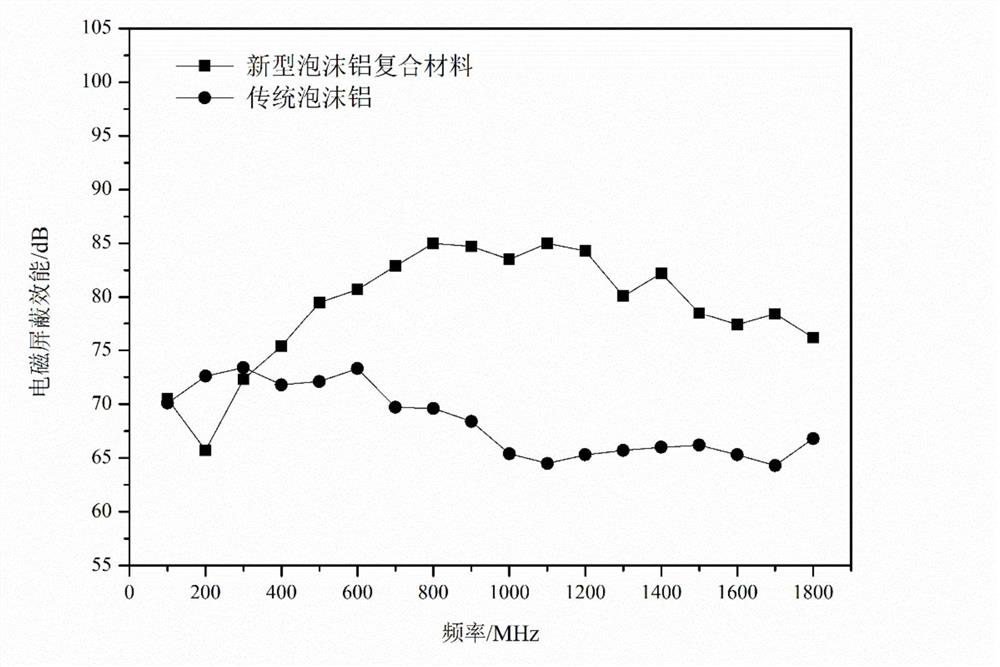

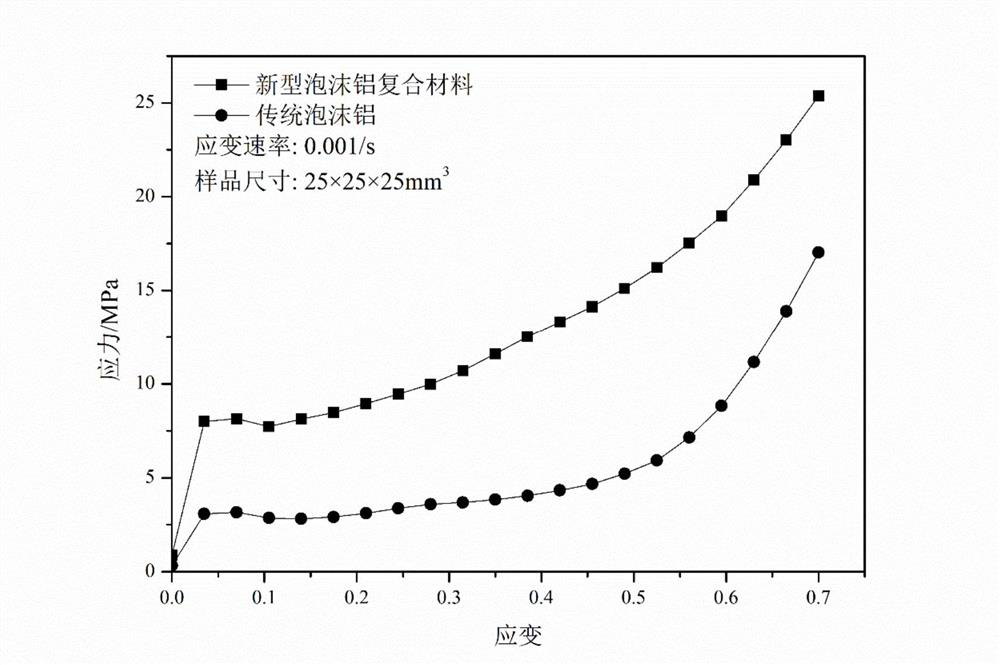

Method for preparing electromagnetic shielding foamed aluminum composite material

ActiveCN109881036AReduce burning lossReduce clumpingTransition element hydridesFoaming agentMicrosphere

The invention discloses a method for preparing an electromagnetic shielding foamed aluminum composite material. The method includes the steps that a magnesium block and a hollow ceramics microsphere are added by stepping composition, then, after a pre-treated titanium hydride foaming agent is added, the surface is provided with a layer of dense oxidation film, thus the mixture can be foamed intensively in a certain temperature range, the effect of aperture decreasing is realized, and finally, a novel closed-cell foamed aluminum composite material is obtained. According to the method for preparing the electromagnetic shielding foamed aluminum composite material, the obtained closed-cell foamed aluminum composite material has the characteristics of being low in cost, small in aperture, highin strength, excellent in electromagnetic shielding performance and the like.

Owner:HEBEI UNIV OF TECH

Sn-Ag-Cu lead-free solder with high interface bonding strength and a preparation method thereof

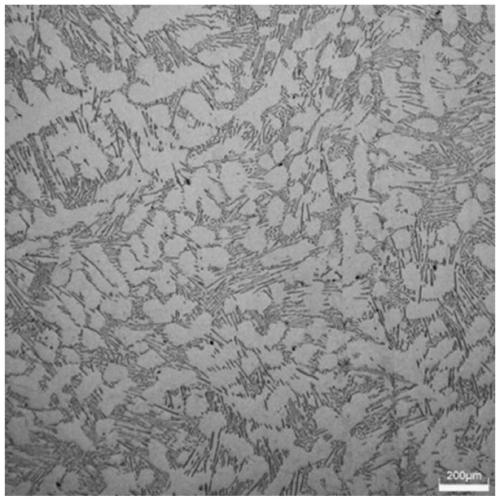

InactiveCN109848606AInhibited DiffusionLow aging resistanceWelding/cutting media/materialsSoldering mediaSurface oxidationMechanical property

The invention discloses improved Sn-Ag-Cu lead-free solder and a preparation method thereof. Zr and Ni are added in Sn-Ag-Cu lead-free solder, the amount of the Zr and the amount of the Ni are controlled, addition of the Ni can further promote the dispersion distribution of the Zr so as to further refine the microstructure of the solder; the surface tension of a molten pool is reduced, a wetting and spreading area is expanded, and the welding wettability and the oxidation resistance of a solder alloy are improved; and formation of the defects such as cavities and bridging in the welding process is inhibited, surface oxidation of welding spots during the long-term use process is prevented, and the welding spots still have excellent electricity and heat conduction performance in long-term use. By means of the synergistic effect of the two elements, the welding wettability as well as the mechanical property, the high-temperature anti-aging performance and the electricity conduction and heat conduction performance of the welding spots are comprehensively improved, and the development requirements of electronic components are met.

