Patents

Literature

35results about How to "Promoting dispersive precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper chromium zirconium alloy and preparing method thereof

A copper chromium zirconium alloy comprises, by weight, 0.7% to 2.0% of chromium, 0.05% to 0.3% of zirconium, 0.01% to 0.08% of magnesium, 0.01% to 0.1% of yttrium and the balance copper. The invention further provides a preparing method of the copper chromium zirconium alloy. The preparing method sequentially comprises the following steps that firstly, the copper, the chromium, the zirconium, the magnesium and the yttrium are prepared according to the proportion and are subject to vacuum purified smelting and flow dividing type casting, and a casting blank is prepared; secondly, the casting blank is subject to homogenization treatment and hot extrusion, and a sheared billet is prepared; thirdly, the sheared billet is subject to solid-solution treatment; fourthly, the sheared billet obtained after the solid-solution treatment is subject to cold deformation machining; and fifthly, a material obtained after cold deformation machining is subject to aging treatment, and the needed copper chromium zirconium alloy is obtained. The copper chromium zirconium alloy has the good comprehensive performance, the room temperature tensile strength of the copper chromium zirconium alloy is larger than 520 MPa, the room temperature elongation of the copper chromium zirconium alloy is larger than or equal to 22%, the room temperature electric conductivity of the copper chromium zirconium alloy is larger than or equal to 90%IACS, and the 350 DEG C high-temperature tensile strength of the copper chromium zirconium alloy is larger than 390 MPa.

Owner:SHANTOU HUAXING (RAOPING) COPPER IND CO LTD +1

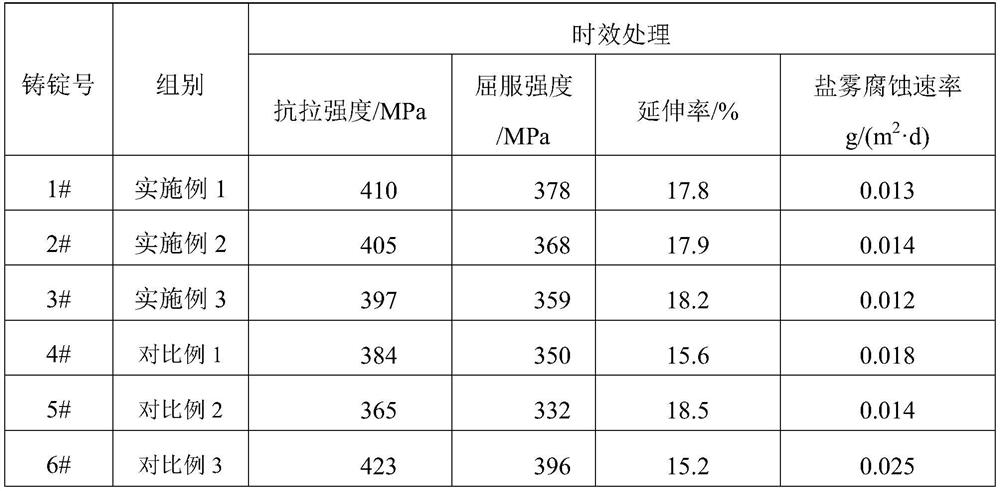

Production technology of high-strength 7-series aluminum alloy pipe

ActiveCN109355538AHigh strengthIncreased resistance to stress corrosion susceptibilityFurnace typesHeat treatment furnacesIngot castingMechanical property

The invention belongs to the technical field of heat treatment of aluminum alloy, and relates to a production technology of a high-strength 7-series aluminum alloy pipe. An aluminum alloy ingot casting is prepared from the following raw materials according to the mass percentage: 7.5-8.5% of Zn, 1.0-3.5% of Mg, 0.10-0.20% of Cu, 0.05-0.3% of Zr, 0.1-1.5% of Mn, 0.05-0.3% of Cr, 0 .05% of Ti, 0.05%of B, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of impurities in total and the balance Al. The two-stage homogenizing treatment and the two-stage aging heat treatment are adopted in the production technology of the aluminum alloy pipe, wherein according to the two-stage homogenizing system, the heat preservation is carried out for 24 hours at the temperature of 470 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 480 DEG C; and according to the two-stage aging system, the heat preservation is carried out for 7 hours at the temperature of 110 DEG C to 130 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 165 DEG C to 170 DEG C. The overall mechanical property of the high-strength 7-series aluminum alloy pipe is effectively improved.

