Non-slip surgical scalpel

A scalpel, anti-skid technology, applied in the field of medical equipment, can solve the problems of the blade falling off and high risk, and achieve the effects of sharp knife edge, improved wear resistance, and increased chipping resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

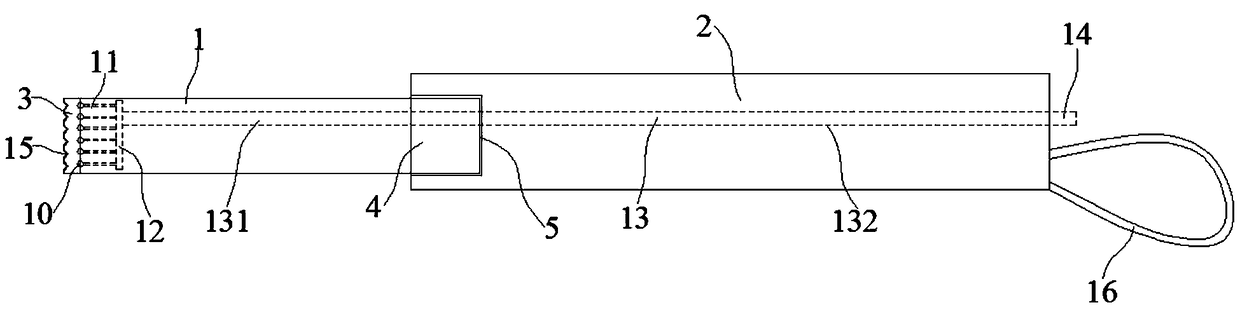

[0029] Embodiments 1 to 4: A non-slip surgical scalpel, comprising: a blade 1, a strip handle 2, one end of the blade 1 is a blade 3, and the other end is a socket 4, and the strip handle 2 The front end has a socket 5 for inserting the socket part 4;

[0030] There are several blood-sucking holes 10 on the blade 3, and the blood-sucking holes 10 communicate with the liquid collection pipe 12 through the sub-conduit 11, and the liquid collection pipe 12 is connected to the liquid suction interface 14 through the conduit 13, and the sub-conduit 11 is connected to the liquid collection pipe 12. The liquid collecting pipe 12 is located in the blade 1;

[0031] The edge of the blade 3 has several serrated cutting edges 15 arranged at intervals, and a noose 16 for putting on the hand is installed on the rear portion of the bar handle 2 .

[0032] The blade 1 is obtained through the following steps:

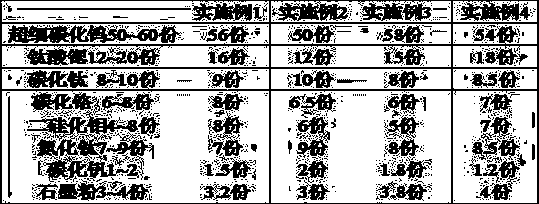

[0033] Step 1: Add 50-60 parts of superfine tungsten carbide, 12-20 parts of str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com