Vacuum electron beam welding method for low-activation martensitic steel and nuclear fusion reactor

A vacuum electron beam and martensitic steel technology, applied in electron beam welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of low production efficiency, complicated process, high production cost, etc., and achieve weldment deformation Small, simple process, small splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

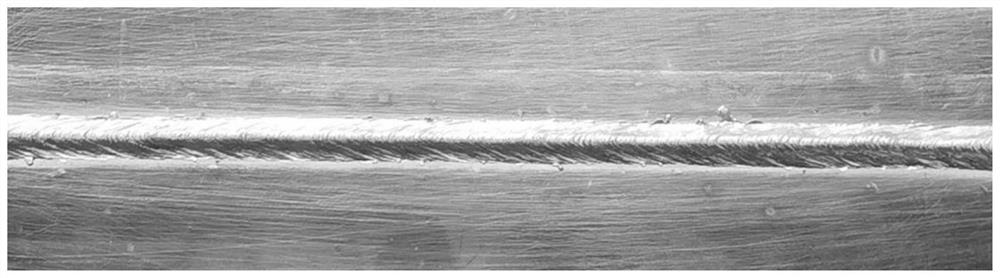

Examples

Embodiment 1

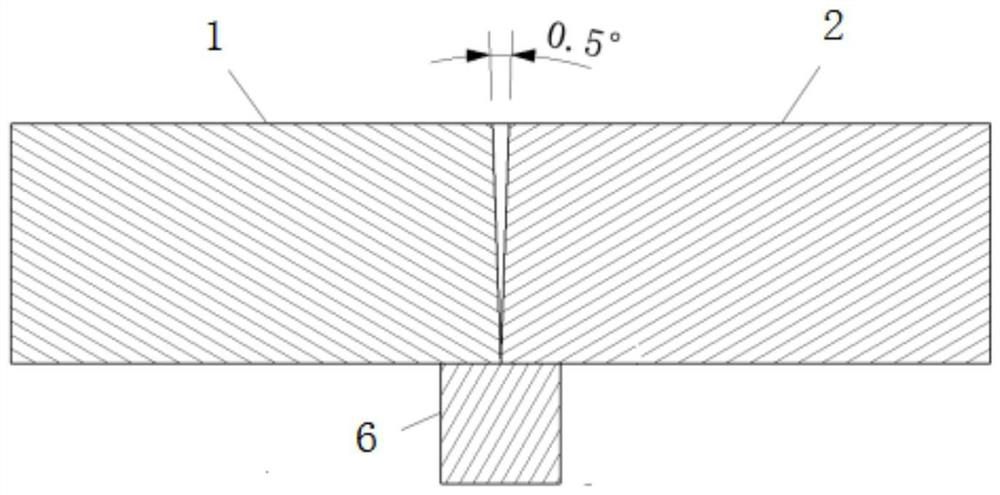

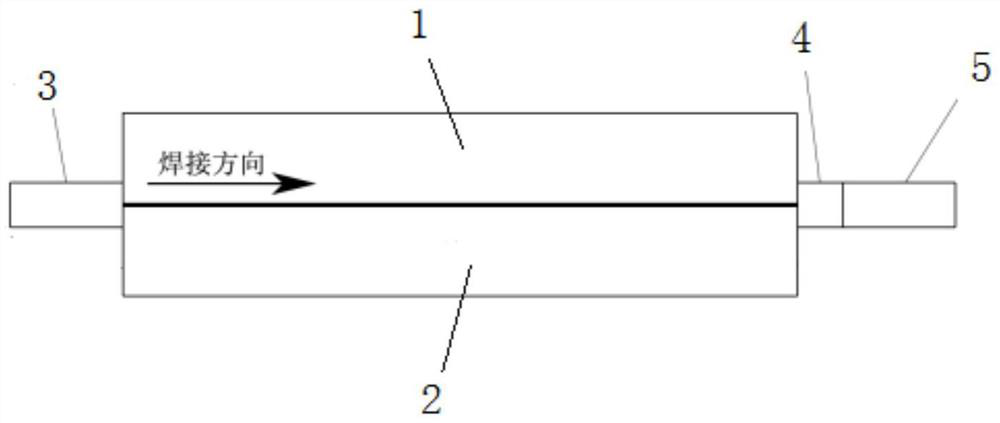

[0029] like figure 1 As shown, the two clam steel plates are strip-shaped, the first steel plate 1 and the second steel plate 2, the plate thickness δ: 20mm, the length 300mm, the width 150mm, and the welding penetration is required;

[0030] A method for vacuum electron beam welding of low-activation martensitic steel provided by this embodiment includes the following steps:

[0031] (1) The adjacent parts to be welded of the two first steel plates 1 and the second steel plate 2 are processed into a V-shaped groove of 0.5° (the effect of the tiny V-shaped groove of 0.5° can alleviate the low activation martensitic steel. The stress concentration of the weld during the welding process, and at the same time of the heat input, can significantly improve the weld penetration compared with the non-groove weld, thereby ensuring that a large weld can be obtained with a very small heat input. Penetration, reducing the risk of weld cracking, and reducing the advantages of deformation ...

Embodiment 2

[0042] The two clam steel plates are strip-shaped, the first steel plate 1 and the second steel plate 2, the plate thickness δ: 4mm, the length 300mm, the width 150mm, and no penetration is required;

[0043] A method for vacuum electron beam welding of low-activation martensitic steel provided by this embodiment includes the following steps:

[0044] (1), the adjacent to-be-welded parts of two first steel plates 1 and second steel plates 2 are processed into a V-shaped groove of 0.5°;

[0045] (2), polish the first steel plate 1 and the second steel plate 2 to be welded and the metal surface in the peripheral 40mm range with fine sandpaper to expose metallic luster;

[0046] (3), use the demagnetizer to demagnetize the first steel plate 1 and the second steel plate 2, and the residual magnetic induction intensity is checked to be 1.5 Gauss;

[0047] (4), clean the first steel plate 1 and the second steel plate 2 with water, and then wipe the surface of the workpiece with a sil...

Embodiment 3

[0055] The difference from Example 1 is that the two clam steel plates are annular clam steel plates with closed welds, the steps are the same as those of Example 1, and the beam attenuation length at the end of the welding is greater than 6 times the penetration depth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com