Owner:CENT SOUTH UNIV +1

Copper-aluminum composite material and preparation method thereof

ActiveCN111424274AAchieve interlockReduce interfacial internal resistanceMaterial nanotechnologyRoll force/gap control deviceEtchingAluminum composites

The invention provides a copper-aluminum composite material and a preparation method thereof. The copper-aluminum composite material comprises a Cu metal plate and an Al metal plate which are compounded into a whole through cold rolling. Before cold rolling compounding, Cu nano sol particles are evenly sprayed to the surfaces of the metal plates, rich active sites are formed through in-situ etching, a three-dimensional rough structure is constructed on the Cu and / or Al metal surface, and the copper-aluminum composite material is formed. The method comprises the steps that the Cu nano sol particles are synthesized through a sol-gel method; the Cu nano sol particles are evenly sprayed to the surfaces of the Cu and / or Al metal plates, rich active sites are formed through in-situ etching, thethree-dimensional rough structure is constructed on the Cu and / or Al metal surface, and the Cu and / or Al metal plates with the surfaces subjected to in-situ activation etching are obtained; and then the Cu and Al metal plates with the surfaces subjected to in-situ activation etching are subjected to cold rolling compounding solid state connection, and the copper-aluminum composite material is obtained. The copper-aluminum composite material and the preparation method thereof are simple in process, high in production efficiency and low in manufacturing cost.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

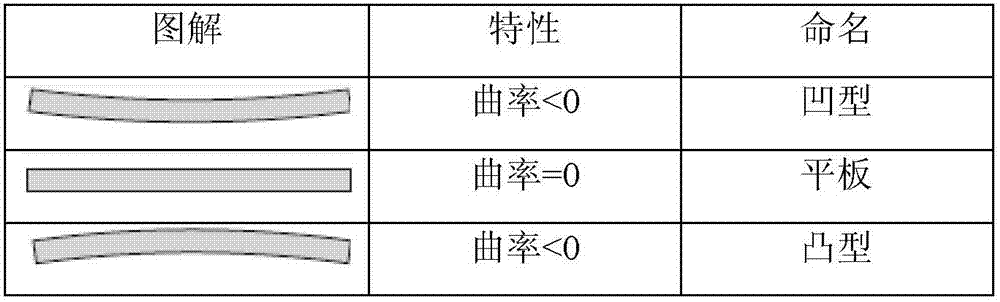

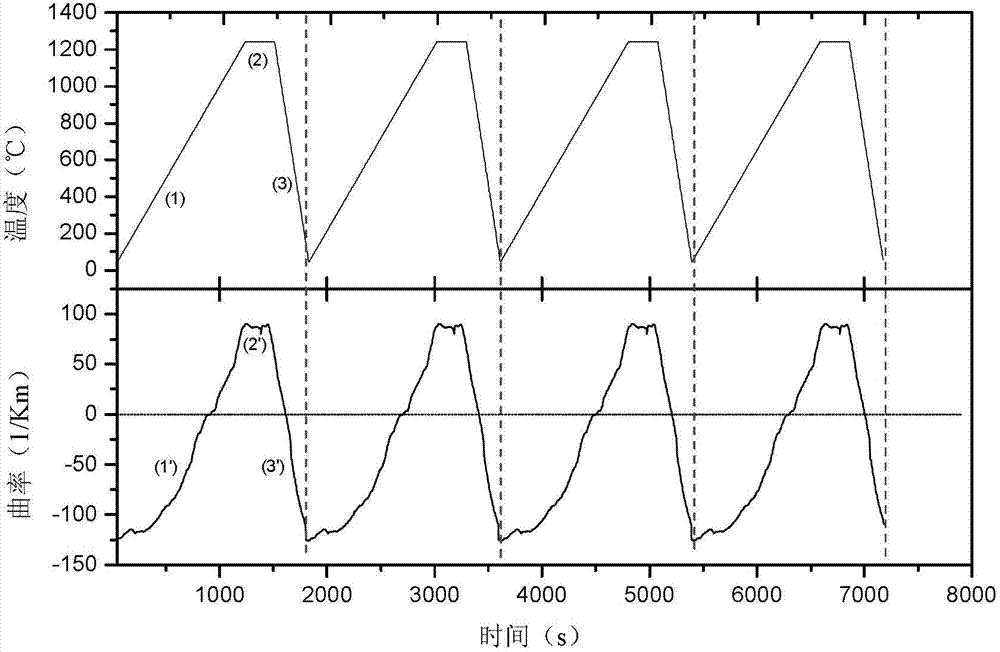

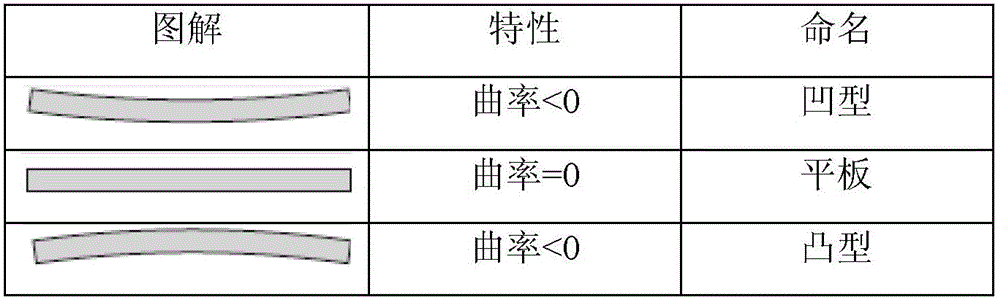

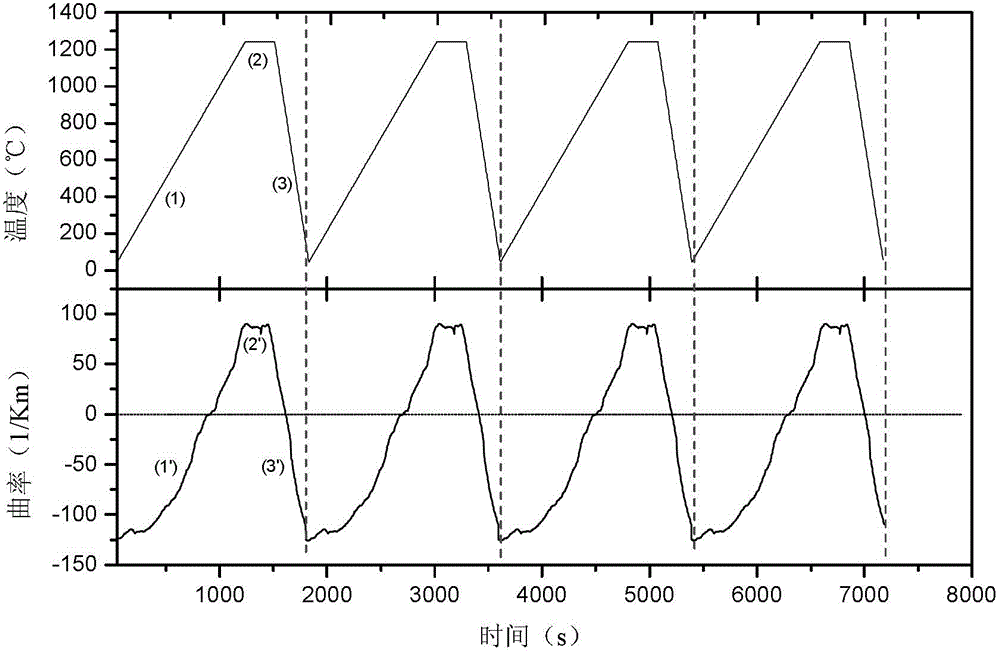

In-situ stress control-based self-separation method for III-nitride thick membrane

InactiveCN102817074AAchieve self-separationReduced interfacial bond strengthPolycrystalline material growthFrom chemically reactive gasesStress concentrationStressed state

The invention discloses an in-situ stress control-based self-separation method for an III-nitride thick membrane. Under a proper annealing condition, the III-nitride thick membrane growing on a substrate is gradually heated, and an on-the-spot stress monitoring system is used for monitoring the stress of the III-nitride thick membrane at the same time; when a stress state shifts to a positive stress state from a negative stress state, the III-nitride thick membrane is maintained at a high temperature for a period of time and then gradually cooled, and the positive stress state is switched to the negative stress state; such a process of heating and cooling is cyclically repeated until the III-nitride thick membrane is separated from the substrate. According to the invention, through adjustment of heat cycle conditions, stress concentration of a thick membrane material at a specific position is realized, the specific position of the thick membrane material is allowed to undergo deformation in the process of continuous switching between positive stress and negative stress, which enables interfacial bonding strength at the specific position to be reduced, and therefore, self-separation of the thick membrane is realized; and the method provided by the invention can be used for separation of a GaN thick membrane, is simple and controllable and has a good application prospect.

