Patents

Literature

191results about How to "Sharp edge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

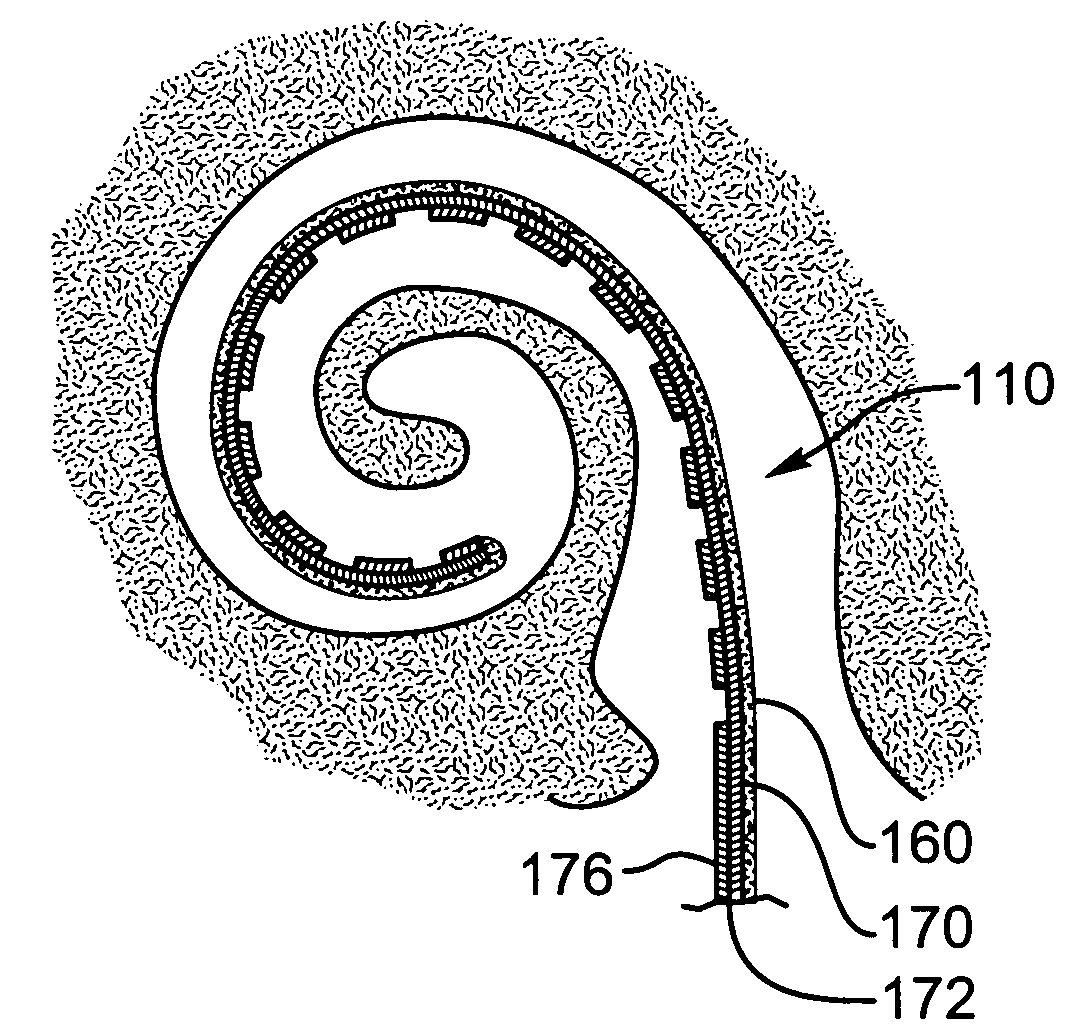