Owner:CHINA ZHONGWANG

Copper-chromium-zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

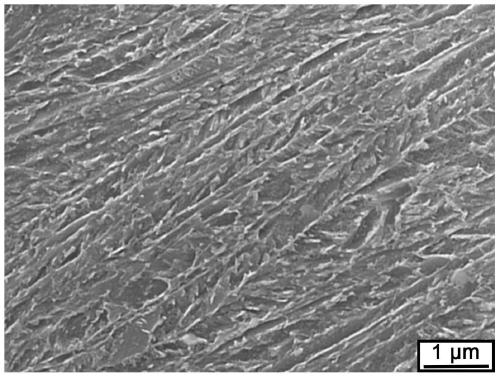

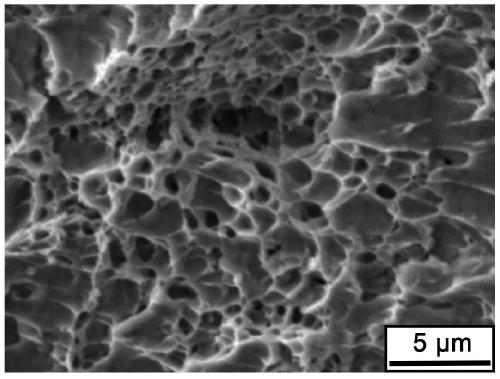

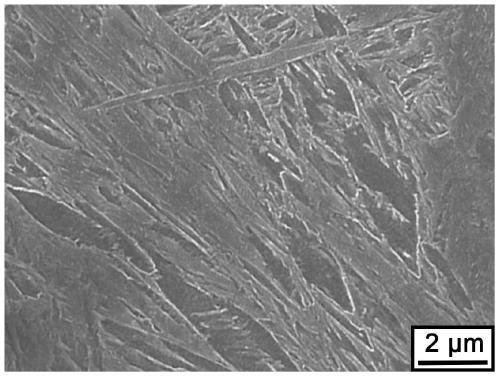

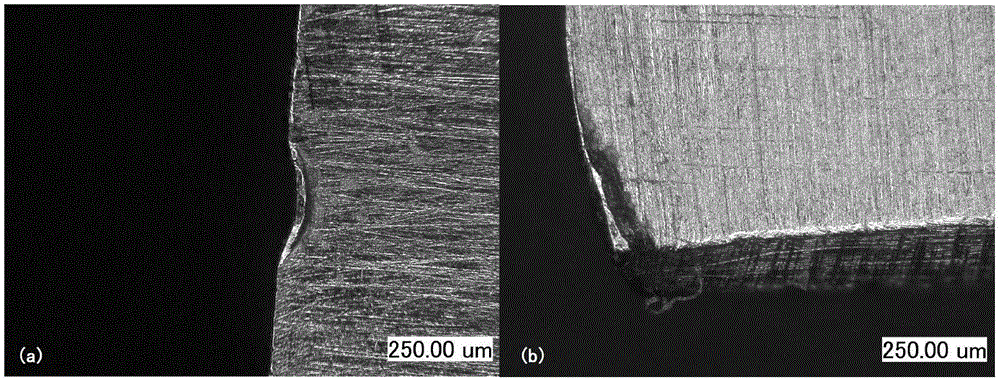

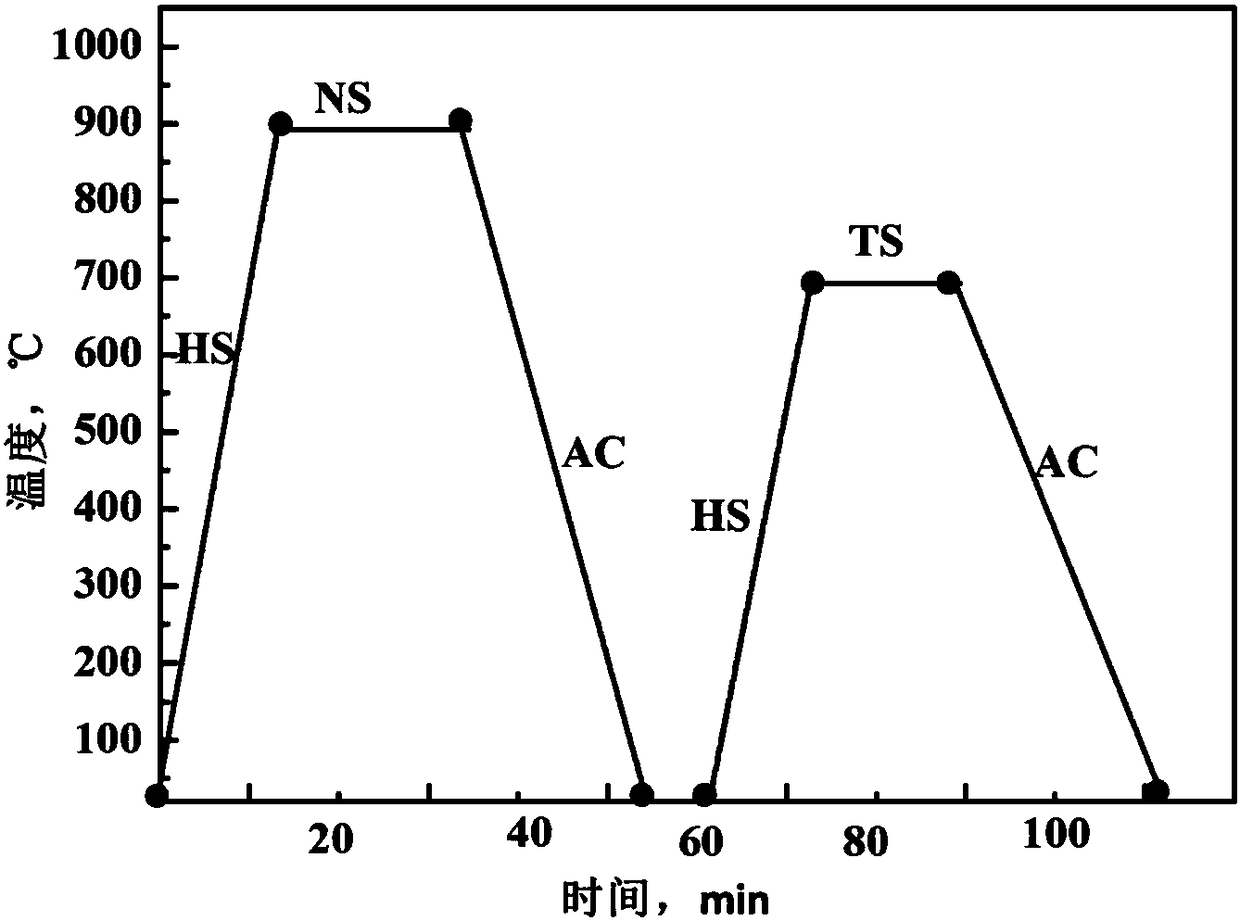

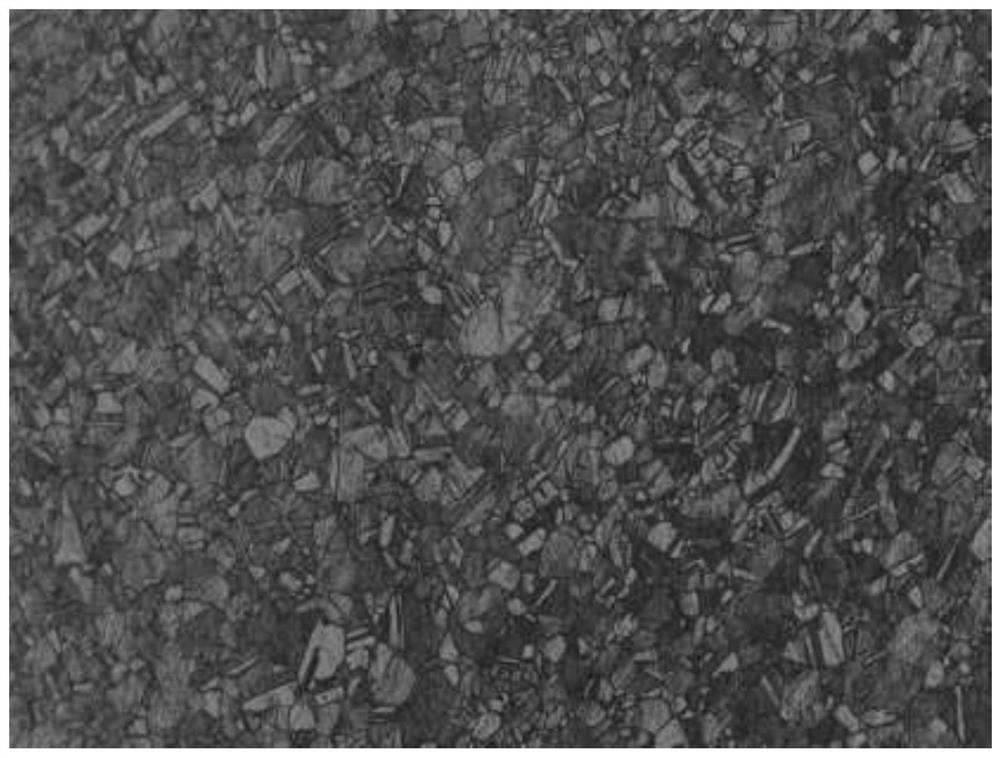

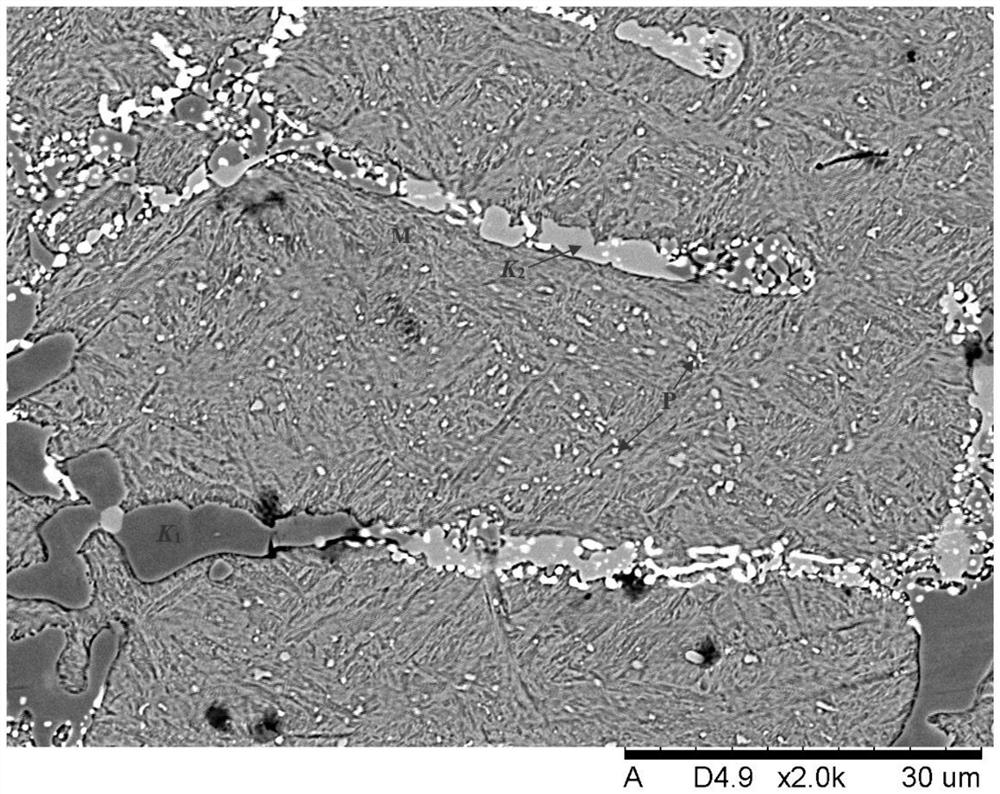

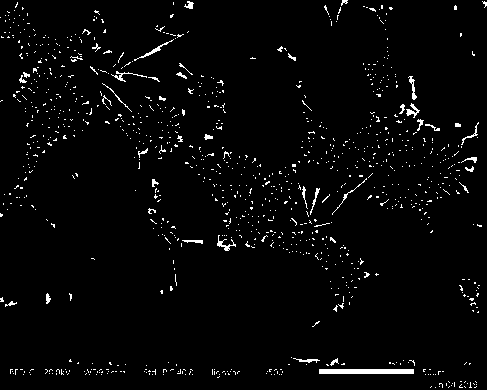

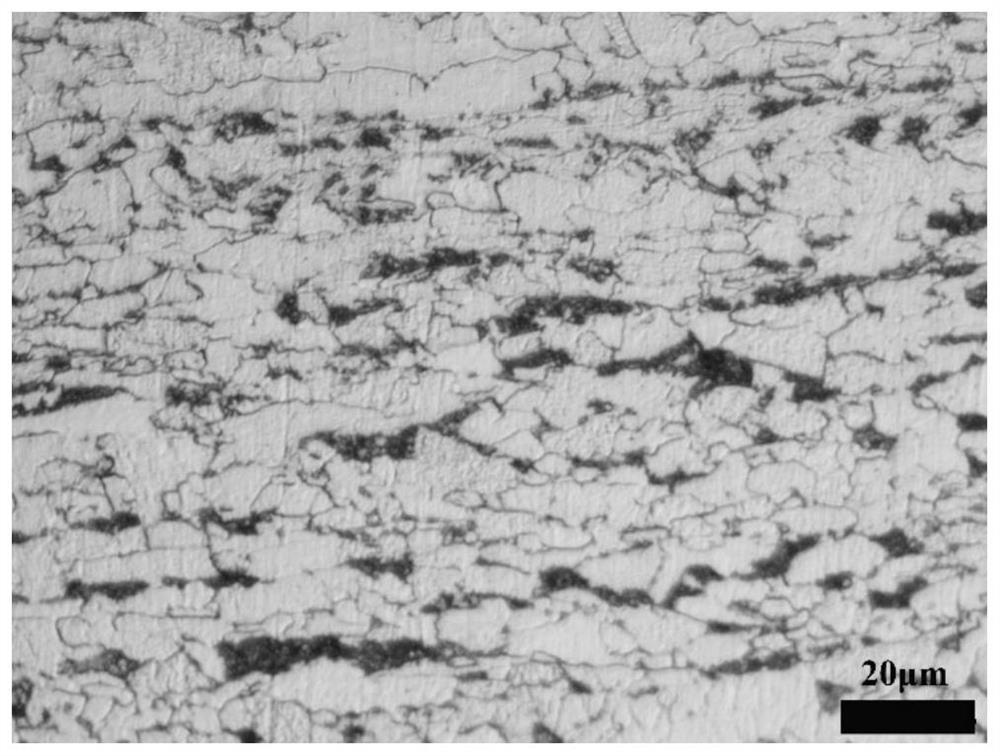

Low-alloy martensite steel high-toughness treatment method and martensite steel

ActiveCN111455146ASolve the problem of poor forging effectHigh strengthMetal-working apparatusMartensite transformationTempering

The invention discloses a low-alloy martensite steel high-toughness treatment method and martensite steel. The low-alloy martensite steel high-toughness treatment method comprises the following steps:(1) pretreatment, wherein a uniform single-phase austenite structure is obtained; (S2) high-temperature forging, wherein a forging ratio is 50-80%, a final forging temperature is higher than a martensite transformation temperature by 50-100 DEG C, and the austenite structure is cooled to the room temperature to obtain a structure taking martensite as the principal thing; (S3) medium-temperature forging, wherein heat is preserved at a temperature higher than the martensite transformation temperature by 30-70 DEG C, air cooling is performed, forging begins while the temperature is cooled to a temperature lower than an eutectoid transformation temperature by 30-100 DEG C, the forging ratio is 70-90%, the final forging temperature is lower than the eutectoid transformation temperature by 150-250 DEG C, forging total time is within 2 minutes, quenching cooling is performed until the room temperature, and the structure taking the uniform fine batten as the principal thing is obtained; and (S4), low-temperature tempering. According to the method disclosed by the invention, high-temperature forging and medium-temperature forging are combined, so that original austenite grains can be remarkably refined, and therefore, plasticity and toughness are remarkably improved while strength of the martensite steel is increased.

Owner:广东泰邦耐磨金属科技有限公司

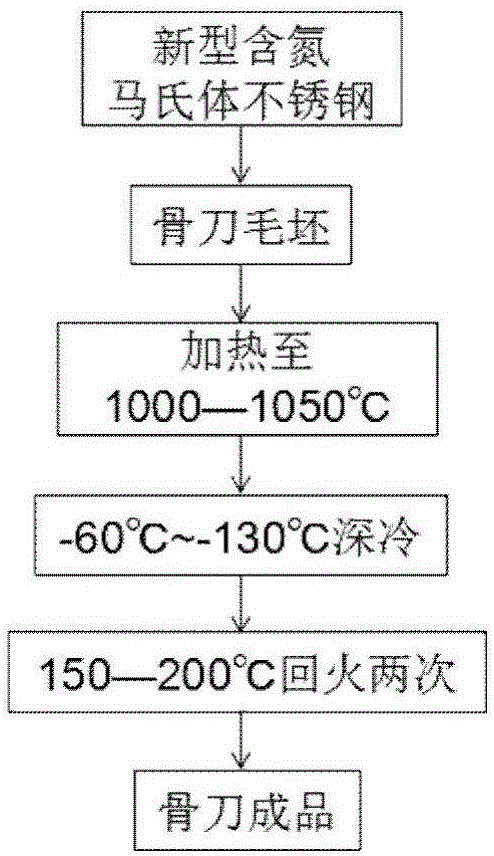

Medical osteotome for mandible plastic surgery and preparation method thereof

InactiveCN106567002APromote changeRefined tempered structureFurnace typesHeat treatment furnacesCryogenic treatmentSurgery procedure

The invention discloses a medical osteotome for mandible plastic surgery and a preparation method thereof. The medical osteotome comprises the following material components: 0.20% to 0.55% of C, 12% to 20% of Cr, 0.2% to 0.8% of Si, 0.5% to 1.5% of Mn, 0.3% to 1.0% of Ni, 0.5% to 1.5% of Mo, 0.2% to 0.5% of N, Fe and a small amount of impurity elements. The preparation method comprises the steps of heating a roughly machined osteotome blank to 1000 DEG C to 1050 DEG C for austenitizing; then, carrying out cryogenic treatment on the osteotome at the temperature of minus 60 DEG C to minus 130 DEG C; then, carrying out tempering on the osteotome at the temperature of 150 DEG C to 200 DEG C two times, wherein tempering is carried out for not less than 2 hours each time; then, air cooling the osteotome to the room temperature; and carrying out finish machining treatment on the osteotome blank to obtain a final finished product. The osteotome is applicable to mandible plastic surgery and has relatively high hardness and toughness, the edge of the osteotome is not liable to curl during the surgery, the service life of the osteotome is greatly prolonged, and safety and reliability of the surgery are guaranteed.

