Aluminum-based composite piston for heavy-duty diesel engine and preparation method thereof

An aluminum-based composite material, heavy-duty diesel technology, applied in engine components, machines/engines, pistons, etc., can solve the problems of long process flow of pistons and high hidden dangers of thermal stress cracking, and improve its high-temperature mechanical properties and high-temperature tensile strength. Low, the effect of hindering the deformation of the alloy matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A piston of aluminum-based composite material for a heavy-duty diesel engine, the piston includes a piston body, and the piston body is made of an aluminum-based composite material through gravity casting; the piston body is provided with an insert ring and a salt core internal cooling oil road.

[0043] The aluminum-based composite material in this example is made of components by mass percentage: Si 13.5%, Cu 6.6%, Ni4.7%, Mg 1.3%, Fe 0.1%, Mn 0.2%, Zr 0.01%, V 0.01 %, TiB 2 Particles 1%, the balance is Al.

[0044] Its preparation steps are as follows:

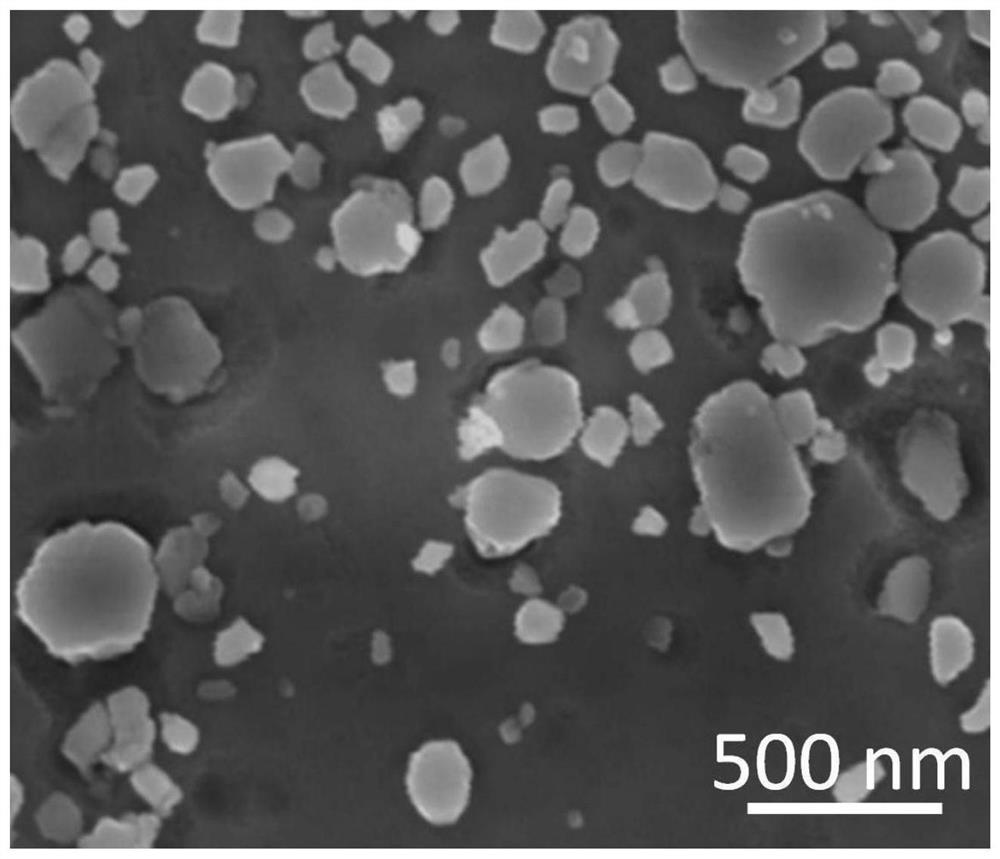

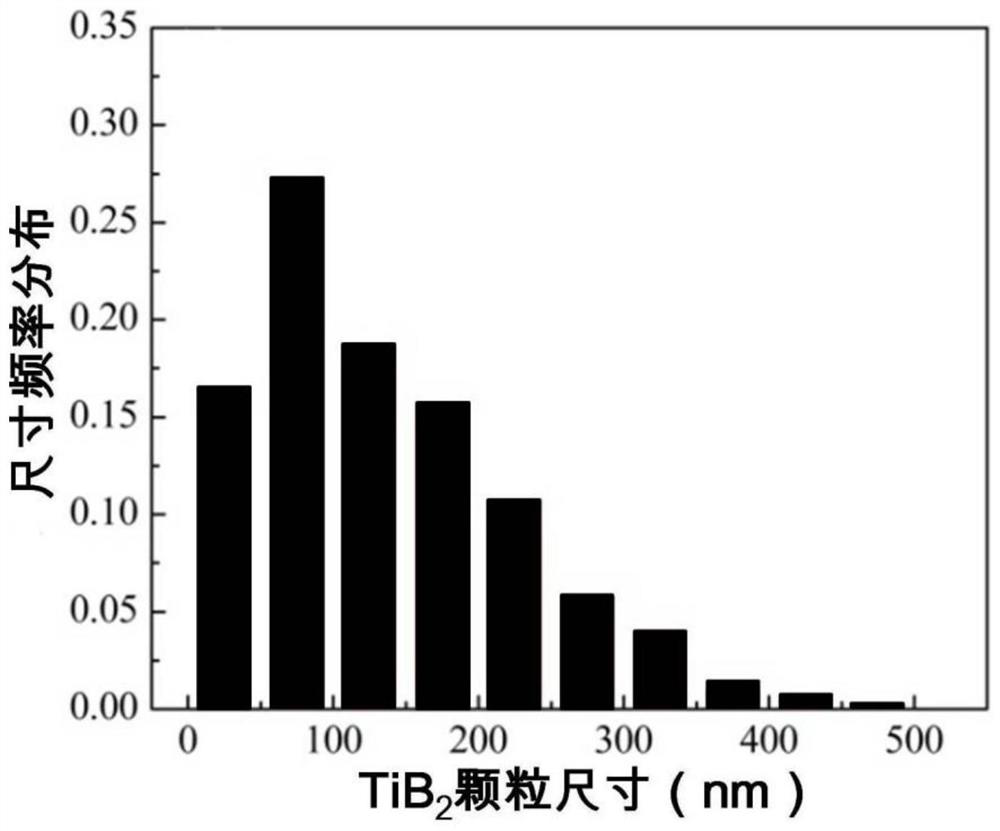

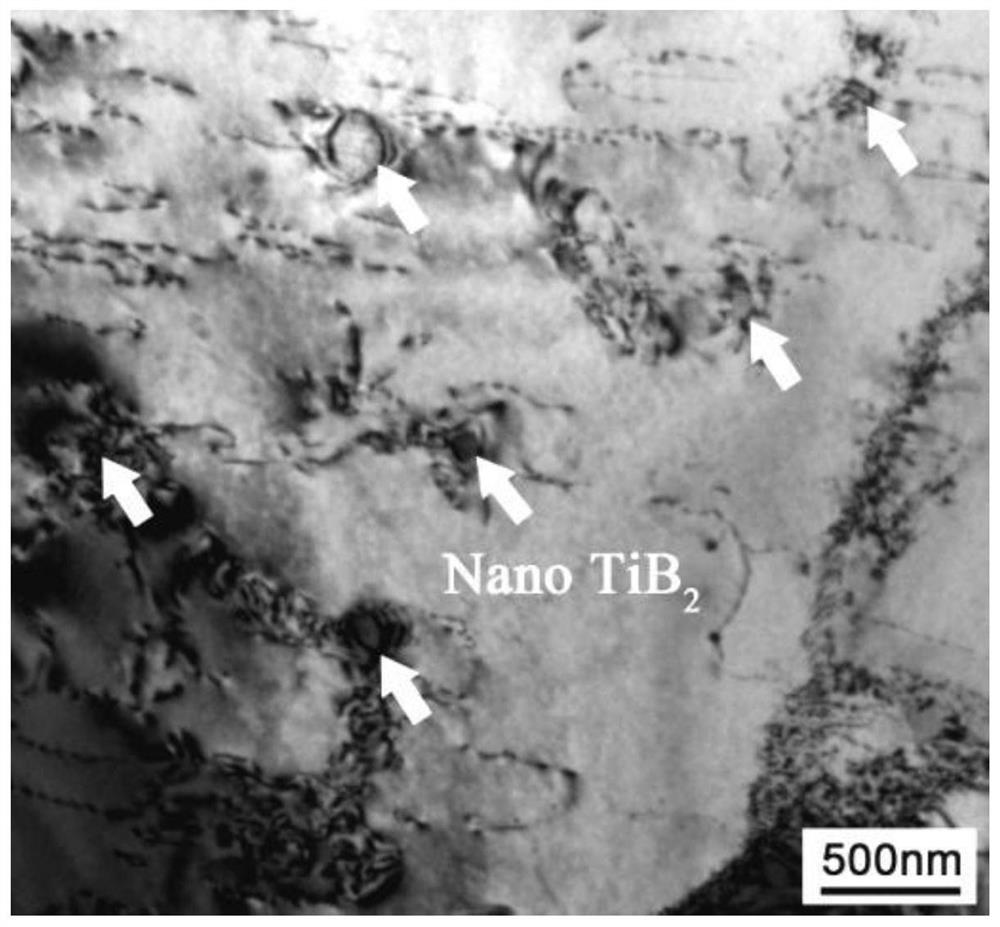

