Copper-chromium-zirconium alloy and preparation method thereof

A copper-chromium-zirconium and alloy technology, applied in metal/alloy conductors, cable/conductor manufacturing, conductive materials, etc., can solve the problems of short service life, high current and high resistance, and achieve long service life, high yield and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

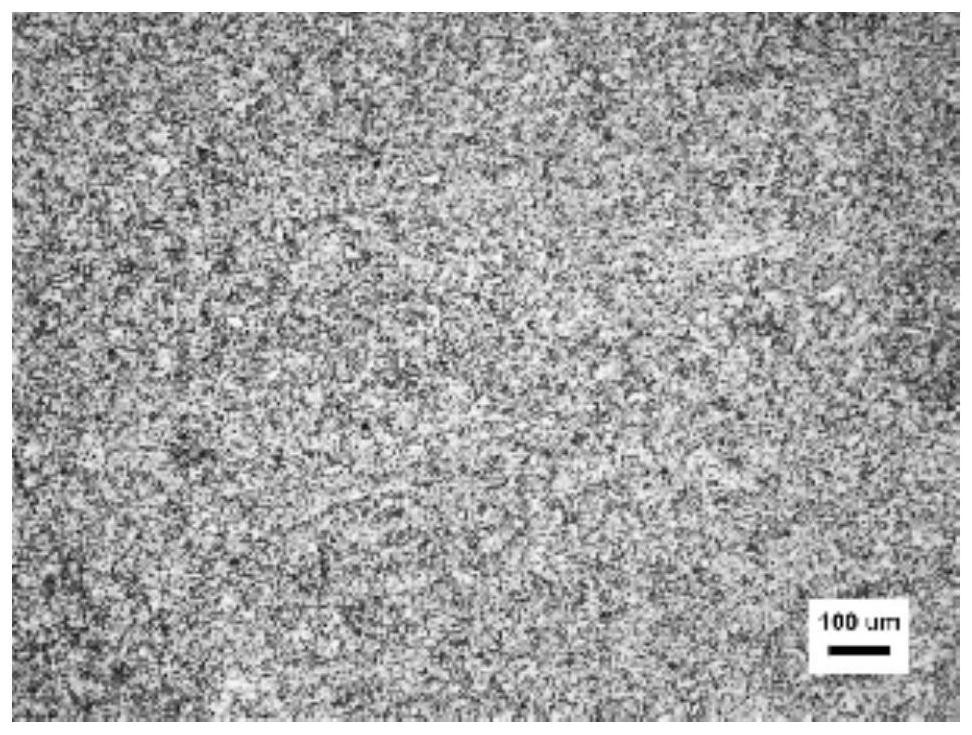

Image

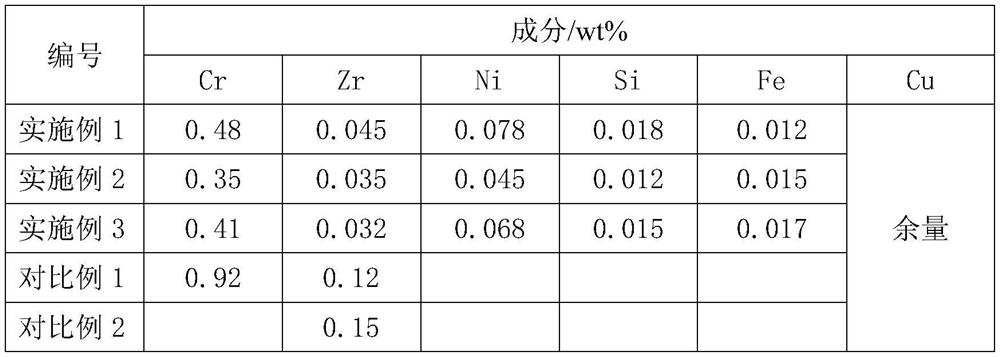

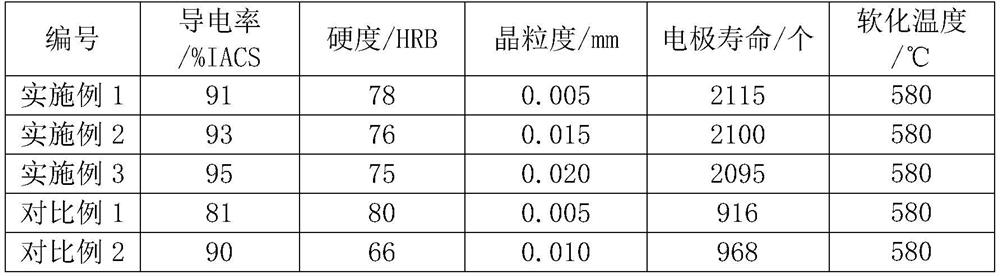

Examples

Embodiment 1

[0028] The preparation steps of this copper-chromium-zirconium alloy are as follows:

[0029] Step 1: A copper alloy wire billet is produced by a continuous casting method, and the diameter of the wire billet is 35mm.

[0030] Step 2: the first cold deformation: drawing the copper alloy wire blank obtained in step 1 with a deformation amount of 36%;

[0031] Step 3: Perform recrystallization annealing on the wire blank after cold working in step 2, the temperature is controlled at 800°C, and the holding time is 5h;

[0032] Step 4: Repeat step 2;

[0033] Step 5: Repeat step 3;

[0034] Step 6: The second cold deformation: drawing the wire billet after recrystallization annealing in step 5 with a deformation amount of 30%;

[0035] Step 7: Perform solution treatment on the wire billet after cold working in step 6, the solution temperature is controlled at 940°C, and the holding time is 1.5h;

[0036] Step 8: The third cold deformation: cold working the wire blank after sol...

Embodiment 2

[0040] The preparation steps of this copper-chromium-zirconium alloy are as follows:

[0041] Step 1: A copper alloy wire billet is produced by a continuous casting method, and the diameter of the wire billet is 30mm.

[0042] Step 2: the first cold deformation: drawing the copper alloy wire blank obtained in step 1 with a deformation amount of 30%;

[0043] Step 3: Perform recrystallization annealing on the wire blank after cold working in step 2, the temperature is controlled at 900°C, and the holding time is 1h;

[0044] Step 4: Repeat step 2;

[0045] Step 5: Repeat step 3;

[0046] Step 6: The second cold deformation: the wire billet after the recrystallization annealing in step 5 is subjected to drawing processing with a deformation amount of 36%;

[0047] Step 7: Perform solution treatment on the wire billet after cold working in step 6, the solution temperature is controlled at 980°C, and the holding time is 0.5h;

[0048] Step 8: The third cold deformation: cold wor...

Embodiment 3

[0052] The preparation steps of this copper-chromium-zirconium alloy are as follows:

[0053] Step 1: A copper alloy wire billet is produced by a continuous casting method, and the diameter of the wire billet is 25mm.

[0054] Step 2: the first cold deformation: drawing the copper alloy wire blank obtained in step 1 with a deformation amount of 30%;

[0055] Step 3: Perform recrystallization annealing on the wire blank after cold working in step 2, the temperature is controlled at 840°C, and the holding time is 4h;

[0056] Step 4: The second cold deformation: the wire billet after the recrystallization annealing in step 3 is subjected to drawing processing with a deformation amount of 32%;

[0057] Step 5: Perform solution treatment on the wire billet after cold working in step 4, control the solution temperature at 960° C., and hold for 1 hour;

[0058] Step 6: The third cold deformation: cold working the wire blank after solid solution in step 5 with a deformation amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com