Patents

Literature

35results about How to "High temperature tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper-chromium-zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

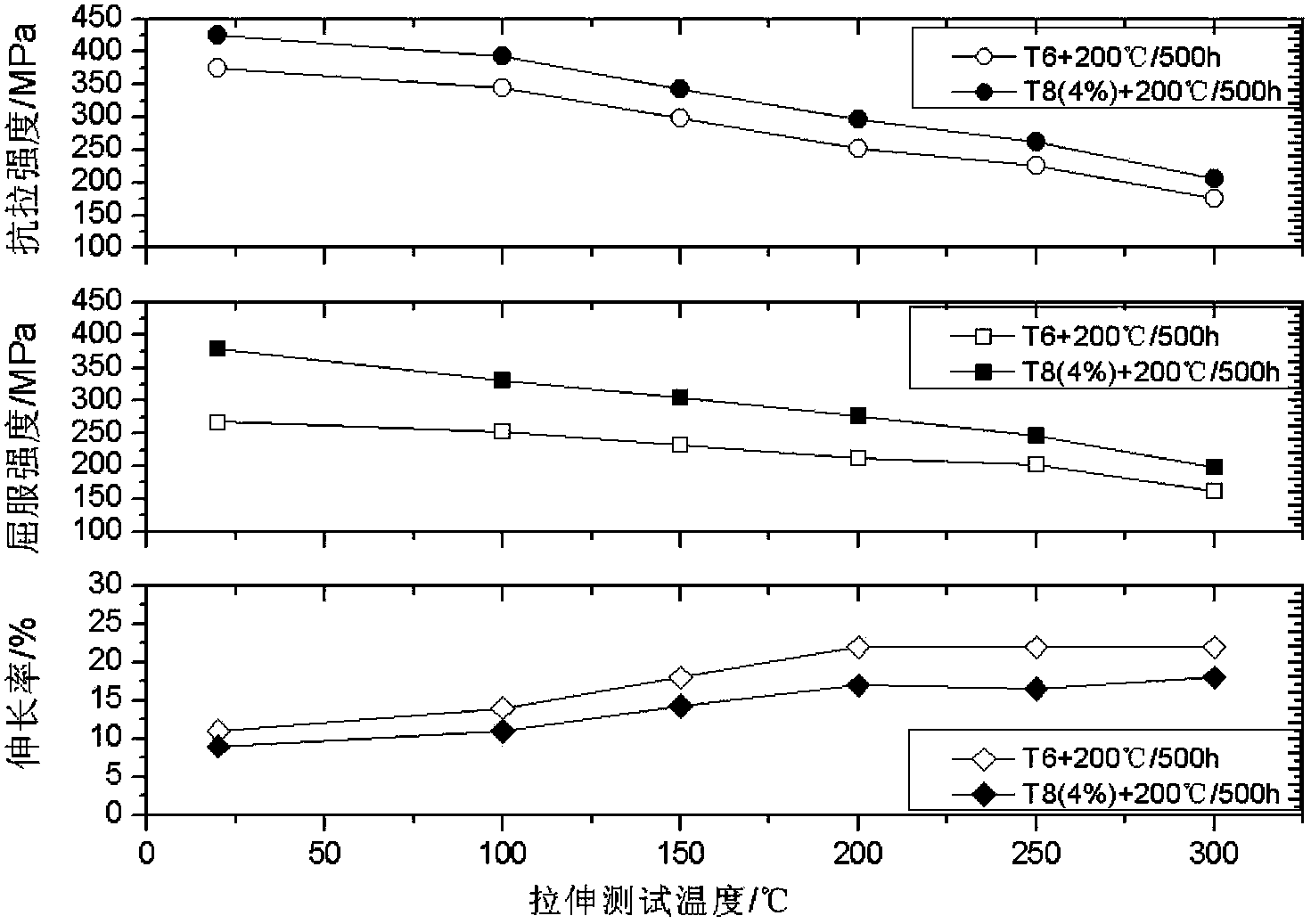

Method for improving room temperature strength and high-temperature performance of Al-Cu-Mg alloy for aluminum alloy drilling rod

InactiveCN104164635AHigh tensile strength at normal room temperatureHigh tensile strengthSolution treatmentHeat stability

The invention discloses a method for improving room temperature strength and high-temperature performance of Al-Cu-Mg alloy for an aluminum alloy drilling rod. The method comprises the steps that the Al-Cu-Mg alloy is pre-stretched and deformed by 0 percent to eight percent after solution treatment, and then is heated to 160 DEG C to 190 DEG C, heat preservation is carried out on the alloy for four hours to 120 hours, then, the alloy is taken out of a furnace, air cooling is carried out on the alloy, and the content ratio of copper to magnesium in the Al-Cu-Mg alloy is smaller than or equal to five. Through the suitable heat treatment technology, the Al-Cu-Mg alloy is made to obtain a strengthening phase which has the better dispersion and heat stability performance, and therefore compared with the conventional T6 state, the alloy has the better excellent room temperature tensile property, the higher high-temperature tensile strength and residual tensile strength after being thermally exposed for a long time

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

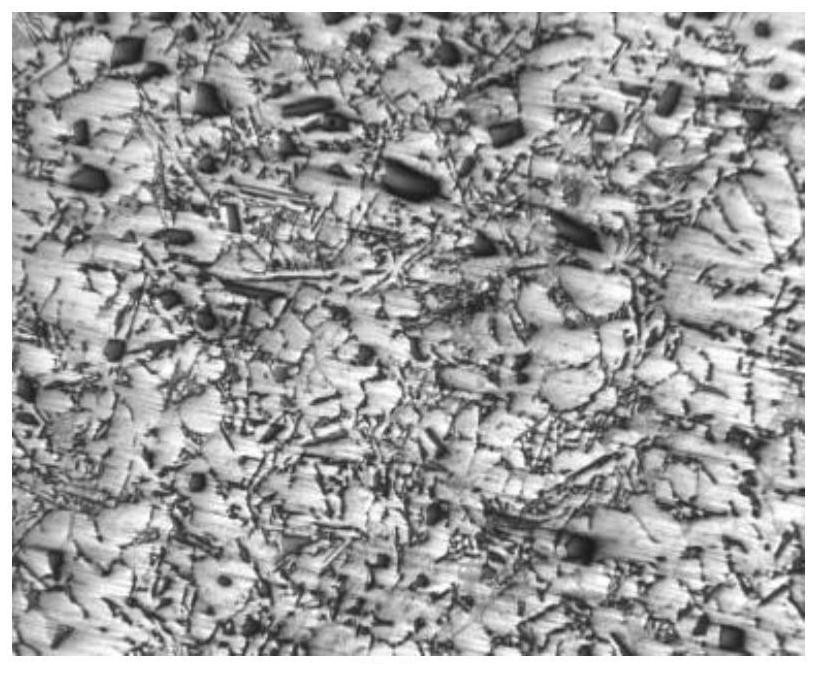

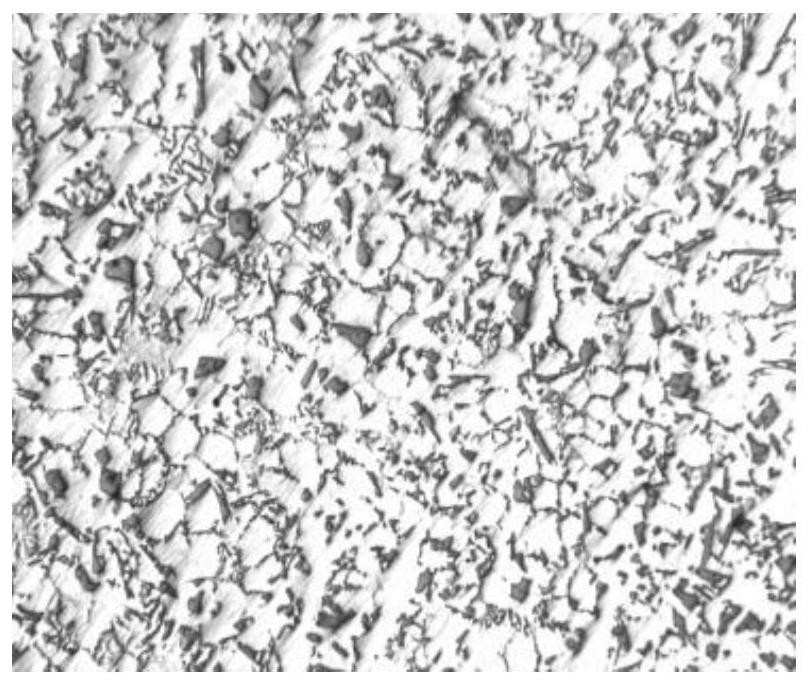

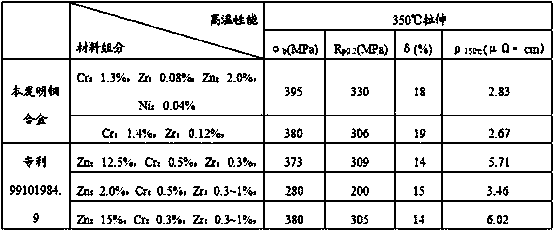

High-strength and high-conductivity copper alloy material

ActiveCN102392154AImprove high temperature softening performanceAvoid crackingHardnessUltimate tensile strength

Embodiments of the invention disclose a high-strength and high-conductivity copper alloy material, comprising by mass: 1.3%-1.5% of Cr, 0.4%-0.5% of Zr, 30% of Zn, and the balance Cu as well as inevitable impurities. The material can further include one or several of Zn, Fe, Mg and Ni. The material of the invention improves the high temperature softening resistance of products, and can prevent cracking caused by reduced material strength due to temperature rise. While ensuring high high-temperature tensile strength, yield strength and hardness, the material provided in the invention can simultaneously maintain high electroconductivity and heat conductivity.

Owner:RAOPING YUEXING COPPER PROCESSING CO LTD

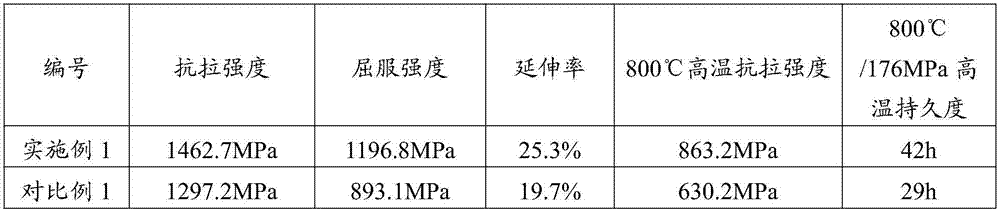

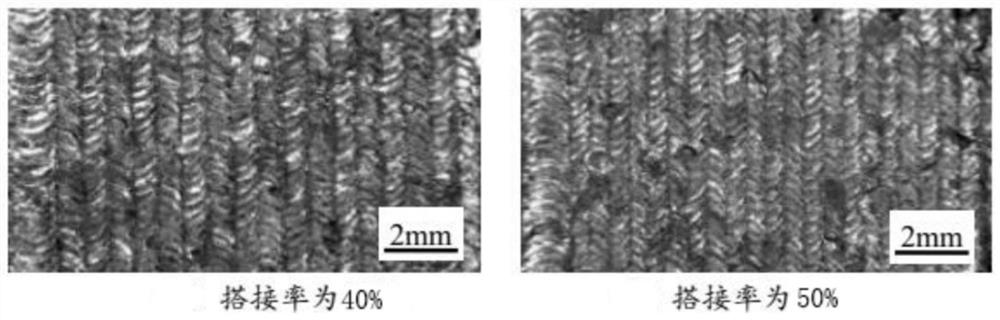

Heat treatment technique for additive component

InactiveCN107470629AOptimize heat treatment processHigh elongationAdditive manufacturing apparatusPerformance indexQuenching

The invention discloses a heat treatment technique for an additive component. The heat treatment technique for the additive component is used for improving the overall mechanical performance index of the additive component. The heat treatment technique for the additive component comprises the following steps of annealing, specifically, annealing treatment is conducted on the additive component; and quenching, specifically, quenching treatment is conducted on the annealed additive component twice, low-temperature quenching is conducted on the additive component firstly, and then high-temperature quenching is conducted on the additive component. By adoption of the heat treatment technique, the overall mechanical performance index of the additive component can be improved, and the using requirements in the aviation field are met.