Owner:SHANGHAI UNIV

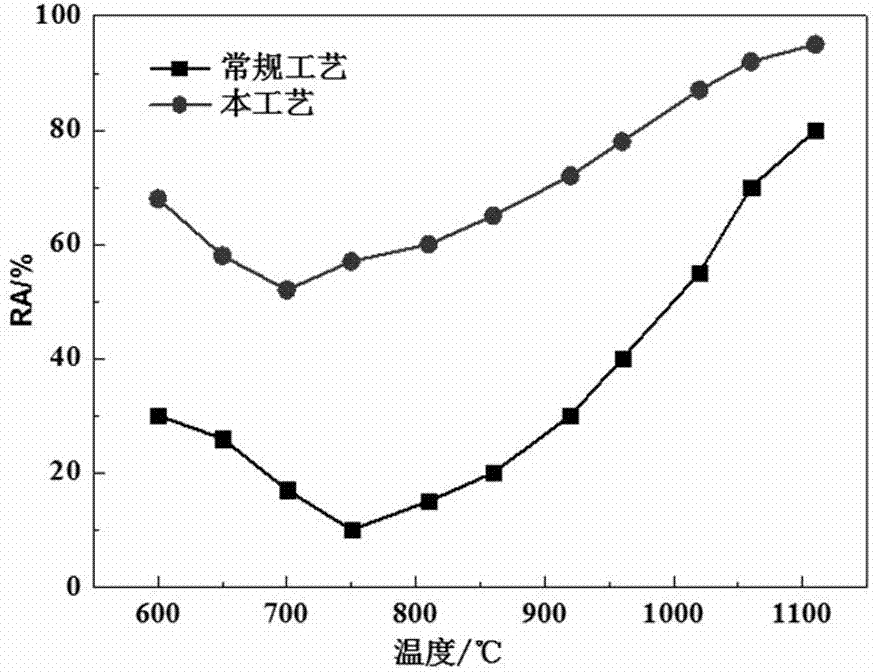

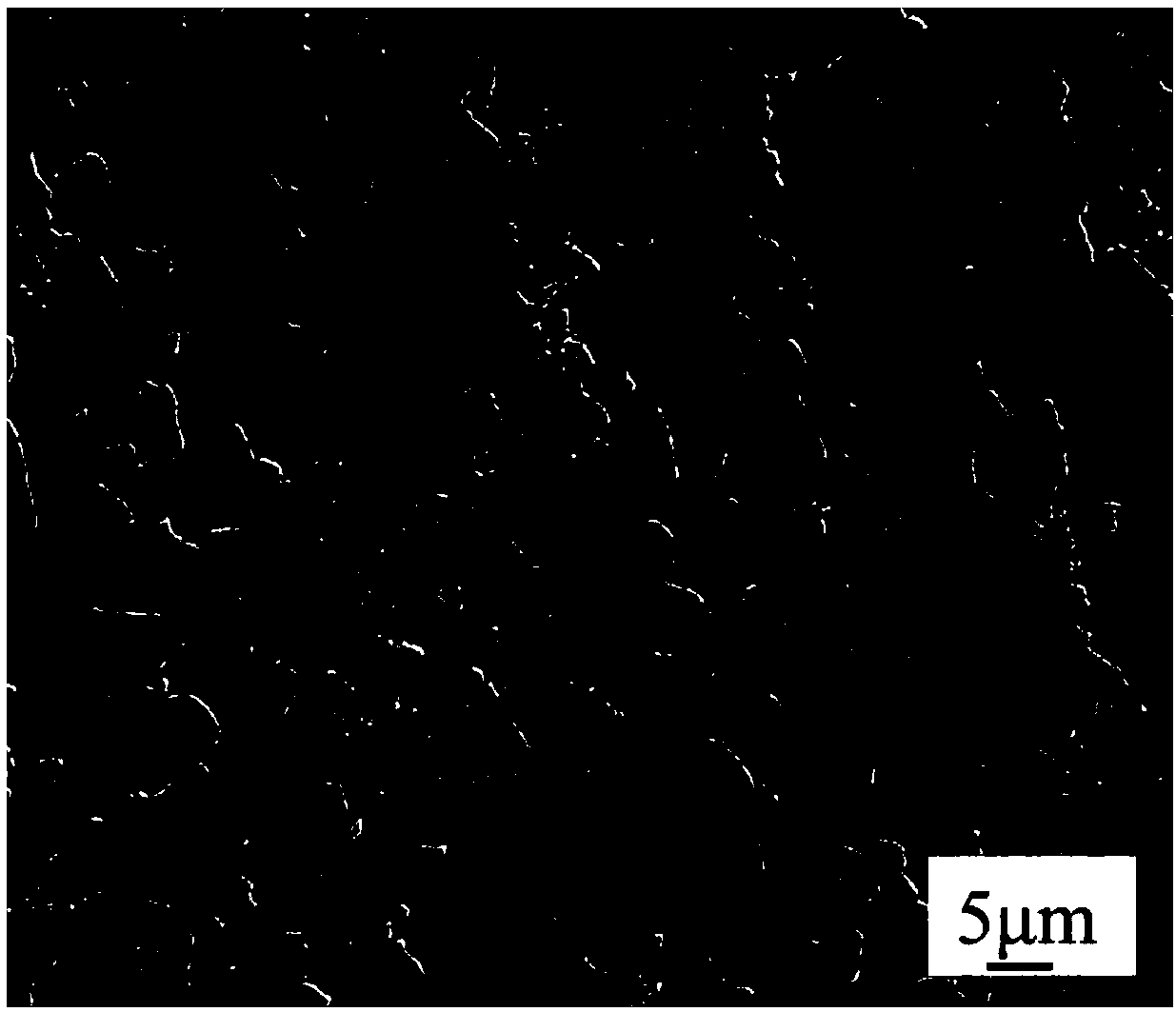

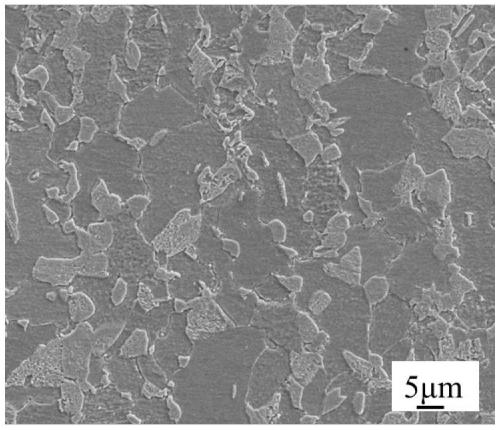

Method for improving high temperature plasticity of steel

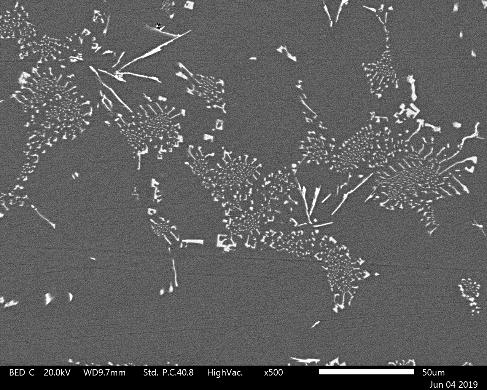

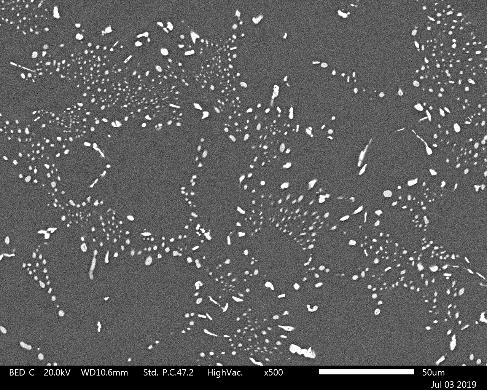

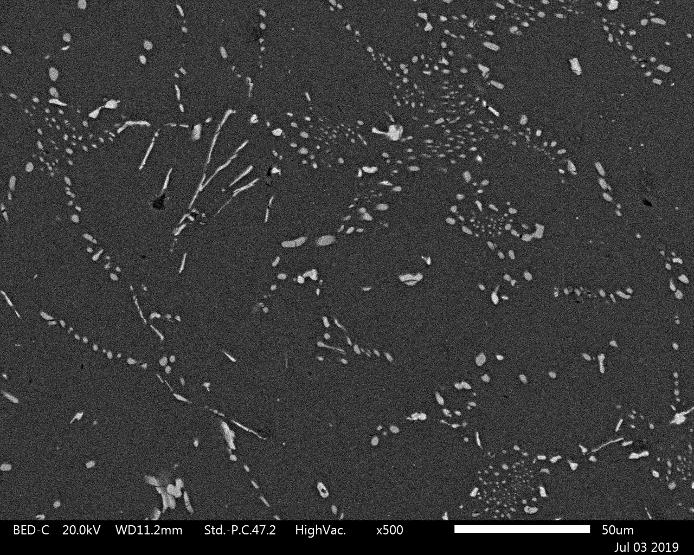

ActiveCN107881289AImprove high temperature plasticityPromoting dispersive precipitationAustenite grainAlloy

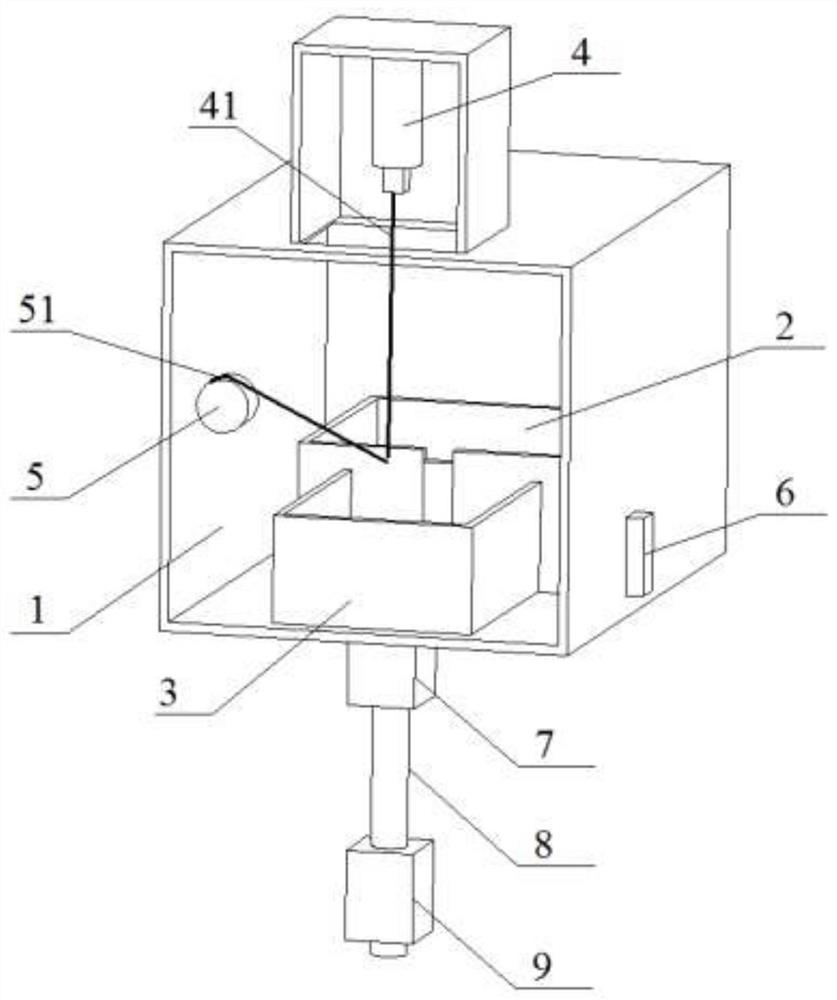

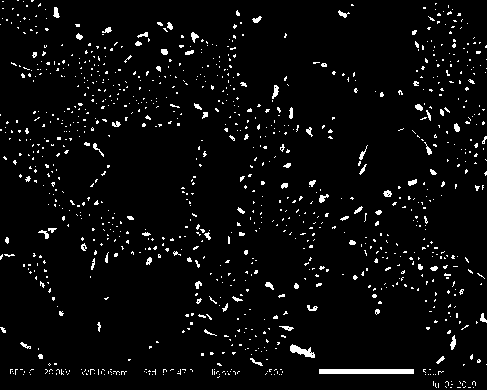

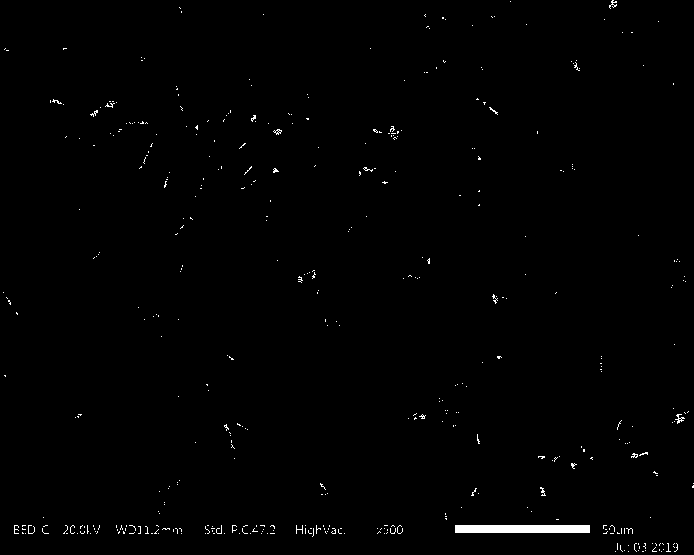

The invention belongs to the field of steel-making continuous casting production of micro-alloy high-strength steel, and discloses a method for improving the high temperature plasticity of steel basedon a synergistic effect of magnesium treatment and two-times cooling. By the synergistic effect of a magnesium treatment process and a novel two-times cooling control process, components, the size and the distribution state of second-phase particles in a micro-alloy high-strength steel casting blank can be effectively controlled, the thickness of a proeutectoid ferrite film distributed along an original austenite grain boundary is controlled, the percentage reduction of area of the casting blank is increased significantly through detection with Gleeble3800 and is higher than 50%. Thus the effects that method can significantly improve the high temperature plasticity of the micro-alloy high-strength steel and the surface crack defects of the casting blank can be overcome effectively are verified.

Owner:SUZHOU UNIV

Overlaying welding repairing technology of stainless steel cold-rolled bearing roller

InactiveCN102837116AImprove wear resistanceImprove heat resistanceArc welding apparatusMetalworkingThermal treatment

The invention relates to an overlaying welding repairing technology of a stainless steel cold-rolled bearing roller, and the technology belongs to the field of metal processing. According to the use conditions of a narrow-band stainless steel cold-rolled bearing roller, a YJ012-S overlaying welding transition layer and a YJ243-S flux-cored wire are selected as overlaying welding working layers to carry out overlaying welding repairing to the cold-rolled bearing roller together with an automatic submerged arc overlaying welding process of preheating before welding and tempering heat treatment after welding. According to the cold-rolled bearing roller after subjected to overlaying welding repairing, the toughness and the wear resistance are better than those of original 9Cr2Mo roller surface metal. The repaired cold-rolled bearing roller is operated and assessed on an actual production line. Compared with an original roller, the service life is doubled and the use requirements on the cold-rolled bearing roller are met. A main process comprises processing and detection before welding, ,preheating, overlaying welding and destressing and tempering after welding.

Owner:ZHANGJIAGANG KAINA INFORMATION TECH

High-strength magnesium-lithium alloy and preparation method of cryogenic strengthening treatment of high-strength magnesium-lithium alloy

The invention provides a high-strength magnesium-lithium alloy and a preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy, and belongs to the technicalfield of high-strength alloys and preparation thereof. The high-strength magnesium-lithium alloy comprises Li, Y, Zn, unavoidable impurity elements and Mg. The atomic ratio of Y and Zn is higher than1.32. The preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy comprises the steps of smelting and casting, homogenization heat treatment, 77 K cryogenic treatment, plastic forming machining and the like. According to the high-strength magnesium-lithium alloy and the preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy, the Y and Zn elements are dissolved into a magnesium-lithium alloy matrix by simultaneously adding the Y and Zn elements, twin crystal refined grains are obtained in an alpha-Mg phase through homogenization heat treatment, cryogenic treatment, plastic forming machining, self-generating in a beta-Li phase is conducted to obtain an X-Mg12YZn phase of a layered LPSO structure, the effect of strengthening the beta-Li phase is achieved, and therefore the alloy is strengthened.