Owner:北京燕园中镓半导体工程研发中心有限公司

Metal surface anti-corrosive paint

PendingCN110157297AImprove permeabilityReduced interfacial bond strengthAnti-corrosive paintsEpoxy resin coatingsEpoxyThermal insulation

The invention discloses a metal surface anti-corrosive paint, and belongs to the technical field of building material. A preparation method comprises following steps: rice husk, biogas slurry, cane sugar, and water are mixed for fermentation, a sodium hydroxide solution is added to adjust the pH value, filtering, refrigeration, ball milling, sieving, washing, drying, and nitrogen filling thermal insulation carbonization are carried out so as to obtain a modified filling material; Chinese medical stone is subjected to ball milling and sieving so as to obtain Chinese medical stone powder; the Chinese medical stone powder and a urea solution are mixed, and are subjected to ultrasonic treatment, filtering, and drying so as to obtain pre-treated Chinese medical stone powder; the pre-treated Chinese medical stone powder, carbomer 934, and ethanol are mixed, pressure reduction condensation and drying are carried out so as to obtain a modified additive; epoxy resin, a diluent, a curing agent,the modified filling material, the modified additive, a silane coupling agent, nanometer zinc oxide, phosphatide, ephedrine, polyisocyanate, and a mineral filler are stirred and mixed so as to obtainthe metal surface anti-corrosive paint. The metal surface anti-corrosive paint possesses excellent corrosion resistance.

Owner:陈理抗

Preparation method of composite adhesive for automotive interior material

InactiveCN110079262AIncrease roughnessIncrease elasticityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFiberSucrose

The invention discloses a preparation method of a composite adhesive for an automotive interior material and belongs to the technical field of adhesives. The method comprises the steps as follows: mixing rice husk fiber, biogas slurry, sucrose and water for fermentation, and performing filtration, freezing, ball-milling, drying and carbonization to obtain modified fiber; placing polyether polyol in a reactor, performing heating, vacuum dehydration and cooling, then, adding isocyanate and an accelerator, performing a constant-temperature stirring reaction, next, adding trichloromethane, benzoylchloride, phospholipid, organic acid, plant essential oil, grease and mica powder, and performing stirring, mixing and discharging to obtain the composite adhesive for the automotive interior material. The composite adhesive for the automotive interior material has excellent bonding performance.

Owner:常州明华运输有限公司

A kind of preparation method of electromagnetic shielding aluminum foam composite material

ActiveCN109881036BReduce burning lossReduce clumpingTransition element hydridesFoaming agentMicrosphere

Owner:HEBEI UNIV OF TECH

Composite piston material and preparation method thereof

InactiveCN108342623AImproved high temperature strength and wear resistanceGood high temperature strengthAlloy elementSilica fume

The invention discloses a composite piston material. The composite piston material comprises the following raw materials including, by weight, 6.5-7.5 parts of silicon powder, 0.3-0.5 part of magnesium powder, 0.06-0.10 part of titanium powder, 0.1-0.2 part of yttrium powder, 6-7 parts of silicon carbide powder, 2-3 parts of molybdenum disulfide, 0.2-0.5 part of hafnium powder and 85-100 parts ofaluminum powder. The invention further discloses a preparation method of the composite piston material. The preparation method includes the following steps that (1) the raw materials are weighed; (2)the silicon powder, the magnesium powder, the titanium powder, the yttrium powder, the hafnium powder and the aluminum powder are ball-milled, sieved and mixed; (3) the silicon carbide powder is heated and kept warm to fully react with oxygen, and then silicon dioxide is formed on the surface layer; and (4) a mixed raw material is heated, degassed, kept warm and then cooled, then the molybdenum disulfide and the silicon carbide are added, stirring is performed, and the composite piston material is obtained. According to the composite piston material and the preparation method thereof, alloy elements which have large influences on the high temperature property and the abrasion resistance are added according to a certain proportion to adjust the matching ratio, so that the high temperature strength and the abrasion resistance of the material are improved.

Owner:安徽宝泰汽车部件有限公司

Tungsten-containing composite piston material, and preparation method thereof

The invention discloses a tungsten-containing composite piston material comprising, by weight, 5-6 parts of silicon powder, 0.6-0.9 part of magnesium powder, 0.15-0.35 part of manganese powder, 0.1-0.2 part of tungsten powder, 8-10 parts of silicon carbide powder, 4-5 parts of molybdenum disulfide, 0.6-0.8 parts of hafnium powder and 90-98 parts of aluminum powder. The invention further disclosesa preparation method of the tungsten-containing composite piston material. The preparation method comprises the step (1) of weighing raw materials; the step (2) of ball-milling, sieving and mixing thesilicon powder, the magnesium disulfide, the manganese powder, the tungsten powder, the hafnium powder and the aluminum powder; the step (3) of heating the silicon carbide powder and holding the temperature, and forming silicon dioxide on the surface layer after the silicon carbide powder reacts with oxygen fully; the step (4) of heating and degassing the mixed materials, holding the temperatureand cooling the mixed materials again, then adding the molybdenum disulfide and the silicon carbide to the mixed materials, and stirring the mixtures so that the tungsten-containing composite piston material is obtained. According to the tungsten-containing composite piston material and the preparation method thereof, by adding alloy elements with great influence on high-temperature performance and wear resistance proportionally and adjusting the proportion, the high-temperature strength and wear resistance of the materials are improved.

Owner:安徽宝泰汽车部件有限公司

Composite piston material containing nickel and preparation method thereof

InactiveCN108359854AImprove thermal conductivityHigh temperature strengthMachines/enginesPistonsOxygenSilicon dioxide

The invention discloses a composite piston material containing nickel which is prepared from the following raw materials in parts by weight: 4.5-5.5 parts of silicone powder, 0.4-0.48 part of magnesium powder, 0.02-0.05 part of titanium powder, 0.1-0.2 part of nickel powder, 5-6 parts of silicon carbide powder, 2.2-2.8 parts of molybdenum disulfide, 0.3-0.6 part of thulium powder and 90-95 parts of aluminum powder. The invention also discloses a preparation method of the composite piston material containing nickel. The preparation method comprises the following steps: (1) weighing raw materials; (2) ball-milling, screening and mixing the silicone powder, the magnesium powder, the titanium powder, the nickel powder, the thulium powder and the aluminum powder; (3) heating and insulating thesilicon carbide powder, and carrying out a reaction with oxygen fully to form silicon dioxide in the surface layer; and (4) heating, degassing, insualting and cooling the mixed raw materials, then adding molybdenum disulfide and silicon carbide, and stirring the mixture. By adding alloy elements which are relatively large in influence on high-temperature performance and wear resistance in a certain proportion to adjust the proportion, the high-temperature strength and wear resistance of the material are improved.

Owner:安徽宝泰汽车部件有限公司

Lanthanum-containing composite piston material, and preparation method thereof

The invention discloses a lanthanum-containing composite piston material comprising, by weight, 10-13 parts of silicon powder, 1-2 parts of magnesium powder, 0.1-0.2 part of lanthanum powder, 5.2-5.8parts of silicon carbide powder, 1.2-1.8 parts of molybdenum disulfide, 0.15-0.18 part of hafnium powder and 74-84 parts of aluminum powder. The invention further discloses a preparation method of thelanthanum-containing composite piston material. The preparation method comprises the step (1) of weighing raw materials; the step (2) of ball-milling, sieving and mixing the silicon powder, the magnesium disulfide, the lanthanum powder, the hafnium powder and the aluminum powder; the step (3) of heating the silicon carbide powder and holding the temperature, and forming silicon dioxide on the surface layer after the silicon carbide powder reacts with oxygen fully; and the step (4) of heating and degassing the mixed materials, holding the temperature and cooling the mixed materials again, thenadding the molybdenum disulfide and the silicon carbide to the mixed materials, and stirring the mixtures so that the lanthanum-containing composite piston material is obtained. According to the lanthanum-containing composite piston material and the preparation method thereof, by adding alloy elements with great influence on high-temperature performance and wear resistance proportionally and adjusting the proportion, the high-temperature strength and wear resistance of the materials are improved.