Owner:ADVANCED FOR MATERIALS & EQUIP

Moderate-temperature Zr-based brazing filler metal special for Ti2AlNb-based alloy identical or different material brazing and preparation method and brazing process of brazing filler metal

ActiveCN111702281AImprove wettabilityImprove liquidityWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalRaw material

The invention belongs to the field of welding and particularly relates to moderate-temperature Zr-based brazing filler metal special for Ti2AlNb-based alloy identical or different material brazing anda preparation method and a brazing process of the brazing filler metal. According to weight percentage, the brazing filler metal comprises 5%-30% of Fe, 1%-15% of Nb or 1%-20% of Cu, <=5% of oligoelements including one or two or more of Al, B, Co, Cr, Mn, Mg, Ni, Ag, and Zn, <=2% of microelements including one or two or more of Ti, Hf, V, Ta, Mo, W, Au, Si, Sn, Pd and Ga, and the balance of Zr elements and unavoidable impurity elements. The preparation method of the brazing filler metal comprises the steps that firstly, raw materials are weighed; secondly, mother alloy of the brazing filler metal is smelted; and thirdly, the smelted mother alloy is subjected to quenching melt-spinning, and then the brazing filler metal is obtained. The brazing filler metal is used for brazing according tothe brazing process of 960 DEG C to 1,030 DEG C and 0-120min. Compared with existing brazing filler metal, the prepared brazing filler metal has an appropriate melting point, excellent wettability and high-temperature mechanical properties, and brazing filler metal preparation and the brazing process are simple.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Diffusion welding method for fixing supporting plate with supporting plate head

ActiveCN108015409ASimple processGood processing consistencyNon-electric welding apparatusEngineeringMachining

The invention discloses a diffusion welding method for a fixing supporting plate with a supporting plate head. The method specifically comprises the steps that linear cutting is carried out on a blank, grinding machining and other treatment are carried out on the surface of a to-be-welded surface, assembling positioning is carried out before welding, a compression amount supporting block is presetto ensure the compression amount, the corresponding welding parameters are controlled to carry out diffusion welding, the compression amount is checked after welding, welding seam metallographic inspection is carried out and other steps to complete the diffusion welding for the fixing supporting plate with the supporting plate head, wherein the welding percent of pass is larger than 95%. According to the method, the diffusion welding method is adopted to complete welding of the fixing supporting plate with the supporting plate head, the diffusion welding link for portions between layered plates of a conventional three-layer plate superplastic forming diffusion welding supporting plate is removed, hollowing of a strengthening rib triangular region of the inner cavity of the supporting plate is avoided, the faults of bulging and cracking of multi-layer plate diffusion connection fixing supporting plate are overcome, meanwhile, the supporting plate and the supporting plate head are of anintegral structure; and the diffusion welding process for the fixing supporting plate with the supporting plate head has the multiple advantages that the technological process is simple, the qualityis easy to control, the quality is stable, the consistency of inner molded surface and the outer molded surface of the fixing supporting plate is good, the size precision is high, and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