Owner:铜川华铸精密科技有限公司

A kind of copper chromium zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

Vanadium nitride and ferrovanadium nitride alloy reinforcing agent and preparing method and application thereof

The invention discloses a vanadium nitride and ferrovanadium nitride alloy reinforcing agent and a preparing method and application thereof, and belongs to the field of special alloy materials. The reinforcing agent comprises 23%-66% of Si, 0.1%-17.5% of Mn, 11%-37% of N, 0%-9.6% of Ti, 0%-7.3% of Cr, 0.03%-5.6% of Al, 0.1%-1.9% of C, smaller than or equal to 0.10% of P, smaller than or equal to 0.15% of S and the balance Fe and impurities. Nitrogen fixation alloy elements such as the element Si and the element Mn are preferably selected, and nitride is formed by the N and the nitrogen fixation alloy elements. Preferable selection of the nitrogen fixation alloy elements mainly has the following beneficial effects that the combination rate of the nitrogen fixation alloy elements and the N is high; secondly, the nitrogen fixation alloy elements are beneficial to and harmless to molten steel; and thirdly, the thermodynamics environment of molten steel deoxidization, desulfuration vanadium nitride optimization and vanadium nitride iron microalloying is facilitated, more nitrogen ions can be cured, and the utilization rate of the alloy elements is greatly increased.

Owner:马鞍山市恒兴耐火炉料厂

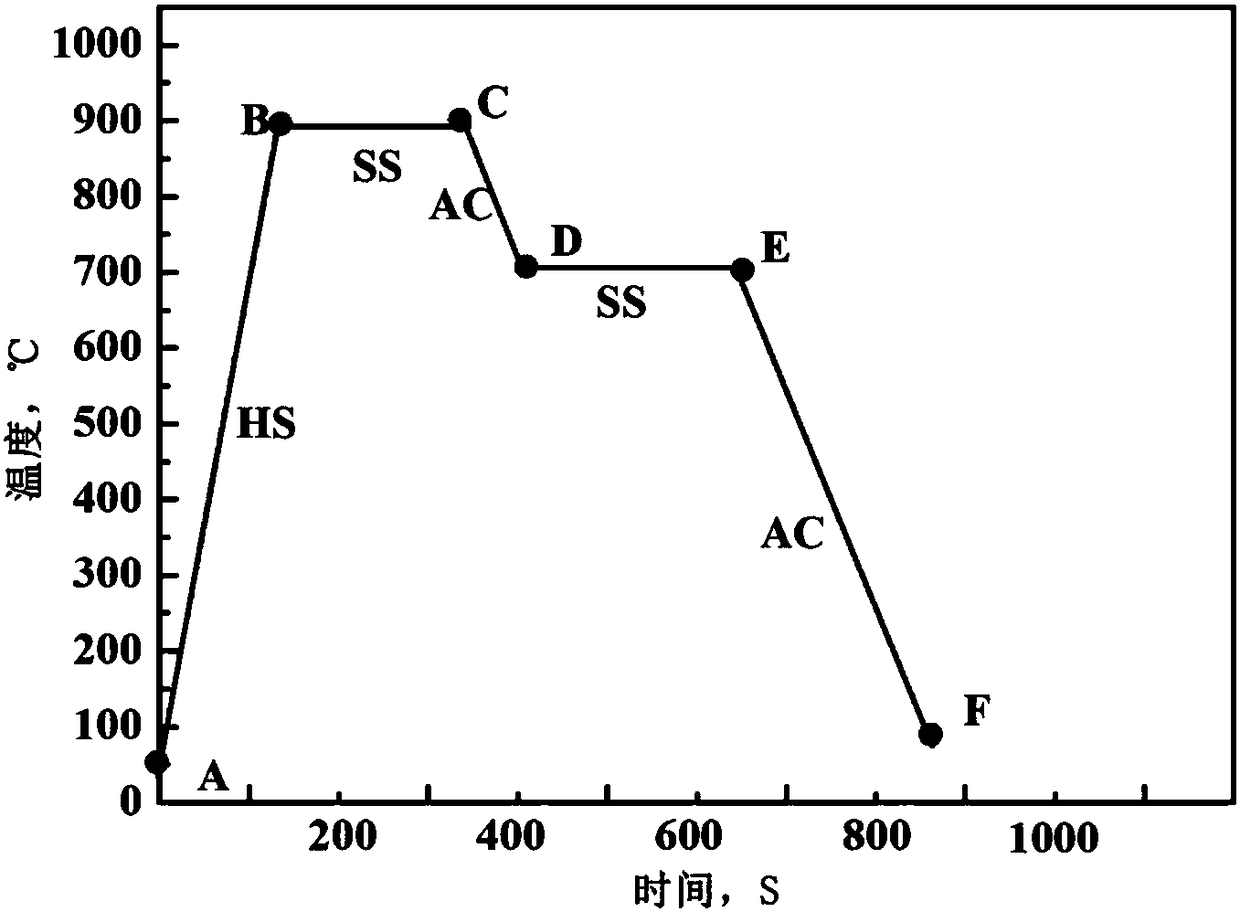

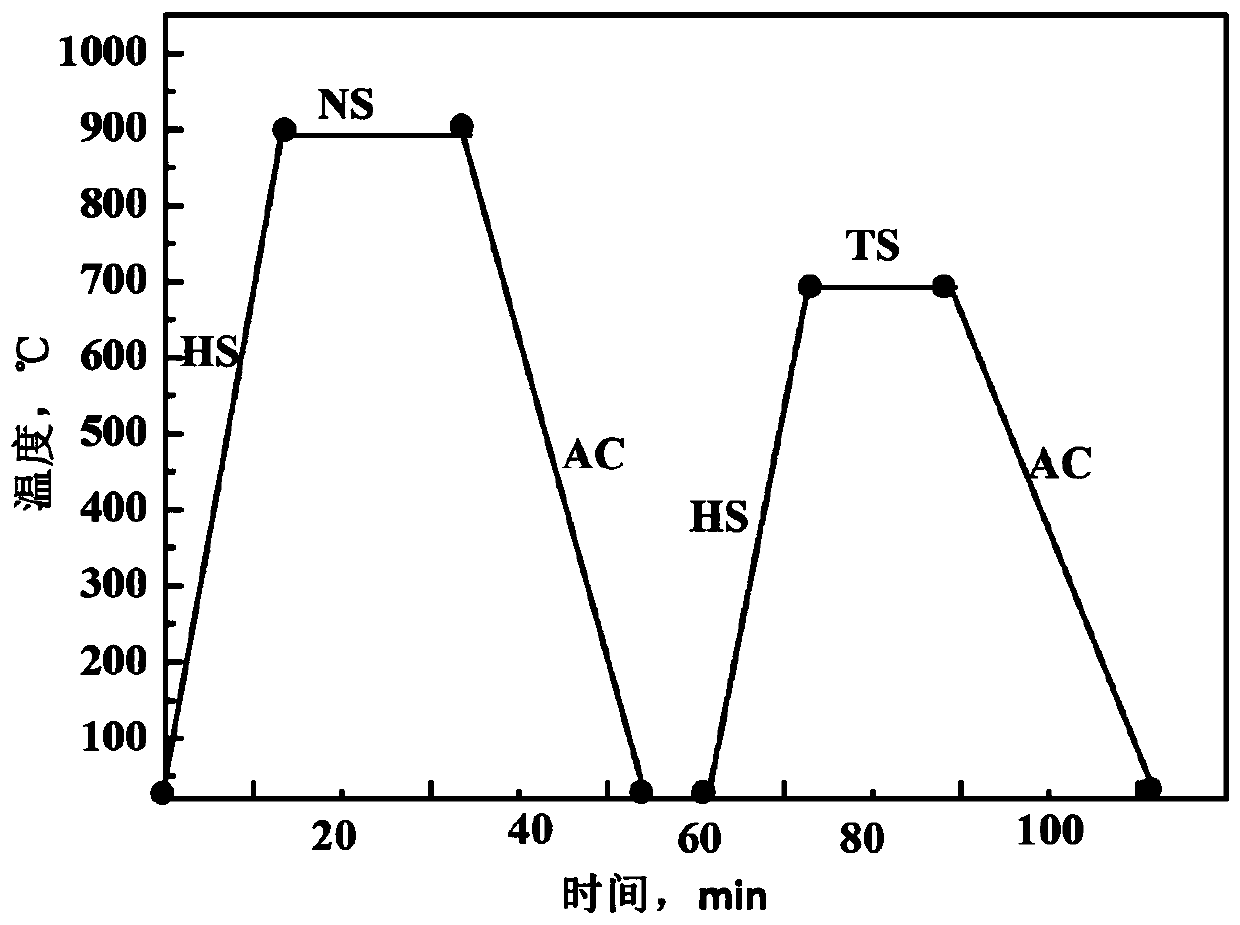

Preparation method of 12Cr2Mo1 hot-rolling container steel plate

InactiveCN108425002AIncrease productivityPromotes nucleation and dispersive precipitationSteel platesSheet steel

The invention relates to a preparation method of a 12Cr2Mo1 hot-rolling container steel plate, and belongs to the technical field of a metallurgical material. The preparation method comprises the following steps: heating the hot-rolled steel plate to 900 to 940 DEG C, preserving heat for 30 to 50 minutes and performing heat-preserving treatment for the first time; and after performing heat-preserving treatment for the first time, cooling to 670 to 730 DEG C, preserving heat for 20 to 30 minutes, performing heat-preserving treatment for the second time and then cooling to a room temperature after performing heat-preserving treatment for the second time. The continuous heat treatment method is high in production efficiency.

Owner:NORTHEASTERN UNIV

Corrosion-resistant aluminum alloy and preparation method and application thereof

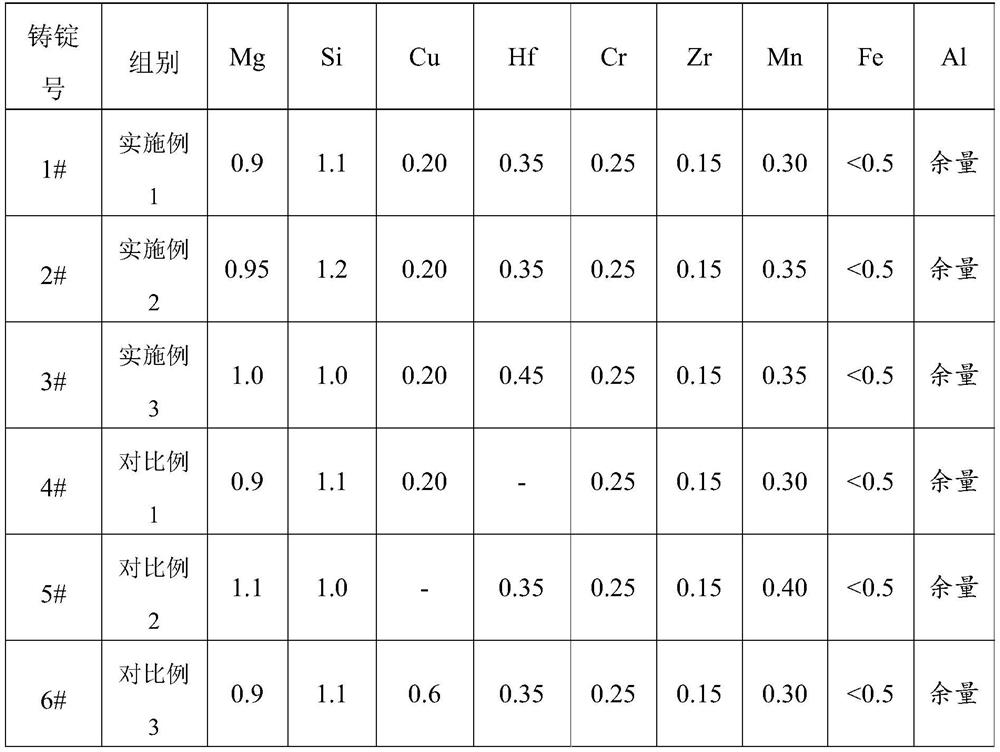

The invention belongs to the field of metal material preparation, and discloses a corrosion-resistant aluminum alloy and a preparation method and application thereof. The corrosion-resistant aluminumalloy comprises, by weight percentage, 0.8-1.2% of Mg, 0.9-1.3% of Si, 0.1-0.3% of Cu, 0.2-0.4% of Mn, 0.15-0.35% of Cr, 0.1-0.3% of Zr, 0.2-0.6% of Hf and less than or equal to 0.5% of Fe. Accordingto the corrosion-resistant aluminum alloy and the preparation method and application thereof, a trace of Hf, Zr and Cr elements are added, a three-stage homogenization process is adopted, so that theprecipitation of a saturated matrix is promoted to form a high-stability (Al, Cr) 3 (Hf, Zr) phase, the growth of recrystallized grains is inhibited, the grains are refined, and the corrosion resistance of the alloy is improved; a high-density (Al, Cr) 3 (Hf, Zr) dispersed phase is formed, so that the strength of the alloy is further improved; by optimizing the contents of Mg, Si and Cu elements,the Mg / Si ratio and the like, Cu-Si and a vacancy form an early aging cluster, dispersion and precipitation of a strengthening phase are promoted, the content of an aging strengthening phase (Mg2Si) is increased, and the alloy achieves high strength; and a proper amount of Cu element is also added, meanwhile, a Q phase, a theta phase and other Cu-containing phases are prevented from being formed,and excellent corrosion resistance can be obtained. The obtained aluminum alloy is suitable for being used as aluminum alloy for automobile structural components or applied to other profiles.

