Two-phase cobalt tantalate ceramic block and preparation method thereof

A technology of ceramic block and tantalic acid, which is applied in the field of two-phase cobalt tantalate ceramic block and its preparation, can solve the problems of poor fracture toughness, limited application, and high thermal conductivity of ceramics, and prevent over-burning and excessive grain growth big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

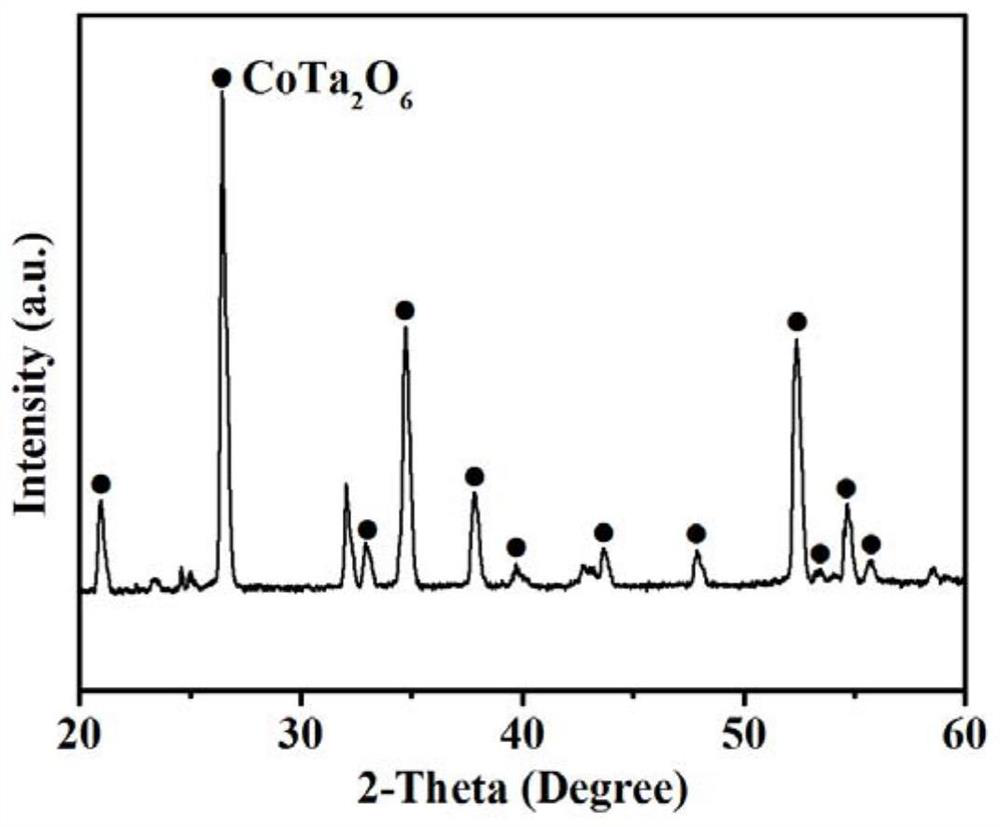

[0026] The invention also discloses a method for preparing a two-phase cobalt tantalate ceramic block. The two-phase cobalt tantalate ceramic block is made of Co 4 Ta 2 o 9 and CoTa 2 o 6 constitute, and Co 4 Ta 2 o 9 and CoTa 2 o 6 The molar ratio is X: (1-X), 1>X>0; Concretely comprises the following steps:

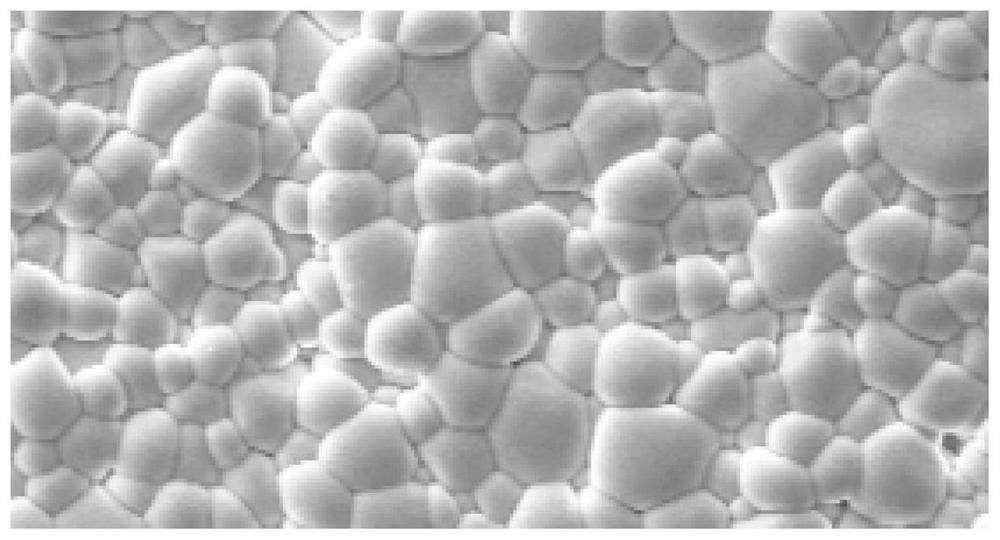

[0027] Cobalt carbonate is calcined and decomposed at a calcining temperature of 430-450°C to obtain cobalt oxide powder; tantalum oxalate is calcined and decomposed at a calcining temperature of 910-920°C to obtain tantalum oxide powder. The thermally decomposed cobalt oxide and tantalum oxide have extremely high activity, which makes the energy and temperature required for the reaction of cobalt oxide and tantalum oxide drop sharply. Original Co 4 Ta 2 o 9 has a lower melting point than CoTa 2 o 6 , after using highly active raw material oxides, the two can be reacted simultaneously at low temperature.

[0028] In the present invention, the single-phase...

Embodiment 1

[0035] After cobalt carbonate and tantalum oxalate are placed in an alumina crucible, they are calcined and decomposed in a medium temperature furnace. The calcination temperature of cobalt carbonate is 450°C, and the holding time is 1 hour; the calcination temperature of tantalum oxalate is 910°C, and the holding time is 1 hour.

[0036] According to (Co 4 Ta 2 o 9 ) 0.2 (CoTa 2 o 6 ) 0.8 Molar ratio Weigh cobalt oxide and tantalum oxide powder raw materials, add absolute ethanol and place them in a grinder for ball milling and mixing while refining the powder particle size, the speed is 2400 rpm, and the grinding and mixing time is 24 hours. After taking it out, it was kept at 80° C. for 7 hours, and powder A was obtained after drying. Directly heat powder A at 860°C for 1 hour to obtain evenly mixed (Co 4 Ta 2 o 9 ) 0.2 (CoTa 2 o 6 ) 0.8 Two-phase powder B.

[0037] Weighed 2.6g of powder B and placed it in a cold isostatic press for compression molding at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com