Owner:安徽宝泰汽车部件有限公司

A kind of high-strength, high-plasticity and corrosion-resistant aluminum alloy layered composite material and preparation method thereof

ActiveCN110665968BHigh strengthImprove plasticityTemperature control deviceFurnace typesCorrosion resistantPlastic property

The invention discloses a high-strength, high-plasticity, corrosion-resistant aluminum alloy layered composite material and a preparation method thereof, belonging to the technical field of aluminum alloy layered composite materials. The high-strength, high-plasticity and corrosion-resistant aluminum alloy layered composite material is composed of a 1-series or 3-series aluminum alloy cladding material and a 6-series aluminum alloy base material. Anneal the aluminum alloy cladding material and the aluminum alloy base material, clean, degrease and polish the surface to be composited. The direction of the grinding stripes is perpendicular to the rolling direction. A high-strength, high-plasticity, corrosion-resistant aluminum alloy layered composite material with a strong metallurgical interface is obtained by cold-rolling pre-compositing, heating, single-pass hot-rolling and compounding, and finally solution-aging treatment. The invention has low equipment requirements, simple process flow, short cycle, high production efficiency, low energy consumption and low cost, and the prepared aluminum alloy layered composite material has high strength, high plasticity and excellent corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

A kind of preparation method of high-strength and high-toughness Ti(c,n)-based cermet

ActiveCN110358960BReduce defectsInhibit denitrification behaviorTransportation and packagingMetal-working apparatusLattice mismatchUltimate tensile strength

The invention discloses a method for preparing a high-strength and high-toughness Ti(C,N)-based cermet. Firstly, by adding vanadium carbide and excess carbon to the raw material, the lattice parameter of the ring phase can be reduced and the bonding in the cermet can be reduced. In addition, nitrogen partial pressure needs to be introduced in the solid phase sintering stage to reduce the nitrogen loss of Ti(C,N)-based cermet. ) for an additional 1 to 3 hours of heat preservation, so that the lattice of the outer ring phase is complete and the lattice parameters change little. Therefore, the crystal lattice mismatch degree at the interface between the outer ring phase and the metal of the Ti(C,N)-based cermet prepared by the present invention is low, and the interface bonding strength between the ceramic and the bonding phase is high. The reduction of the lattice mismatch degree in the outer ring phase promotes the transformation of the ceramic fracture mode from intergranular fracture to transgranular fracture, and in-situ dimples near the fracture of the ceramic can effectively improve the strength and toughness of the cermet. The cermet can be widely used in the fields of bearing materials, cutting tools, mold materials and the like.

Owner:CENT SOUTH UNIV

Self-separation method of III-nitride thick film based on in-situ stress control

InactiveCN102817074BAchieve self-separationReduced interfacial bond strengthPolycrystalline material growthFrom chemically reactive gasesStress concentrationStressed state

The invention discloses an in-situ stress control-based self-separation method for an III-nitride thick membrane. Under a proper annealing condition, the III-nitride thick membrane growing on a substrate is gradually heated, and an on-the-spot stress monitoring system is used for monitoring the stress of the III-nitride thick membrane at the same time; when a stress state shifts to a positive stress state from a negative stress state, the III-nitride thick membrane is maintained at a high temperature for a period of time and then gradually cooled, and the positive stress state is switched to the negative stress state; such a process of heating and cooling is cyclically repeated until the III-nitride thick membrane is separated from the substrate. According to the invention, through adjustment of heat cycle conditions, stress concentration of a thick membrane material at a specific position is realized, the specific position of the thick membrane material is allowed to undergo deformation in the process of continuous switching between positive stress and negative stress, which enables interfacial bonding strength at the specific position to be reduced, and therefore, self-separation of the thick membrane is realized; and the method provided by the invention can be used for separation of a GaN thick membrane, is simple and controllable and has a good application prospect.