Owner:FOSHAN UNIVERSITY

Preparation method of vanadium nitride and nitride ferrovanadium alloy reinforcing agent

Owner:马鞍山市恒兴耐火炉料厂

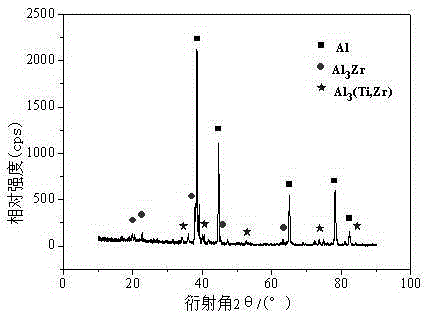

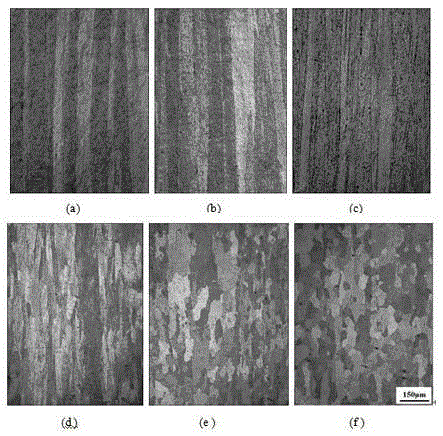

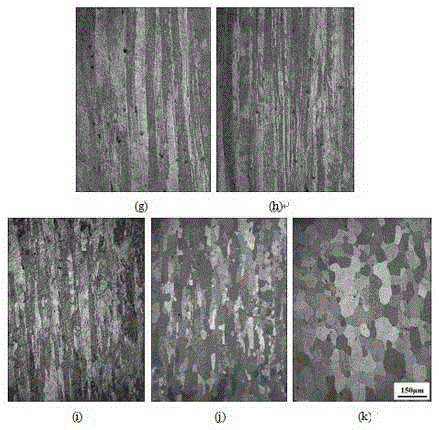

Alloying method for restraining aluminum alloy recrystallization

InactiveCN106555065AInhibition of recrystallizationImprove thermal stabilityHeat stabilityDislocation

The invention provides an alloying method for restraining aluminum alloy recrystallization. The alloying method only involves three kinds of alloy elements being Al, Ti and Zr, involves no precious metal and is low in cost. A melt is obtained through high-frequency electromagnetic oscillation treatment in the vacuum environment under high-purity argon shield, the ally impurity and air hole content is quite small, and all components are dispersedly and uniformly distributed in alloy. Meanwhile, the Ti and Zr elements are separated out in the mode of fine highly-dispersed Al3Zr and Al3(Ti and Zr) second-phase particles in the follow-up ally hot working process, and the dispersed second-phase particles are good in heat stability, can effectively pin dislocation and subboundary in a deformation structure and have a strong restraining effect on the alloy recrystallization process. In other words, the obtained alloy has strong recrystallization resistance, and the state of the deformation structure is well kept. The prepared alloyed aluminum alloy is Ti and Zr high-saturability solid solution state alloy.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Low-cost anti-HIC oil and gas pipeline L290 hot-rolled steel plate and manufacturing method thereof

ActiveCN114774770AReduce central porosity levelAvoid defectsProcess efficiency improvementChemical compositionEngineering

The invention discloses a low-cost anti-HIC L290 hot-rolled steel plate for an oil and gas pipeline and a manufacturing method of the low-cost anti-HIC L290 hot-rolled steel plate. The low-cost anti-HIC L290 hot-rolled steel plate comprises the following chemical components in percentage by weight: 0.03%-0.042% of C, 0.10%-0.20% of Si, 0.30%-0.50% of Mn, 0.08%-0.15% of Cu, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.035%-0.055% of Nb, 0.015%-0.0250% of Ti, 0.015%-0.045% of Al, 0.004%-0.006% of N and the balance of Fe and inevitable impurities. The manufacturing method is used for manufacturing the L290 steel-grade longitudinal welded pipe for the HIC-resistant oil and gas pipeline with the diameter of 10-25 mm and the diameter phi of 914 mm or below. And 2-10 nm Cu-rich and Nb-rich nano precipitated phases are distributed in the structure in a dispersed mode, the comprehensive performance is good, and the service safety of oil and gas pipelines is guaranteed.

Owner:ANGANG STEEL CO LTD

A production process of high-strength 7-series aluminum alloy pipe

ActiveCN109355538BHigh strengthIncreased resistance to stress corrosion susceptibilityFurnace typesHeat treatment furnacesIngot castingHeat conservation

The invention belongs to the technical field of heat treatment of aluminum alloy, and relates to a production technology of a high-strength 7-series aluminum alloy pipe. An aluminum alloy ingot casting is prepared from the following raw materials according to the mass percentage: 7.5-8.5% of Zn, 1.0-3.5% of Mg, 0.10-0.20% of Cu, 0.05-0.3% of Zr, 0.1-1.5% of Mn, 0.05-0.3% of Cr, 0 .05% of Ti, 0.05%of B, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of impurities in total and the balance Al. The two-stage homogenizing treatment and the two-stage aging heat treatment are adopted in the production technology of the aluminum alloy pipe, wherein according to the two-stage homogenizing system, the heat preservation is carried out for 24 hours at the temperature of 470 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 480 DEG C; and according to the two-stage aging system, the heat preservation is carried out for 7 hours at the temperature of 110 DEG C to 130 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 165 DEG C to 170 DEG C. The overall mechanical property of the high-strength 7-series aluminum alloy pipe is effectively improved.

Owner:CHINA ZHONGWANG

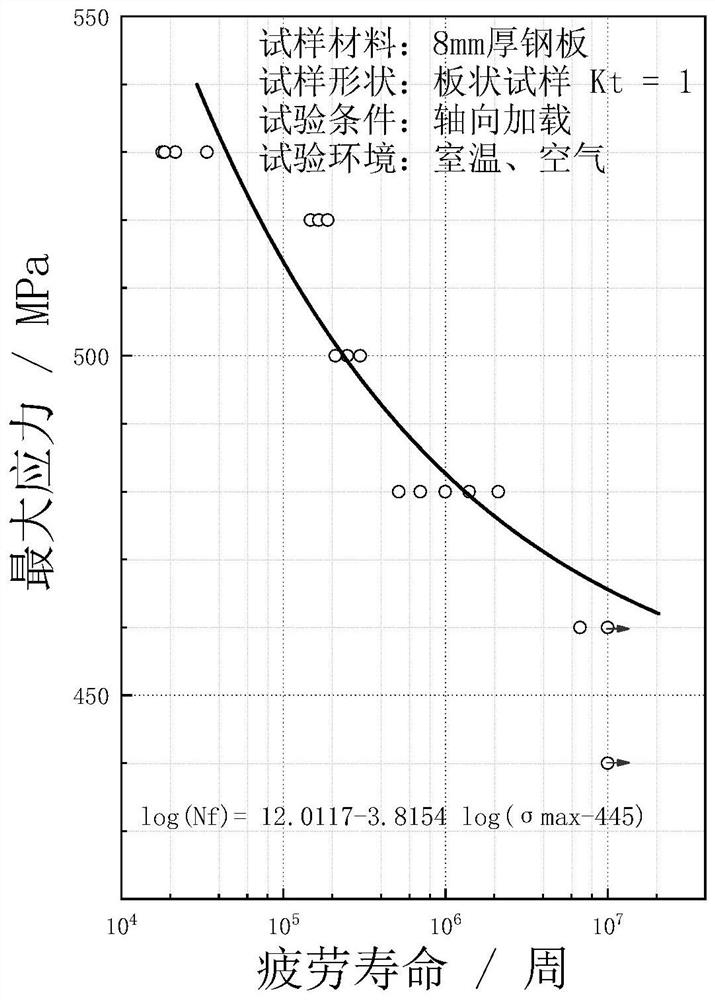

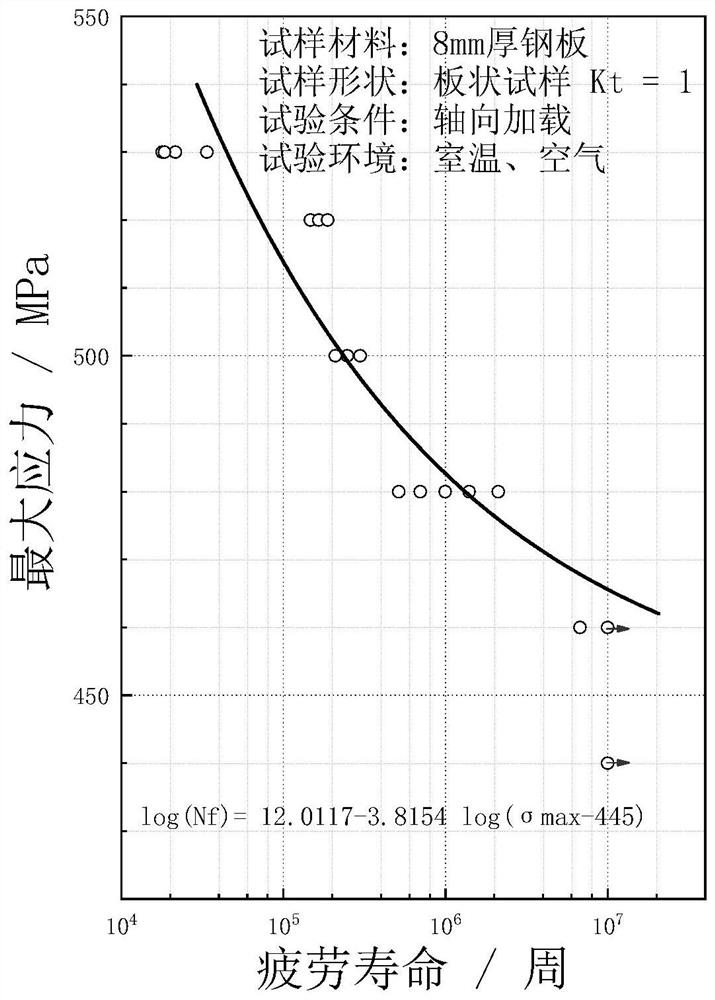

Low-carbon anti-fatigue steel plate for wind power and preparation method thereof

The invention discloses a low-carbon anti-fatigue steel plate for wind power and a preparation method thereof, and belongs to the technical field of ferrous metallurgy. The steel plate for wind power comprises the following chemical components in percentage by mass: 0.08%-0.12% of C, 0.25%-0.35% of Si, 1.45%-1.60% of Mn, 0.02%-0.03% of Nb, 0.03%-0.05% of Al, 0.01%-0.02% of Ti, 0.10%-0.20% of Ni, 0.02%-0.03% of V, less than or equal to 0.10% of Cr, less than or equal to 0.008% of N, less than or equal to 0.012% of P, less than or equal to 0.005% of S, less than or equal to 0.002% of O and the balance of Fe and inevitable impurities. The preparation method comprises billet heating, a rough rolling procedure, a finish rolling procedure, a cooling procedure and tempering heat treatment. The yield strength and fatigue strength of the steel plate for wind power are improved, the welding performance is excellent, and the service life of the steel plate for wind power is prolonged.