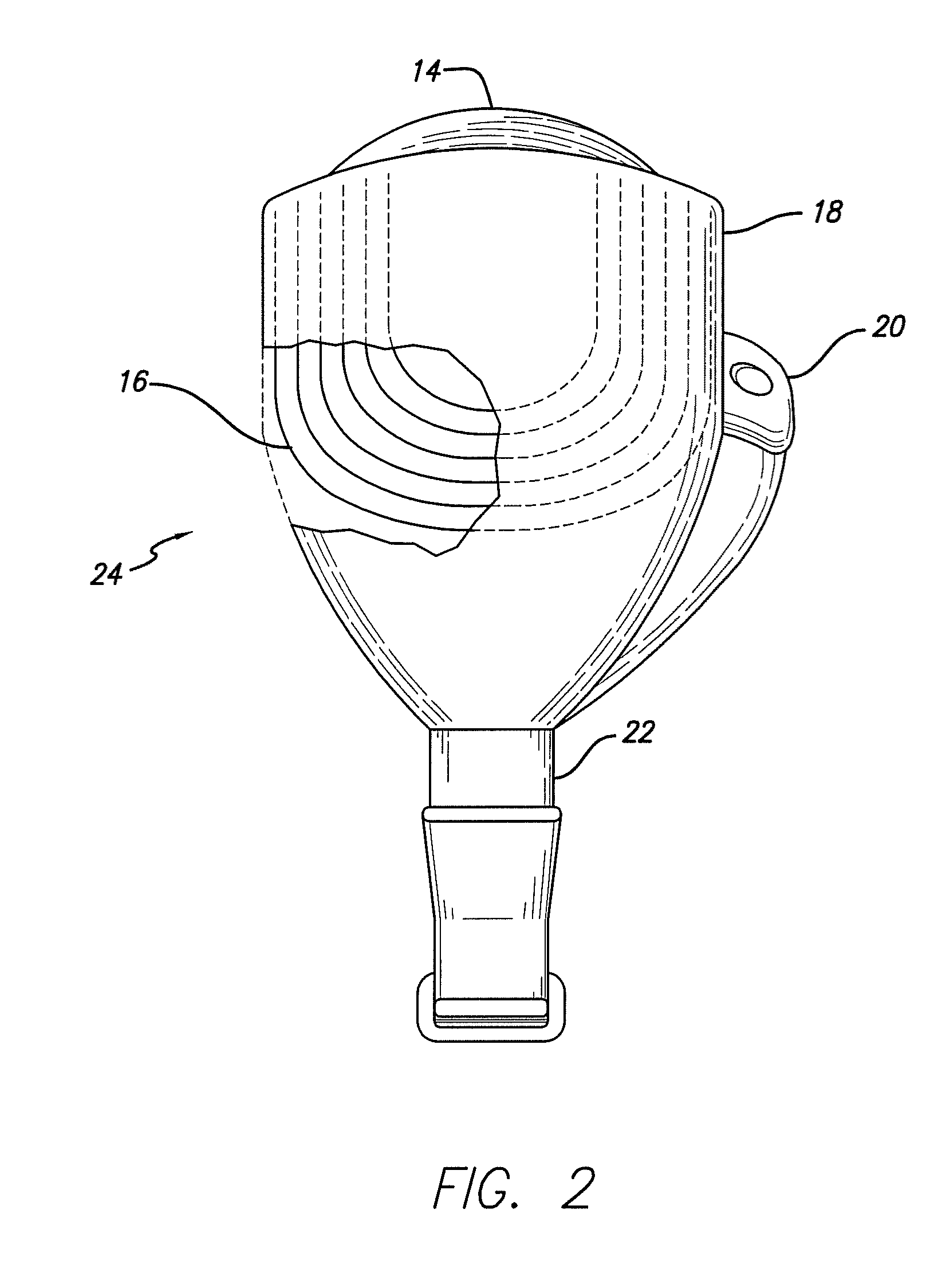

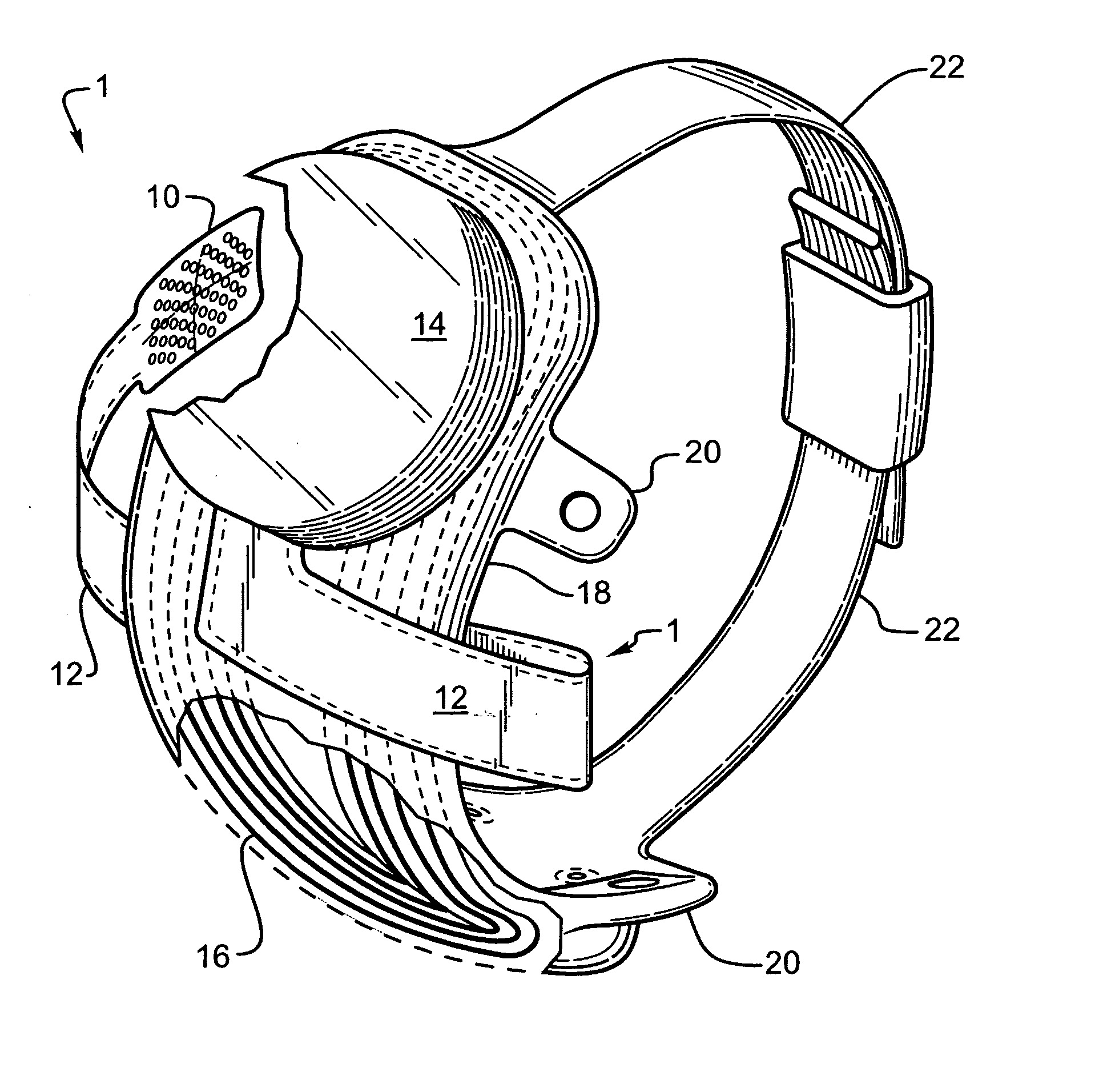

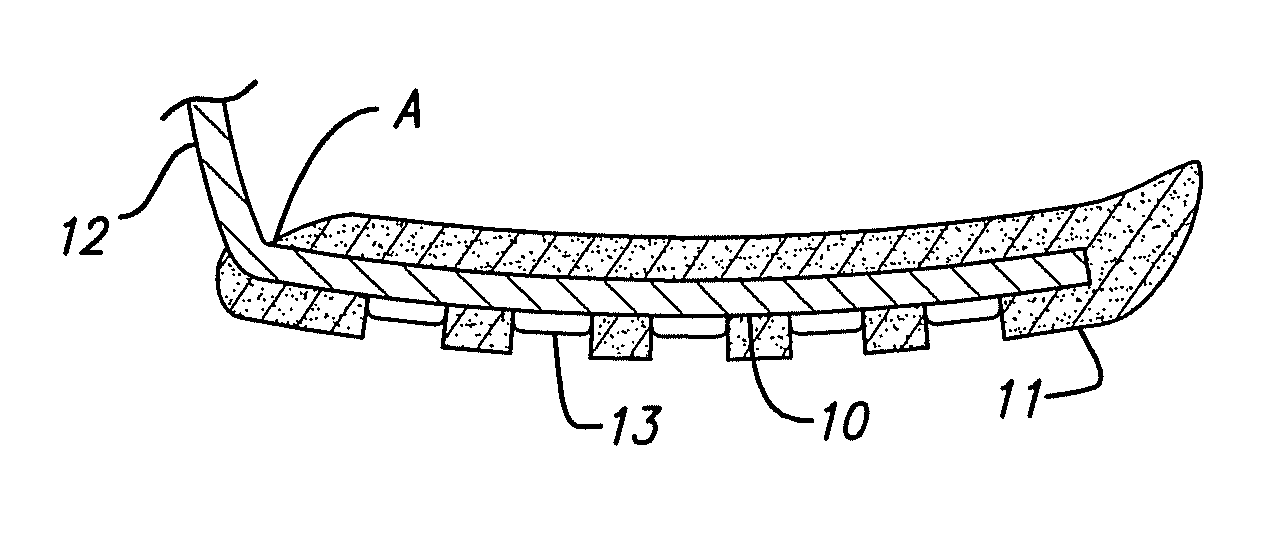

Flexible circuit electrode array

ActiveUS20060247754A1Improve the immunityCut the delicate retinal tissueHead electrodesPrinted circuit manufactureFlexible circuitsHearing perception