Owner:北京燕园中镓半导体工程研发中心有限公司

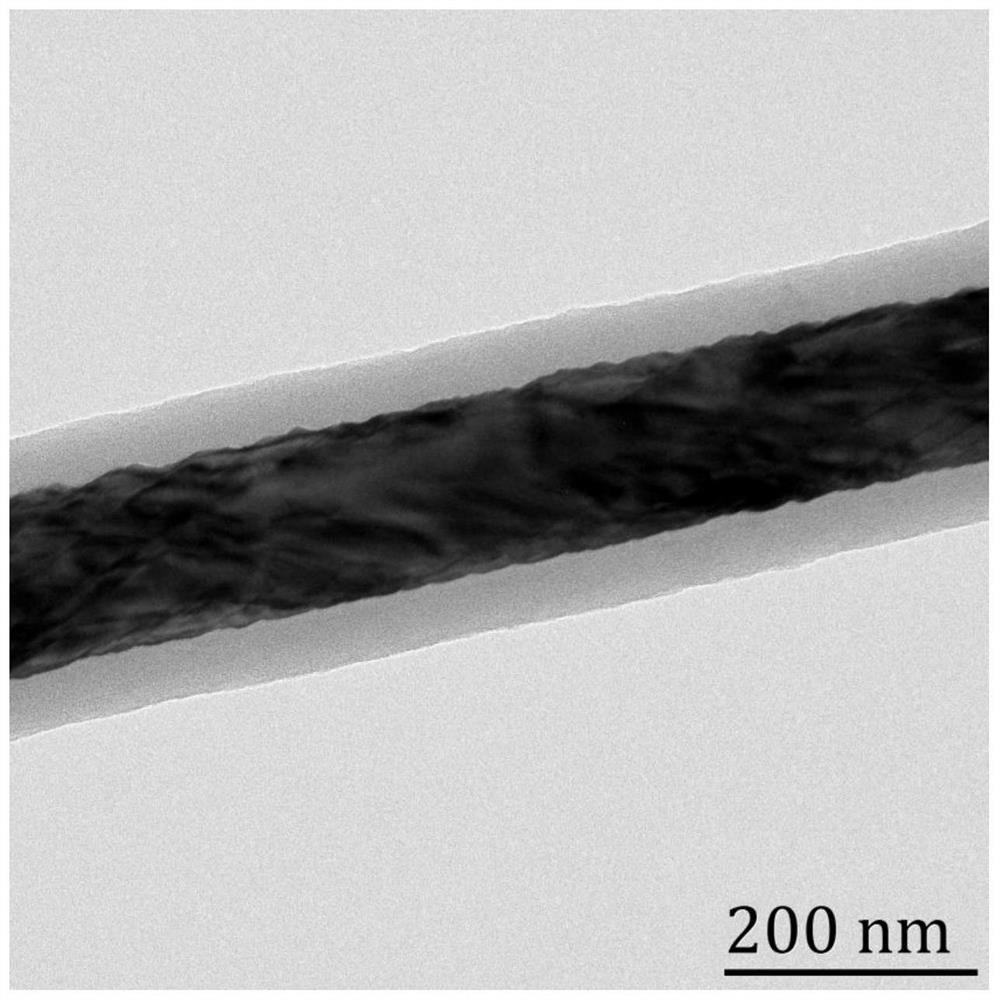

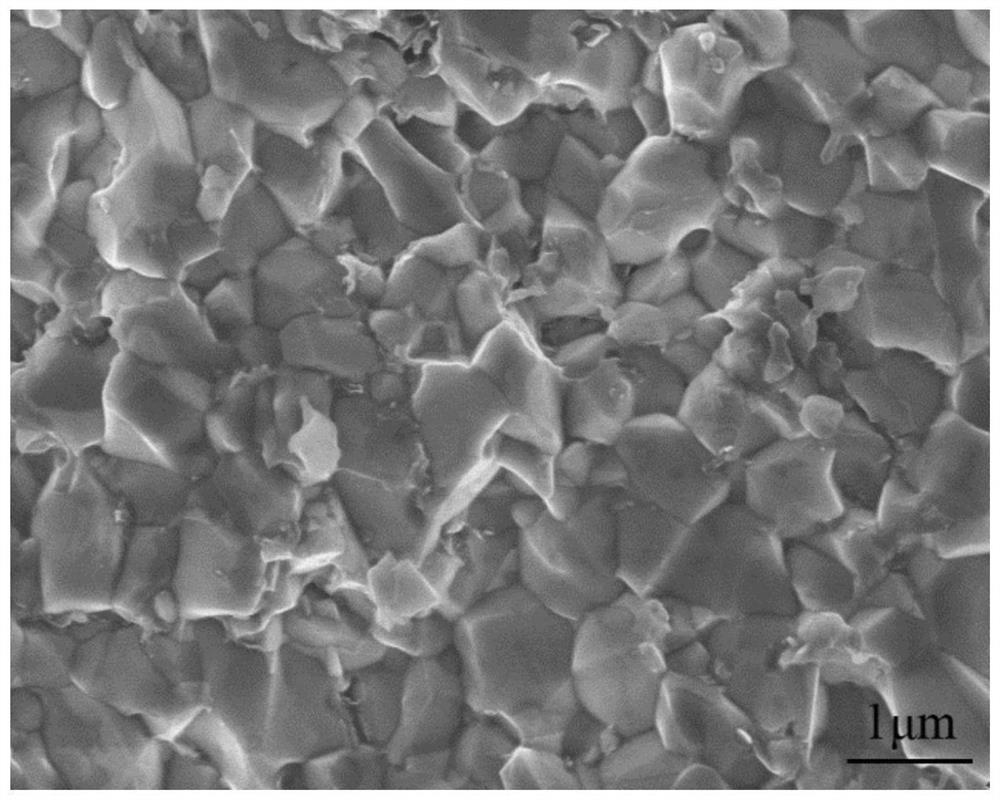

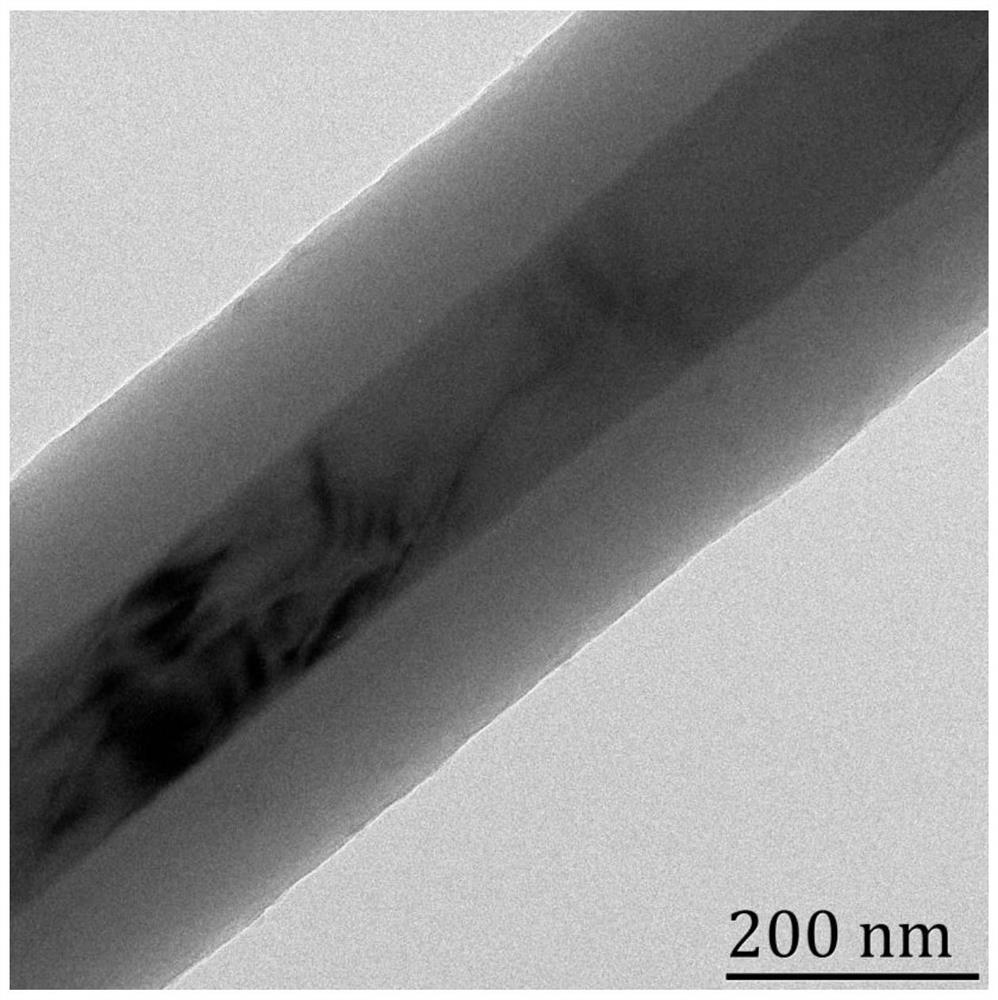

A preparation method of silicon carbide nanowire reinforced silicon carbide ceramic composite material with high strength and high toughness

The invention relates to a method for preparing a high-strength and high-toughness silicon carbide nanowire-reinforced silicon carbide ceramic composite material, comprising: preparing silicon carbide nanowires modified by a silane coupling agent, and preparing silicon carbide nanowires coated with a phenolic resin coating , Preparation of carbon-coated silicon carbide nanowires, preparation of silicon carbide nanowire-reinforced silicon carbide ceramic composites. This method ensures the effective transfer of load between the silicon carbide ceramic matrix and the nanowire reinforcement, and the carbon coating on the surface of the silicon carbide nanowire can effectively protect the inner silicon carbide nanowire from reacting with the matrix during high-temperature sintering. destroy.

Owner:DONGHUA UNIV

Preparation method for aerogel composite material

The invention provides a preparation method for an aerogel composite material. The aerogel composite material is composed of an aerogel and a resin phase which is used for bonding the aerogel. The preparation method comprises the following steps: (1) mixing: uniformly mixing the aerogel with resin powder; (2) spreading: spreading a layer of a mixture obtained in the step (1) on the substrate of amold; (3) melting: rapidly heating the resin powder in the mixture obtained in the step (2) by using a laser in a step scan manner until the resin powder is molten; (4) alternate spreading and melting: alternately repeating the step (2) and the step (3) on a former deposition layer; and (5) curing. The aerogel composite material disclosed by the invention has good heat insulation performance, light transmittance, safety performance, sound insulation performance and noise reduction performance, and is applicable to the field of doors and windows, curtain wall glass, lighting roofs and the likeof green buildings, ultralow-energy-consumption buildings and near-zero-energy-consumption buildings and to the fields of artistic glass and the like.

Owner:CHANGSHA XINGNA AEROGEL

Badminton racket middle tube manufacturing process and badminton racket middle tube

The invention provides a badminton racket middle tube manufacturing process and a badminton racket middle tube. The badminton racket middle tube manufacturing process comprises the following steps: S1, selecting high-toughness fibers, cutting the fibers to a proper fiber length, twisting the fibers into a round rod core, soaking the round rod core in a thermosetting resin diluent, taking out the round rod core after soaking, airing the round rod core, and hardening the resin; s2, the hardened round rod core is ground to be in a true circle, and a middle tube core part is manufactured; s3, coating the core part of the middle tube with epoxy resin, and airing; s4, cutting a plurality of pieces of epoxy resin-based carbon fiber reinforced prepreg, and laying according to different angles; s5, paving the prepreg and rolling the core part of the middle pipe to obtain a middle pipe preform; s6, uniformly winding an OPP belt on the middle pipe preform, and baking to harden the middle pipe preform into a middle pipe rough blank; and S7, redundant materials of the middle pipe rough blank are cut and ground to be in a true circle, and the middle pipe is manufactured. The method has the advantages that industrial processing is facilitated, and the performance of products in each batch is uniform; the rigidity, impact resistance and bending strength of the whole middle tube can be improved, and the phenomenon that the racket head flies out due to brittle fracture of the middle tube of the racket is avoided.