Owner:UNIV OF SCI & TECH BEIJING +1

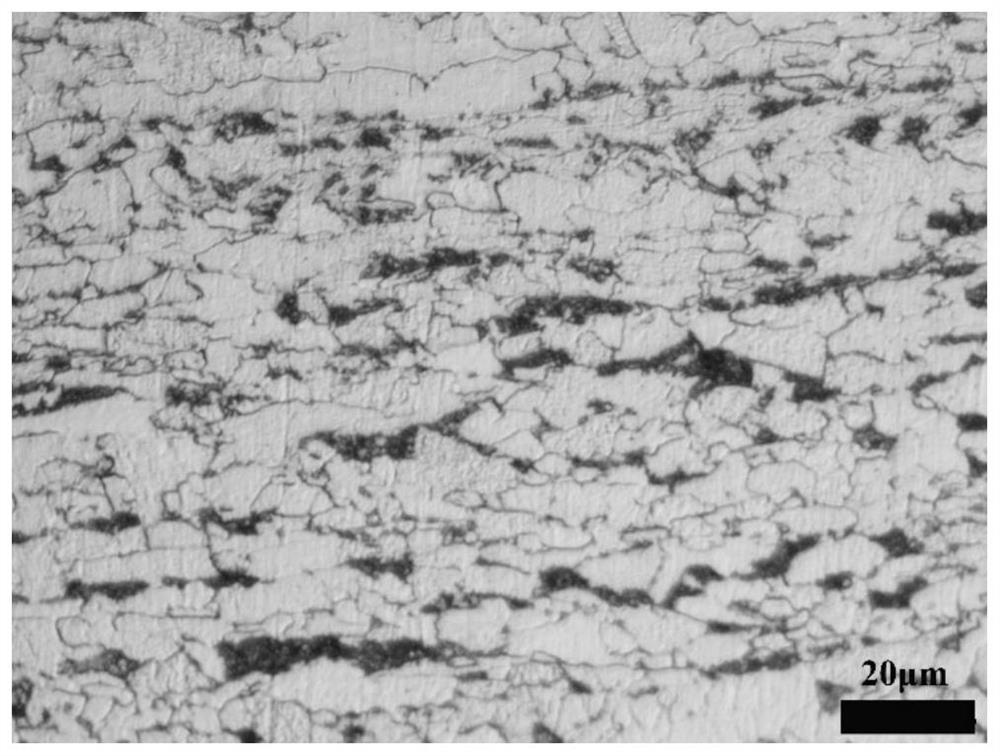

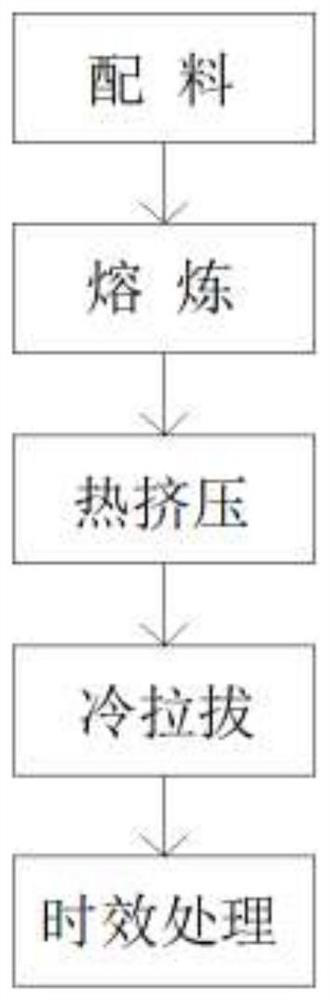

Semi-continuous metal casting process of novel heat-resistant copper alloy and application of novel heat-resistant copper alloy

The invention discloses a semi-continuous metal casting process of a novel heat-resistant copper alloy and application of the novel heat-resistant copper alloy. The copper alloy comprises, by weight, 0.1%-5.0% of Ni, 0.01%-0.5% of Al, 0.01%-2.0% of Si, 0.01%-1.0% of Cr and the balance Cu. The preparation processes of a copper alloy profile include burdening, smelting, hot extrusion, cold drawing and aging treatment. According to the semi-continuous metal casting process of the novel heat-resistant copper alloy and the application of the novel heat-resistant copper alloy, on the basis of a copper alloy material containing Ni and Al, Si and Cr elements are further added, the reasonable ratio of all metal elements is balanced through semi-continuous casting, the performance of a nickel-silicon-copper alloy is improved, the Be-free and Co-free CuNi2SiCrAl high-performance copper alloy is developed and used for replacing beryllium-cobalt-copper series alloys, meanwhile, the raw material cost of the material is greatly reduced, and the copper alloy can be applied to a slot wedge copper alloy part of a steam turbine generator.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

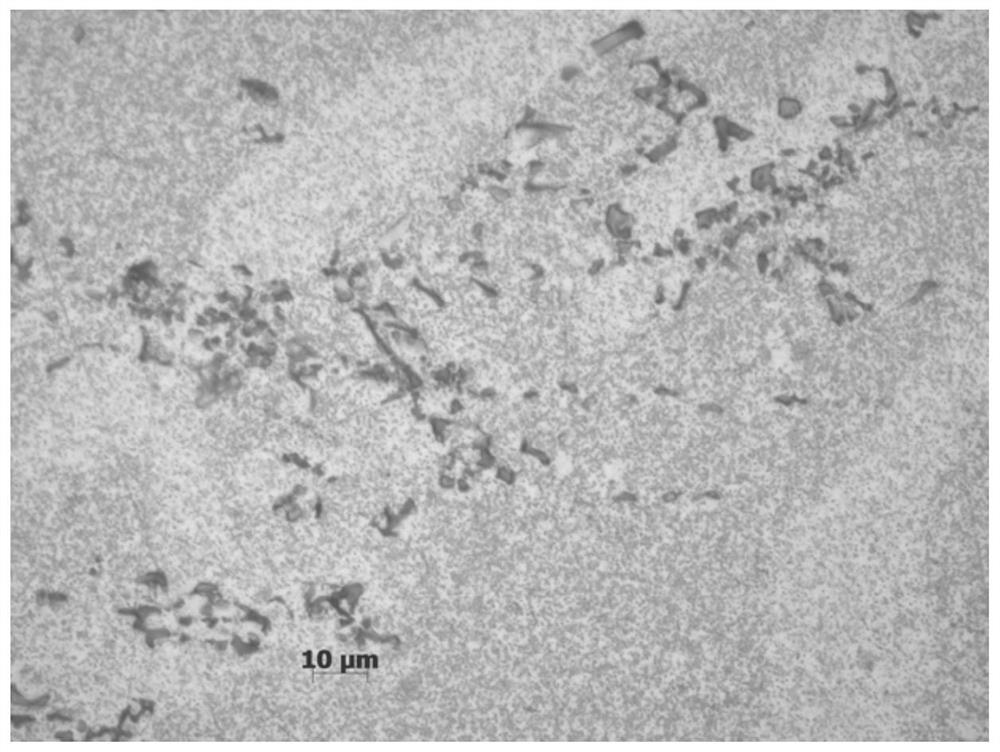

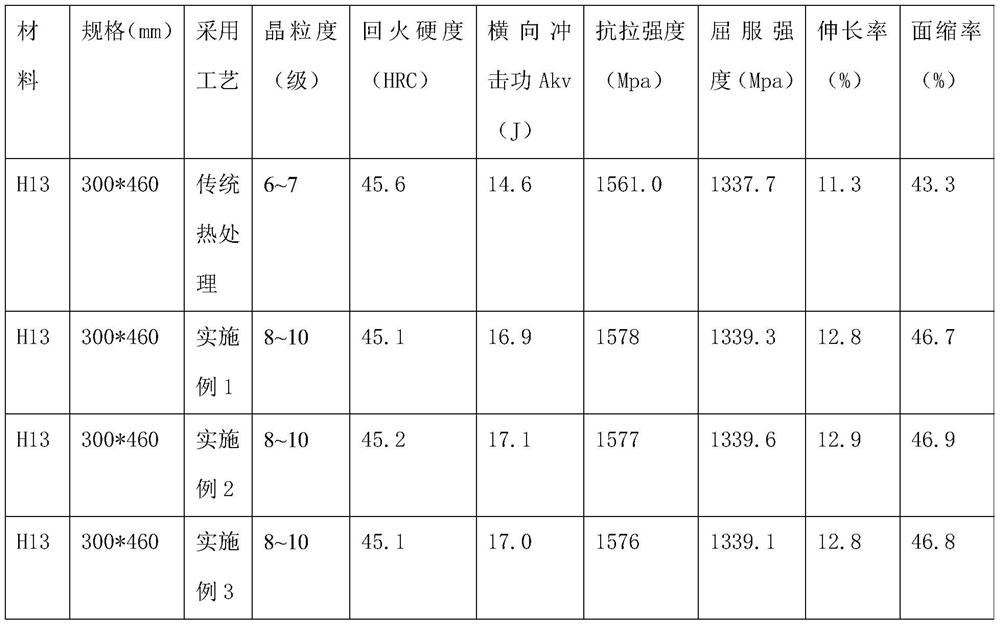

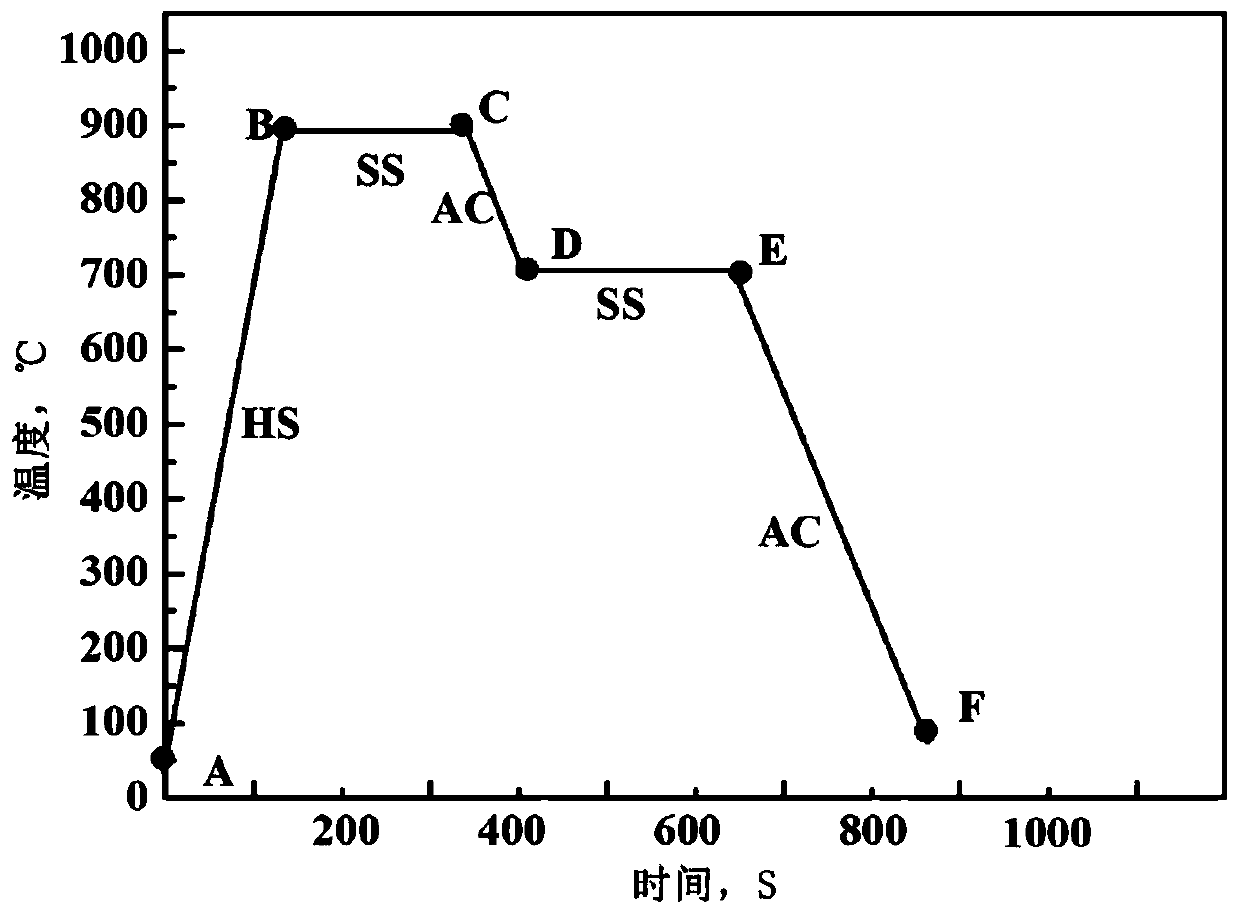

Heat treatment process for ultra-fine grain structure of annealed hot work die steel

ActiveCN114410893AIncreased risk of crackingSmall sizeHeat treatment process controlTemperingStress relief

The invention discloses a heat treatment process for an ultra-fine grain structure of annealed hot work die steel, and belongs to the technical field of heat treatment of hot work die steel. The heat treatment material is an annealed hot-working die blank, and a plurality of thermocouples for detecting temperature are mounted on the core part and the surface of the die; comprising the steps of first-time high-temperature homogenization, first-time air / water alternate quenching, first-time high-temperature tempering, second-time high-temperature quenching after tempering, stress relief annealing, mold quenching and tempering and the like. The method has the beneficial effects that the heat treatment process is completely utilized for regulation and control, liquation carbides, martensite structures and austenite grains can be refined at the same time, and the impact toughness is improved while the material strength is kept. And the grain size can be improved from 6-7 grades to 8-10 grades, the transverse impact toughness can be improved by 15% or above, and the room-temperature plasticity is also improved.

