Method for casting bimetallic brake drum in short process

A brake drum and bimetallic technology, applied in the direction of brake drums, etc., can solve the problems of environmental pollution, waste of zinc resources, serious volatilization of zinc elements, etc., and achieve the effects of short production cycle, low production cost, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

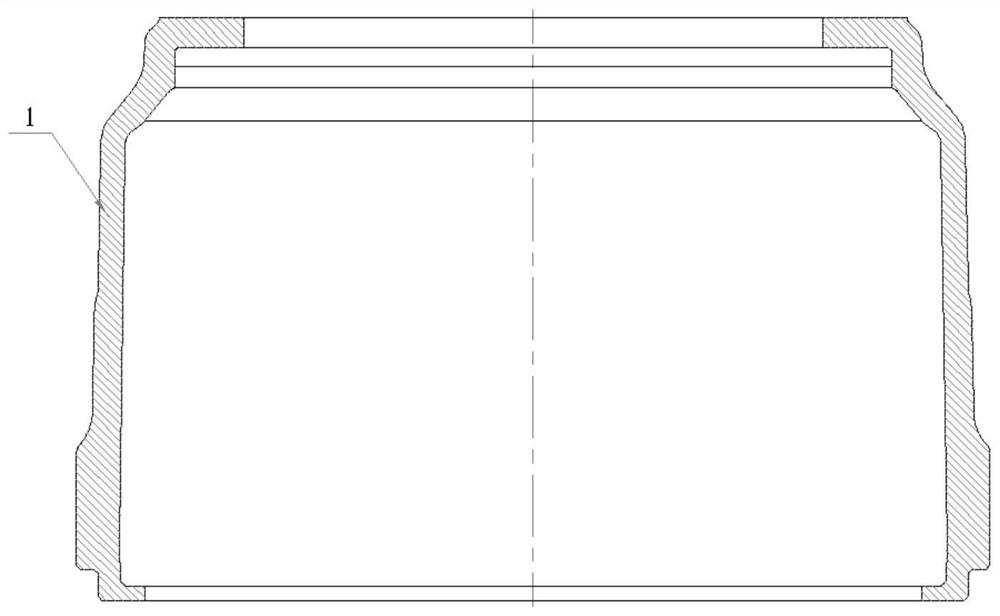

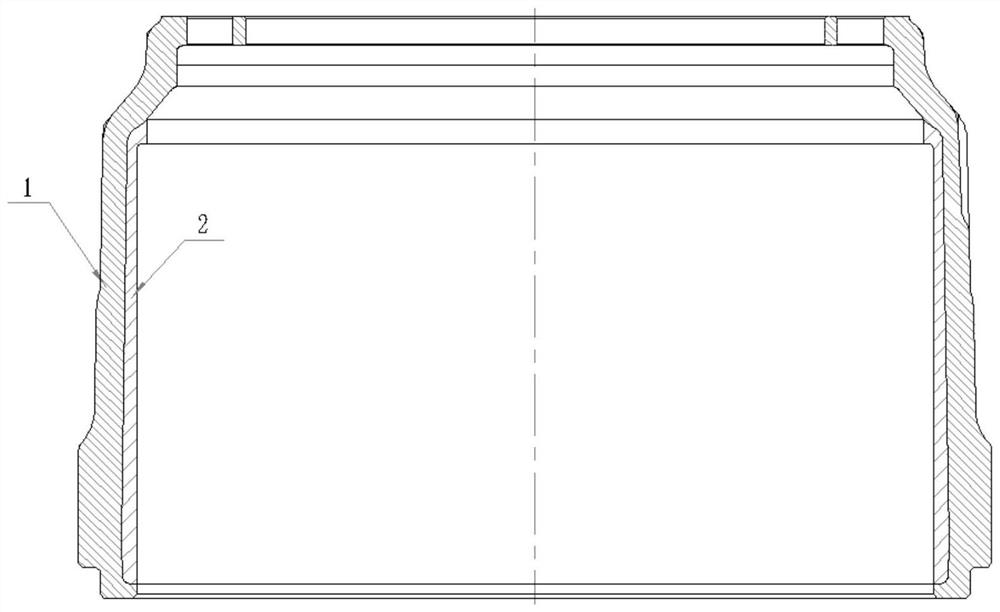

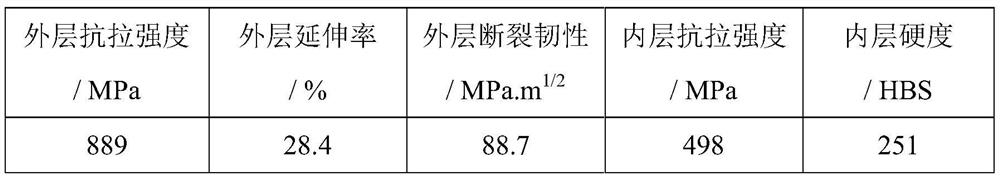

[0034] A method for casting a bimetal brake drum in a short process, which is characterized in that the outer layer is made of continuous casting steel plate mainly smelted by scrapped car shells, the inner layer is made of high-strength wear-resistant gray cast iron, and the two are compounded by centrifugal Casting into a metallurgical bond, the specific process steps are as follows:

[0035] ① First use a scrap car shredder to roughly shred the scrap car shell, and then use a scrap baler to pack the roughly shredded car shell into steel blocks with a size of 150-250mm×150-250mm×150-250mm;

[0036] ②Use the steel block and Q235 scrap in step ① (the chemical composition and mass fraction of the Q235 scrap are 0.17%C, 0.54%Mn, 0.23%Si, 0.041%S, 0.039%P, and the balance is Fe and unavoidable impurities), high carbon ferrochromium (the chemical composition and mass fraction of the high carbon ferrochromium are 62.70% Cr, 8.26% C, 2.39% Si, and the balance is Fe) and ferromangane...

Embodiment 2

[0042] A method for casting a bimetal brake drum in a short process, which is characterized in that the outer layer is made of continuous casting steel plate mainly smelted by scrapped car shells, the inner layer is made of high-strength wear-resistant gray cast iron, and the two are compounded by centrifugal Casting into a metallurgical bond, the specific process steps are as follows:

[0043] ① First use a scrap car shredder to roughly shred the scrap car shell, and then use a scrap baler to pack the roughly shredded car shell into steel blocks with a size of 150-250mm×150-250mm×150-250mm;

[0044]②Use the steel block and Q235 scrap in step ① (the chemical composition and mass fraction of the Q235 scrap are 0.14%C, 0.65%Mn, 0.21%Si, 0.031%S, 0.043%P, and the balance is Fe and unavoidable impurities), high carbon ferrochromium (the chemical composition and mass fraction of the high carbon ferrochromium are 62.77% Cr, 7.94% C, 2.63% Si, the balance is Fe) and ferromanganese ni...

Embodiment 3

[0050] A method for casting a bimetal brake drum in a short process, which is characterized in that the outer layer is made of continuous casting steel plate mainly smelted by scrapped car shells, the inner layer is made of high-strength wear-resistant gray cast iron, and the two are compounded by centrifugal Casting into a metallurgical bond, the specific process steps are as follows:

[0051] ① First use a scrap car shredder to roughly shred the scrap car shell, and then use a scrap baler to pack the roughly shredded car shell into steel blocks with a size of 150-250mm×150-250mm×150-250mm;

[0052] ②Use the steel block and Q235 scrap in step ① (the chemical composition and mass fraction of the Q235 scrap are 0.22%C, 0.30%Mn, 0.18%Si, 0.038%S, 0.044%P, and the balance is Fe and unavoidable impurities), high carbon ferrochromium (the chemical composition and mass fraction of the high carbon ferrochromium are 65.67% Cr, 8.38% C, 2.94% Si, and the balance is Fe) and ferromangane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com