Novel material for retraction ring of traction motor of high-speed train and preparation method of novel material

A technology for traction motors and high-speed trains is applied in the field of motor rotor material manufacturing, which can solve the problems of high strength, high elongation and high temperature resistance, and achieve the effects of high strength, high room temperature tensile strength, and high high temperature strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

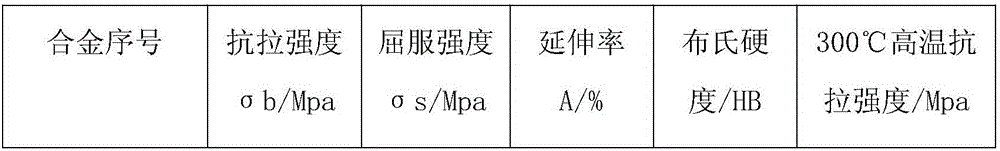

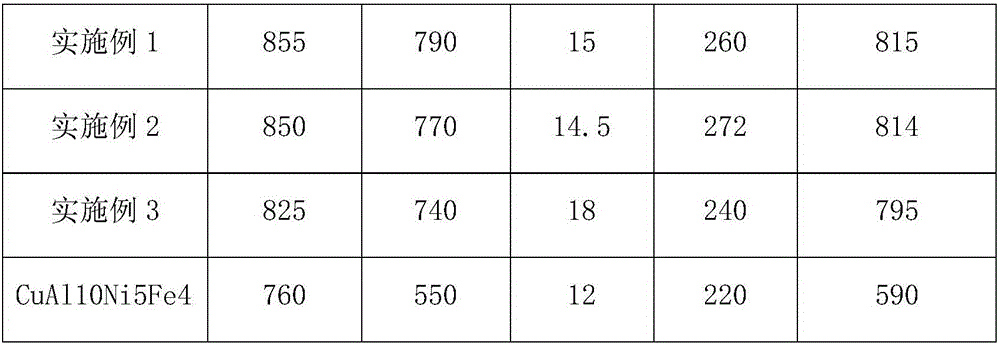

Examples

Embodiment 1

[0030] A new material and a preparation method thereof for a traction motor shrink ring of a high-speed train, the composition and weight percentage of the material are:

[0031] Ni: 13.0%; Al: 1.8%; Mn: 0.5%; Fe: 0.8%; Cu: balance.

[0032] The method for preparing the shrink ring of the traction motor of the high-speed train comprises the following steps:

[0033] (1) Ingredients: Weigh the corresponding raw materials according to the stated ratio. Cu is added by electrolytic copper plate, Ni is added by electrolytic nickel plate, Al is added by pure aluminum block, Fe is added by industrial pure iron, and Mn is added by manganese Join in block mode;

[0034] (2) Melting: Melting in a vacuum intermediate frequency induction furnace, all raw materials are added together during smelting, the smelting process ensures that the vacuum degree is lower than 4Pa, and the melt surface is protected with a covering agent;

[0035] (3) Pouring: After all the alloying elements have bee...

Embodiment 2

[0040] A new material and a preparation method thereof for a traction motor shrink ring of a high-speed train, the composition and weight percentage of the material are:

[0041] Ni: 14.5%; Al: 2.3%; Mn: 1.0%; Fe: 1.3%; Cu: balance.

[0042] The method for preparing the shrink ring of the traction motor of the high-speed train comprises the following steps:

[0043] (1) Ingredients: Weigh the corresponding raw materials according to the stated ratio. Cu is added by electrolytic copper plate, Ni is added by electrolytic nickel plate, Al is added by pure aluminum block, Fe is added by industrial pure iron, and Mn is added by manganese Join in block mode;

[0044] (2) Melting: Melting in a vacuum intermediate frequency induction furnace, all raw materials are added together during smelting, the smelting process ensures that the vacuum degree is lower than 4Pa, and the melt surface is protected with a covering agent;

[0045] (3) Pouring: after all the alloying elements have bee...

Embodiment 3

[0050]A new material and a preparation method thereof for a traction motor shrink ring of a high-speed train, the composition and weight percentage of the material are:

[0051] Ni: 16.0%; Al: 2.8%; Mn: 1.5%; Fe: 1.8%; Cu: balance.

[0052] The method for preparing the shrink ring of the traction motor of the high-speed train comprises the following steps:

[0053] (1) Ingredients: Weigh the corresponding raw materials according to the stated ratio. Cu is added by electrolytic copper plate, Ni is added by electrolytic nickel plate, Al is added by pure aluminum block, Fe is added by industrial pure iron, and Mn is added by manganese Join in block mode;

[0054] (2) Melting: Melting in a vacuum intermediate frequency induction furnace, all raw materials are added together during smelting, the smelting process ensures that the vacuum degree is lower than 5Pa, and the surface of the melt is protected with a covering agent;

[0055] (3) Pouring: After all the alloying elements ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature strength | aaaaa | aaaaa |

| High temperature strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com