Owner:CENT IRON & STEEL RES INST

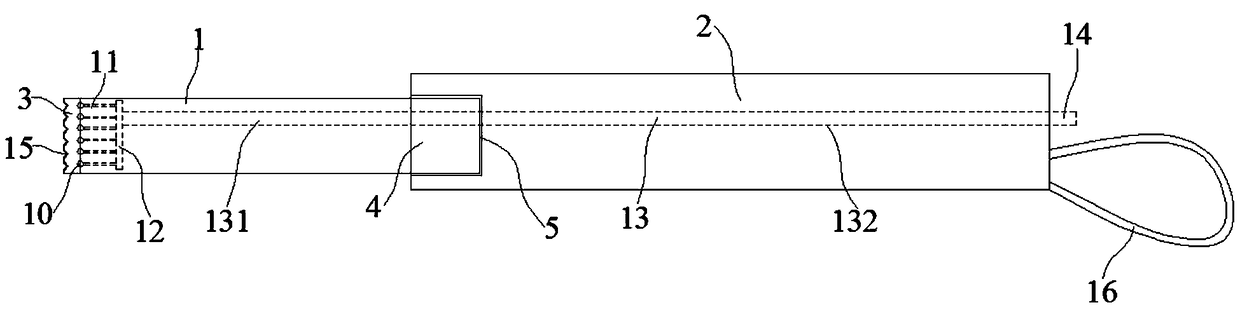

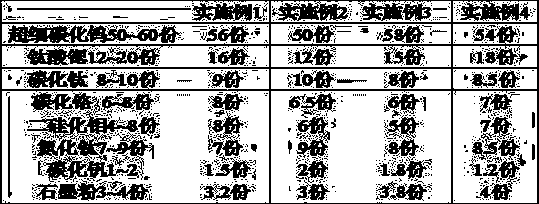

Non-slip surgical scalpel

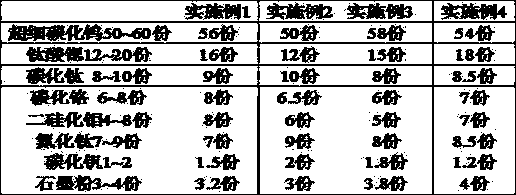

InactiveCN108236488ATight textureImprove flexural strengthIncision instrumentsChromium carbideStrontium titanium oxide

The invention discloses a non-slip surgical scalpel, which comprises a blade and a strip-shaped scalpel handle. A making method comprises the following steps: I, crushing the following materials in apulverizer: 50-60 parts of superfine tungsten carbide, 12-20 parts of strontium titanate, 8-10 parts of titanium carbide, 6-8 parts of chromium carbide, 4-8 parts of molybdenum disilicide, 7-9 parts of titanium nitride, 1-2 parts of vanadium carbide and 3-4 parts of graphite powder, so that mixed powder, which is less than 20mm in diameter, is formed; II, heating the mixed powder obtained from thestep I to 850 DEG C under a vacuum condition for 4h, then adding 4-6 parts of phenolic resin, fully stirring all materials uniformly so as to obtain a mixture, and cooling the mixture; III, forming and pressing the mixture via a press machine, so that a pressed blank is formed; and IV, sintering the pressed blank in a sintering furnace, so that a blade blank is formed. According to the multifunctional scalpel provided by the invention, the cutting edge is sharper, and hard tissues can be cut open quite easily; and the blade is quite shape, quite high in intensity and cannot get bent easily.

Owner:源科弘森精密科技(昆山)有限公司

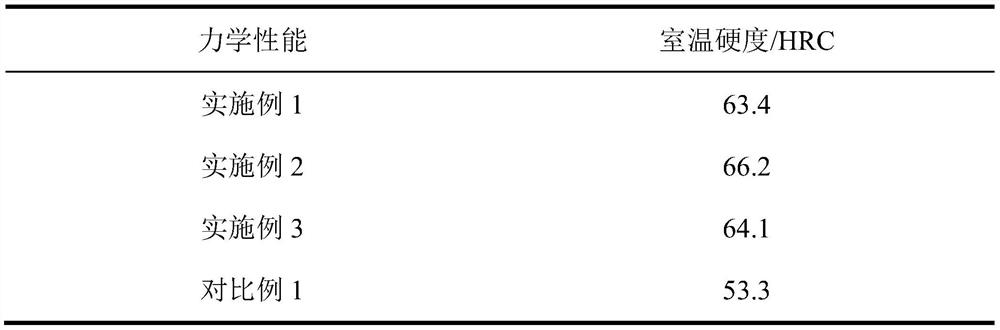

Heat-treated vanadium-containing high-boron high-speed steel and heat treatment method thereof

The invention discloses a heat-treated vanadium-containing high-boron high-speed steel and a heat treatment method thereof. According to the heat treatment method, quenching treatment is conducted on the vanadium-containing high-boron high-speed steel at the temperature of 1010-1060 DEG C to obtain a quenched part; and the quenched part is subjected to tempering treatment twice, and after the part is subjected to air cooling to the room temperature, the heat-treated vanadium-containing high-boron high-speed steel is obtained. According to the vanadium-containing high-boron high-speed steel and the preparation method thereof, the form of boron carbide is improved through vanadium addition and a heat treatment process, matrix strengthening is promoted, the vanadium-containing high-boron high-speed steel with excellent strength and toughness is obtained, and the vanadium-containing high-boron high-speed steel subjected to heat treatment can be better adapted to severe working conditions when being applied to actual production.

Owner:XI AN JIAOTONG UNIV

A kind of preparation method of 12cr2mo1 hot-rolled container steel plate

The invention relates to a preparation method of 12Cr2Mo1 hot-rolled container steel plates and belongs to the technical field of metallurgical materials. The preparation method of the present invention is as follows: heating the hot-rolled steel plate to 900-940°C, holding it for 30-50 minutes, and performing a primary heat preservation treatment; after the primary heat preservation treatment, cool it to 670-730°C, hold it for 20-30 minutes, and conduct a second heat preservation treatment. Heat preservation treatment, then lower to room temperature after secondary heat preservation treatment. The continuous heat treatment method of the present invention has high production efficiency.

Owner:NORTHEASTERN UNIV LIAONING

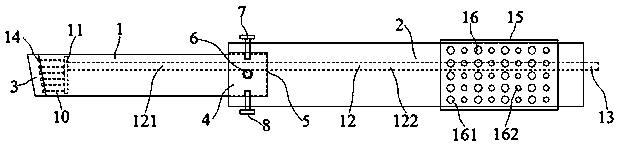

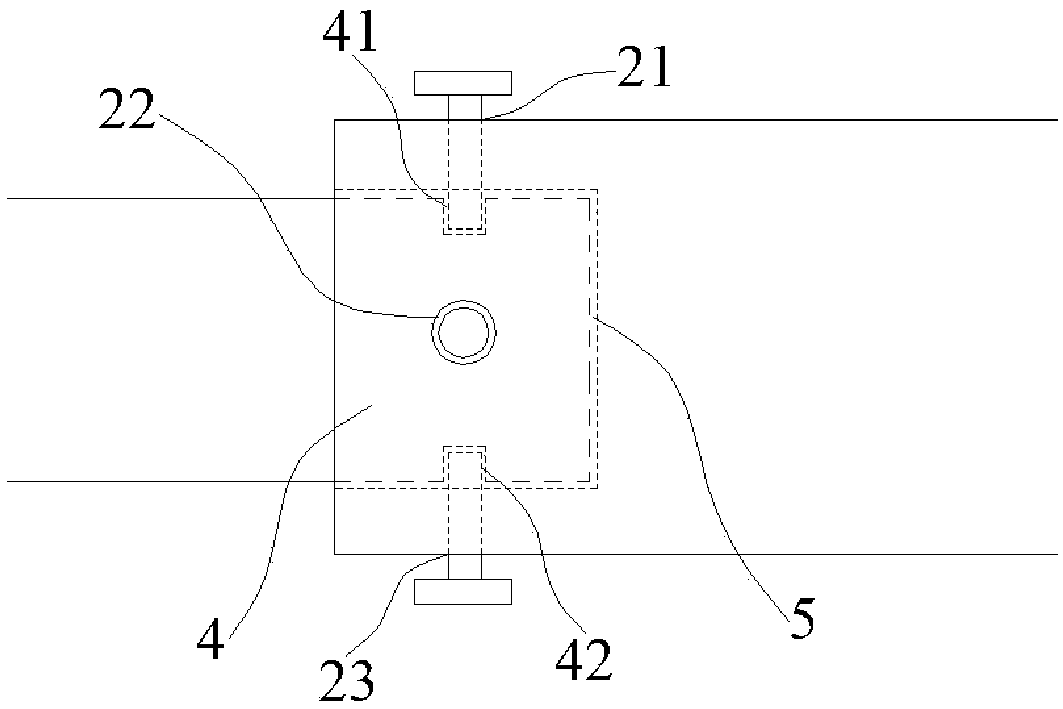

Making method of minimally invasive scalpel

InactiveCN108236486ATight textureImprove flexural strengthIncision instrumentsChromium carbidePulverizer

The invention discloses a making method of a minimally invasive scalpel. One end of a blade is a cutting edge and the other end is provided with an inserting part; a lower bolt rod is screwed into a lower threaded hole and is embedded into a lower concave hole of the inserting part; a plurality of blood suction holes are formed in the cutting edge, and the blood suction holes communicate with a liquid collection tube via branch catheters; a chamfered inclined plane is arranged at the upper side of the cutting edge; a rubber sleeve sleeves the middle-rear part of a strip-shaped scalpel handle;and a plurality of convex points are uniformly distributed on the outer surface of the rubber sleeve. The blade is made by the following steps: crushing the following materials in a pulverizer: 50-60parts of superfine tungsten carbide, 12-20 parts of strontium titanate, 8-10 parts of titanium carbide, 6-8 parts of chromium carbide, 4-8 parts of molybdenum disilicide, 7-9 parts of titanium nitride, 1-2 parts of vanadium carbide and 3-4 parts of graphite powder, so that mixed powder, which is less than 20mm in diameter, is formed. According to the minimally invasive scalpel obtained by the making method provided by the invention, the blade of the scalpel is ultrahigh in hardness, and moreover, the blade, which is forged is quite sharp and is quite high in intensity so as to avoid easy bending; the minimally invasive scalpel is stable and reliable; and three-dimensional location is achieved.

