Rare earth magnesium alloy and preparation method thereof

A technology of rare earth magnesium and magnesium alloys, which is applied in the field of alloy materials, can solve the problems of low high temperature strength and achieve high high temperature tensile strength, high room temperature tensile strength, and improved plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

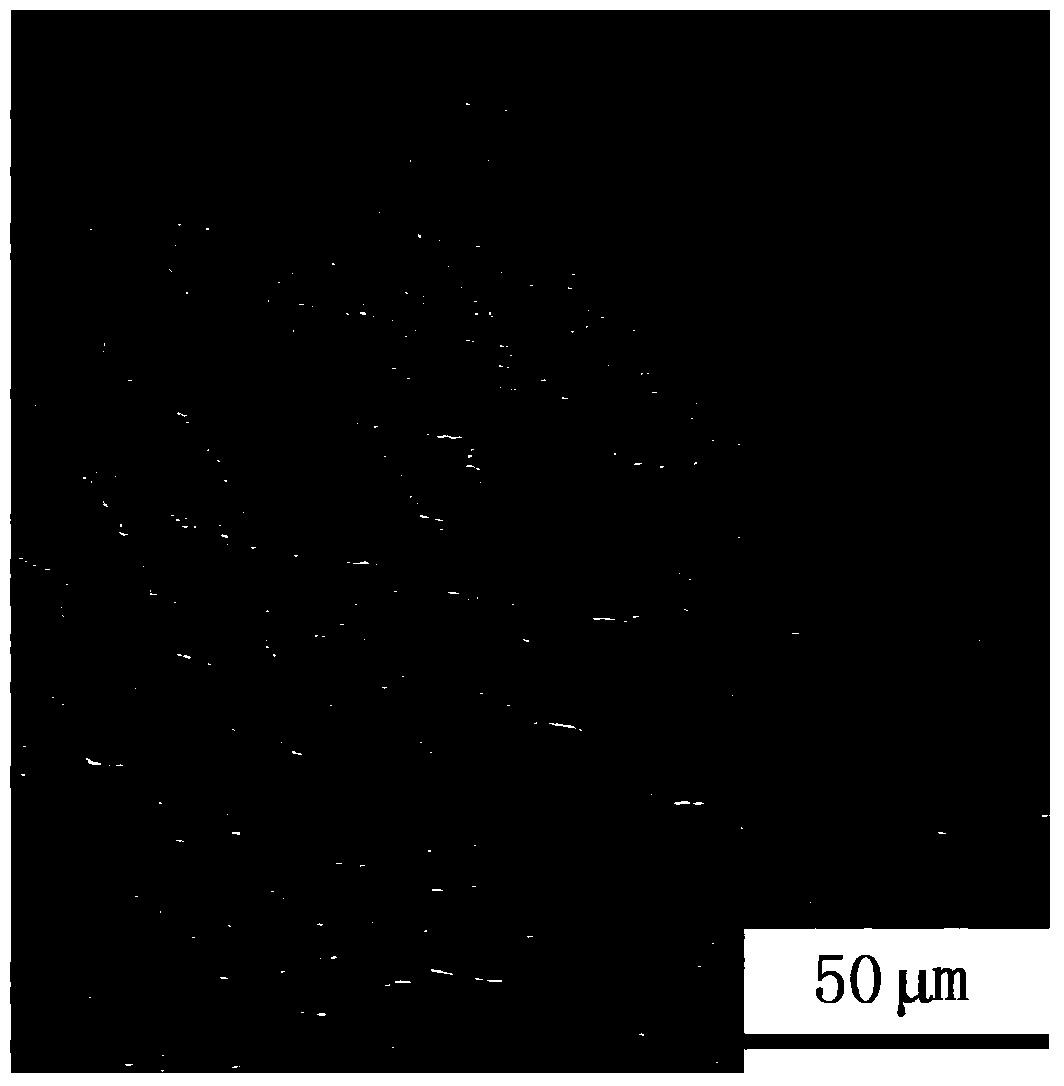

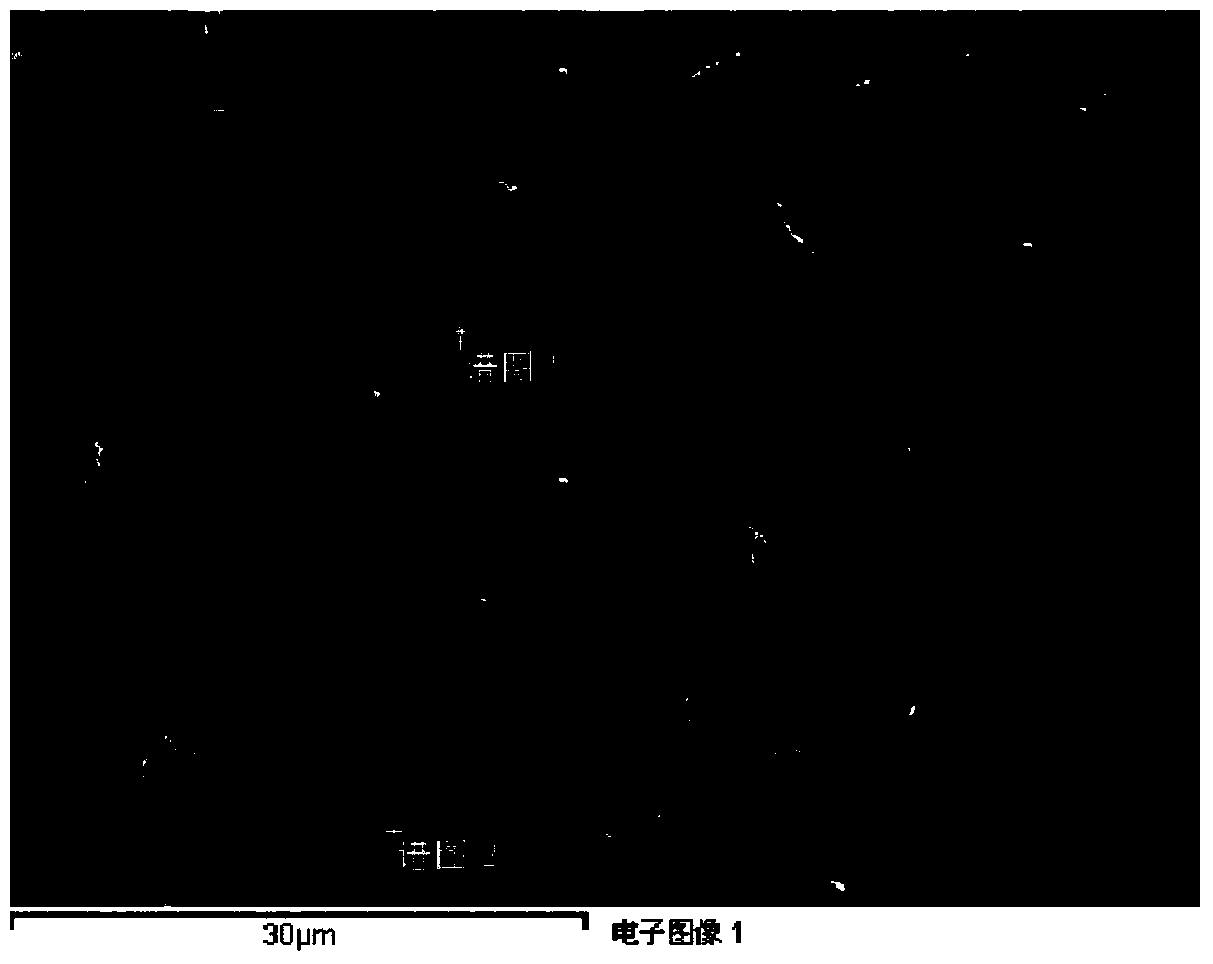

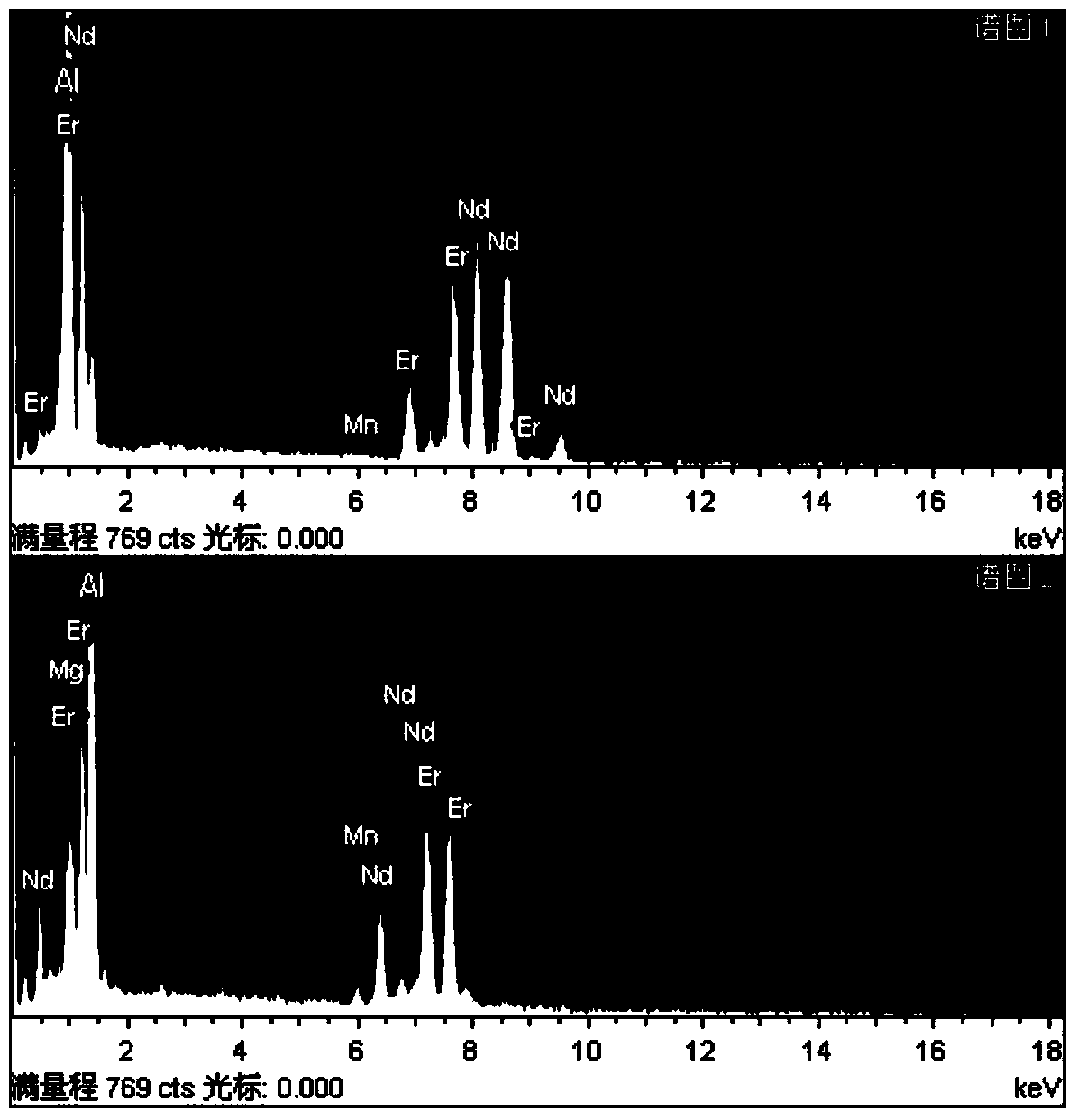

Image

Examples

Embodiment 1

[0030] A kind of rare earth magnesium alloy

[0031] Its composition mass percentage is: Al8.6%, Zn0.89%, Mn0.30%, Nd0.83%, Er0.42%, impurity elements are Si, Fe, Cu, the total content is less than 0.04%, and the rest is Mg.

[0032] A preparation method of a rare earth magnesium alloy, comprising the following steps:

[0033] a) The prepared industrial product AZ91D magnesium alloy, the magnesium neodymium master alloy containing 26.35% Nd and the magnesium erbium master alloy containing 30.6% Er are mixed according to the mass percentage of the above components. The prepared magnesium alloy raw material is placed in an oven and preheated to 150°C.

