Hot work die steel and preparation method thereof

A technology of hot work die steel and content, applied in the field of new materials, can solve the problems of low heat treatment deformation rate, low area shrinkage rate, low tensile strength, etc., achieve comprehensive mechanical properties enhancement, improve thermal fatigue resistance, and tensile strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

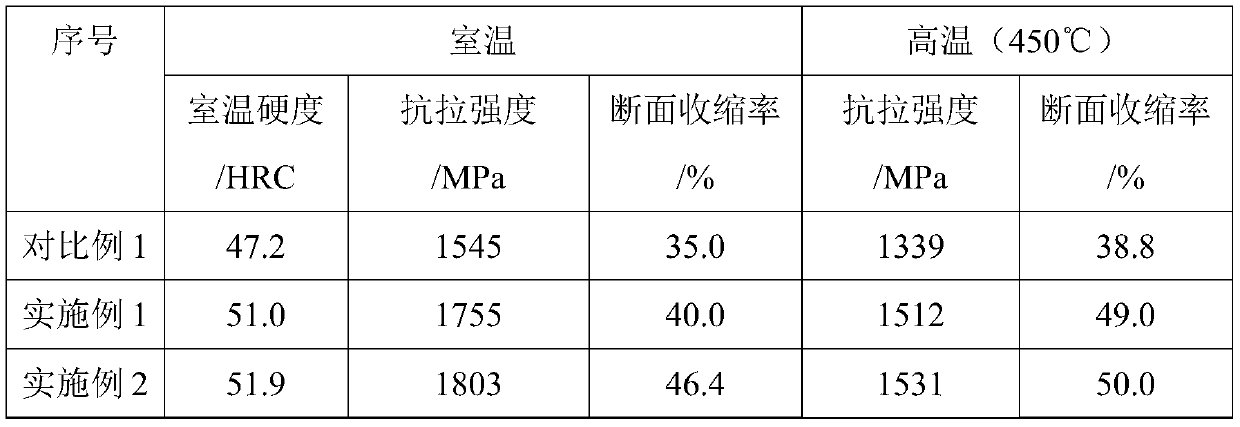

Examples

Embodiment 1

[0028] The hot work die steel of this embodiment is composed of the following constituent elements: carbon 0.397wt%, silicon 1.03wt%, manganese 0.514wt%, molybdenum 1.59wt%, chromium 4.94wt%, vanadium 1.04wt%, titanium 0.044wt% , the balance is iron and unavoidable impurities.

Embodiment 2

[0030] The hot work die steel of this embodiment is composed of the following constituent elements: carbon 0.396wt%, silicon 0.975wt%, manganese 0.427wt%, molybdenum 1.55wt%, chromium 5.10wt%, vanadium 0.984wt%, titanium 0.127wt% , the balance is iron and unavoidable impurities.

[0031] Preparation method embodiment 1 of hot work die steel of the present invention

[0032] The preparation method of the hot work die steel of the present embodiment comprises the following steps:

[0033] (1) The hot work die steel is composed of the following constituent elements: carbon 0.397wt%, silicon 1.03wt%, manganese 0.514wt%, molybdenum 1.59wt%, chromium 4.94wt%, vanadium 1.04wt%, titanium 0.044wt% , the balance is iron and unavoidable impurities; according to the weight percentage of each constituent element in the hot work die steel, the raw materials are industrial pure iron rods, industrial silicon bars, electrolytic manganese, industrial molybdenum bars, metal chromium, vanadium i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com