High-strength and high-conductivity copper alloy material

A technology of copper alloy and high conductivity, which is applied in the field of copper alloy materials, can solve the problems that the conductivity cannot meet the demand, the connectors are prone to cracks, and the temperature of the material rises, so as to improve the resistance to high temperature softening and avoid the coarsening of material grains Or segregation, fine and uniform metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

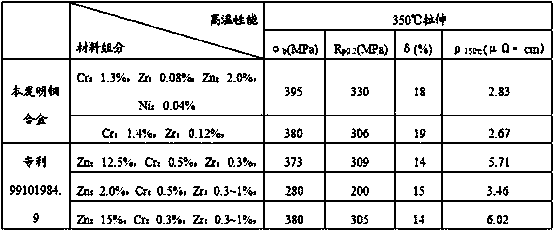

[0020] This example provides an embodiment in which the copper alloy conductor material of the present invention is applied to precision copper parts of a squirrel-cage motor rotor.

[0021] In this embodiment, the copper alloy conductor material applied to the precision copper parts of the motor rotor includes Cu, Cr, and Zr components, and the mass percentages of each component are: Cr: 1.4%, Zr: 0.5%, and the balance is Cu and unavoidable impurities.

[0022] Among the above alloy components, Cr and Zr mainly play the role of aging precipitation strengthening and hindering recrystallization. Adding alloying elements (such as Cr, Zr) whose solubility decreases significantly with the decrease of temperature into copper forms a saturated solid solution through high-temperature solid solution treatment, and then through aging, the supersaturated solid solution is decomposed, and the alloying elements are precipitated in the form of precipitated phases and distributed in a dispe...

Embodiment 2

[0024] The copper alloy conductor material that the present invention is applied to motor rotor conductor comprises Cu, Cr, and Zr composition, and further comprises Zn, Fe, Mg, one or more in Ni, in the present embodiment, each component mass The percentages are: Cr: 1.3%, Zr: 0.4%, Zn: 2.0%, Ni: 0.04%, and the balance is Cu and unavoidable impurities.

[0025] The addition of Zn can adjust the resistivity. Among all the elements that can form a solution with copper, Zn has the least effect on the resistivity, and can be used to adjust the resistance of copper alloys. At the same time, zinc also has obvious solid solution strengthening effects in copper alloys. , it is beneficial to improve the room temperature and high temperature strength of the copper alloy, so that the resistance of the motor rotor conductor can be adjusted, and also ensure the casting performance and tensile strength of the motor rotor conductor.

Embodiment 3

[0027] The present invention is applied to the copper alloy conductor material of motor rotor conductors, connectors of high-voltage power grids, transformer connectors and railway rail electrical connectors, including Cu, Cr, and Zr components, and further includes Zn, Fe, Mg, Ni One or more, in this embodiment, the mass percentage of each component is: Cr: 1.5%, Zr: 0.5%, Fe: 0.08%, Ni: 0.1%, and the balance is Cu and unavoidable impurities.

[0028] Among them, the addition ratio of Fe and Ni is generally about 0.8:1, and their addition can improve the strength of the alloy while maintaining the good plasticity of the alloy. Fe and Ni can also refine the casting structure of the alloy and hinder recrystallization, thereby improving the high temperature performance of the alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com