Method for preparing aluminum-silicon alloy by using high-iron-content ZL102 infiltrated aluminum alloy and aluminum-silicon alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

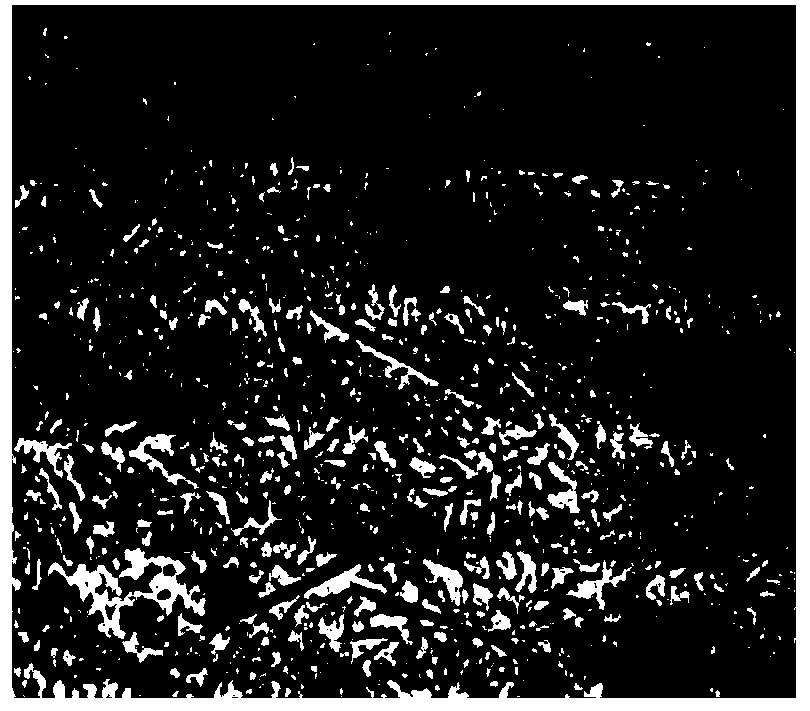

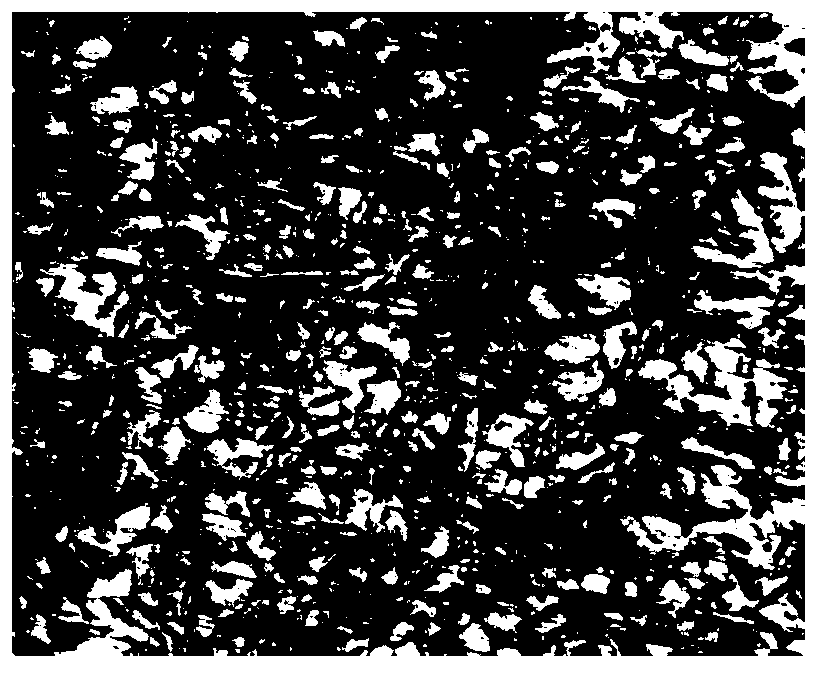

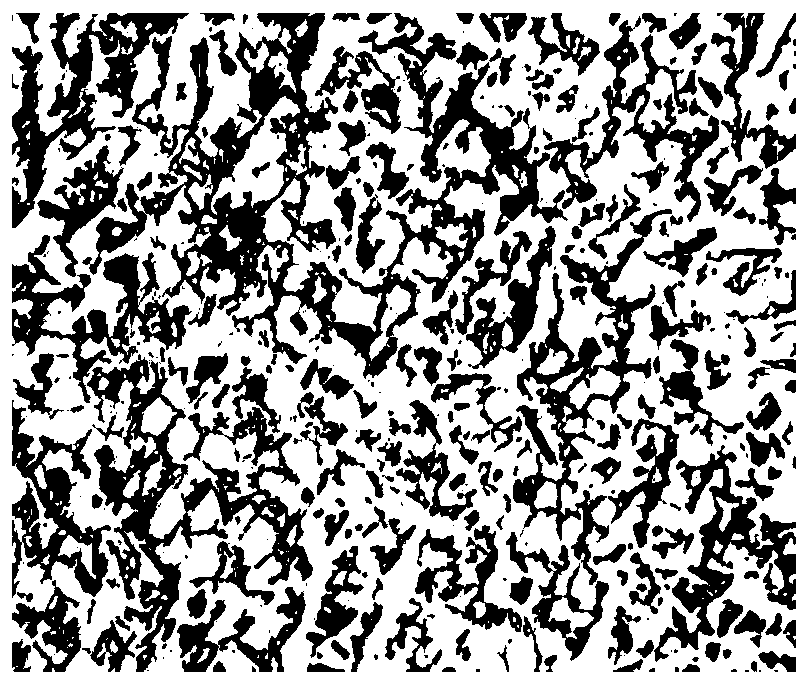

Image

Examples

Embodiment 1

[0044] (1) Manganese-added remelting is carried out on ZL102 infiltrated aluminum alloy with high iron content to obtain remelted ZL102 ingot with refined iron phase;

[0045] ①Weigh the ZL102 infiltrated aluminum alloy and Mn according to the proportion; the amount of manganese added is added according to the weight ratio Mn:Fe=0.3:1;

[0046] ②Put ZL102 infiltrated aluminum alloy and Mn into the remelting furnace and rapidly raise the temperature to 875°C, and heat and diffuse at 875°C for 30min;

[0047] ③ After 30 minutes of diffusion, cast the remelted ZL102 ingot with refined iron phase, and the weight of the prepared remelted ZL102 ingot is 4.8kg-5.2kg; half ingot casting is required and the ingot is quenched and turned by using a water-cooled ingot trough, and the alloy Liquid solidification time is 25S.

[0048] (2) Preparation of ZL109:

[0049] ① Prepare raw materials, including aluminum ingots;

[0050] ② Put all the raw materials into the smelting furnace, heat...

Embodiment 2

[0053] (1) Manganese-added remelting is carried out on ZL102 infiltrated aluminum alloy with high iron content to obtain remelted ZL102 ingot with refined iron phase;

[0054] ①Weigh the ZL102 infiltrated aluminum alloy and Mn according to the proportion; the amount of manganese added is added according to the weight ratio Mn:Fe=0.4:1;