Owner:LI NING CHINA SPORTS GOODS

Strontium-containing composite piston material and preparation method thereof

InactiveCN108277402AHigh temperature tensile strengthImprove thermal conductivityOxygenSilicon dioxide

The invention discloses a strontium-containing composite piston material. The strontium-containing composite piston material comprises, by weight part, 11-15 parts of silicon powder, 0.5-0.8 part of magnesium powder, 0.05-0.09 part of titanium powder, 0.2-0.7 part of strontium powder, 8-12 parts of silicon carbide powder, 5-7 parts of molybdenum disulfide, 0.3-0.6 part of hafnium powder and 75-85parts of aluminum powder. The invention further discloses a preparation method of the strontium-containing composite piston material. The preparation method comprises the steps of 1, weighing raw materials; 2, conducting ball milling, sieving and mixing on the silicon powder, the magnesium powder, the titanium powder, the strontium powder, the hafnium powder and the aluminum powder; 3, conductingheating and heat preservation on the silicon carbide powder, and making the silicon carbide powder react with oxygen completely, so that silicon dioxide is formed on a surface layer; and 4, conductingheating, degassing and heat preservation on the mixed raw materials, then lowering the temperature, subsequently adding the molybdenum disulfide and silicon carbide, and conducting stirring. According to the strontium-containing composite piston material and the preparation method thereof, alloy elements which produce great influence on the high temperature performance and the wear resistance areadded according to certain ratios, and the mixing ratios are adjusted, so that the high temperature strength and wear resistance of the material are improved.

Owner:安徽宝泰汽车部件有限公司

A kind of sn-ag-cu lead-free solder with high interfacial bonding strength and preparation method thereof

InactiveCN109848606BInhibited DiffusionLow aging resistanceWelding/cutting media/materialsSoldering mediaSurface oxidationOxidation resistant

The invention discloses improved Sn-Ag-Cu lead-free solder and a preparation method thereof. Zr and Ni are added in Sn-Ag-Cu lead-free solder, the amount of the Zr and the amount of the Ni are controlled, addition of the Ni can further promote the dispersion distribution of the Zr so as to further refine the microstructure of the solder; the surface tension of a molten pool is reduced, a wetting and spreading area is expanded, and the welding wettability and the oxidation resistance of a solder alloy are improved; and formation of the defects such as cavities and bridging in the welding process is inhibited, surface oxidation of welding spots during the long-term use process is prevented, and the welding spots still have excellent electricity and heat conduction performance in long-term use. By means of the synergistic effect of the two elements, the welding wettability as well as the mechanical property, the high-temperature anti-aging performance and the electricity conduction and heat conduction performance of the welding spots are comprehensively improved, and the development requirements of electronic components are met.

Owner:CENT SOUTH UNIV +1

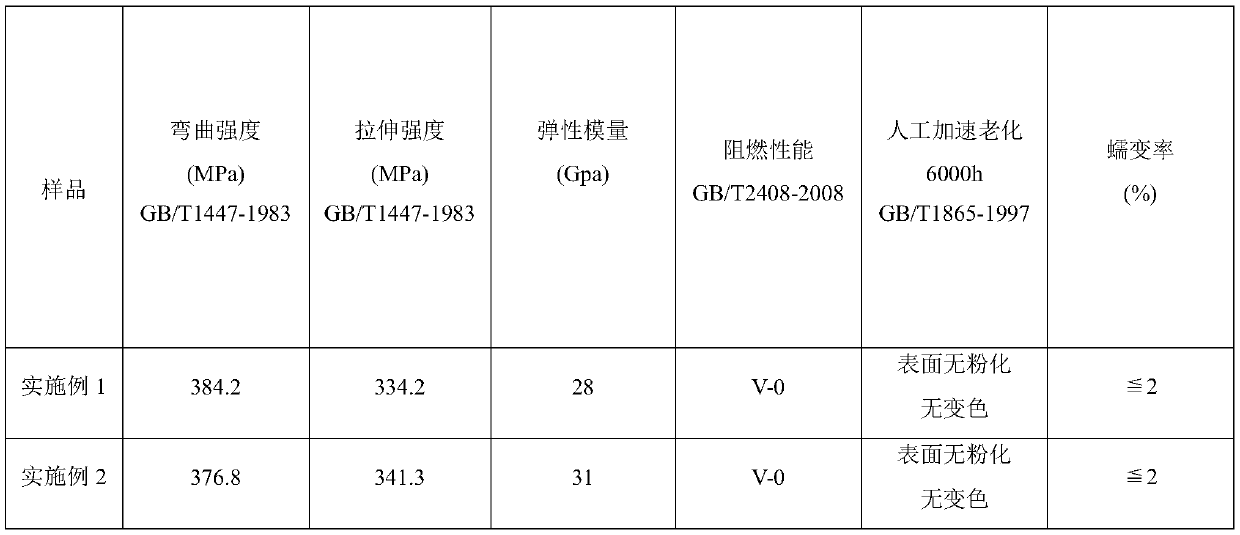

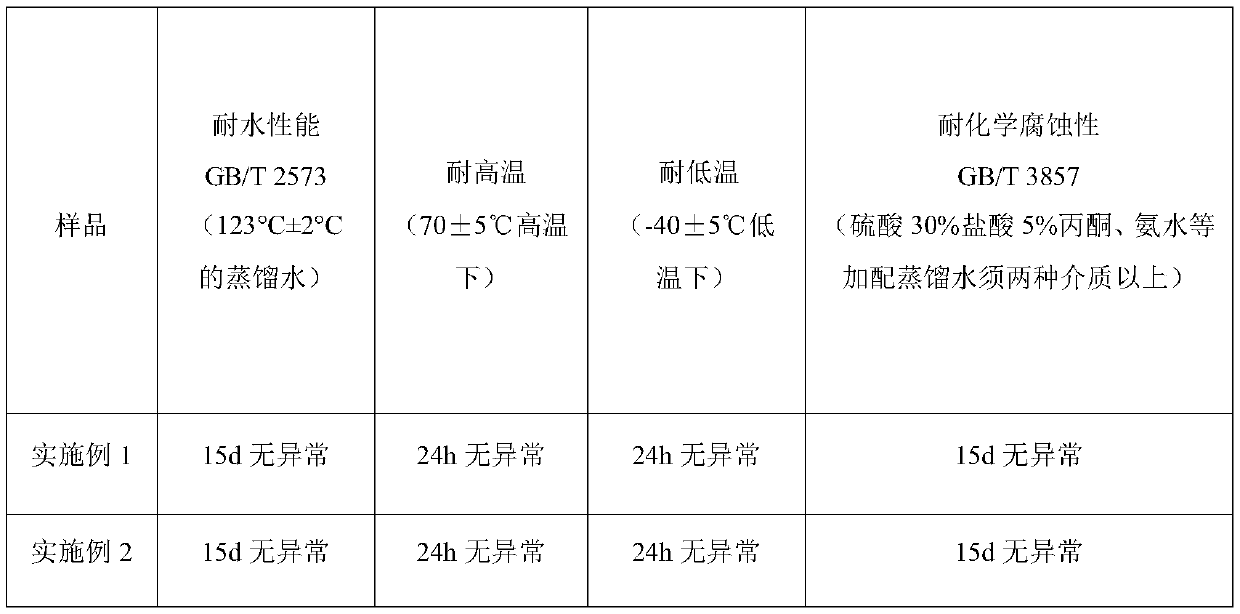

Molded glass fiber-reinforced plastic cable bridge

InactiveCN110066490AImprove hydrophobicityImprove corrosion resistanceElectrical apparatusChemical industryResin matrixNitrogen gas

The invention discloses a molded glass fiber-reinforced plastic cable bridge. The molded glass fiber-reinforced plastic cable bridge is prepared from, by weight, 50-75 parts of ABS resin, 35-55 partsof modified glass fiber complex liquid, 4-7 parts of rectorite, 3-6 parts of magnesium oxide, 3-5 parts of a curing agent, 6-12 parts of a flame retardant, 5-8 parts of an accelerating agent and 1-3 parts of an antistatic agent, wherein the preparation method of the modified glass fiber complex liquid comprises the steps of preparation of a modifying agent, preparation of a modifying agent hydrolysate and preparation of the modified glass fiber complex liquid. The preparation method comprises the specific steps that 20-50 parts of glass fibers are subjected to heat treatment, wherein accordingto the heat treatment conditions, the glass fibers are fired for 20-30 minutes at the temperature of 600 DEG C in the nitrogen atmosphere, absorbed water and impurities on the surface of the glass fibers are removed, 30-50 parts of the modifying agent hydrolysate and 8-15 parts of polyether urethane are added immediately, and evenly mixed in a high-speed mixing machine, and the modified glass fiber complex liquid is obtained. The modified glass fibers are bonded to the surface of an ABS resin matrix, low critical surface tension is obtained, and due to the low critical surface tension, the glass fiber-reinforced plastic cable bridge is high in hydrophobicity and obviously higher in corrosion resistance.