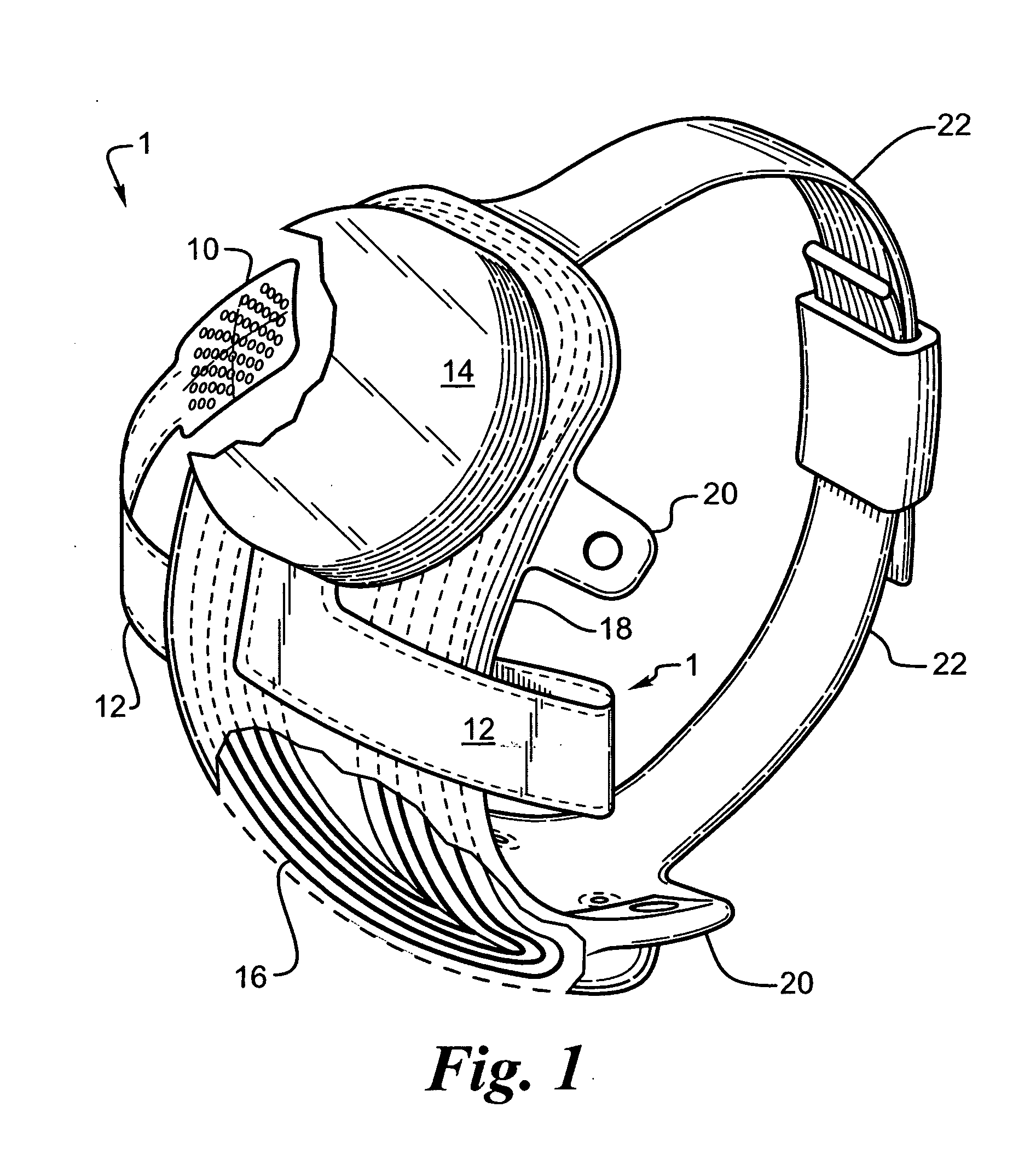

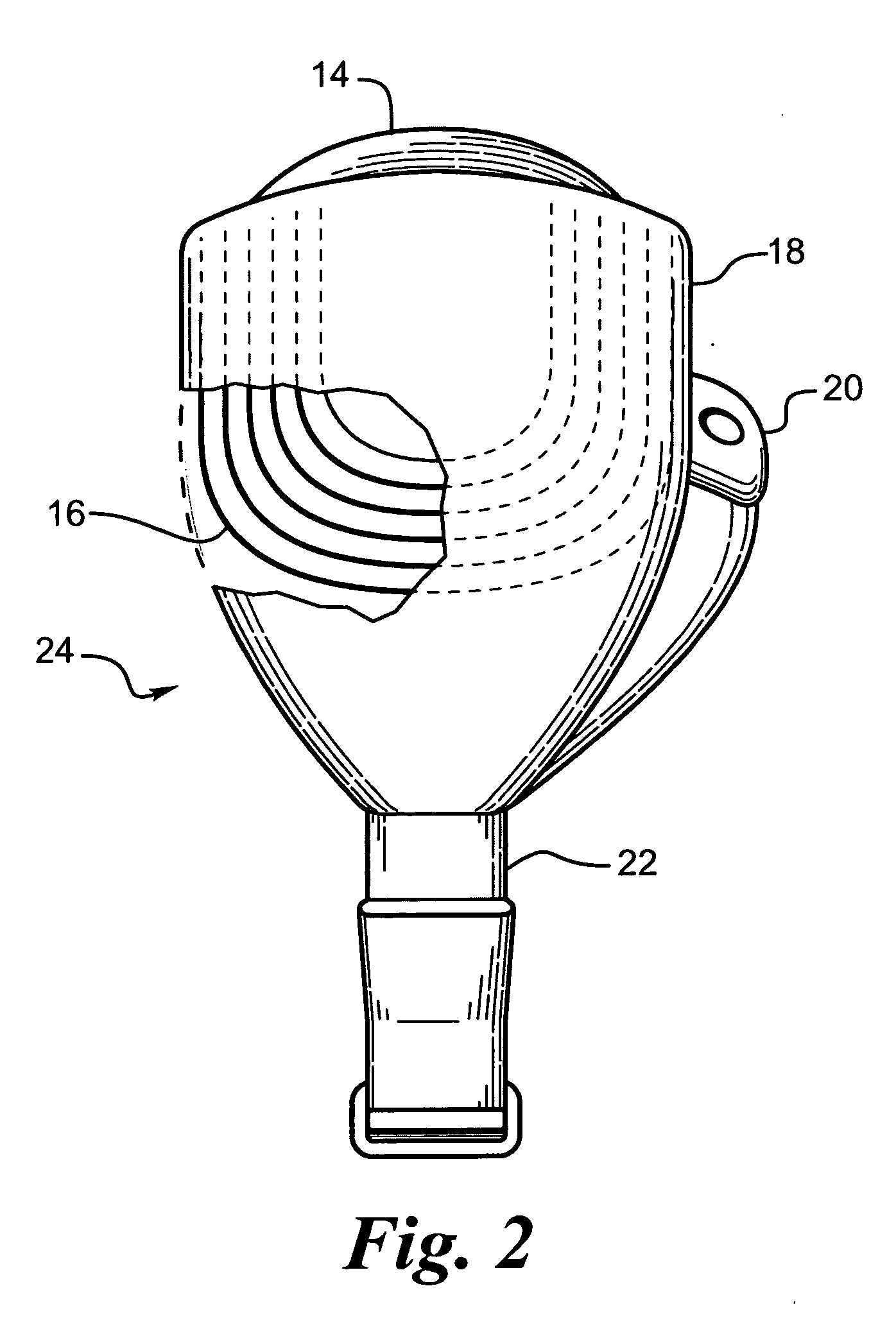

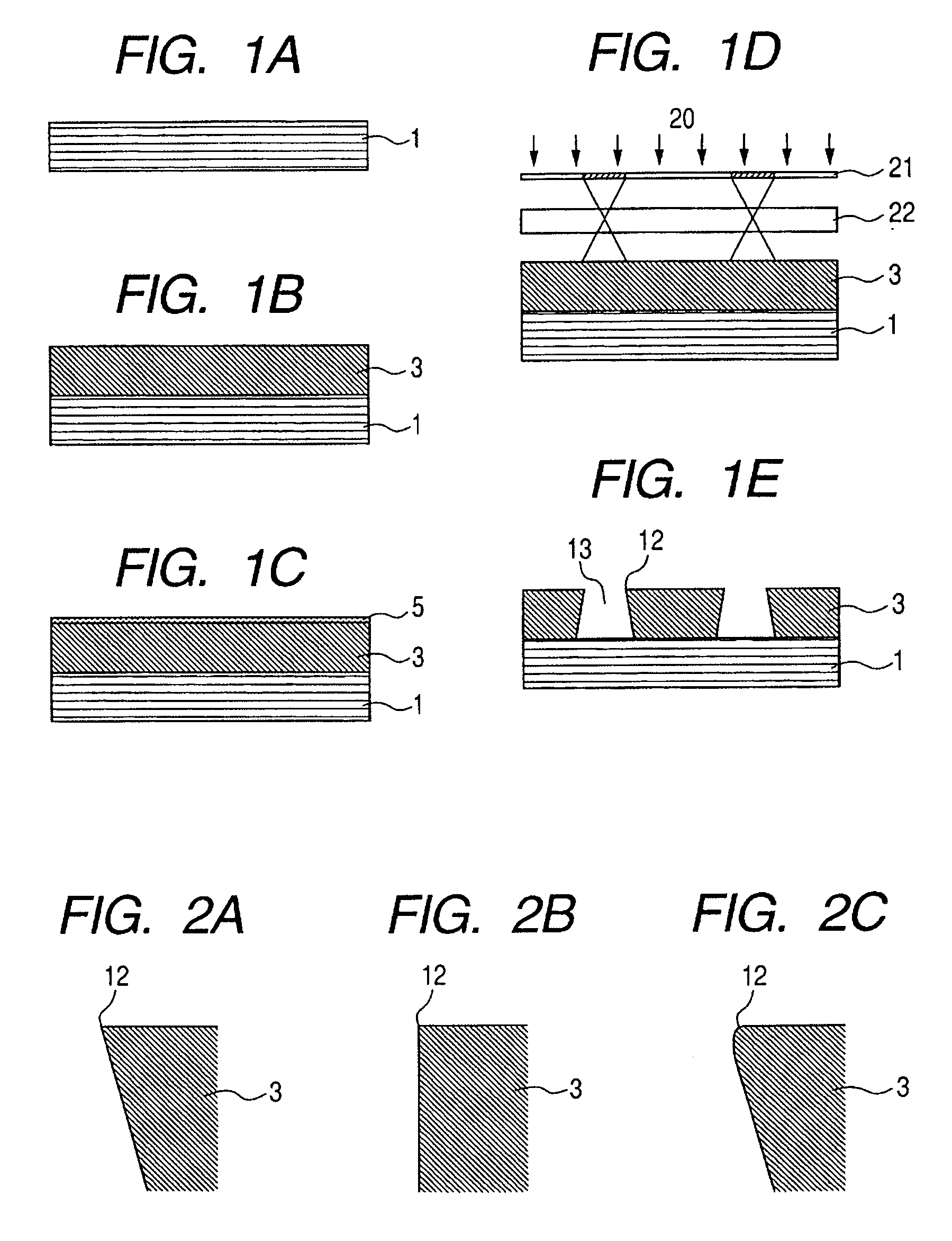

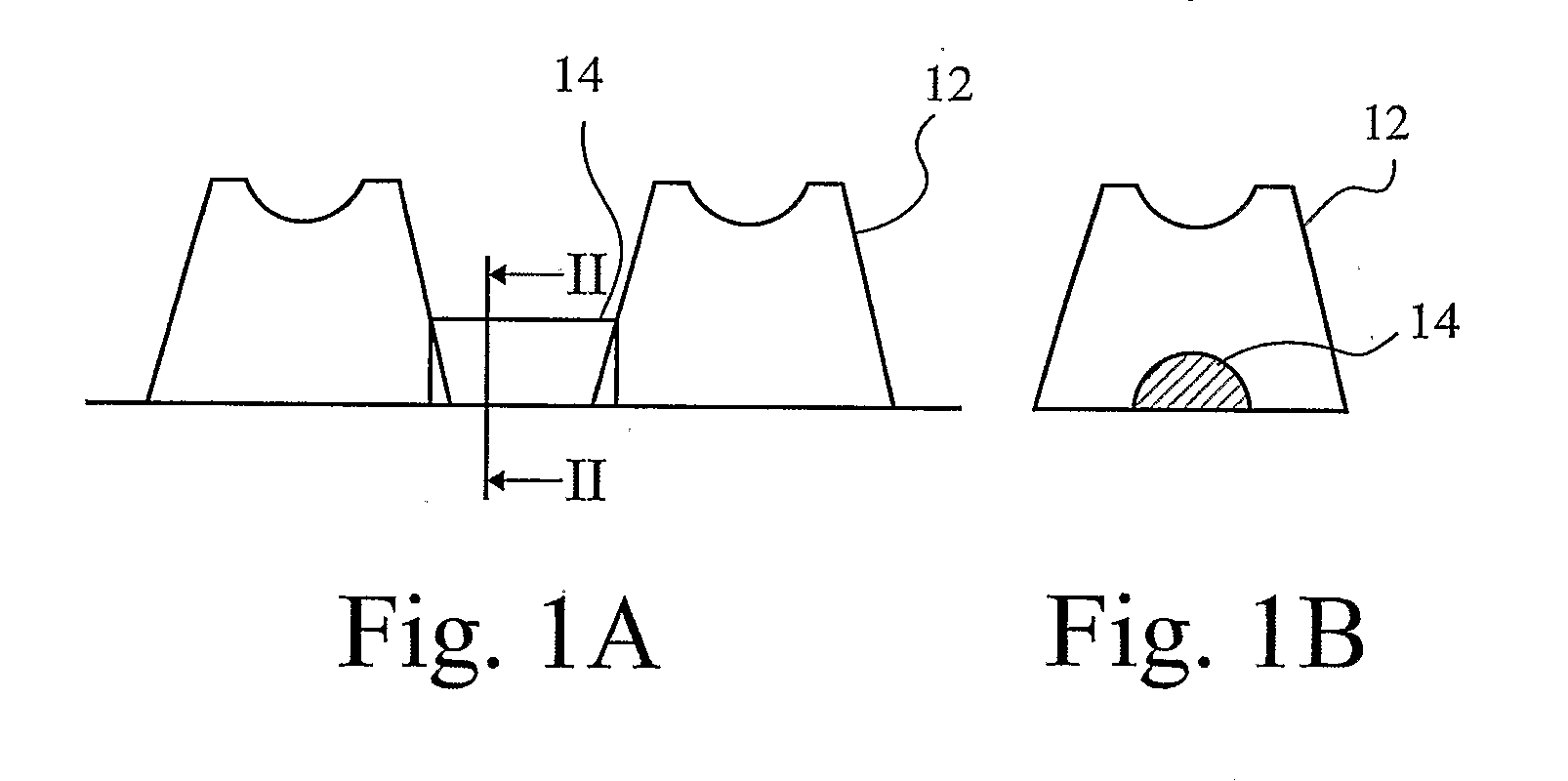

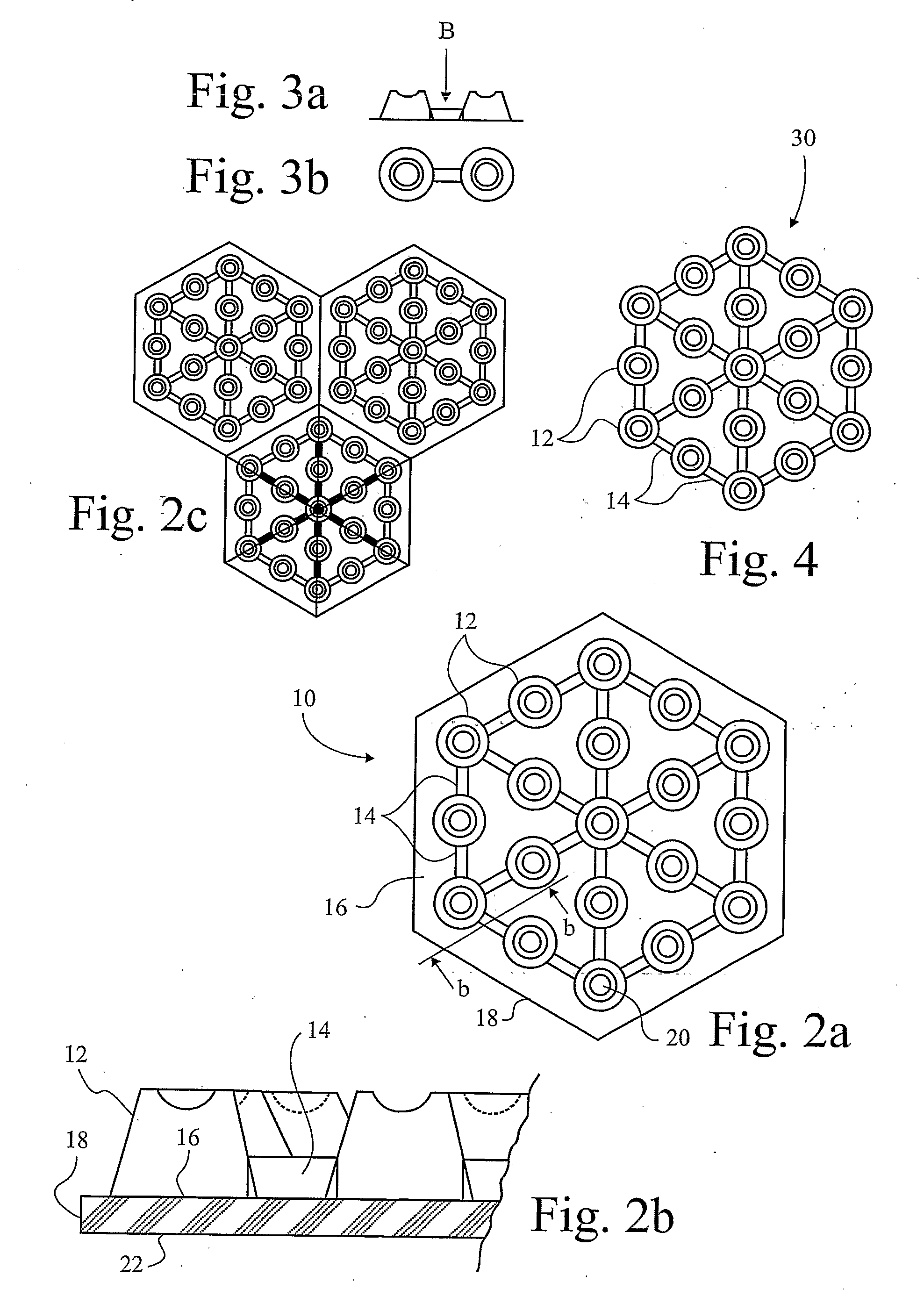

Polymer materials are useful as electrode array bodies for neural stimulation. They are particularly