[0055] ②Put ZL102 infiltrated aluminum alloy and Mn into the remelting furnace and rapidly raise the temperature to 900°C, and heat and diffuse at 900°C for 40 minutes;

[0056] ③ After 40 minutes of diffusion, cast remelted ZL102 ingots with refined iron phases. The weight of the remelted ZL102 ingots prepared is 4.8kg-5.2kg; half ingots need to be cast and quenched by water-cooled ingot grooves. Liquid solidification time is 20S.

[0057] (2) Preparation of ZL109:

[0058] ① Prepare raw materials, including aluminum ingots;

[0059] ② Put all the raw materials into the smelting furnace, heat up to 800°C after all the aluminum ingots are m...

Embodiment 3

[0062] (1) Manganese-added remelting is carried out on ZL102 infiltrated aluminum alloy with high iron content to obtain remelted ZL102 ingot with refined iron phase;

[0063] ①Weigh the ZL102 infiltrated aluminum alloy and Mn according to the proportion; the amount of manganese added is added according to the weight ratio Mn:Fe=0.2:1;

[0064] ②Put ZL102 infiltrated aluminum alloy and Mn into the remelting furnace and rapidly raise the temperature to 850°C, and heat and diffuse at 850°C for 20 minutes;

[0065] ③ After 20 minutes of diffusion, cast the remelted ZL102 ingot with refined iron phase, and the weight of the prepared remelted ZL102 ingot is 4.8kg-5.2kg. Liquid solidification time is 30S.

[0066] (2) Preparation of ZL109:

[0067] ① Prepare raw materials, including aluminum ingots;

[0068] ② Put all the raw materials into the smelting furnace, heat up to 760°C after all the aluminum ingots are melted, and then add the remelted ZL102 ingot prepared in step (1) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com