Owner:江苏隆鑫电气设备有限公司

A kind of highly polar polyolefin material and preparation method thereof

ActiveCN109517268BLower surface energy percolation thresholdImprove wettabilityPolymer sciencePolyolefin

The invention discloses a highly polar polyolefin material and a preparation method thereof, belonging to the technical field of materials. The material of the present invention comprises the following components in parts by weight: 70-90 parts of polyolefin, 6-20 parts of filler, 1-15 parts of polar additive, 2-10 parts of compatibilizer, and 0.5-2 parts of nano-synergist part, other additives 0.5‑2 part. And discloses the preparation method. The material of the invention has the characteristics of excellent processing fluidity, good mechanical properties, high dimensional stability, short molding cycle, good appearance of the product, and can also meet the requirements of more lightweight and thin-walled design for injection molding and other products, reducing the material cost of the product. and manufacturing cost; at the same time, the material preparation method of the present invention is easy to operate, high in production efficiency, and easy to realize industrialization.

Owner:NANJING JULONG SCI&TECH CO LTD

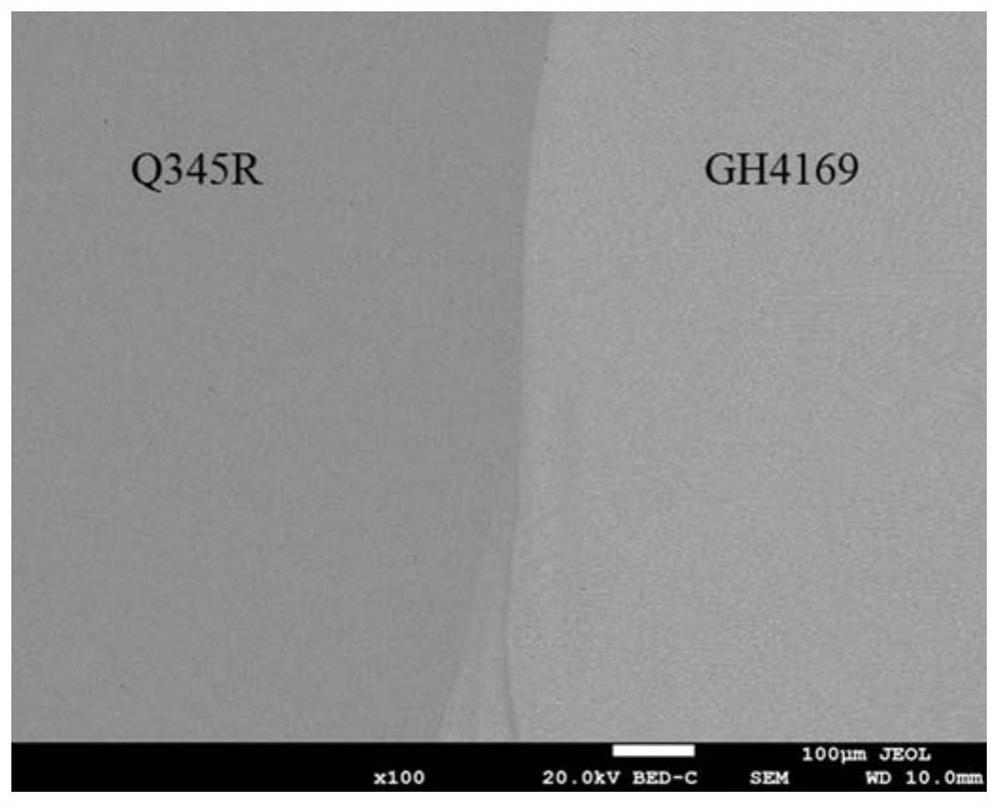

Titanium/nickel alloy parts and preparation method based on explosive welding and laser additive manufacturing

ActiveCN111215855BOvercoming the problem of interface crackingFast formingAdditive manufacturing apparatusGrinding machinesNickel alloyTitanium

The invention discloses a titanium / nickel alloy component and a preparation method based on explosive welding and laser additive manufacturing, which belong to the technical field of connection of bimetal components. The titanium / nickel alloy parts include connected explosive welding parts and laser additive manufacturing parts, the explosive welding parts are titanium / steel composite plates or titanium / nickel composite plates, and the materials of the laser additive manufacturing parts are titanium alloys or F. The invention prepares titanium / nickel alloy components based on explosive welding and laser additive manufacturing methods, and the intermediate transition layer is connected by explosive welding, which overcomes the problem of interface cracking caused by brittle intermetallic compounds produced by direct contact of titanium / nickel alloys; The explosively welded parts are used as the substrate to prepare titanium / nickel alloy parts by laser additive manufacturing process, which has fast forming speed, good flexibility and high efficiency.

Owner:有研金属复材技术有限公司

A kind of copper-aluminum composite material and preparation method thereof

ActiveCN111424274BAchieve interlockReduce interfacial internal resistanceMaterial nanotechnologyRoll force/gap control deviceEtchingAluminum composites

The invention provides a copper-aluminum composite material and a preparation method thereof, comprising a Cu metal plate and an Al metal plate, the two are combined into one body through cold rolling, and before the cold rolling and compounding, Cu nano-sol is uniformly sprayed on the surface of the metal plate Particles are etched in situ to form abundant active sites, and a three-dimensional rough structure is constructed on the surface of Cu and / or Al metal to form a copper-aluminum composite material. The method comprises synthesizing Cu nano sol particles by a sol-gel method; uniformly spraying the Cu nano sol particles onto the surface of Cu and / or Al metal sheets, forming abundant active sites through in-situ etching, and forming a rich active site on the Cu and / or Al metal surface Construct a three-dimensional rough structure to obtain Cu and / or Al metal sheets with in-situ active etching on the surface; then connect the Cu and Al metal sheets after in-situ active etching on the surface to obtain copper-aluminum composite through cold rolling composite solid-state connection Material. The invention has the advantages of simple process, high production efficiency and low production cost.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Preparation method of composite adhesive specially used for aluminum foil lining paper

InactiveCN110129002AImprove liquidityImprove mechanical propertiesNon-macromolecular adhesive additivesOil/fat/wax adhesivesFiberAdhesive

The invention discloses a preparation method of a composite adhesive special for aluminum foil lining paper, and belongs to the technical field of adhesive preparation. The method comprises the following steps: 1) mixing and fermenting bamboo fibers, biogas slurry, a glucose solution and water; 2) adding tetraethoxysilane, stirring and mixing, filtering and freezing the components, performing ballmilling on the components, sieving the material through a 300-mesh sieve, and drying and carbonizing the material to obtain modified bamboo fibers; 3) heating, stirring, mixing casein, urea and water, then adding ammonia water, stirring the mixture to dissolve all the components, then adding borax, and stirring and mixing all the components to obtain a mixed dissolving solution; 4) stirring and mixing the following components including, by weight, 30-40 parts of mixed dissolving solution, 8-10 parts of modified bamboo fiber, 3-5 parts of emulsifier, 2-3 parts of defoaming agent, 2-3 parts ofdry oil, 3-5 parts of modified additive, 2-3 parts of modified sepiolite, 2-3 parts of starch, 30-50 parts of water, 2-3 parts of shell powder, 2-3 parts of organic acid and 2-3 parts of asphalt to obtain the composite adhesive. The composite adhesive specially used for the aluminum foil lining paper has excellent flowing property and bonding property.