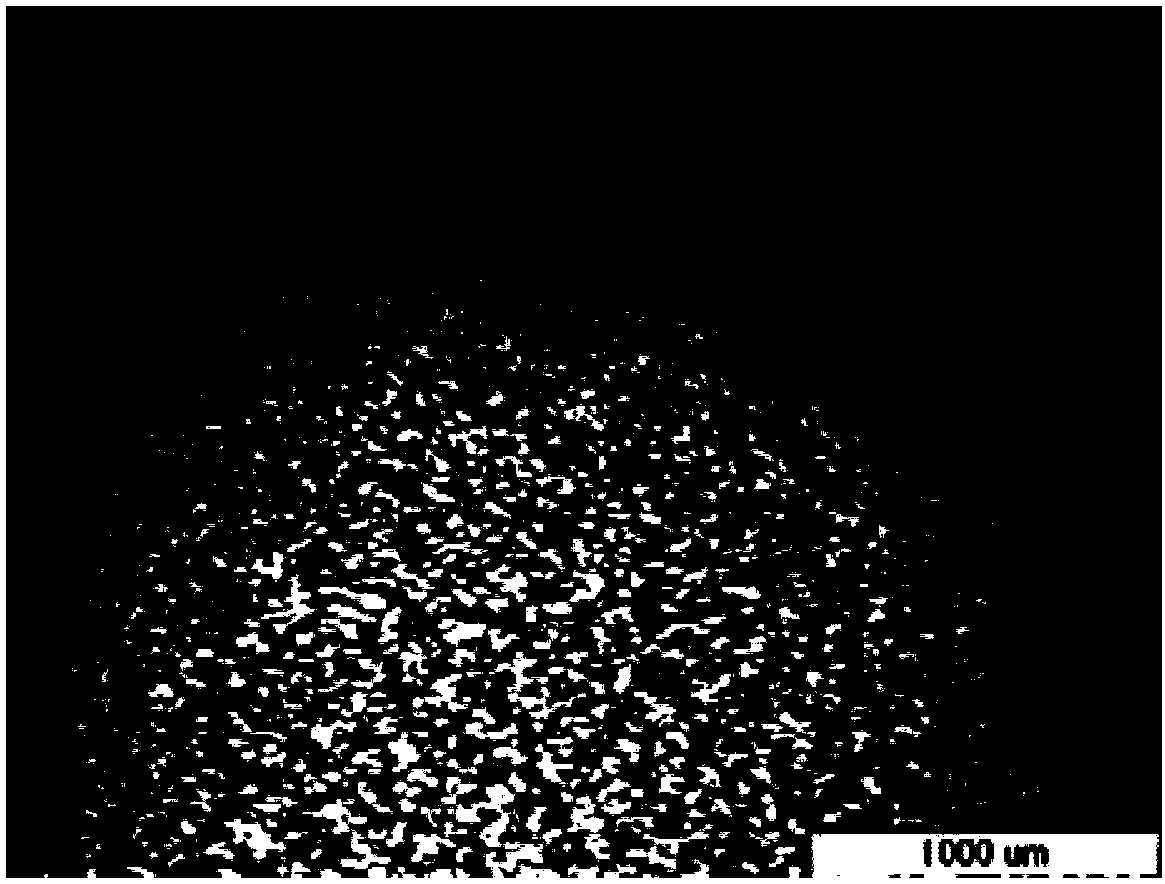

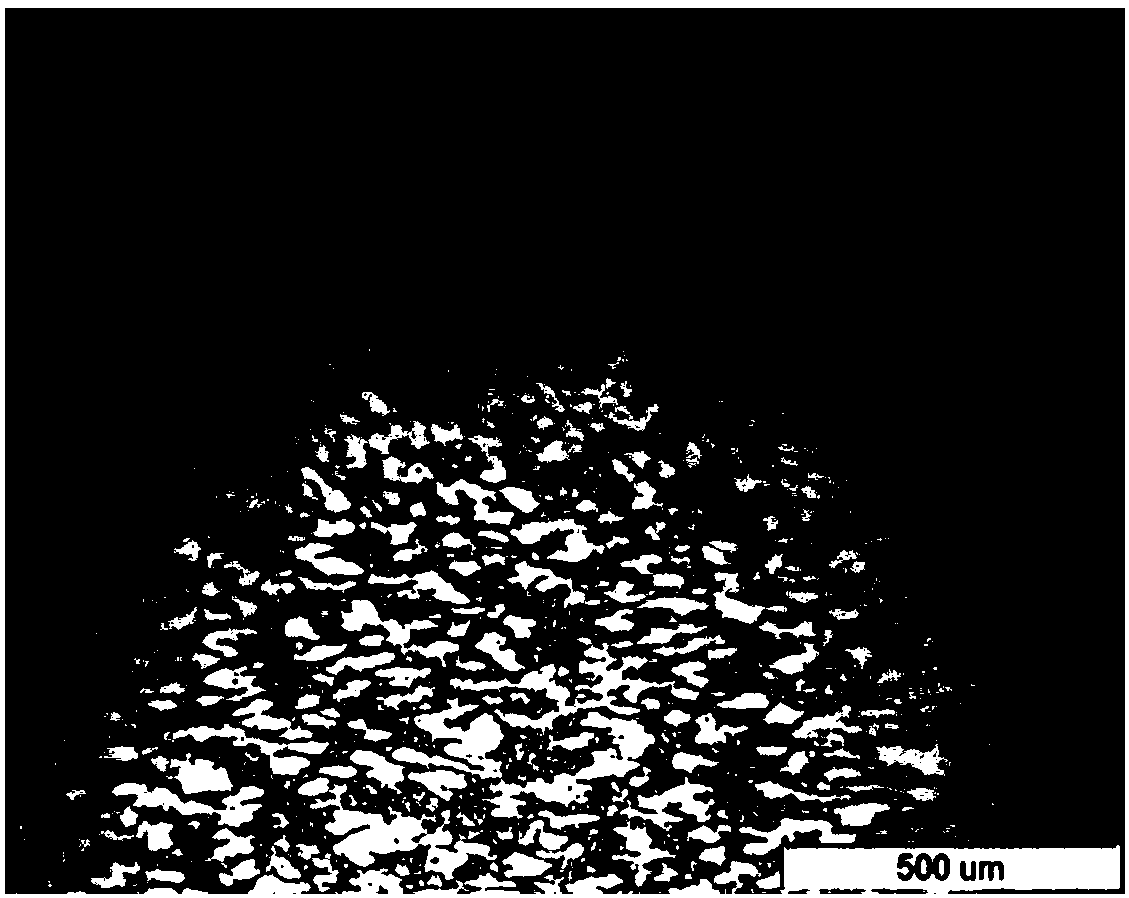

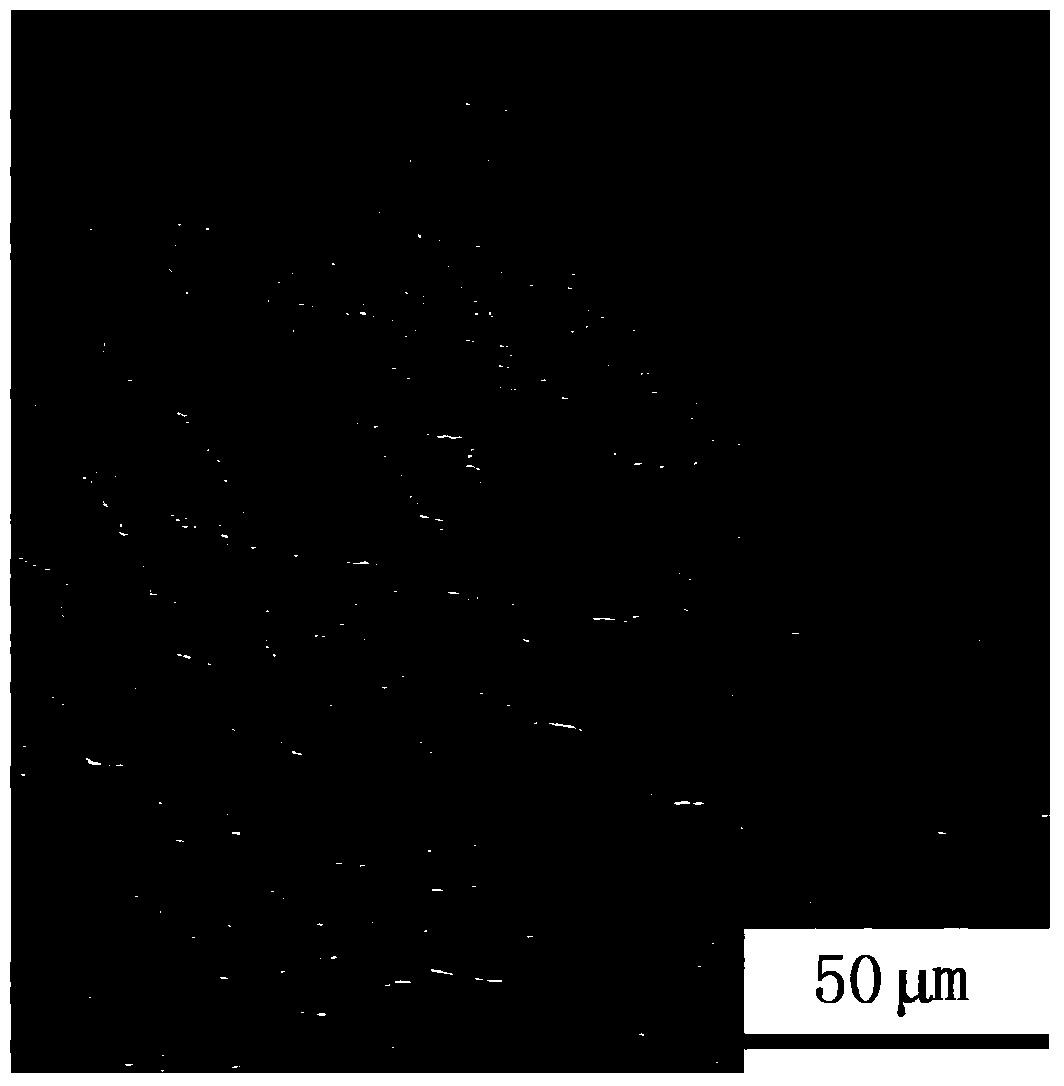

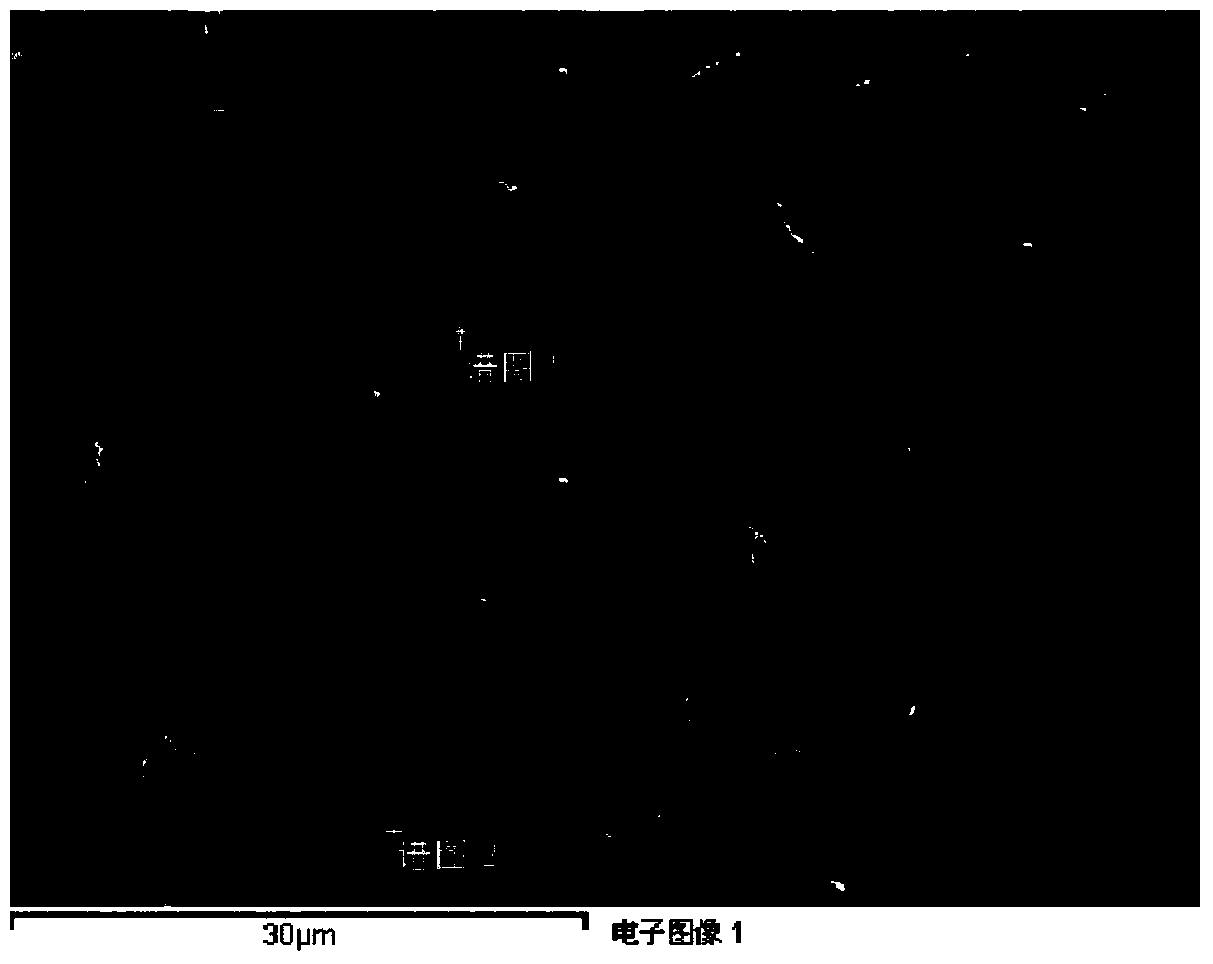

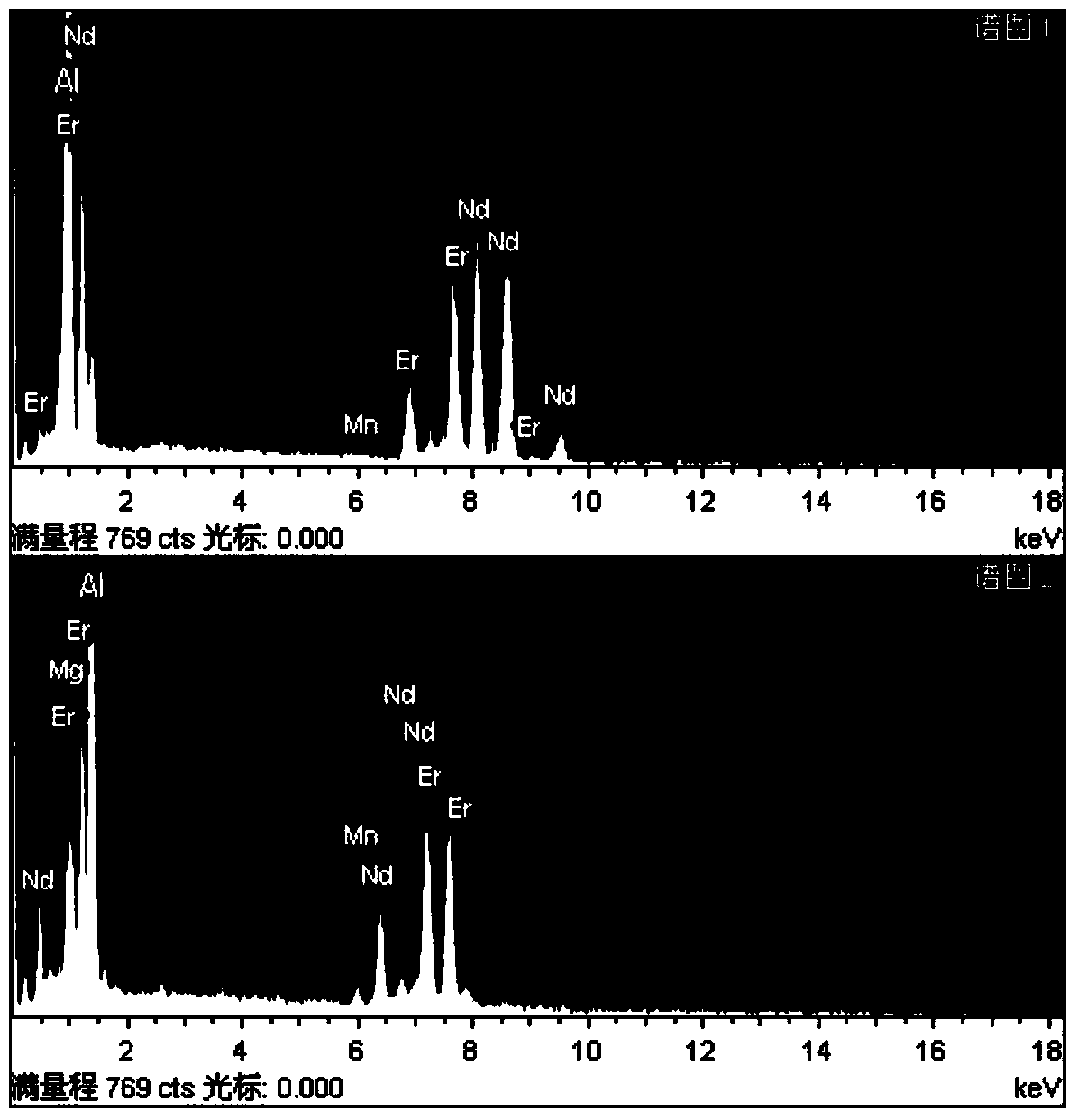

Rare earth magnesium alloy and preparation method thereof

ActiveCN103911534AIncreased tensile strength at room temperatureHigh temperature tensile strengthRare-earth elementRoom temperature

The invention discloses a rare earth magnesium alloy and a preparation method thereof. The rare earth magnesium alloy contains the following components in percentage by mass: 8.4-8.7% of Al, 0.85-0.89% of Zn, 0.28-0.30% of Mn, 0.39-1.21% of Nd, 0.41-0.43% of Er, less than 0.04% of impurity elements (Si, Fe and Cu) in total, and the balance of Mg. According to the method, rare earth elements Nd and Er are compounded and added in a magnesium alloy by smelting so as to modify the magnesium alloy and the obtained casting-state rare earth magnesium alloy is subjected to T6 heat treatment. Compared with the prior art, the rare earth magnesium alloy prepared by the method is relatively high in room-temperature tensile strength and high-temperature tensile strength and the plasticity is enhanced greatly.

Owner:WUHU INST OF TECH

A kind of copper chromium zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

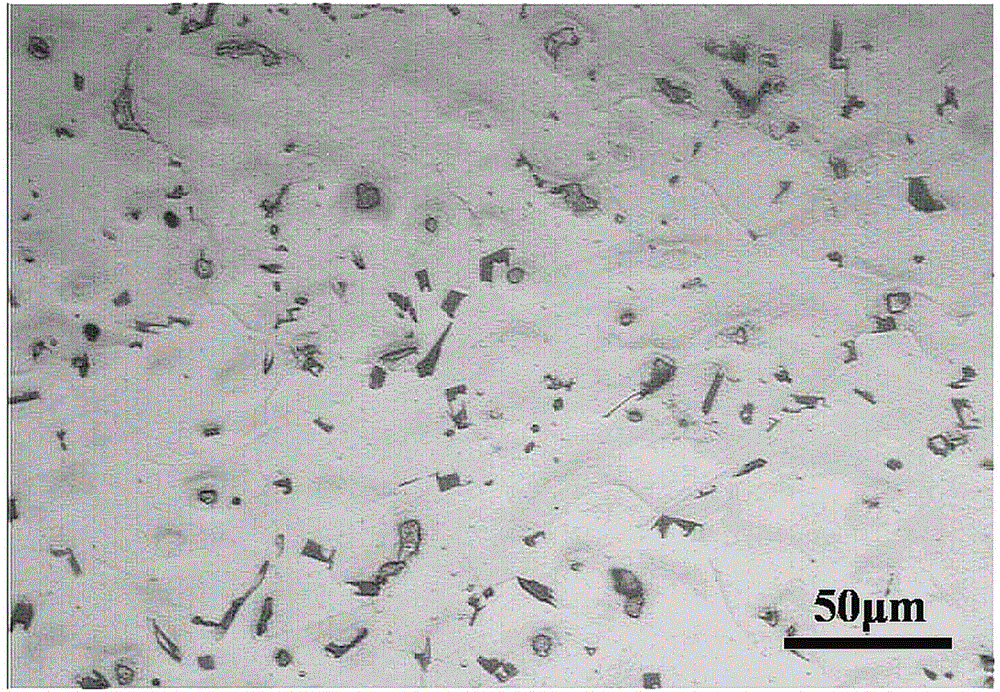

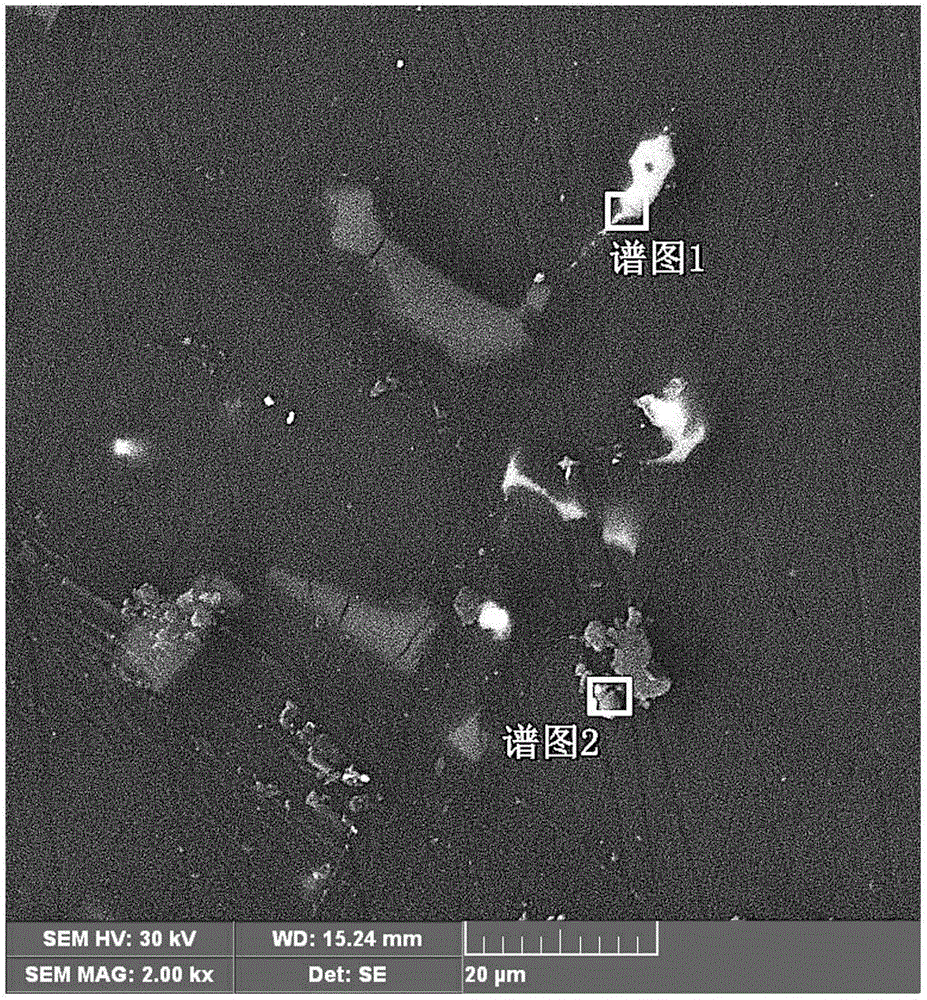

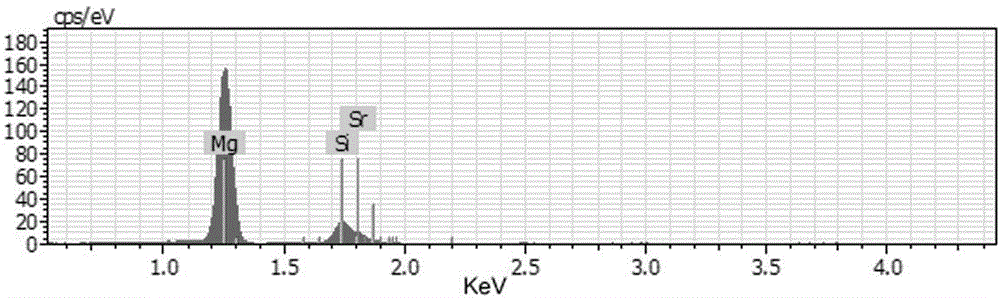

Alkaline-earth element modified heat-resistant magnesium alloy and preparation method thereof

