Semi-continuous metal casting process of novel heat-resistant copper alloy and application of novel heat-resistant copper alloy

A metal casting, heat-resistant copper technology, applied in the field of semi-continuous metal casting technology, can solve the problems of generator set explosion, human and environmental poisoning, slot wedge flying off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

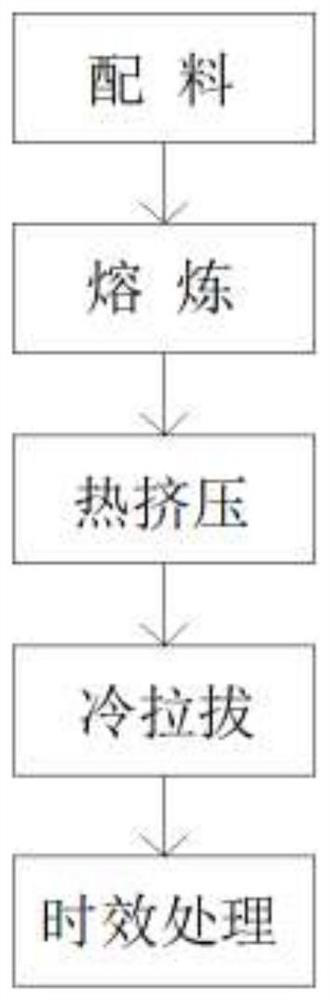

[0037] Such as figure 1 As shown, a semi-continuous metal casting process of a novel heat-resistant copper alloy, the novel heat-resistant copper alloy is a CuNi2SiCrAl high-performance copper alloy without Be and without Co, comprising the following steps:

[0038] S1 ingredients: Weigh Cu, Ni, Si, Cr, Al according to the composition ratio, wherein Ni: 2.17wt%, Al: 0.09wt%, Si: 0.28wt%, Cr: 0.22wt%, Cu: balance, where The total content of Cu, Ni, Al, Si, and Cr elements is 99.98%, and the atomic percentage ratio of Si to Cr is: Si / Cr=1.27;

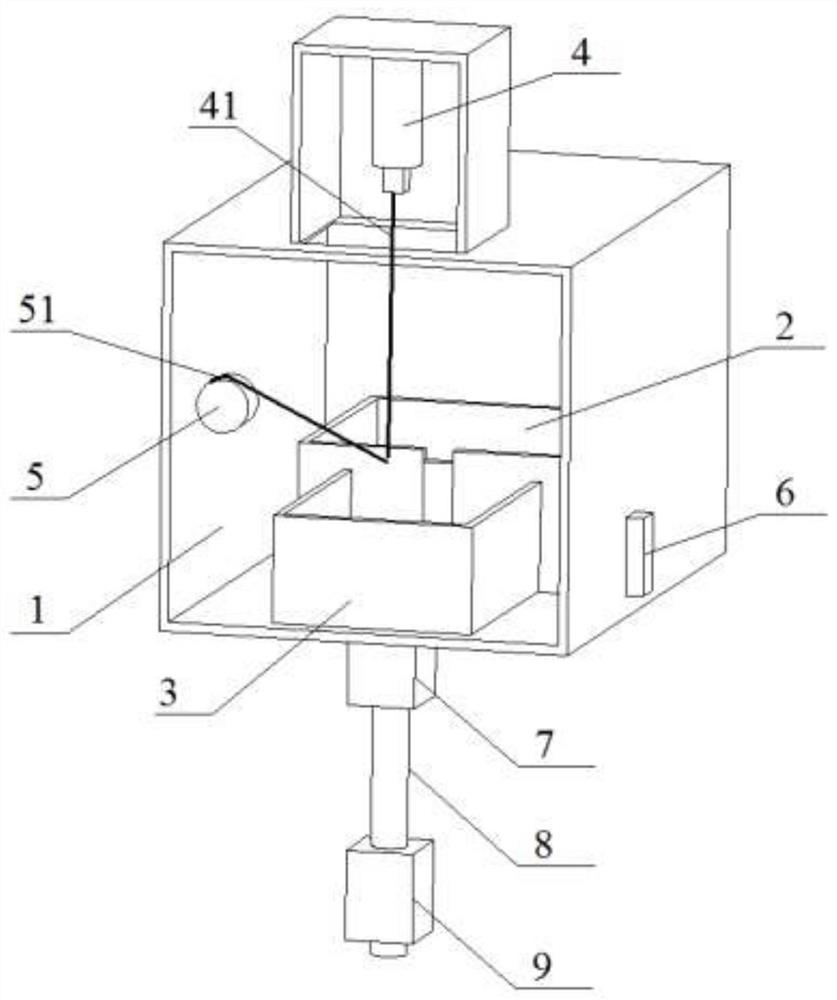

[0039] S2 smelting: as figure 2 As shown, the metal components after batching are smelted by semi-continuous casting. During the smelting process, the intermediate alloys are successively added into the crucible according to the melting point and the degree of easy oxidation and burning, and the ingot with a diameter of 200 is manufactured. The specific steps include: :

[0040] S2-1: Place the first graphite crucible 2 and the second g...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, the difference is:

[0052] S1 ingredients: Weigh Cu, Ni, Si, Cr, Al according to the composition ratio, wherein Ni: 2.68wt%, Al: 0.18wt%, Si: 0.44wt%, Cr: 0.40wt%, Cu: balance, where The total content of Cu, Ni, Al, Si, and Cr elements is 99.97%, and the atomic percentage ratio of Si and Cr is: Si / Cr=1.1.

Embodiment 3

[0054] This embodiment is basically the same as Embodiment 1, the difference is:

[0055] S1 ingredients: Weigh Cu, Ni, Si, Cr, Al according to the composition ratio, wherein Ni: 3.51wt%, Al: 0.22wt%, Si: 0.86wt%, Cr: 0.53wt%, Cu: balance, where The total content of Cu, Ni, Al, Si, and Cr elements is 99.98%, and the atomic percentage ratio of Si and Cr is: Si / Cr=1.62.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com