Alkaline-earth element modified heat-resistant magnesium alloy and preparation method thereof

An alkaline earth element, magnesium alloy technology, applied in the field of metal materials, can solve the problem that AS series heat-resistant magnesium alloys are difficult to adapt to industrial application requirements, and achieve the effects of high-temperature tensile strength, improved plasticity, and high room temperature tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

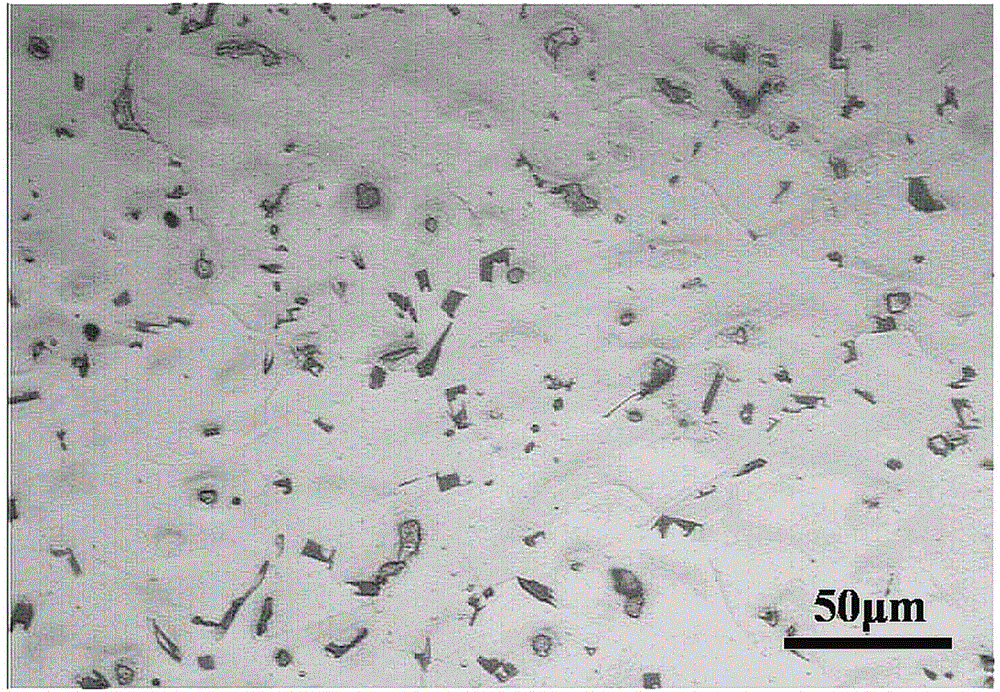

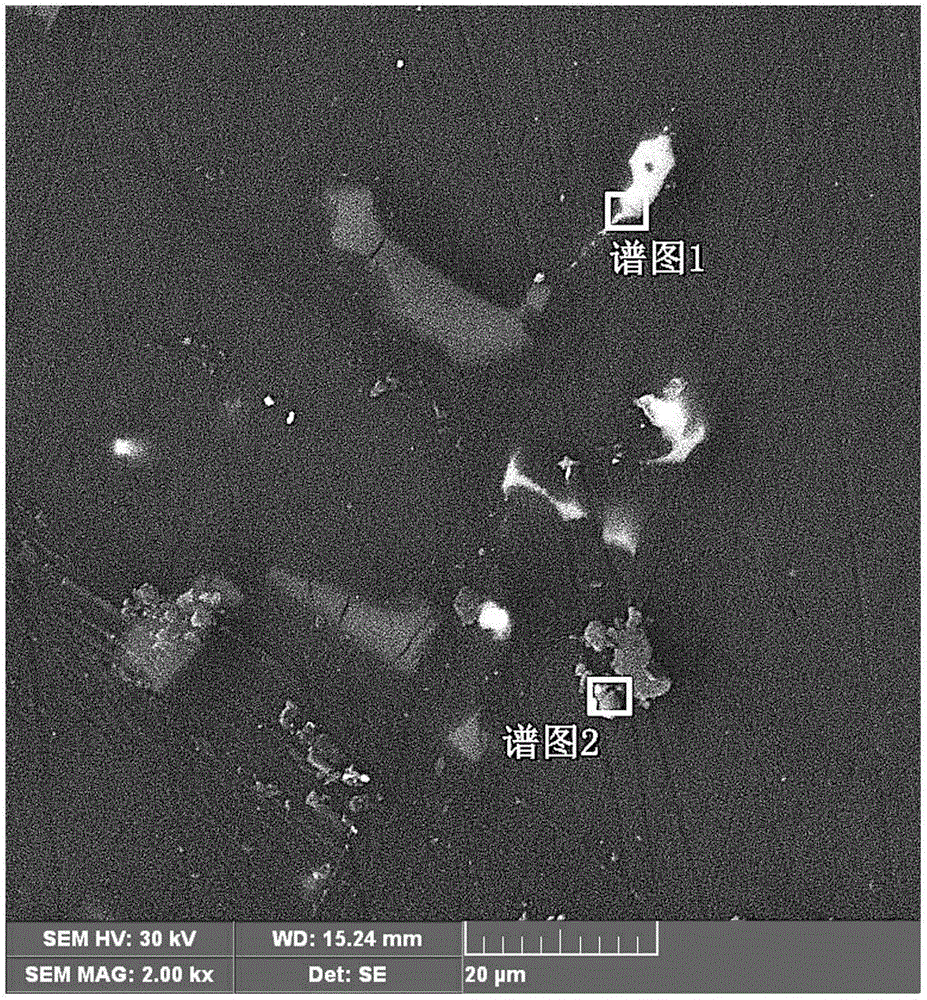

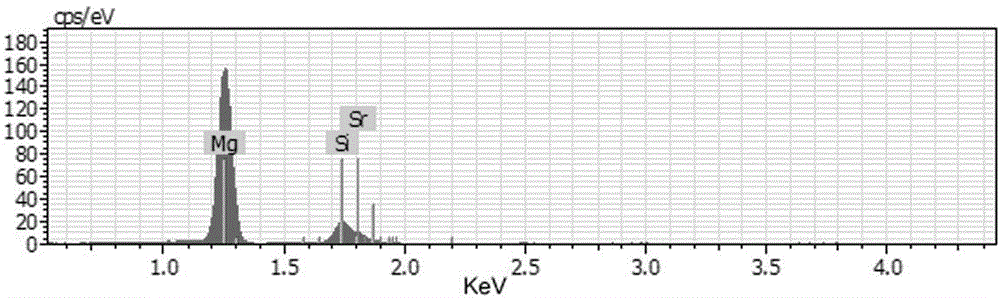

[0028] An alkaline-earth heat-resistant magnesium alloy, the composition mass percent of which is: Al 2.9%, Si 1.1%, Mn 0.09%, Sr 0.2%, the total amount of impurity elements is less than 0.04%, and the rest is Mg.

[0029] A method for preparing an alkaline earth heat-resistant magnesium alloy, comprising the following steps:

[0030] a) Mix industrially pure magnesium ingot (99.97wt.%), pure aluminum ingot (99.95wt.%), magnesium-silicon master alloy (Mg-30Si) and magnesium-strontium master alloy (Al-10Sr) according to the above mass percentage, and Preheat to 130-170 o C;

[0031] b) The above alloys are smelted in a crucible resistance furnace. In order to prevent the oxidation and combustion of the magnesium alloy, the melting and pouring process uses SF 6 +CO 2 Mixed gas protection;

[0032] c) Put the above pure magnesium into the preheated to 200 o C in a mild steel crucible, when the temperature reaches 680 oC When pure magnesium is completely melted, add ...

Embodiment 2