Owner:源科弘森精密科技(昆山)有限公司

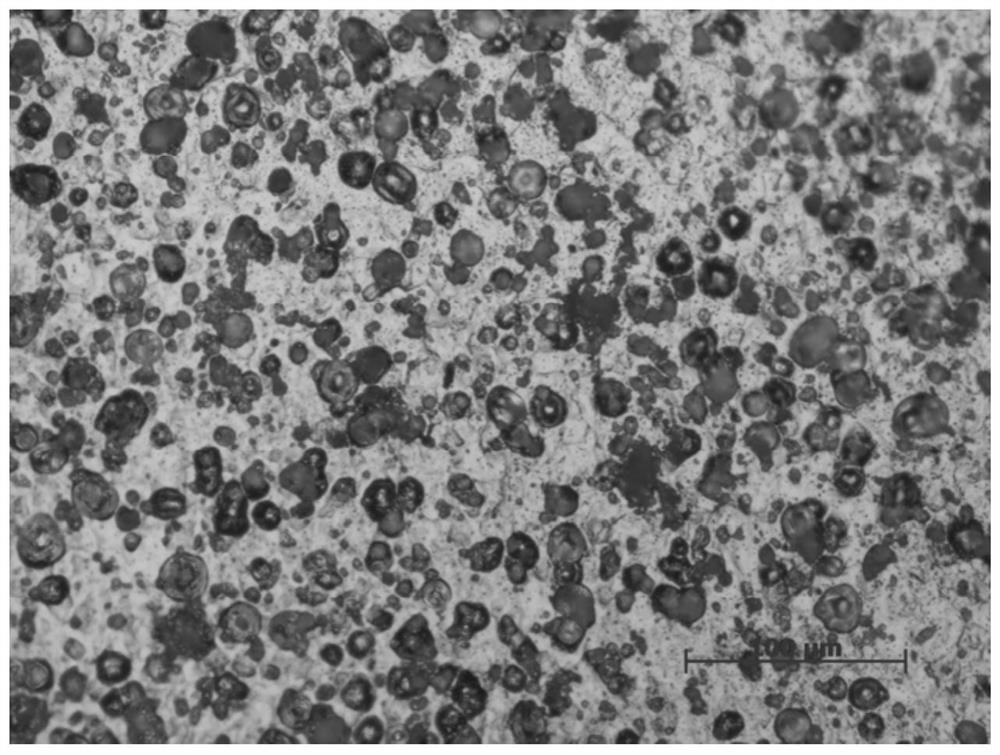

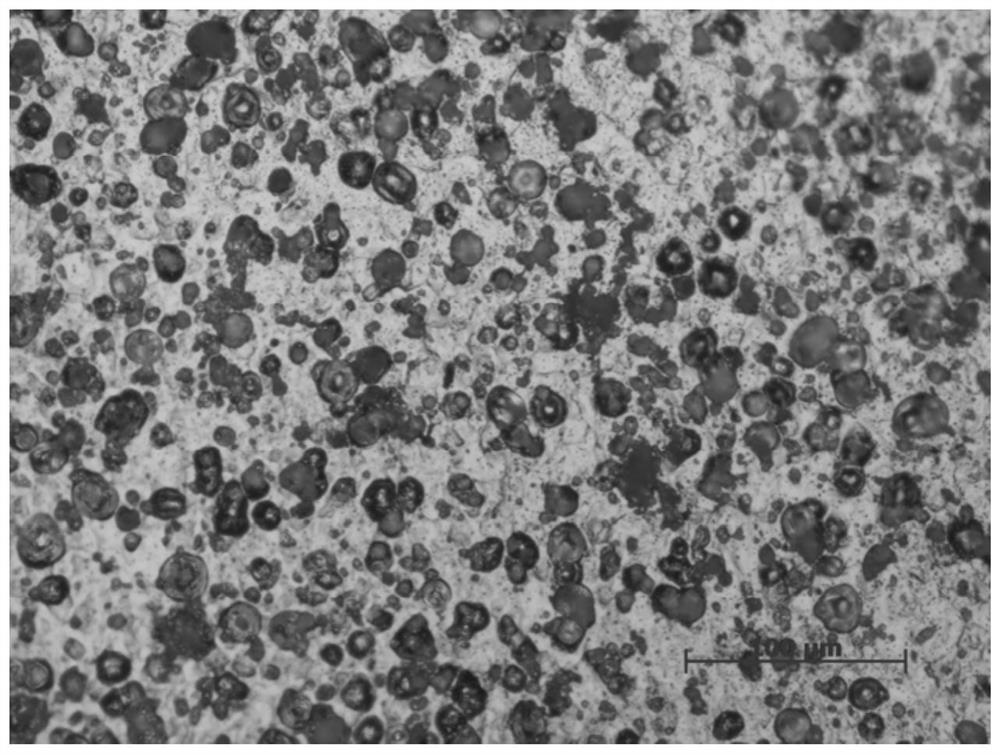

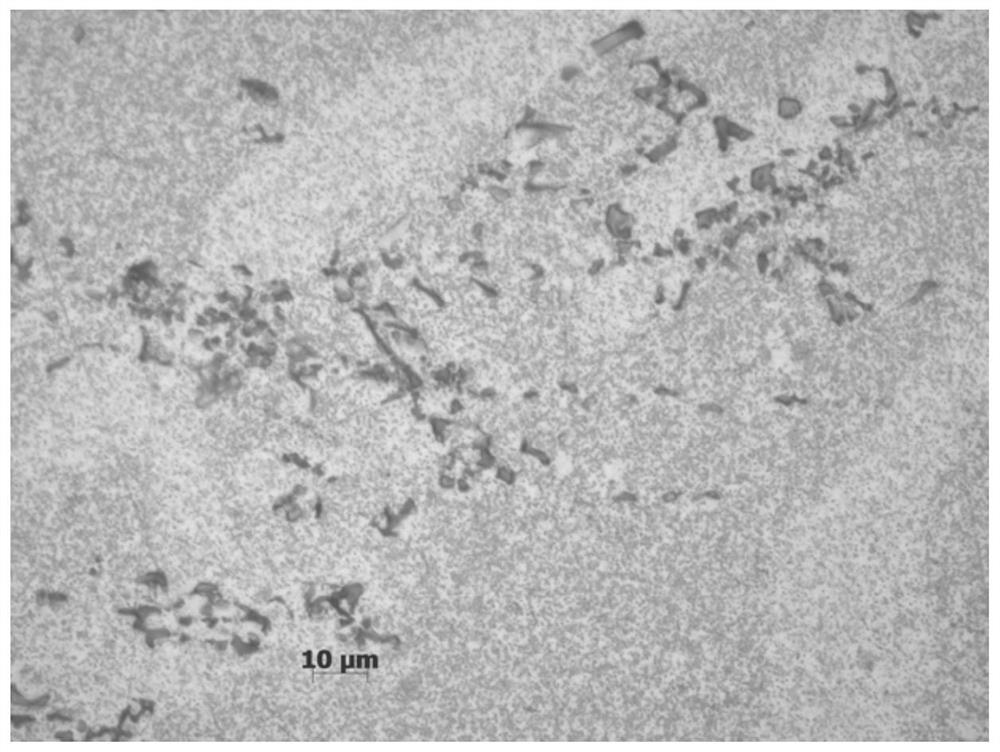

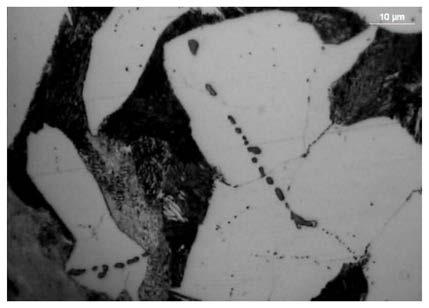

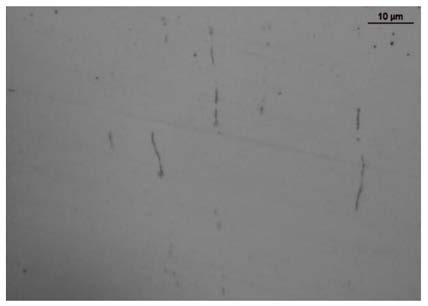

Homogenization and heating combined integrated heat treatment technology and aluminum alloy cast ingot

ActiveCN111020422AImprove pass rateImprove uniformityFurnace typesHeat treatment furnacesIngotFe element

The invention provides a homogenization and heating combined integrated heat treatment technology and an aluminum alloy cast ingot. Aiming at 8000-series aluminum alloy with high Fe element content, the technology comprises a homogenizing heat treatment process and a heating heat treatment process, Fe-containing second phase dispersed distribution in a cast ingot structure can be promoted, rod-shaped intermittent distribution at a grain boundary and spherical dispersion distribution in grains are realized, and the material performance is improved. The aluminum alloy casting part adopting the technology is subsequently processed into a mirror plate, the surface of the mirror plate has no stripe-shaped and pocking mark defects, the glossiness is high, the overall manufacturing cost is reduced, and the technology is suitable for industrial production of high-end 8000-series mirror surface aluminum alloy plate strips.

Owner:中铝河南洛阳铝加工有限公司 +1

A kind of copper chromium zirconium alloy and preparation method thereof

A copper chromium zirconium alloy comprises, by weight, 0.7% to 2.0% of chromium, 0.05% to 0.3% of zirconium, 0.01% to 0.08% of magnesium, 0.01% to 0.1% of yttrium and the balance copper. The invention further provides a preparing method of the copper chromium zirconium alloy. The preparing method sequentially comprises the following steps that firstly, the copper, the chromium, the zirconium, the magnesium and the yttrium are prepared according to the proportion and are subject to vacuum purified smelting and flow dividing type casting, and a casting blank is prepared; secondly, the casting blank is subject to homogenization treatment and hot extrusion, and a sheared billet is prepared; thirdly, the sheared billet is subject to solid-solution treatment; fourthly, the sheared billet obtained after the solid-solution treatment is subject to cold deformation machining; and fifthly, a material obtained after cold deformation machining is subject to aging treatment, and the needed copper chromium zirconium alloy is obtained. The copper chromium zirconium alloy has the good comprehensive performance, the room temperature tensile strength of the copper chromium zirconium alloy is larger than 520 MPa, the room temperature elongation of the copper chromium zirconium alloy is larger than or equal to 22%, the room temperature electric conductivity of the copper chromium zirconium alloy is larger than or equal to 90%IACS, and the 350 DEG C high-temperature tensile strength of the copper chromium zirconium alloy is larger than 390 MPa.

Owner:SHANTOU HUAXING (RAOPING) COPPER IND CO LTD +1

A kind of anticorrosion aluminum alloy and its preparation method and application

The invention belongs to the field of metal material preparation, and discloses a corrosion-resistant aluminum alloy and its preparation method and application, including Mg 0.8-1.2%, Si 0.9-1.3%, Cu 0.1-0.3%, Mn 0.2-0.2% by weight percentage 0.4%, Cr 0.15‑0.35%, Zr 0.1‑0.3%, Hf 0.2‑0.6%, and Fe≤0.5%. The present invention adds trace elements of Hf, Zr and Cr, and adopts a three-stage homogenization process to promote the precipitation of saturated matrix to form highly stable (Al, Cr) 3 (Hf, Zr) phase, inhibit the growth of recrystallized grains, refine the grains, improve the corrosion resistance of the alloy; form high-density (Al, Cr) 3 (Hf, Zr) dispersed phase to further improve the strength of the alloy; by optimizing the content of Mg, Si, Cu elements and the ratio of Mg / Si, Cu Si and vacancies form early aging clusters to promote the dispersion precipitation of strengthening phase and improve aging strengthening Phase (Mg 2 Si) content, to obtain higher strength of the alloy; the present invention also adds an appropriate amount of Cu elements, while avoiding the formation of Q phase, θ equal Cu-containing phase, and can obtain better corrosion resistance. The obtained aluminum alloy is suitable as an aluminum alloy for automobile structural parts or applied in its profiles.

Owner:云南律奥新技术开发有限公司

A kind of preparation method of high-strength magnesium-lithium alloy and cryogenic strengthening treatment thereof

The invention provides a high-strength magnesium-lithium alloy and a preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy, and belongs to the technicalfield of high-strength alloys and preparation thereof. The high-strength magnesium-lithium alloy comprises Li, Y, Zn, unavoidable impurity elements and Mg. The atomic ratio of Y and Zn is higher than1.32. The preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy comprises the steps of smelting and casting, homogenization heat treatment, 77 K cryogenic treatment, plastic forming machining and the like. According to the high-strength magnesium-lithium alloy and the preparation method of cryogenic strengthening treatment of the high-strength magnesium-lithium alloy, the Y and Zn elements are dissolved into a magnesium-lithium alloy matrix by simultaneously adding the Y and Zn elements, twin crystal refined grains are obtained in an alpha-Mg phase through homogenization heat treatment, cryogenic treatment, plastic forming machining, self-generating in a beta-Li phase is conducted to obtain an X-Mg12YZn phase of a layered LPSO structure, the effect of strengthening the beta-Li phase is achieved, and therefore the alloy is strengthened.

Owner:铜川华铸精密科技有限公司

A low-carbon anti-fatigue steel plate for wind power and its preparation method

The invention discloses a low-carbon anti-fatigue steel plate for wind power and a preparation method thereof, belonging to the technical field of iron and steel metallurgy. The chemical composition and mass percentage of the steel plate for wind power are: C: 0.08-0.12%, Si: 0.25-0.35%, Mn: 1.45-1.60%, Nb: 0.02-0.03%, Al; 0.03-0.05%, Ti : 0.01‑0.02%, Ni: 0.10‑0.20%, V: 0.02‑0.03%, Cr≤0.10%, N≤0.008%, P≤0.012%, S≤0.005%, O≤0.002%, the rest is Fe and not Avoid impurities. The preparation method includes billet heating, rough rolling process, finish rolling process, cooling process and tempering heat treatment. The invention improves the yield strength and fatigue strength of the steel plate for wind power, has excellent welding performance, and increases the service life of the steel for wind power.

Owner:UNIV OF SCI & TECH BEIJING +1

An integrated heat treatment process combining homogenization and heating and aluminum alloy ingot casting

ActiveCN111020422BImprove pass rateImprove uniformityFurnace typesHeat treatment furnacesIngot castingGrain boundary

The invention provides an integrated heat treatment process combining homogenization and heating and aluminum alloy castings. The process is aimed at 8000 series aluminum alloys with high Fe element content, including a homogenization heat treatment process and a heating heat treatment process, which can promote the ingot microstructure The second phase containing Fe is diffusely distributed, discontinuously distributed in a rod shape at the grain boundary, and spherically dispersed in the grain, which improves the material properties. The aluminum alloy castings using this process are subsequently processed into mirror panels without streaks and pitting defects, with high gloss and reduced overall manufacturing costs, which are suitable for industrial production of high-end 8000 series mirror aluminum alloy sheets and strips.

Owner:中铝河南洛阳铝加工有限公司 +1

A method for producing sulfur-containing gear steel for wind power gears

ActiveCN110184522BReduce peroxidationReduce oxygen contentManufacturing convertersTemperature controlCalcium handling

The invention discloses a method for producing sulphur-containing gear steel for a wind power gear. The method comprises the following steps that end-point carbon and oxygen equilibrium is 0.0026% orbelow during melting in a converter, and FeO content in large ladle slags is 1.5wt% or below; LF refining final slags adopt a high basicity and low Ca-Al ratio, RH adopts high vacuum and large circulation operation, after calcium treatment, sulphur wires are fed at interval time of greater than or equal to 8 minutes, and the soft blowing time is greater than or equal to 10 minutes; in the whole process of continuous casting, protective casting is achieved, and dynamic soft reduction is adopted; the drawing speed is stably controlled within the standard drawing speed range of 0.6+ / -0.025 m / minand the water content of secondary cooling ratio is controlled at 0.45-0.50; after continuous casting, a rectangular billet is subjected to heating and cogging, and then is rolled into the square billet and slowly cooled; after checking the slowly-cooled square billet, four horizontal surfaces are coated with anti-high-temperature and anti-oxidation coatings; and the square billet is heated in a heating furnace, the surface of the square billet is dephosphorized by high pressure water after being heated, then a finished bar is rolled according to the conventional process, and the temperature is controlled at 800-830 DEG C after finishing rolling. By means of the method for producing sulphur-containing gear steel for the wind power gear, the technical problems of high oxygen content, unstable composition content and uniformity, uncontrollable sulfide precipitation and high banded structure grade can be effectively solved.

Owner:HANDAN IRON & STEEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com