A method for improving the heat resistance of ether anhydride type polyimide cage blank

A polyimide and cage technology, applied in the field of engineering plastic cages, can solve problems such as failure, thermal decomposition of deformation, limited improvement of heat resistance, etc., and achieve the effect of light weight and high temperature tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

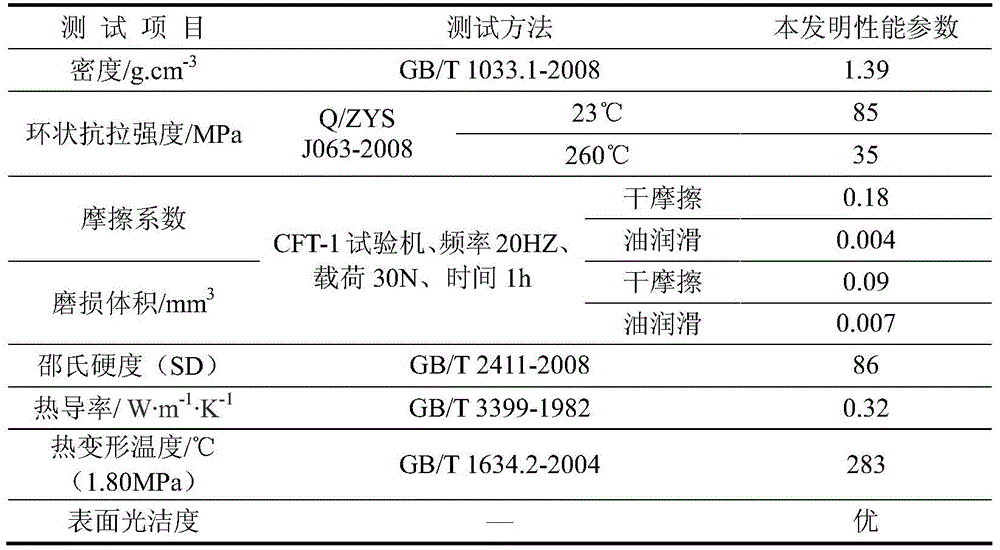

Embodiment 1

[0040] (1) Preparation of cage tube blank material:

[0041] The ratio by weight percentage is: 75% ether anhydride polyimide molding powder, 20% isophthalic polyimide and 5% carbon fiber powder;

[0042] (2) Drying treatment:

[0043] Put the cage tube blank materials obtained in the previous step into a drying oven for drying treatment; the temperature of the drying treatment is 230°C, and the drying time is 3 hours. After drying, take it out and cool it to room temperature, then pass through a 200-mesh sieve and Independently sealed for future use;

[0044] (3) Proportioning process:

[0045] Take the dry 75% ether anhydride type polyimide molding powder obtained in the previous step by weight percentage, 20% homophenylene polyimide molding powder and 5% carbon fiber powder, and put them into a mechanical mixer Stir 3 times, the time of each stirring is controlled at 20 seconds, the rotating speed of the mechanical stirrer is controlled at 10000 rpm during each stirring,...