[0034] The composition and weight percentage of the industrial product AZ91D magnesium alloy: Al is 8.8%, Zn is 0.91%, Mn is 0.32%, impurity elements are Si, Fe, Cu, the total content is less than 0.04%, and the rest is Mg.

[0035] b) The composition and weight percentage of covering agent are: LiCl (analytical pure) is 35%, B...

Embodiment 2

[0046] A kind of rare earth magnesium alloy

[0047] Its composition mass percentage is: Al is 8.7%, Zn is 0.88%, Mn is 0.28%, Nd is 0.39%, Er is 0.41%, impurity elements are Si, Fe, Cu, the total content is less than 0.04%, and the rest is Mg.

[0048] A preparation method of a rare earth magnesium alloy, comprising the following steps:

[0049] Steps a) to g) of this embodiment are the same as steps a) to g) of Embodiment 1.

[0050] The rare earth magnesium alloy of this embodiment has a tensile strength of 218 MPa and an elongation of 3.8% at room temperature; a tensile strength of 169 MPa and an elongation of 7.8% at 175°C.

Embodiment 3

[0052] A kind of rare earth magnesium alloy

[0053] Its composition mass percentage is: Al is 8.4%, Zn is 0.85%, Mn is 0.29%, Nd is 1.21%, Er is 0.43%, impurity elements are Si, Fe, Cu, the total content is less than 0.04%, and the rest is Mg.

[0054] A preparation method of a rare earth magnesium alloy, comprising the following steps:

[0055] Steps a) to g) of this embodiment are the same as steps a) to g) of Embodiment 1.

[0056] The rare earth magnesium alloy of this embodiment has a tensile strength of 228 MPa and an elongation of 3.9% at room temperature; a tensile strength of 174 MPa and an elongation of 7.9% at 175°C.

[0057] The AZ91D-Nd-Er rare earth magnesium alloy prepared in Examples 1-3 and the raw material industrial product AZ91D magnesium alloy were subjected to T6 heat treatment, and the tensile strength was tested at room temperature and 175°C respectively. The results are shown in Table 1 below.

[0058] Table 1

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com