The invention relates to an alkaline-earth element modified heat-resistant magnesium alloy. The magnesium alloy comprises the following components by weight percent: 2.5-3.4% of Al, 0.5-1.4% of Si, 0.05-0.14% of Mn, 0.05-1.54% of Sr and the balance of Mg. The magnesium alloy is modified by adding Mg-Si and Al-Sr intermediate alloys to the magnesium alloy by a smelting method, and T6 heat treatment is carried out on the obtained as-cast heat-resistant magnesium alloy. Compared with the prior art, the prepared heat-resistant magnesium alloy has higher room temperature tensile strength and high temperature tensile strength and better plasticity.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

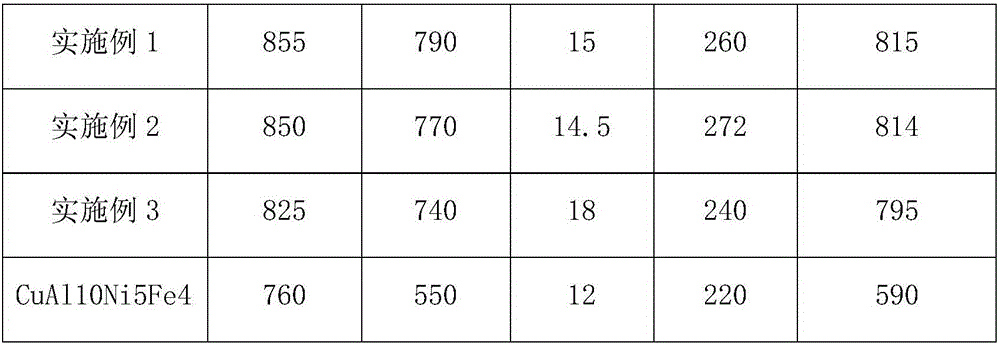

Novel material for retraction ring of traction motor of high-speed train and preparation method of novel material

ActiveCN106676320AIncreased tensile strength at room temperatureHigh temperature tensile strengthElectric machineryHigh intensity

The invention discloses a novel material for a retraction ring of a traction motor of a high-speed train and a preparation method of the novel material and particularly relates to the technical field of motor rotor material manufacturing. The novel material comprises the chemical compositions including, by weight, 13.0-16.0% of Ni, 1.8-2.8% of Al, 0.5-1.5% of Mn, 0.8-1.8% of Fe, and the balance Cu. The preparation method includes the steps of proportioning, smelting, pouring, forging and annealing heat treatment. The alloy retraction ring has high strength, elongation and high-temperature strength, the strength at the room temperature reaches 850 MPa, the elongation reaches 15%, and the strength at the high temperature of 300 DEG C reaches 815 MPa. The cooper alloy retraction ring can meet the requirements for high rotation speed, high working temperature and good stability of asynchronous traction motors, and can particularly meet the requirement for good performance at 350 DEG C.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

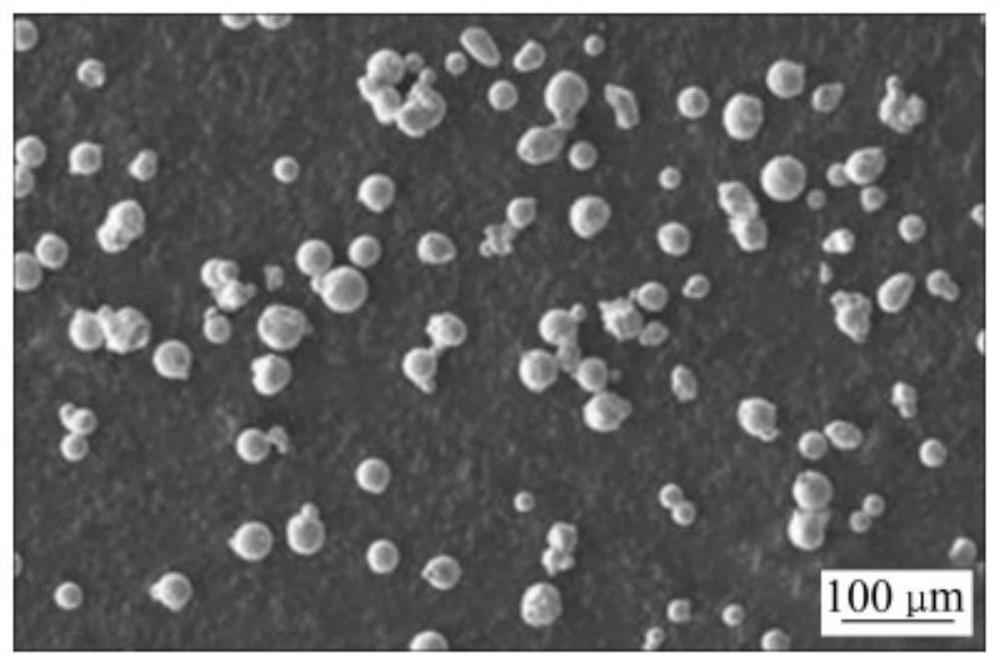

Method for improving high-temperature strength of Inconel 718 laser deposition layer

PendingCN114749660AImprove high temperature performanceHigh temperature tensile strengthTransportation and packagingMetal-working apparatusInconelUltrasonic dispersion

The invention discloses metal powder based on Inconel 718. The metal powder comprises the following components: Inconel 718 powder, Ti powder, Mo powder and nickel-coated graphite. The preparation method comprises the following steps: (1) carrying out ball milling on Inconel 718 powder, Ti powder, Mo powder and nickel-coated graphite, and uniformly mixing; (2) carrying out ultrasonic dispersion treatment on the ball-milled mixed powder for 1-2 hours, and drying in a drying oven at 100-120 DEG C for 2-2.5 hours; (3) the materials are put into a vacuum induction furnace to be smelted, vacuumizing is conducted to 2-8 Pa in the smelting process, then argon is refilled to normal pressure, energization is started to melt metal, when the temperature of metal melt reaches 1600-1700 DEG C, molten metal is conveyed to a flow guiding device, the metal flow is well adjusted, and the flow rate is controlled to be 8-10 kg / min; and (4) after the atomized powder is cooled in a collector, the atomized powder is screened on a mechanical vibration machine through a 150-mesh standard screen, and then the atomized powder is packaged and stored. After aging treatment, the high-temperature performance and the high-temperature tensile strength of a laser deposition layer can be obviously improved, and after diffusion and dissolution, the corrosion resistance is also greatly improved.

Owner:XIAN TECHNOLOGICAL UNIV

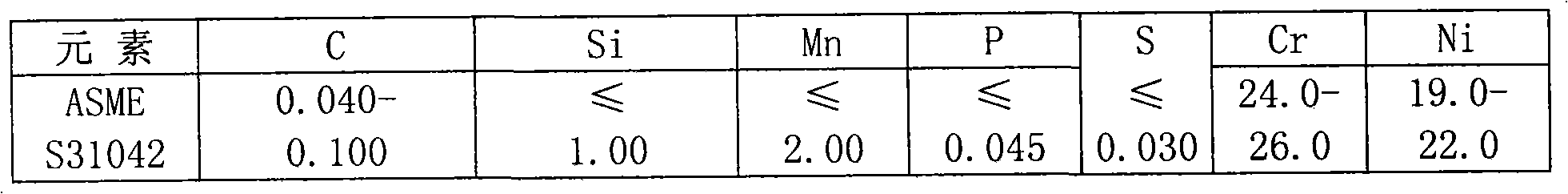

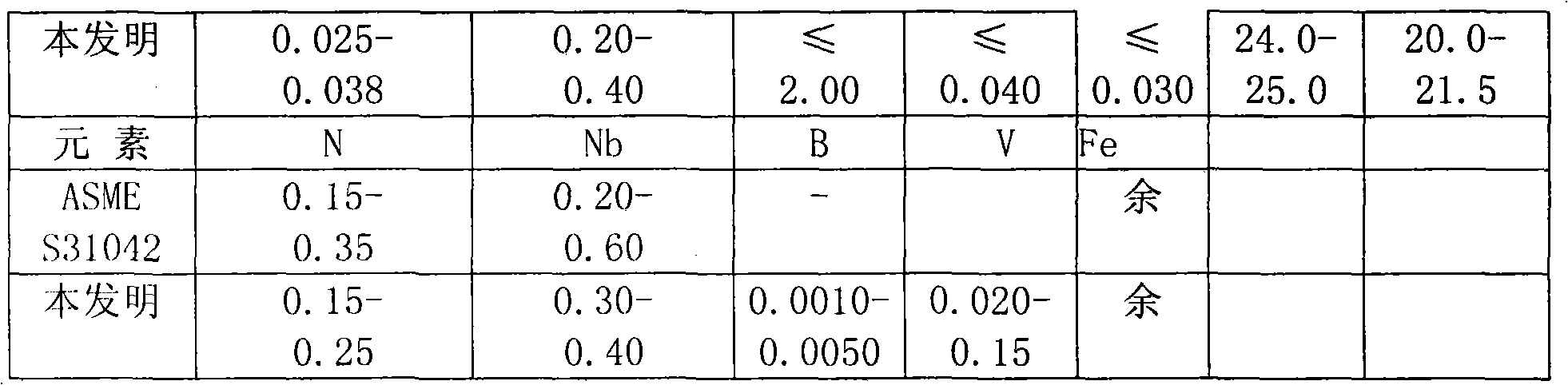

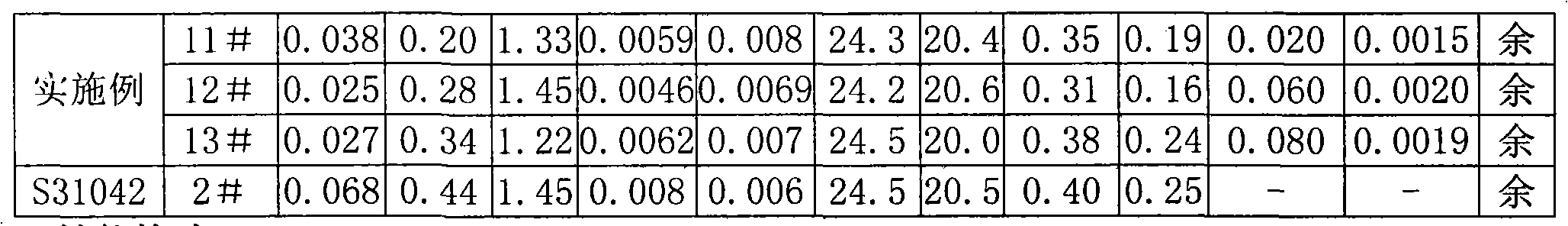

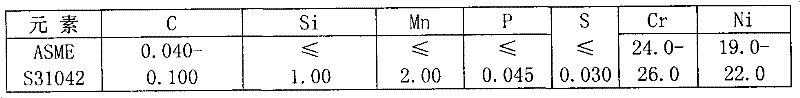

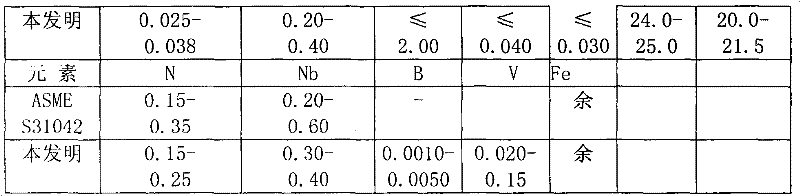

High-toughness austenite boiler steel

InactiveCN101967611AImprove toughnessReasonable design of ingredientsChemical compositionRoom temperature

The invention discloses high-toughness austenite boiler steel belonging to the technical field of austenite boiler steel. The boiler steel comprises the following chemical constituents: 0.025-0.038 wt% of C, 0.20-0.40 wt% of Si, less than or equal to 2.00 wt% of Mn, less than or equal to 0.045 wt% of P, less than 0.03 wt% of S, 20-21.5 wt% of Ni, 0.15-0.20 wt% of N, 0.30-0.40 wt% of Nb, 0.0010-0.050 wt% of element B, 0.020-0.15 wt% of element V and the balance of Fe. The invention has the advantages that when the high-toughness austenite boiler steel is compared with S31042 steel, two alloy elements of B and V are added, and the ingredient range of C, Nb, N, Si, Cr, Ni and other elements is adjusted, so that the high-toughness austenite boiler steel has the characteristics of reasonable constituent design and high toughness. After long aging at 700 DEG C, compared with the S31042 steel subject to same heat treatment, the high-toughness austenite boiler steel has higher room-temperature impact toughness, and tensile strength at high temperature of 700 DEG C is comparative or slightly higher.

