Method for preparing brake servo piston material

A servo piston and piston technology, which is applied in the preparation of brake servo piston materials, can solve the problems of thermal fatigue damage and the difficulty of adapting to the needs of high temperature-resistant aluminum alloys, and achieves prevention of grain boundary slippage, dense, uniform and stable structure and high hardness. and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

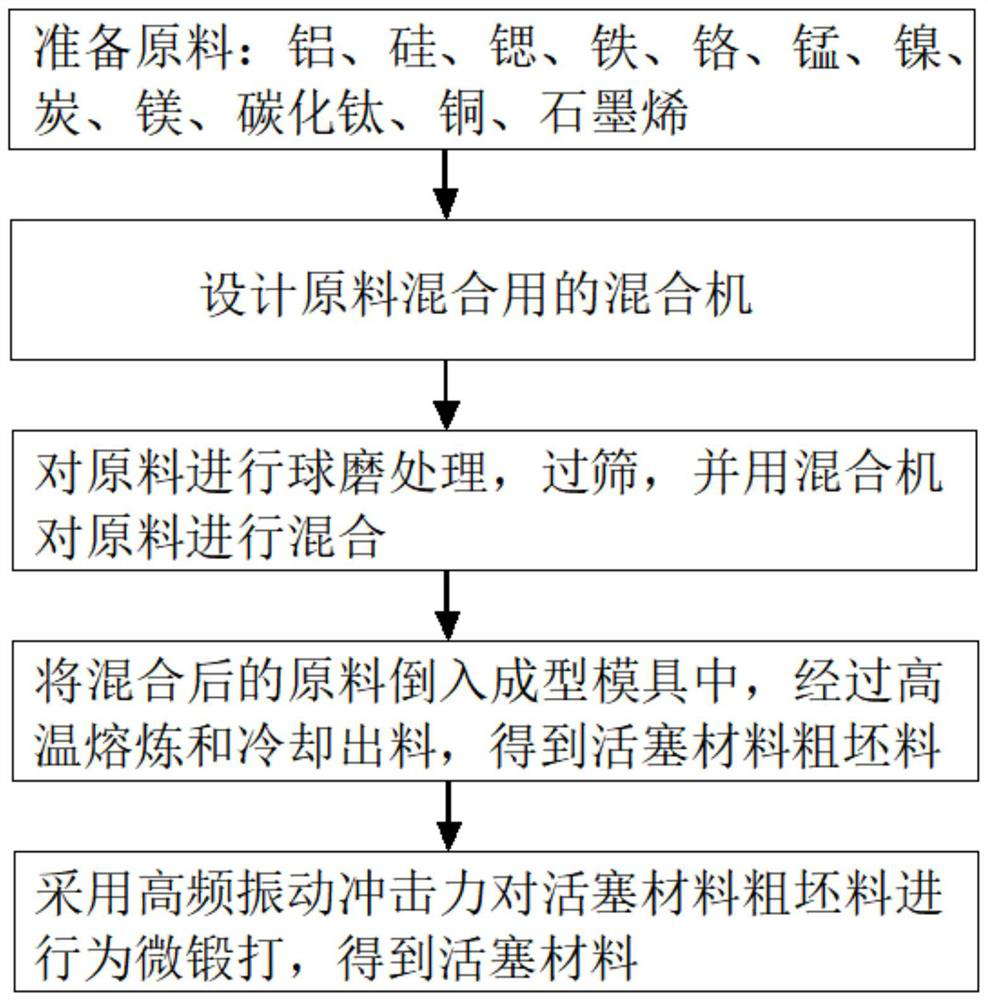

[0026] according to figure 1 , 2 , 3, the present embodiment proposes a preparation method of brake servo piston material, comprising the following steps:

[0027] Step 1: Prepare raw materials for high-strength aluminum alloy materials. The raw materials include the following mass ratio components: 135 parts of aluminum powder, 8 parts of silicon powder, 12 parts of strontium powder, 5 parts of iron powder, 0.5 parts of chromium powder, 2 parts of manganese powder, and 3 parts of Nickel powder, 15 parts of carbon powder, 3 parts of magnesium powder, 35 parts of titanium carbide powder, 1 part of copper powder and 2 parts of graphene powder;

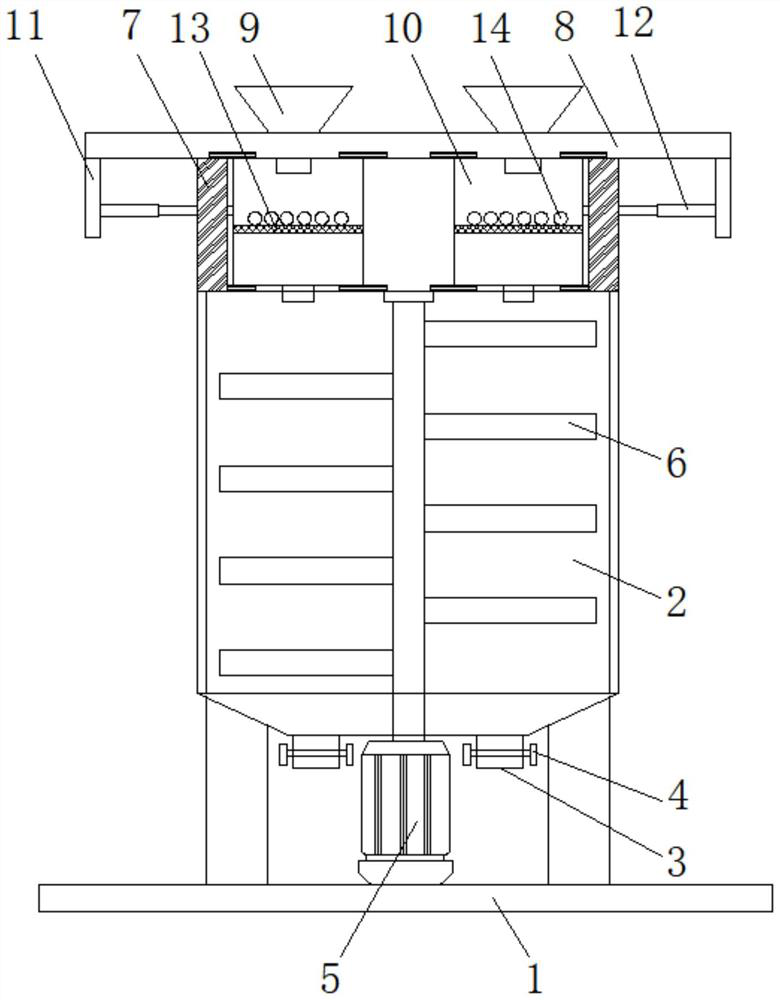

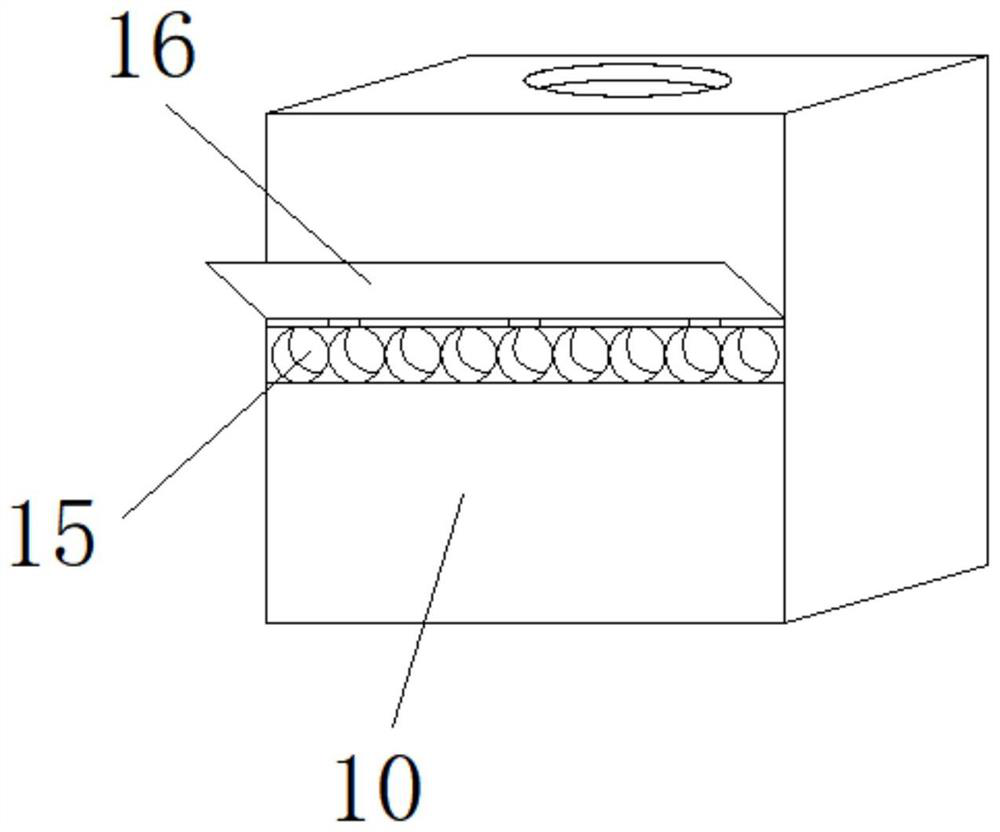

[0028] Step 2: Design a mixer for mixing raw materials, the mixer includes a base 1, a mixer body 2, a stirring device and a feeding device, the base 1 is provided with a mixer body 2, and the mixer body 2 is below A discharge port 3 is provided, a discharge valve 4 is provided on the discharge port 3, a stirring device is provided in ...

Embodiment 2

[0033] according to figure 1 , 2 , 3, the present embodiment proposes a preparation method of brake servo piston material, comprising the following steps:

[0034] Step 1: Prepare raw materials for high-strength aluminum alloy materials. The raw materials include the following mass ratio components: 145 parts of aluminum powder, 9 parts of silicon powder, 14 parts of strontium powder, 6 parts of iron powder, 0.8 parts of chromium powder, 3 parts of manganese powder, 4 parts Nickel powder, 18 parts of carbon powder, 4 parts of magnesium powder, 38 parts of titanium carbide powder, 2 parts of copper powder and 3 parts of graphene powder;

[0035] Step 2: Design a mixer for mixing raw materials, the mixer includes a base 1, a mixer body 2, a stirring device and a feeding device, the base 1 is provided with a mixer body 2, and the mixer body 2 is below A discharge port 3 is provided, a discharge valve 4 is provided on the discharge port 3, a stirring device is provided in the st...

Embodiment 3

[0040] according to figure 1 , 2 , 3, the present embodiment proposes a preparation method of brake servo piston material, comprising the following steps:

[0041] Step 1: Prepare the raw materials of high-strength aluminum alloy materials. The raw materials include the following mass ratio components: 160 parts of aluminum powder, 10 parts of silicon powder, 15 parts of strontium powder, 8 parts of iron powder, 1 part of chromium powder, 4 parts of manganese powder, 5 parts of Nickel powder, 20 parts carbon powder, 5 parts magnesium powder, 40 parts titanium carbide powder, 3 parts copper powder and 4 parts graphene powder

[0042] Step 2: Design a mixer for mixing raw materials, the mixer includes a base 1, a mixer body 2, a stirring device and a feeding device, the base 1 is provided with a mixer body 2, and the mixer body 2 is below A discharge port 3 is provided, a discharge valve 4 is provided on the discharge port 3, a stirring device is provided in the stirring, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com