Making method of minimally invasive scalpel

A manufacturing method and scalpel technology, which is applied in the field of medical equipment, can solve the problems of the blade falling off and high risk, and achieve the effects of avoiding easy loosening, increasing bending strength, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

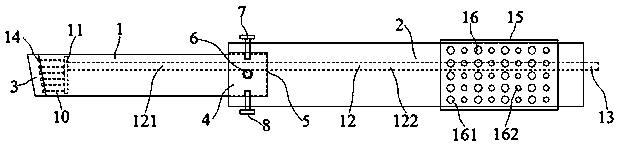

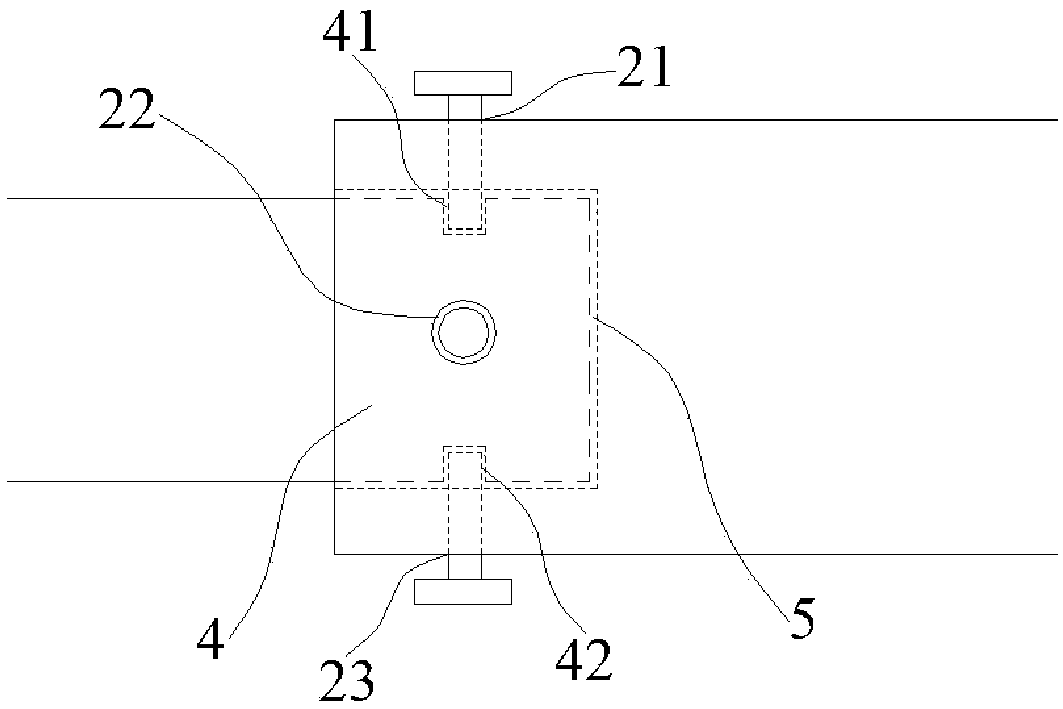

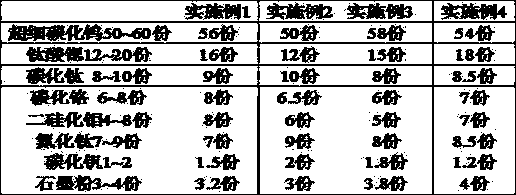

[0029] Embodiment 1: A kind of manufacturing method of minimally invasive scalpel, comprising: blade 1, strip handle 2, one end of described blade 1 is blade 3, and the other end is inserting part 4, and the upper end surface of this inserting part 4 There are upper concave holes 41 and lower concave holes 42 on the lower end surface respectively, and the front end of the bar-shaped knife handle 2 has a socket 5 for inserting the insertion part 4; There are upper threaded hole 21, middle threaded hole 22 and lower threaded hole 23, a locking screw 6 is screwed into the middle threaded hole 22 and presses the socket part 4, and an upper bolt rod 7 is screwed into the upper threaded hole 21 and inserted into the socket. In the upper concave hole 41 of the joint part 4, the lower bolt rod 8 is screwed into the lower threaded hole 23 and embedded in the lower concave hole 42 of the socket part 4; the angle between the edge of the blade 3 of the blade 1 and the length direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com