Owner:CENT IRON & STEEL RES INST

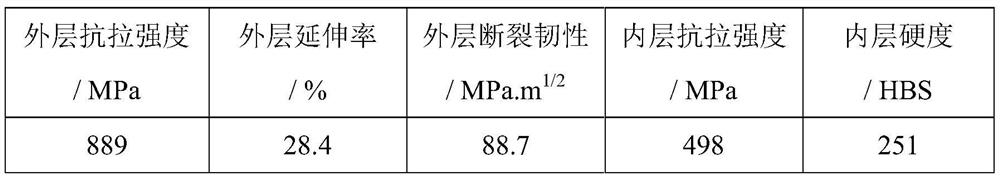

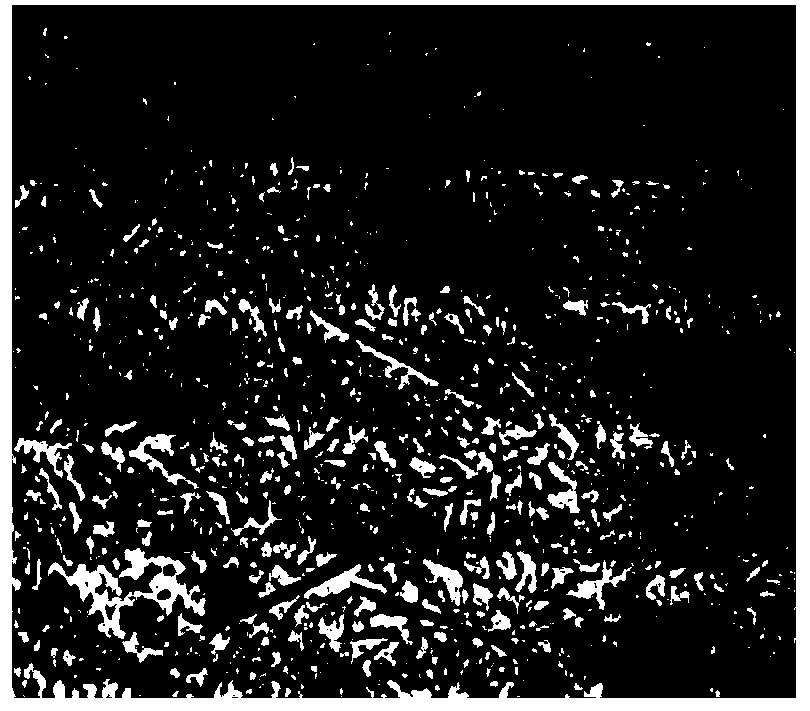

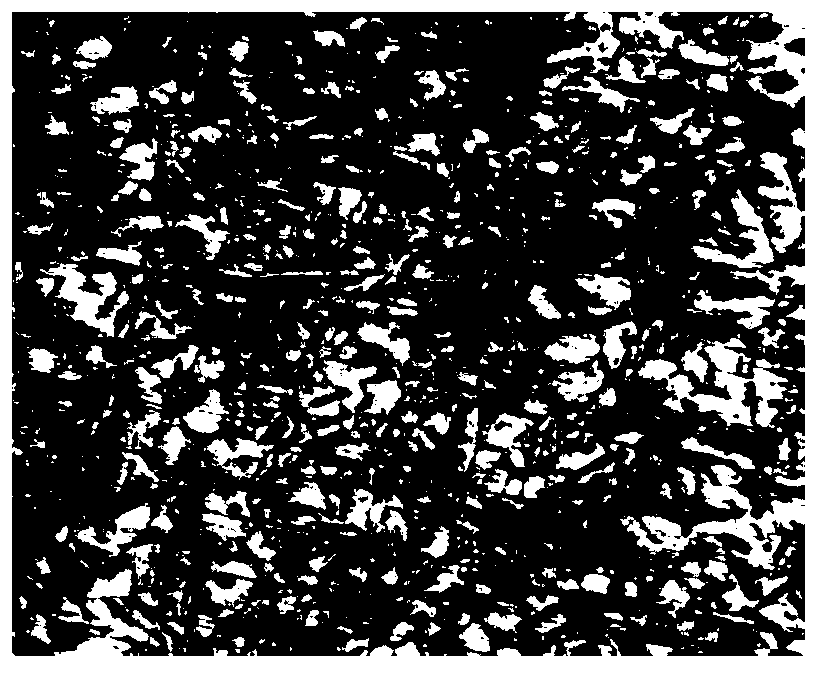

Method for casting bimetallic brake drum in short process

ActiveCN114260440AEfficient use ofHigh yieldBraking drumsProcess efficiency improvementFerrochromeInduction furnace

The invention discloses a short-process bimetal brake drum casting method and belongs to the technical field of casting. The outer layer of the brake drum is formed in the mode that scraped car sheet steel blocks, Q235 scrap steel, high-carbon ferrochrome and nitrided ferromanganese serve as furnace charges and are smelted and continuously cast into a steel plate in a medium-frequency induction furnace and then welded and rolled, the inner layer is made of high-strength abrasion-resistant gray cast iron, and the inner layer and the inner layer are subjected to metallurgical bonding through centrifugal composite casting. The efficient utilization of the waste automobile sheet is realized, and the element yield is high. Compared with HT250 cast iron, the bimetal brake drum inner layer cast iron cast in a short process has the advantages of being high in high-temperature tensile strength and crack initiation and expansion resistance, long in service life, safe and reliable to use and the like. Compared with an HT250 cast iron brake drum, the service life of the brake drum is prolonged by more than 2.5 times, and the brake drum has good economic and social benefits in popularization and application.

Owner:山西汤荣机械制造股份有限公司

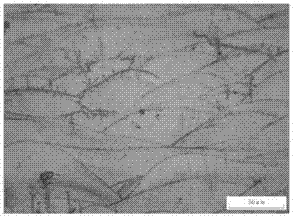

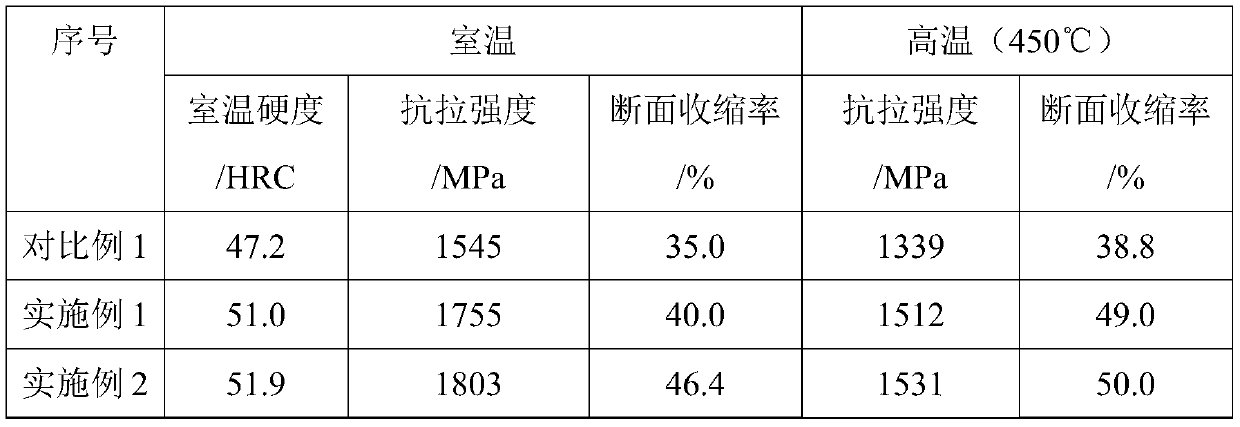

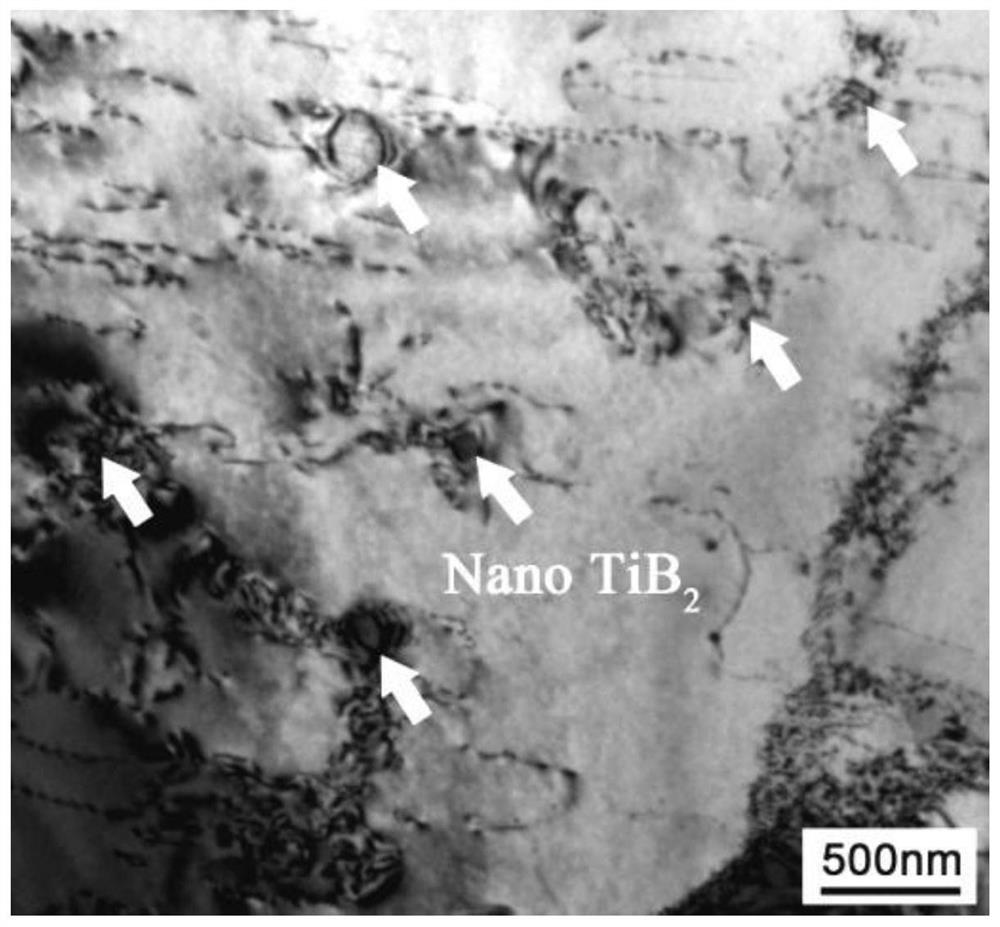

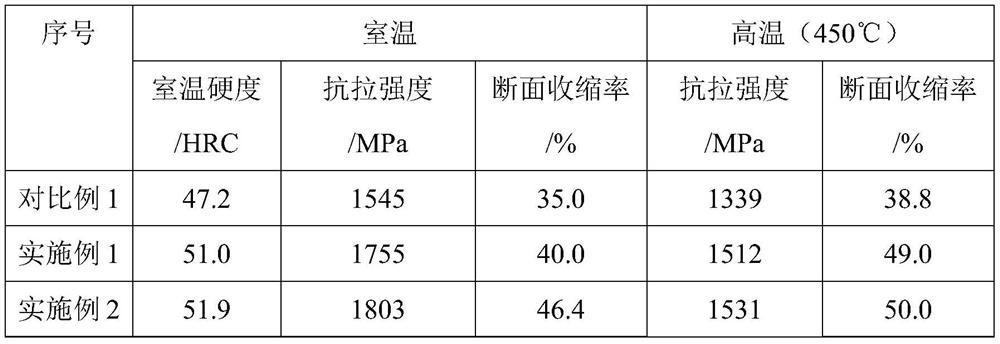

Hot work die steel and preparation method thereof

ActiveCN110343963APrevent excessive grain growthIncrease precipitation strengtheningTitanium carbideHardness

The invention discloses hot work die steel and a preparation method thereof. The hot work die steel is composed of the following constituent elements including, by weight, 0.396%-0.397% of carbon, 0.975%-1.03% of silicon, 0. 427%-0.514% of manganese, 1.55%-1.59% of molybdenum, 4.94%-5.10% of chromium, 0.984%-1.04% of vanadium, 0.044%-0.127% of titanium and the balance iron and inevitable impurities. According to the hot work die steel, the Ti element is added on the basis of H13 steel compositions; on one hand, the effects of controlling the grain size, preventing excessive growth of grains and increasing precipitation strengthening and fine grain strengthening are achieved, and the strength and hardness of the steel are improved; and on the other hand, the titanium reacts with the carbonto generate titanium carbide, the advantages of high hardness and good thermal stability are achieved, the effect of precipitation strengthening is achieved, and micro Ti alloying is formed. The roomtemperature Rockwell hardness, room temperature tensile strength, room temperature tensile section shrinkage, the high-temperature tensile section shrinkage rate and the high-temperature tensile strength of the hot work die steel are significantly improved, and the comprehensive mechanical properties are obviously enhanced.

