Method for preparing concrete preservative

A concrete preservative and preparation process technology, applied in the field of building materials, can solve the problems of poor mechanical properties and durability of concrete, increased slump loss, etc., to improve plasticity and pumpability, improve dispersion performance, The effect of reducing the interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

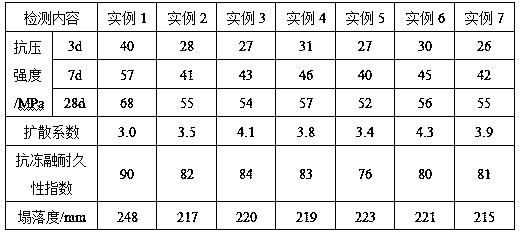

Examples

Embodiment Construction

[0024]Put sodium alginate and water in a No. 1 beaker at a mass ratio of 1:50 to 1:100, stir with a glass rod for 10 to 20 minutes, let it stand for swelling for 3 to 5 hours, and place the No. 1 beaker in a digital display speed measuring constant temperature magnetic force In the stirrer, under the conditions of temperature 90-95°C and rotation speed 300-500r / min, heat and stir to dissolve for 40-60min, then add multi-armed carbon nanotubes 2-3 times the mass of sodium alginate to No. 1 beaker , at a speed of 400-600r / min, stir and mix for 40-60min, then add sodium periodate 0.02-0.03 times the mass of sodium alginate to No. Under the condition of ~500r / min, heat and stir to dissolve for 40~60min to obtain the modified sodium alginate solution; mix (N-amidino)dodecylacrylamide and methoxypolyethylene glycol in a mass ratio of 1:1 ~2:1 is placed in No. 1 beaker, and 0.1-0.2 times the mass of methoxypolyethylene glycol is added to No. 1 beaker, and 0.07-0.10 times the mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com