[0045] (A)TiB 2 Granule reinforced pure aluminum composite material masterbatch preparation:

[0046] (1) Prepare a dry crucible, add weighed pure aluminum into the crucible to melt the aluminum ingot, and heat up to 925°C to melt the aluminum ingot;

[0047] (2) Weigh the inorganic salt potassium fluoroborate (KBF 4 ) and potassium fluorotitanate (K 2 TiF 6 ) uniformly mixed according to the mass ratio of 1:...

Embodiment 2

[0059] The aluminum-based composite material in this example is made by mass percentage of components: Si 14%, Cu 6.7%, Ni4.9%, Mg 1.4%, Fe 0.25%, Mn 0.15%, Zr 0.02%, V 0.02 %, TiB 2 Particles 6%, the balance is Al.

[0060] Its preparation steps are as follows:

[0061] (A)TiB 2 Granule Reinforced Pure Aluminum Composite Material Masterbatch Preparation

[0062] (1) Prepare a dry crucible, add weighed pure aluminum into the crucible to melt the aluminum ingot, and heat up to 925°C to melt the aluminum ingot;

[0063] (2) Weigh the inorganic salt potassium fluoroborate (KBF 4 ) and potassium fluorotitanate (K 2 TiF 6 ) uniformly mixed according to the mass ratio of 1:1.8, baked at 210°C for 3 hours and then set aside;