Owner:HENAN UNIV OF SCI & TECH

Composite piston material and preparation method thereof

InactiveCN108342623AImproved high temperature strength and wear resistanceGood high temperature strengthAlloy elementSilica fume

The invention discloses a composite piston material. The composite piston material comprises the following raw materials including, by weight, 6.5-7.5 parts of silicon powder, 0.3-0.5 part of magnesium powder, 0.06-0.10 part of titanium powder, 0.1-0.2 part of yttrium powder, 6-7 parts of silicon carbide powder, 2-3 parts of molybdenum disulfide, 0.2-0.5 part of hafnium powder and 85-100 parts ofaluminum powder. The invention further discloses a preparation method of the composite piston material. The preparation method includes the following steps that (1) the raw materials are weighed; (2)the silicon powder, the magnesium powder, the titanium powder, the yttrium powder, the hafnium powder and the aluminum powder are ball-milled, sieved and mixed; (3) the silicon carbide powder is heated and kept warm to fully react with oxygen, and then silicon dioxide is formed on the surface layer; and (4) a mixed raw material is heated, degassed, kept warm and then cooled, then the molybdenum disulfide and the silicon carbide are added, stirring is performed, and the composite piston material is obtained. According to the composite piston material and the preparation method thereof, alloy elements which have large influences on the high temperature property and the abrasion resistance are added according to a certain proportion to adjust the matching ratio, so that the high temperature strength and the abrasion resistance of the material are improved.

Owner:安徽宝泰汽车部件有限公司

Method for preparing aluminum-silicon alloy by using high-iron-content ZL102 infiltrated aluminum alloy and aluminum-silicon alloy

The invention provides a method for preparing an aluminum-silicon alloy by using a high-iron-content ZL102 infiltrated aluminum alloy and the aluminum-silicon alloy. Technical problems that a recoveryrate of a process for recycling high-iron-content ZL102 is only 1%, but a yield of the high-iron-content ZL102 is 5%, the recovery rate is low, and economic losses are large in the prior art are solved. The method comprises the following steps of (1) adding manganese into the ZL102 infiltrated aluminum alloy with a high iron content and remelting to obtain a remelted ZL102 ingot with a refined iron phase; and (2) preparing the aluminum-silicon alloy. After the manganese is added into the ZL102 alloy with the high iron content and remelting is performed, and an iron phase structure is shortened and thinned so as to obtain the remelted ZL102 ingot with a refined iron phase; an adding amount can reach 5% of total weight of the aluminum-silicon alloy and can be completely counteracted with output, the recovery rate is greatly increased, and the economic losses are avoided.

Owner:成都银河动力有限公司

Tungsten-containing composite piston material, and preparation method thereof

The invention discloses a tungsten-containing composite piston material comprising, by weight, 5-6 parts of silicon powder, 0.6-0.9 part of magnesium powder, 0.15-0.35 part of manganese powder, 0.1-0.2 part of tungsten powder, 8-10 parts of silicon carbide powder, 4-5 parts of molybdenum disulfide, 0.6-0.8 parts of hafnium powder and 90-98 parts of aluminum powder. The invention further disclosesa preparation method of the tungsten-containing composite piston material. The preparation method comprises the step (1) of weighing raw materials; the step (2) of ball-milling, sieving and mixing thesilicon powder, the magnesium disulfide, the manganese powder, the tungsten powder, the hafnium powder and the aluminum powder; the step (3) of heating the silicon carbide powder and holding the temperature, and forming silicon dioxide on the surface layer after the silicon carbide powder reacts with oxygen fully; the step (4) of heating and degassing the mixed materials, holding the temperatureand cooling the mixed materials again, then adding the molybdenum disulfide and the silicon carbide to the mixed materials, and stirring the mixtures so that the tungsten-containing composite piston material is obtained. According to the tungsten-containing composite piston material and the preparation method thereof, by adding alloy elements with great influence on high-temperature performance and wear resistance proportionally and adjusting the proportion, the high-temperature strength and wear resistance of the materials are improved.

Owner:安徽宝泰汽车部件有限公司

Pipe material used for transmission layer of flexible oil gathering and transportation pipeline in oil field and preparation method thereof

ActiveCN105985624BHigh temperature tensile strengthImprove wear resistanceTransport layerPolystyrene

The invention relates to a pipe material used for oilfield flexible oil gathering and transporting pipe transport layers. The pipe material comprises, by mass, 5-15 parts of an ethylene-vinyl alcohol copolymer, 10-30 parts of nylon, 20-60 parts of polyphenyl ether, 5-15 parts of a compatilizer and 4-8 parts of a flexibilizer, wherein the nylon is one or a mixture of PA6 and PA66, the compatilizer is polystyrene / polyphenyl ether grafted maleic anhydride, and the flexibilizer is a polystyrene / hydrogenated styrene-butadiene-styrene copolymer grafted maleic anhydride. The material has the advantages of high high-temperture tensile strength, good oil resistance, good flexibility and excellent processing performances, and can meet oil well outlet use requirements.

Owner:CHANGZHOU UNIV

a ti 2 Medium-temperature ZR-based brazing filler metal for Alnb-based alloy homogeneous or dissimilar materials and its preparation method and brazing process

ActiveCN111702281BImprove wettabilityImprove liquidityWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalHigh heat

The invention belongs to the field of welding, in particular to a Ti 2 The invention relates to a medium-temperature Zr-based solder special for brazing of the same material or different materials of AlNb-based alloys, a preparation method thereof, and a brazing process. In terms of weight percentage, the composition and content of the solder are: Fe 5% to 30%, Nb 1% to 15% or Cu 1% to 20%, choose one of the two, and a small amount of elements Al, B, Co, Cr , one or more of Mn, Mg, Ni, Ag and Zn≤5%, one or more of trace elements Ti, Hf, V, Ta, Mo, W, Au, Si, Sn, Pd, Ga≤ 2%, the rest is Zr element and unavoidable impurity elements. The preparation method of brazing material: 1. Weighing the raw materials; 2. Melting the master alloy of the brazing material; The brazing material of the present invention is brazed according to the brazing process of 960 DEG C to 1030 DEG C and 0 to 120 minutes. Compared with the existing solder, the brazing filler metal prepared by the invention has suitable melting point, excellent wettability and high-temperature mechanical properties, and the brazing filler metal preparation and brazing process are simple.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Lanthanum-containing composite piston material, and preparation method thereof

The invention discloses a lanthanum-containing composite piston material comprising, by weight, 10-13 parts of silicon powder, 1-2 parts of magnesium powder, 0.1-0.2 part of lanthanum powder, 5.2-5.8parts of silicon carbide powder, 1.2-1.8 parts of molybdenum disulfide, 0.15-0.18 part of hafnium powder and 74-84 parts of aluminum powder. The invention further discloses a preparation method of thelanthanum-containing composite piston material. The preparation method comprises the step (1) of weighing raw materials; the step (2) of ball-milling, sieving and mixing the silicon powder, the magnesium disulfide, the lanthanum powder, the hafnium powder and the aluminum powder; the step (3) of heating the silicon carbide powder and holding the temperature, and forming silicon dioxide on the surface layer after the silicon carbide powder reacts with oxygen fully; and the step (4) of heating and degassing the mixed materials, holding the temperature and cooling the mixed materials again, thenadding the molybdenum disulfide and the silicon carbide to the mixed materials, and stirring the mixtures so that the lanthanum-containing composite piston material is obtained. According to the lanthanum-containing composite piston material and the preparation method thereof, by adding alloy elements with great influence on high-temperature performance and wear resistance proportionally and adjusting the proportion, the high-temperature strength and wear resistance of the materials are improved.

Owner:安徽宝泰汽车部件有限公司

High-toughness austenite boiler steel

The invention discloses high-toughness austenite boiler steel belonging to the technical field of austenite boiler steel. The boiler steel comprises the following chemical constituents: 0.025-0.038 wt% of C, 0.20-0.40 wt% of Si, less than or equal to 2.00 wt% of Mn, less than or equal to 0.045 wt% of P, less than 0.03 wt% of S, 20-21.5 wt% of Ni, 0.15-0.20 wt% of N, 0.30-0.40 wt% of Nb, 0.0010-0.050 wt% of element B, 0.020-0.15 wt% of element V and the balance of Fe. The invention has the advantages that when the high-toughness austenite boiler steel is compared with S31042 steel, two alloy elements of B and V are added, and the ingredient range of C, Nb, N, Si, Cr, Ni and other elements is adjusted, so that the high-toughness austenite boiler steel has the characteristics of reasonable constituent design and high toughness. After long aging at 700 DEG C, compared with the S31042 steel subject to same heat treatment, the high-toughness austenite boiler steel has higher room-temperature impact toughness, and tensile strength at high temperature of 700 DEG C is comparative or slightly higher.

Owner:CENT IRON & STEEL RES INST

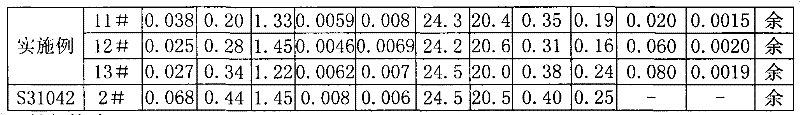

A kind of multi-element rare earth magnesium alloy and preparation method thereof

ActiveCN103146972BIncrease usage intensityWith anomalous temperature effectRare earthRoom temperature

The invention discloses a multielement rare-earth magnesium alloy and a preparation method thereof. The multielement rare-earth magnesium alloy comprises the following components in percentage by mass: 2%-6% of Gd, 2%-3% of Y, 1%-2.5% of Nd, 0.5-1.5% of Sm, 0.4%-0.8% of Sb, less than 0.02% of total impurity elements, namely Si, Fe, Cu and Ni, and the balance of Mg. The multielement rare-earth magnesium alloy disclosed by the invention has the composition of Mg-Gd-Y-Nd-Sm-Sb, and has high high-temperature tensile strength and stable high-temperature performance as well as an abnormal temperature effect in the range from a room temperature to 250 DEG C. Compared with a commercial heat-resisting magnesium alloy WE54, the multielement rare-earth magnesium alloy has higher high-temperature tensile strength and operating temperature and has wide application prospect in fields such as aerospace, automobile industries and weaponry.