[0040] An alkaline-earth heat-resistant magnesium alloy, the composition mass percentage is: Al 3.3%, Si 1.0%, Mn 0.08%, Sr 0.5%, the total amount of impurity elements is less than 0.04%, and the rest is Mg.

[0041] Steps a) to e) of this embodiment are the same as those of a) to e) of Embodiment 1.

[0042] The alkaline earth heat-resistant magnesium alloy of the present embodiment has a tensile strength of 138MPa at room temperature, a yield strength of 112MPa, and an elongation of 6.1%; at 150 o C The tensile strength under high temperature conditions is 118MPa, the yield strength is 93MPa, and the elongation is 6.8%.

Embodiment 3

[0044] An alkaline-earth heat-resistant magnesium alloy, the composition mass percent of which is: Al 3.1%, Si 1.3%, Mn 0.11%, Sr 1.2%, the total amount of impurity elements is less than 0.04%, and the rest is Mg.

[0045] Steps a) to e) of this embodiment are the same as those of a) to e) of Embodiment 1.

[0046] The alkaline earth heat-resistant magnesium alloy of the present embodiment has a tensile strength of 148MPa at room temperature, a yield strength of 130MPa, and an elongation of 5.5%; at 150 o The tensile strength under high temperature conditions is 126MPa, the yield strength is 109MPa, and the elongation is 6.4%.

[0047] Carry out T6 heat treatment to the AS31J alkaline earth magnesium alloy prepared in embodiment 1-3 and the prior art AS31 magnesium alloy without modification treatment, at room temperature and 150 o The tensile properties were tested under high temperature conditions, and the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com