Corrosion-resistant aluminum alloy and preparation method and application thereof

A technology of aluminum alloy and alloy ingot, which is applied in the field of corrosion-resistant aluminum alloy and its preparation, can solve the problems of cost limitation on the industrial application of Sc-containing rare earth aluminum alloy, and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

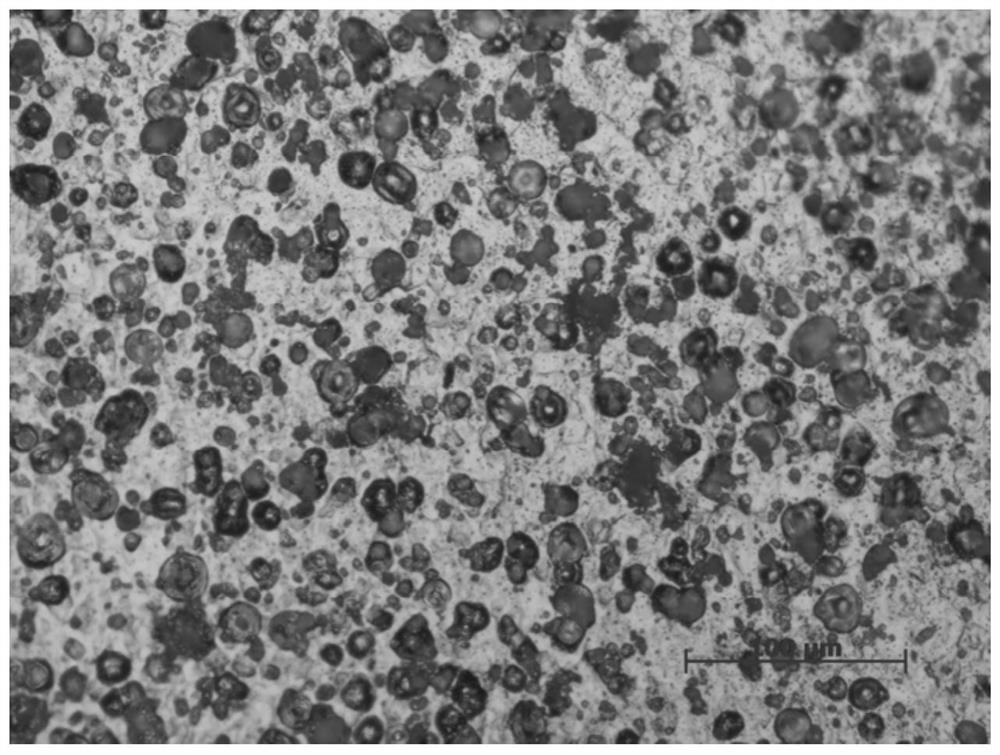

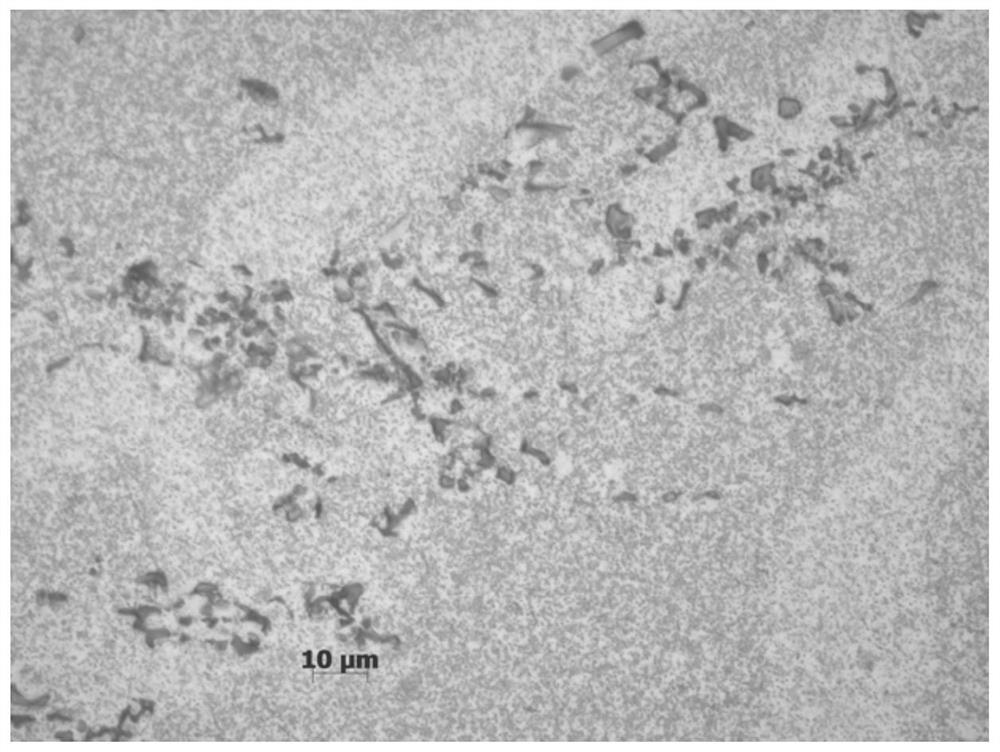

Image

Examples

Embodiment 1-3 and comparative example 1-3

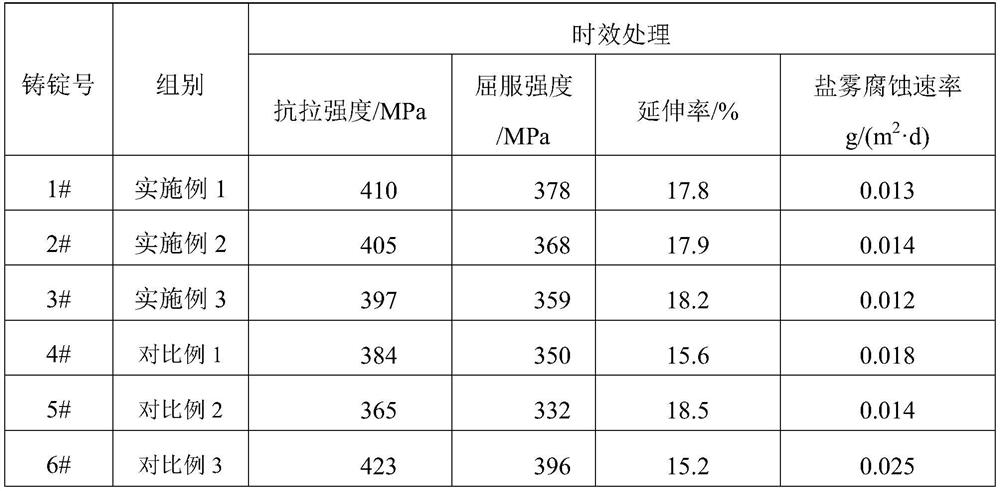

[0039] Table 1-1 Example 1-3 (ingot numbers corresponding to 1#-3#) and comparative examples 1-3 (ingot numbers corresponding to 4#-6#), the components and weight percentages of the aluminum alloys obtained respectively .

[0040] Ingot No. group Mg Si Cu f Cr Zr mn Fe Al 1# Example 1 0.9 1.1 0.20 0.35 0.25 0.15 0.30 <0.5

margin 2# Example 2 0.95 1.2 0.20 0.35 0.25 0.15 0.35 <0.5

margin 3# Example 3 1.0 1.0 0.20 0.45 0.25 0.15 0.35 <0.5

margin 4# Comparative example 1 0.9 1.1 0.20 - 0.25 0.15 0.30 <0.5

margin 5# Comparative example 2 1.1 1.0 - 0.35 0.25 0.15 0.40 <0.5

margin 6# Comparative example 3 0.9 1.1 0.6 0.35 0.25 0.15 0.30 <0.5

margin

[0041] The preparation method of aluminum alloy is:

[0042] 1) Proportioning raw materials: Proportioning raw materials according to the components and weight percentages described in Table 1-1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com