Owner:HENAN UNIV OF SCI & TECH

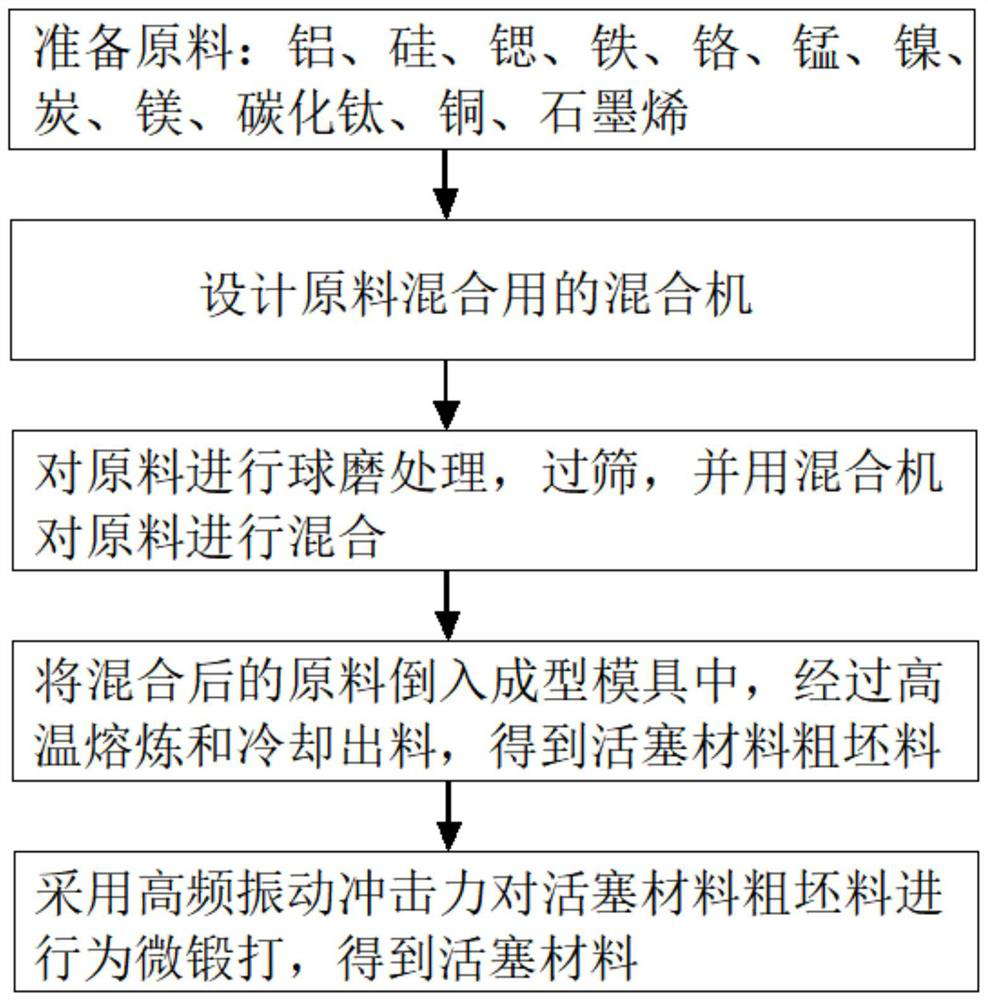

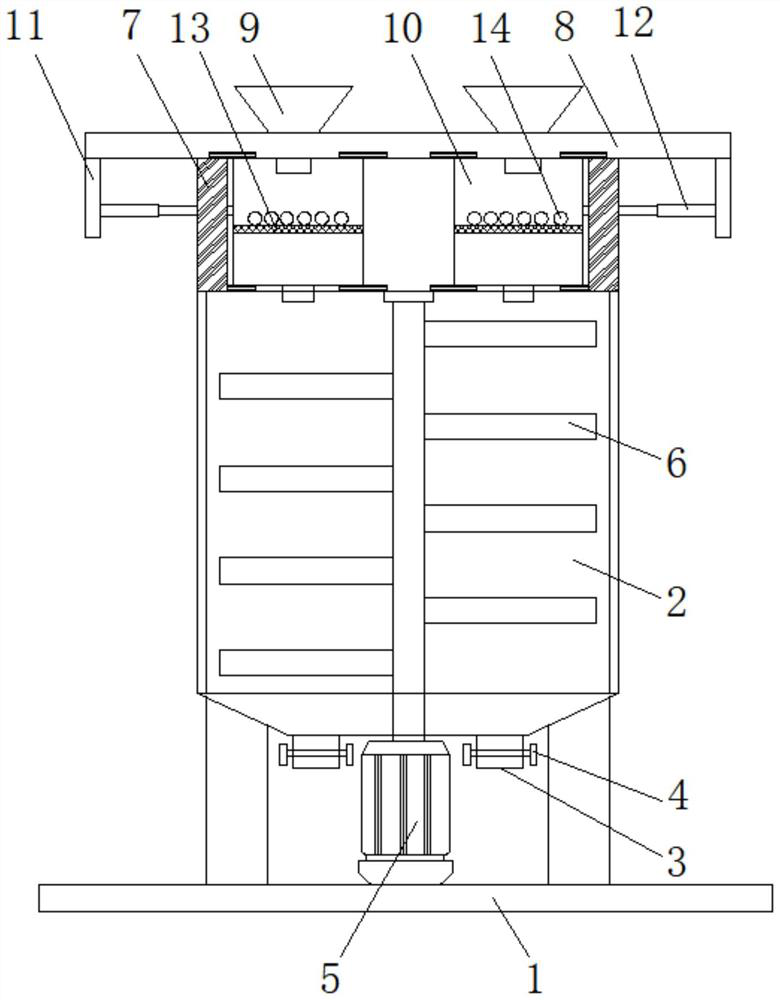

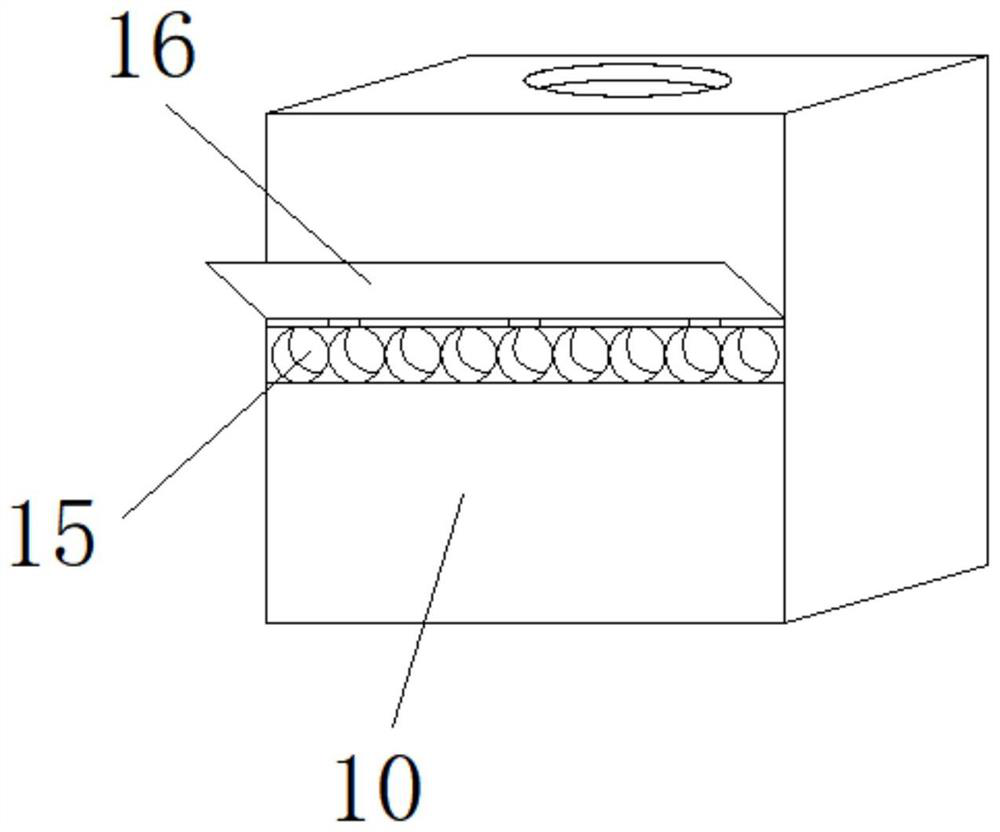

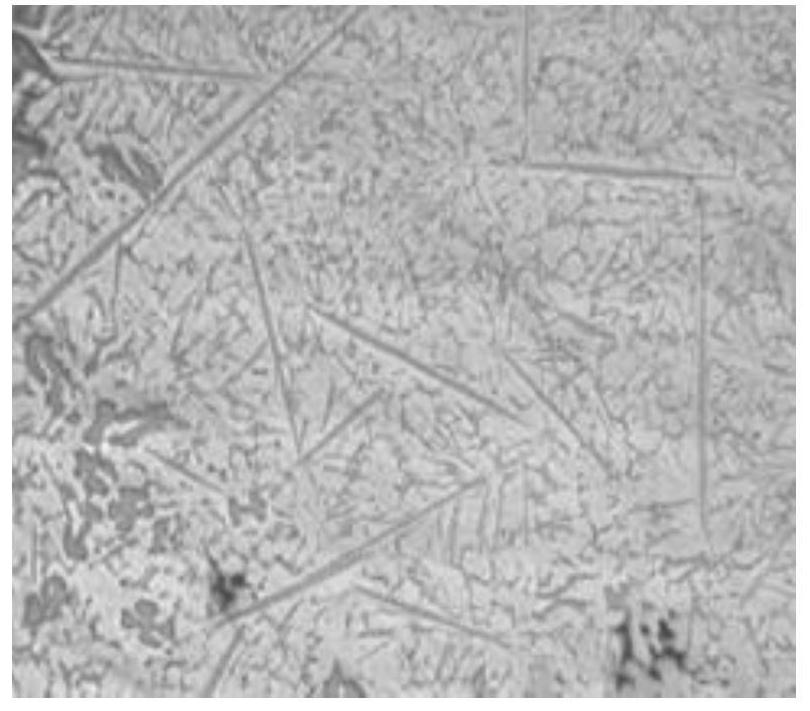

Method for preparing brake servo piston material

InactiveCN112195372AHigh temperature tensile strengthImprove structural strengthManganeseTitanium carbide

The invention discloses a method for preparing a brake servo piston material. The method comprises the steps of: preparing raw materials such as aluminum, silicon, strontium, iron, chromium, manganese, nickel, carbon, magnesium, titanium carbide, copper and graphene; designing a mixer for mixing the raw materials; carrying out ball milling treatment on the raw materials, carrying out screening, and mixing the raw materials by using the mixer; pouring the mixed raw materials into a molding mold, and carrying out high-temperature smelting and cooling discharging to obtain a piston material roughblank; and carrying out micro forging on the piston material rough blank by adopting high-frequency vibration impact force to obtain a piston material. The high-temperature tensile strength of the piston material prepared through the method reaches 98.61 MPa, and the structural strength is obviously improved; through optimization design of the structure of the mixer for mixing the raw materials,the condition that the raw materials of multiple alloying elements can be evenly mixed can be ensured, and the internal structure of the piston material is compact, uniform and stable; and micro forging is carried out on the piston material rough blank by adopting the high-frequency vibration impact force, so that the fatigue strength of the piston material can be improved.

Owner:ZHEJIANG JIAMIN PLASTIC

Nano and submicron aluminum oxide mixing enhanced copper-base composite material and preparation method thereof

The invention discloses a nano- and sub-micron aluminum oxide hybrid reinforced copper matrix composite material and a preparation method thereof. The metallic copper contains nano-alumina particles with a size and a volume fraction of 10-50 nm and 0.5-2.5% respectively, and the size and The volume fractions are respectively 0.1-0.9 μm and 5-10% of submicron alumina particles. The preparation method is to mix Cu-0.5wt% Al alloy powder and CuO powder, oxidize it into a prefabricated block after vacuum heating, and preheat it. After mixing the Al powder and CuO powder, they are added to the copper liquid to react in situ to form submicron alumina particles. Under vacuum and pressure, the copper liquid is infiltrated into the porous prefabricated block and formed after solidification. The strength, electrical conductivity, plasticity and other comprehensive properties of the material of the present invention are superior to traditional single-size reinforced materials, realizing near-net shape of complex shapes and large-sized parts, low cost, improved comprehensive properties of materials, and improved efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing aluminum-silicon alloy and aluminum-silicon alloy by using zl102 infiltrated aluminum alloy with high iron content

The invention provides a method for preparing aluminum-silicon alloy and aluminum-silicon alloy by using high-iron-content ZL102 infiltrated aluminum alloy, which solves the process of recovering high-iron-content ZL102 in the prior art, and the recovery rate is only 1%. Iron amount ZL102 output rate has 5%, and recovery rate is low, and the technical problem of economic loss is bigger. The method comprises the following steps: (1) remelting ZL102 infiltrated aluminum alloy with high iron content by adding manganese to obtain remelted ZL102 ingot with refined iron phase; (2) preparing aluminum-silicon alloy. In the present invention, after the ZL102 alloy with high iron content is remelted with manganese, the iron phase structure becomes shorter and thinner, and a remelted ZL102 ingot with a refined iron phase is obtained; the addition amount can reach 5% of the total weight of the aluminum-silicon alloy, which can completely And output offset, greatly improving the recovery rate, avoiding economic losses.

Owner:成都银河动力有限公司

Strontium-containing composite piston material and preparation method thereof

InactiveCN108277402AHigh temperature tensile strengthImprove thermal conductivityOxygenSilicon dioxide

The invention discloses a strontium-containing composite piston material. The strontium-containing composite piston material comprises, by weight part, 11-15 parts of silicon powder, 0.5-0.8 part of magnesium powder, 0.05-0.09 part of titanium powder, 0.2-0.7 part of strontium powder, 8-12 parts of silicon carbide powder, 5-7 parts of molybdenum disulfide, 0.3-0.6 part of hafnium powder and 75-85parts of aluminum powder. The invention further discloses a preparation method of the strontium-containing composite piston material. The preparation method comprises the steps of 1, weighing raw materials; 2, conducting ball milling, sieving and mixing on the silicon powder, the magnesium powder, the titanium powder, the strontium powder, the hafnium powder and the aluminum powder; 3, conductingheating and heat preservation on the silicon carbide powder, and making the silicon carbide powder react with oxygen completely, so that silicon dioxide is formed on a surface layer; and 4, conductingheating, degassing and heat preservation on the mixed raw materials, then lowering the temperature, subsequently adding the molybdenum disulfide and silicon carbide, and conducting stirring. According to the strontium-containing composite piston material and the preparation method thereof, alloy elements which produce great influence on the high temperature performance and the wear resistance areadded according to certain ratios, and the mixing ratios are adjusted, so that the high temperature strength and wear resistance of the material are improved.

Owner:安徽宝泰汽车部件有限公司

High-strength and high-conductivity copper alloy material

ActiveCN102392154BImprove high temperature softening performanceAvoid crackingHardnessUltimate tensile strength

Embodiments of the invention disclose a high-strength and high-conductivity copper alloy material, comprising by mass: 1.3%-1.5% of Cr, 0.4%-0.5% of Zr, 30% of Zn, and the balance Cu as well as inevitable impurities. The material can further include one or several of Zn, Fe, Mg and Ni. The material of the invention improves the high temperature softening resistance of products, and can prevent cracking caused by reduced material strength due to temperature rise. While ensuring high high-temperature tensile strength, yield strength and hardness, the material provided in the invention can simultaneously maintain high electroconductivity and heat conductivity.