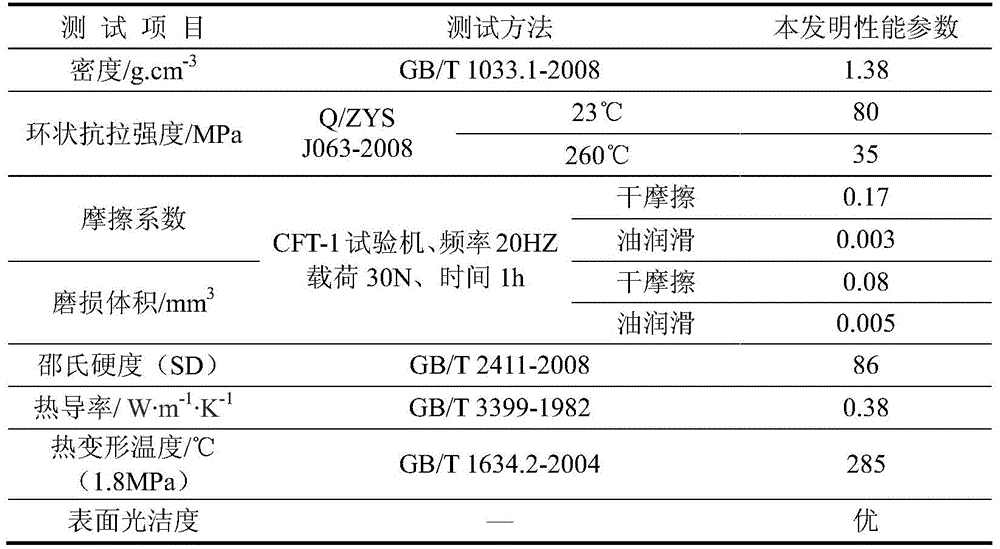

Embodiment 2

[0056] (1) Preparation of cage tube blank material:

[0057] The ratio by weight percentage is: 70% ether anhydride polyimide molding powder, 25% isophthalic polyimide and 5% graphite;

[0058] (2) Drying treatment:

[0059] Put the cage tube blank materials obtained in the previous step into a drying oven for drying treatment; the temperature of the drying treatment is 230°C, and the drying time is 3 hours. After drying, take it out and cool it to room temperature, then pass through a 200-mesh sieve and Independently sealed for future use;

[0060] (3) Proportioning process:

[0061] Take the dry 70% ether anhydride polyimide molding powder obtained in the previous step by weight percentage, 25% isophthalic polyimide molding powder and 5% graphite, and put them into a mechanical mixer for stirring 3 times, the time of each stirring is controlled at 20 seconds, and the rotating speed of the mechanical mixer is controlled at 10,000 rpm during each stirring, and the ether anh...

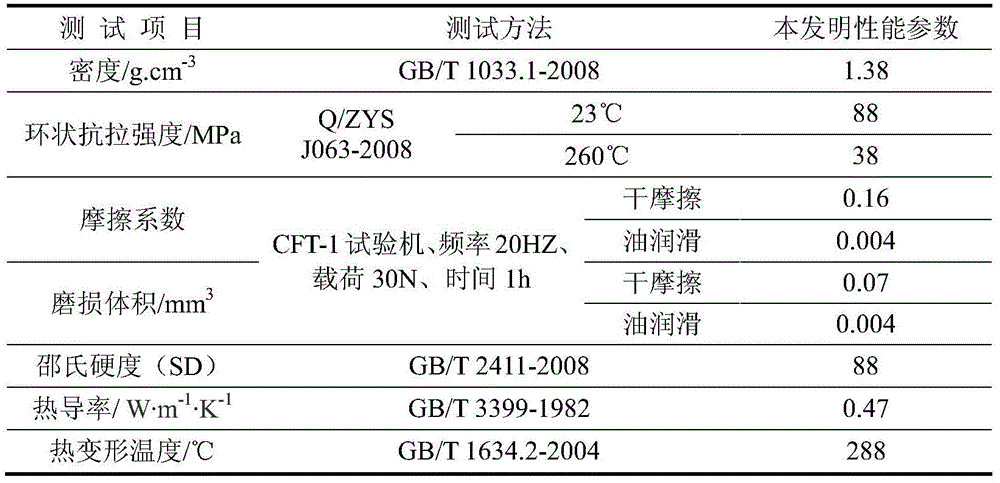

Embodiment 3

[0071] (1) Preparation of cage tube blank material:

[0072] The ratio by weight percentage is: 69% ether anhydride polyimide molding powder, 30% isophthalic polyimide and 1% carbon nanotubes;

[0073] (2) Drying treatment:

[0074] Put the cage tube blank materials obtained in the previous step into a drying oven for drying treatment; the temperature of the drying treatment is 230°C, and the drying time is 3 hours. After drying, take it out and cool it to room temperature, then pass through a 200-mesh sieve and Independently sealed for future use;

[0075] (3) Proportioning process:

[0076] Take the dry 69% ether anhydride polyimide molding powder and 1% carbon nanotubes of 30% polyimide molding powder obtained in the previous step and put them into a mechanical mixer Stir within 5 times, the time of each stirring is controlled at 30 seconds, and the rotating speed of the mechanical mixer is controlled at 12000 rpm during each stirring, and the ether anhydride type polyim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com