Owner:刘勇

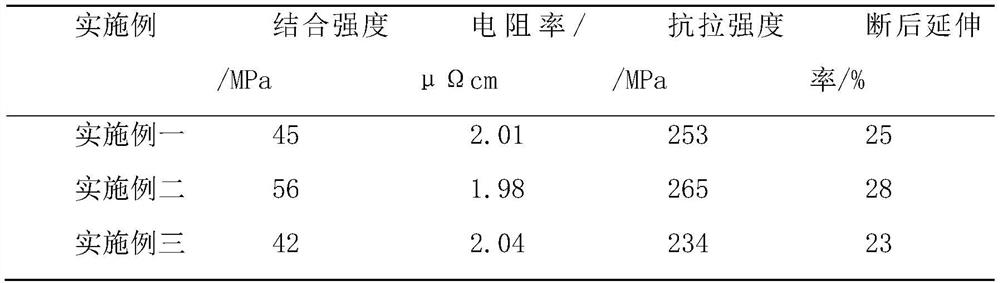

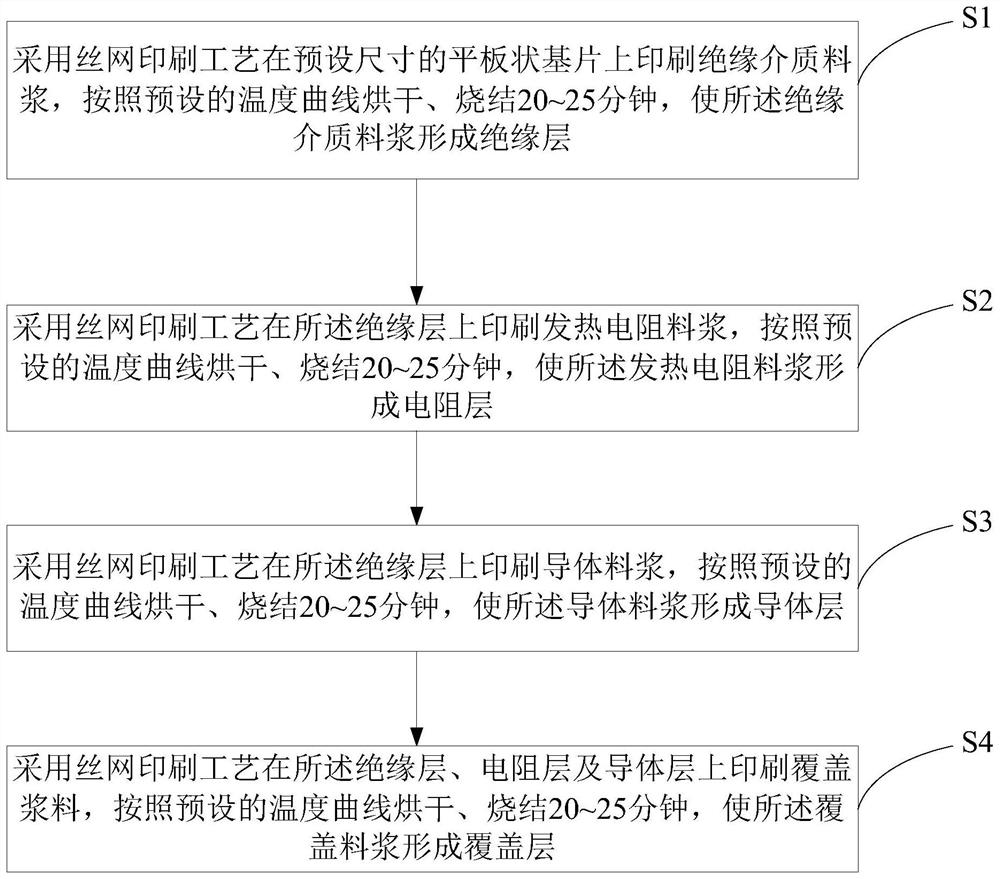

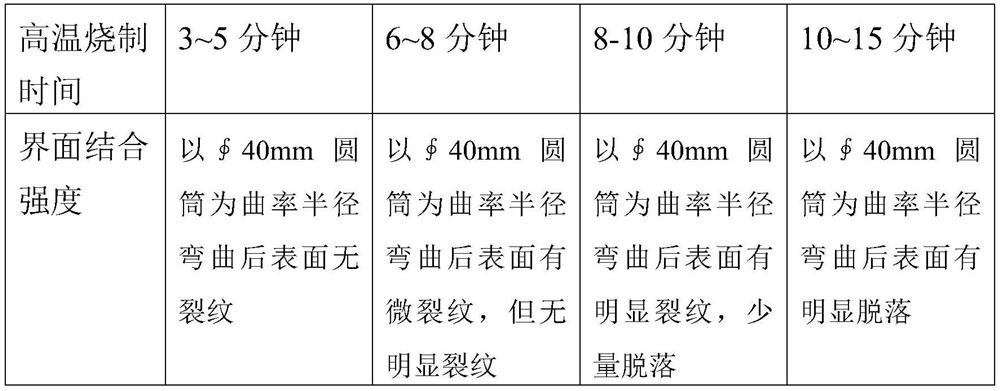

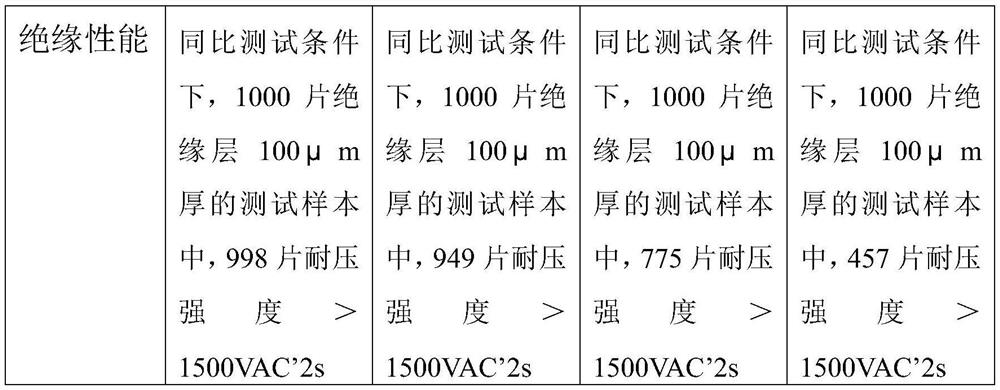

A kind of preparation method of stainless steel substrate thick film heating element

ActiveCN108901091BReduced interfacial bond strengthImprove the bonding strength of the interfaceOhmic-resistance heatingScreen printingElectrical conductor

The invention discloses a method for preparing a thick-film heating element with a stainless steel substrate, which comprises the following steps: printing insulating medium slurry on a flat substrate with a preset size by a screen printing process, drying and sintering according to a preset temperature curve for 20-20 ~ For 25 minutes, the insulating dielectric slurry is formed into an insulating layer; the heating resistor slurry is printed on the insulating layer by a screen printing process, and dried and sintered for 20 to 25 minutes according to a preset temperature curve to make the heating The resistance paste forms a resistance layer; the conductor paste is printed on the insulating layer by a screen printing process, dried and sintered for 20 to 25 minutes according to a preset temperature curve, so that the conductor paste forms a conductor layer; The covering paste is printed on the insulating layer, the resistance layer and the conductor layer by a screen printing process, dried and sintered for 20-25 minutes according to a preset temperature curve, so that the covering paste forms a covering layer. This solution well solves the problems of low production efficiency and high energy consumption, greatly improves production efficiency and saves electric energy.

Owner:湖南特发新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com