Method for improving high-temperature strength of Inconel 718 laser deposition layer

A laser deposition, metal powder technology, applied in coating, metal material coating process, transportation and packaging, etc., can solve the problems of difficult to meet the requirements of high-end field equipment, unstable process, low efficiency, etc., to achieve excellent high temperature The effect of friction and wear performance, process stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

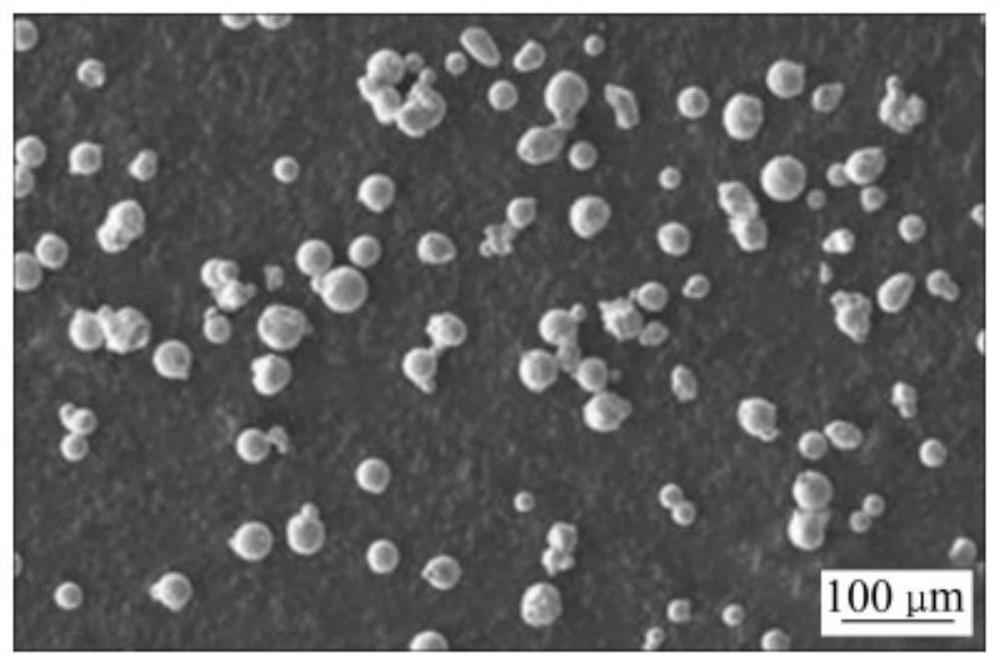

[0023] Example 1, please refer to Figure 1-2 , The present invention provides a technical solution: a metal powder based on Inconel718, including the following components Inconel718 powder, Ti powder, Mo powder and nickel-coated graphite.

[0024] The particle size of Inconel718 powder is 48 μm, the particle size of Ti powder is 70 μm, the mass fraction of nickel in nickel-coated graphite is 70%, and the particle size is 40 μm;

[0025] The weight percentages of the above components are: Inconel718 is 63%, Ti is 12%, Mo powder is 10%, and nickel-coated graphite is 15%.

[0026] A preparation method of metal powder based on Inconel718, comprising the following steps;

[0027] Step (1), carry out ball-milling mixing with Inconel718 powder, Ti powder, Mo powder and nickel-coated graphite;

[0028] The adopted ball milling process parameters are: the rotational speed is 200r / min, the forward and reverse running time is 0.5h, the 6mm grinding ball is selected, the ball-to-materi...

Embodiment 2

[0036] Example 2, please refer to Figure 1-2 , the present invention provides another technical solution: a metal powder based on Inconel718, including the following components Inconel718 powder, Ti powder, Mo powder and nickel-coated graphite.

[0037] The particle size of Inconel718 powder is 53 μm, the particle size of Ti powder is 75 μm, the mass fraction of nickel in nickel-coated graphite is 75%, and the particle size is 45 μm;

[0038] The weight percentages of the above components are: Inconel718 is 63%, Ti is 10%, Mo powder is 11%, and nickel-coated graphite is 16%.

[0039] A preparation method of metal powder based on Inconel718, comprising the following steps;

[0040] Step (1), carry out ball-milling mixing with Inconel718 powder, Ti powder, Mo powder and nickel-coated graphite;

[0041] The adopted ball milling process parameters are: the rotational speed is 300r / min, the forward and reverse running time is 0.8h, the 10mm grinding ball is selected, the ball-to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com