Owner:RAOPING YUEXING COPPER PROCESSING CO LTD

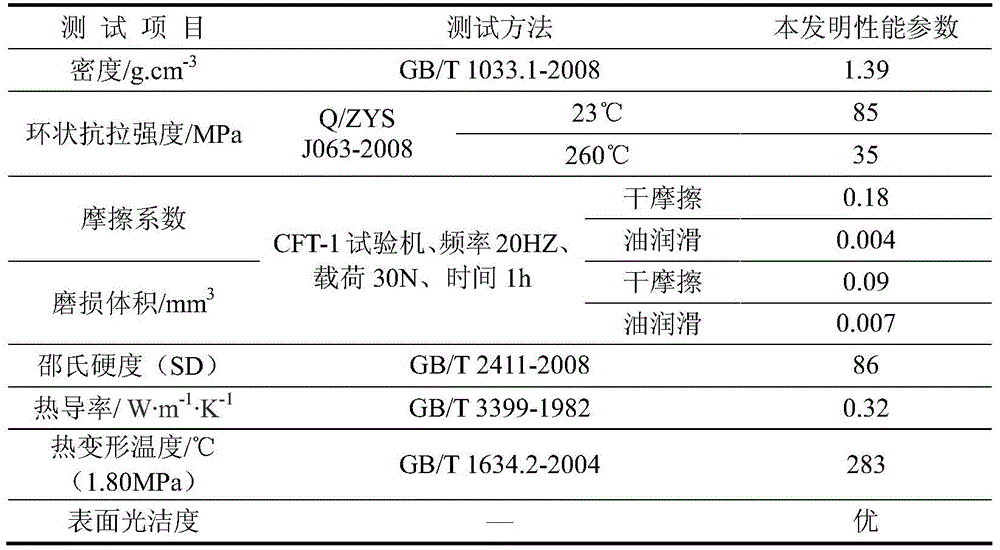

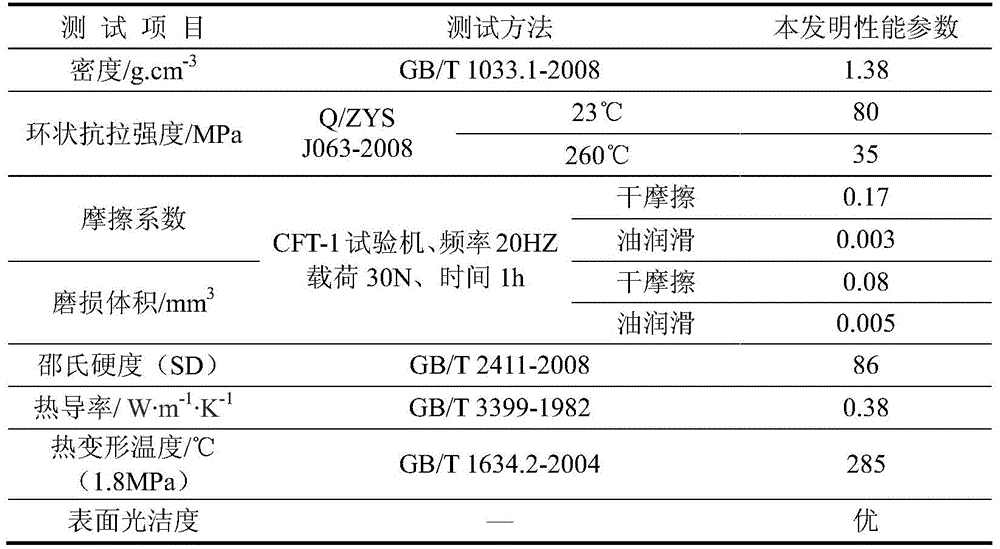

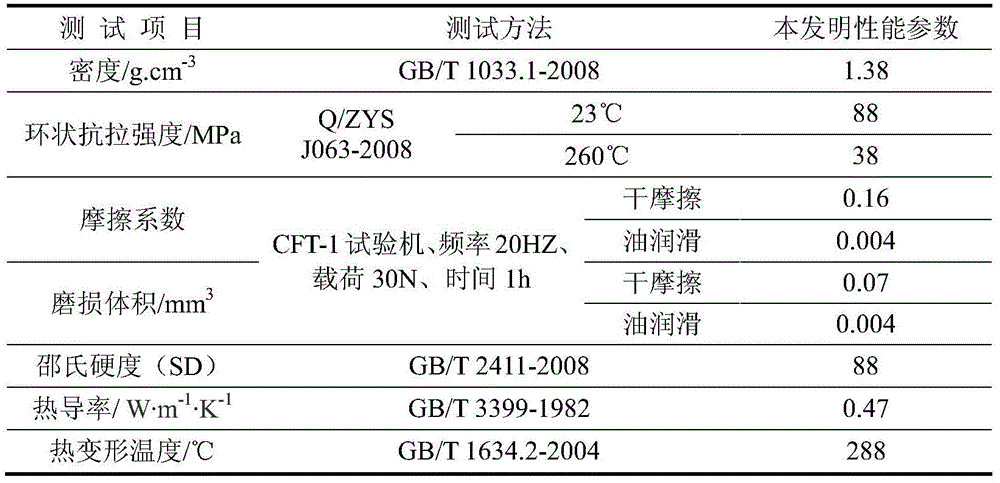

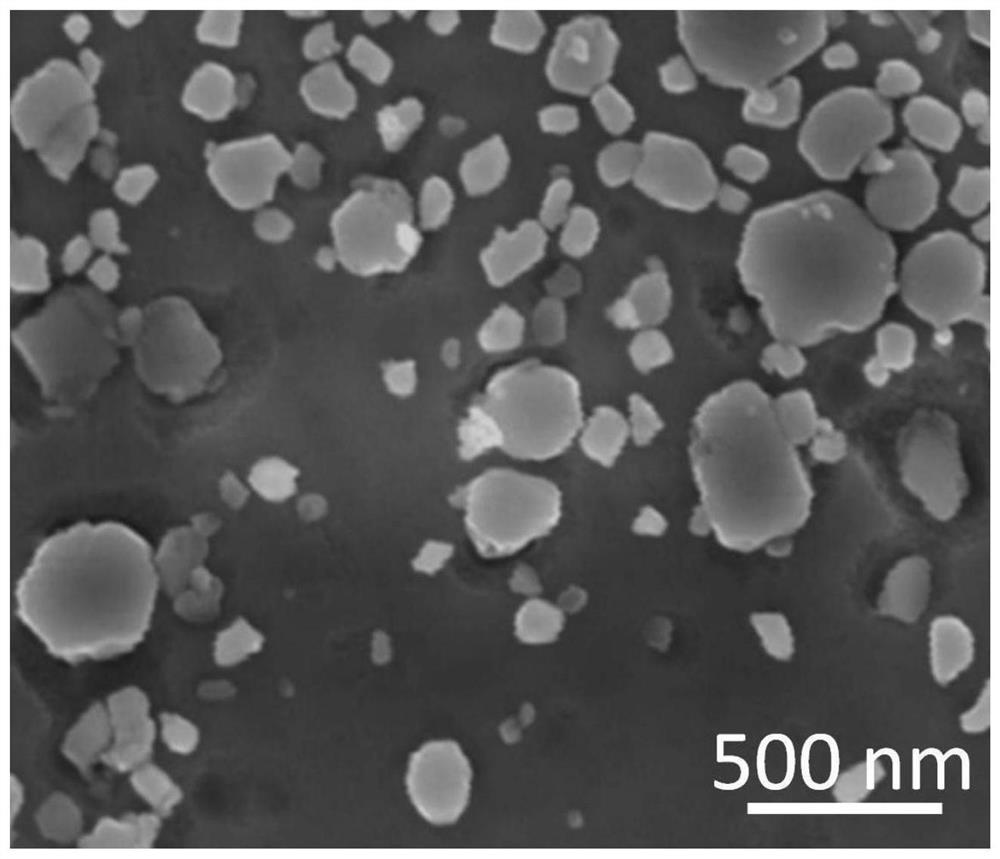

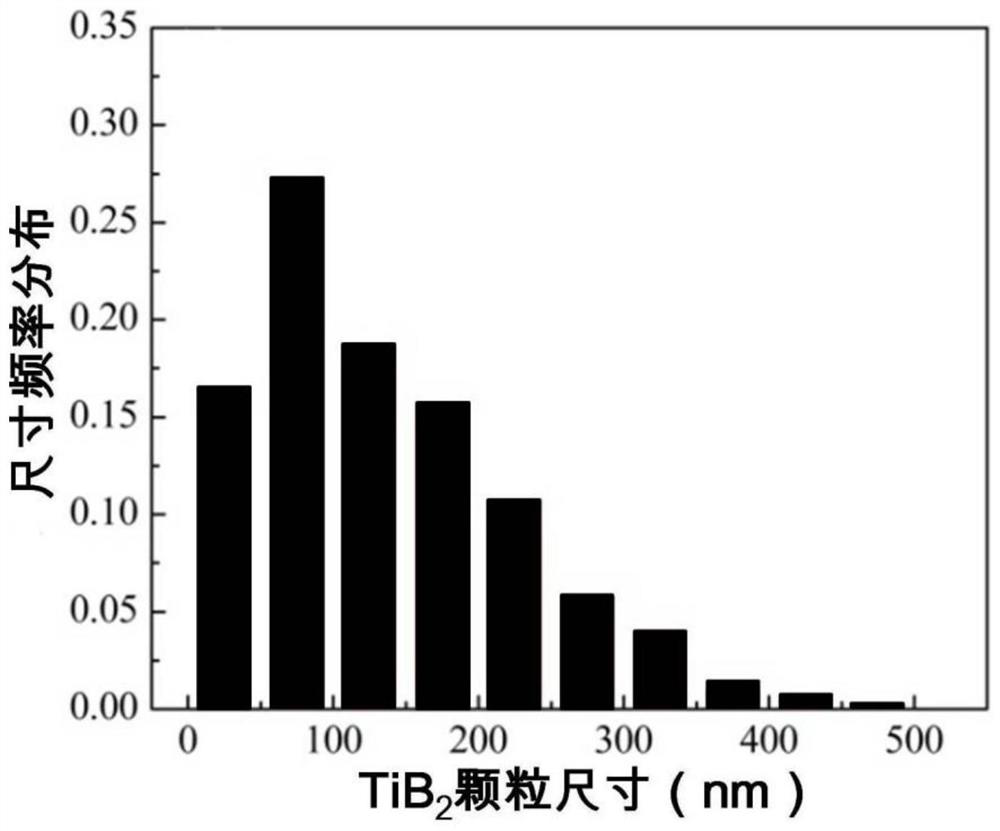

A method for improving the heat resistance of ether anhydride type polyimide cage blank

The invention discloses a method used for increasing hear resistance of ketone-anhydride type polyimide retainer tube blank, and belongs to the field of engineering plastic retainer technology. The method comprises steps of preparation of a retainer tube blank material, drying, mixing, hot press molding, and annealing treatment. According to the method, the retainer tube blank material is subjected to drying and mixing, and then is subjected to hot press molding using a programmed type thermocompressor so as to obtain ketone-anhydride type polyimide composite retainer tube blank; and then the obtained ketone-anhydride type polyimide composite retainer tube blank is subjected to annealing treatment. The obtained ketone-anhydride type polyimide composite retainer tube blank is light, and high temperature tensile strength, tribological properties, and heat resistance are improved effectively.

Owner:LUOYANG BEARING RES INST CO LTD

Aluminum-based composite piston for heavy-duty diesel engine and preparation method thereof

ActiveCN108796316BImprove high temperature resistanceEasy to processMachines/enginesPistonsMechanical engineeringHeavy duty diesel

Owner:ANHUI XIANGBANG COMPOSITE MATERIAL +1

A kind of hot work die steel and preparation method thereof

ActiveCN110343963BIncreased reduction in areaHigh temperature tensile strengthManganeseTitanium carbide

The invention discloses hot work die steel and a preparation method thereof. The hot work die steel is composed of the following constituent elements including, by weight, 0.396%-0.397% of carbon, 0.975%-1.03% of silicon, 0. 427%-0.514% of manganese, 1.55%-1.59% of molybdenum, 4.94%-5.10% of chromium, 0.984%-1.04% of vanadium, 0.044%-0.127% of titanium and the balance iron and inevitable impurities. According to the hot work die steel, the Ti element is added on the basis of H13 steel compositions; on one hand, the effects of controlling the grain size, preventing excessive growth of grains and increasing precipitation strengthening and fine grain strengthening are achieved, and the strength and hardness of the steel are improved; and on the other hand, the titanium reacts with the carbonto generate titanium carbide, the advantages of high hardness and good thermal stability are achieved, the effect of precipitation strengthening is achieved, and micro Ti alloying is formed. The roomtemperature Rockwell hardness, room temperature tensile strength, room temperature tensile section shrinkage, the high-temperature tensile section shrinkage rate and the high-temperature tensile strength of the hot work die steel are significantly improved, and the comprehensive mechanical properties are obviously enhanced.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com