[0064] (3) After the pure aluminum is completely melted, add the dried inorganic salt to the aluminum melt, and carry out mechanical stirring (stirring speed is 100 rpm, the time lasts 30 minutes), and at the same time, argon gas is introduced into the m...

Embodiment 3

[0074] In this example, the aluminum-based composite material is made of components by mass percentage: Si 14.5%, Cu 7%, Ni4.5%, Mg 1.5%, Fe 0.1%, Mn 0.2%, Zr 0.04%, V 0.04 %, TiB 2 12% particles, the balance is Al.

[0075] Its preparation steps are as follows:

[0076] (A)TiB 2 Granule reinforced pure aluminum composite material masterbatch preparation:

[0077] (1) Prepare a dry crucible, add weighed pure aluminum into the crucible to melt the aluminum ingot, and heat up to 925°C to melt the aluminum ingot;

[0078] (2) Weigh the inorganic salt potassium fluoroborate (KBF 4 ) and potassium fluorotitanate (K 2 TiF 6 ) uniformly mixed according to the mass ratio of 1:1.8, baked at 210°C for 3 hours and then set aside;

[0079] (3) After the pure aluminum is completely melted, add the dried inorganic salt to the aluminum melt, and carry out mechanical stirring (the stirring speed is 100 rpm, and the time lasts for 30 minutes), and at the same time, argon gas is introduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com