useful for retinal stimulation to create artificial vision, cochlear stimulation to create artificial hearing, or cortical stimulation many purposes. The pressure applied against the retina, or other neural tissue, by an electrode array is critical. Too little pressure causes increased electrical resistance, along with electric field dispersion. Too much pressure may block blood flow. Common flexible circuit fabrication techniques generally require that a flexible circuit electrode array be made flat. Since neural tissue is almost never flat, a flat array will necessarily apply uneven pressure. Further, the edges of a flexible circuit polymer array may be sharp and cut the delicate neural tissue. By applying the right amount of heat to a completed array, a curve can be induced. With a thermoplastic polymer it may be further advantageous to repeatedly heat the flexible circuit in multiple molds, each with a decreasing radius. Further, it is advantageous to add material along the edges. It is further advantageous to provide a fold or twist in the flexible circuit array. Additional material may be added inside and outside the fold to promote a good seal with tissue.

Owner:CORTIGENT INC +1

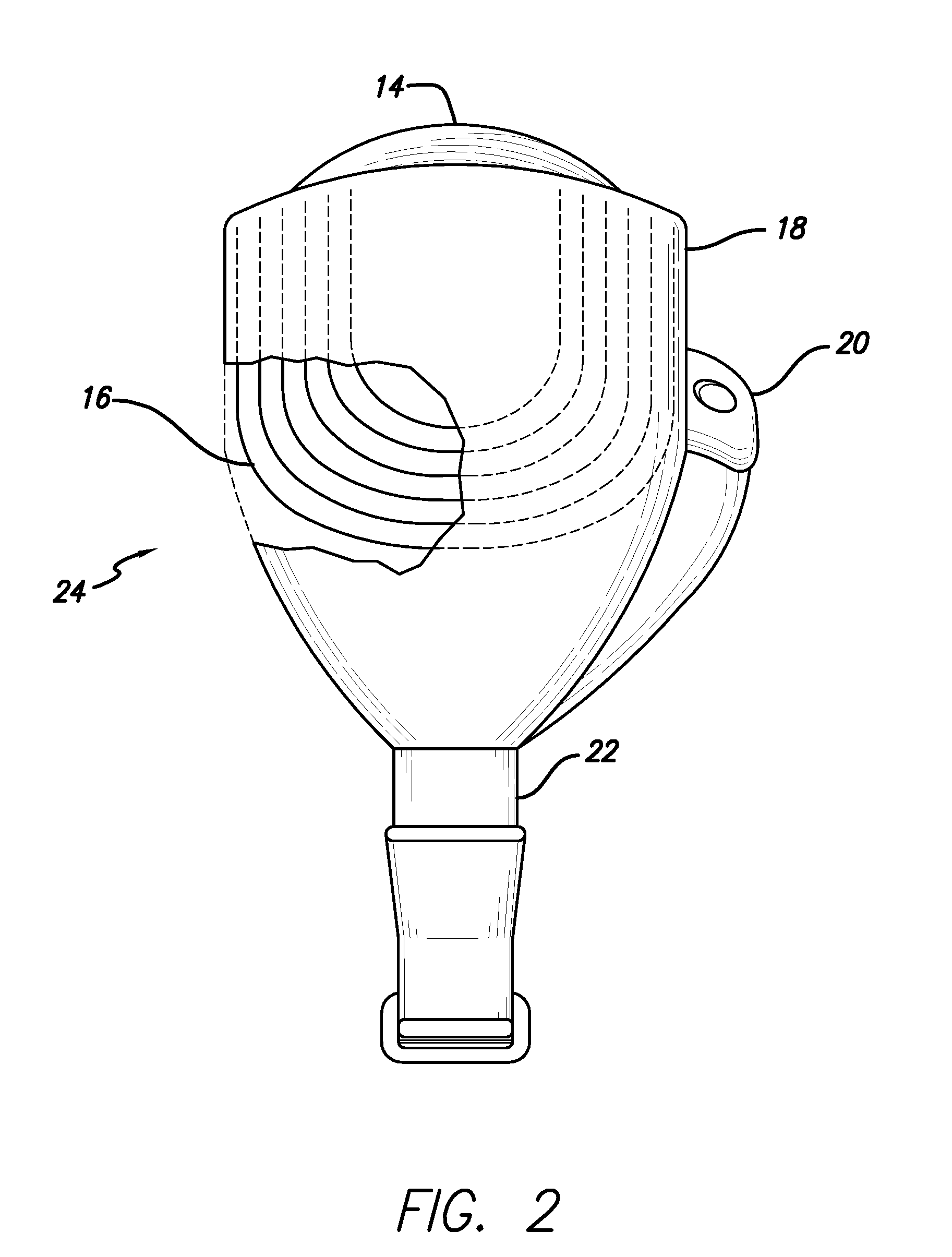

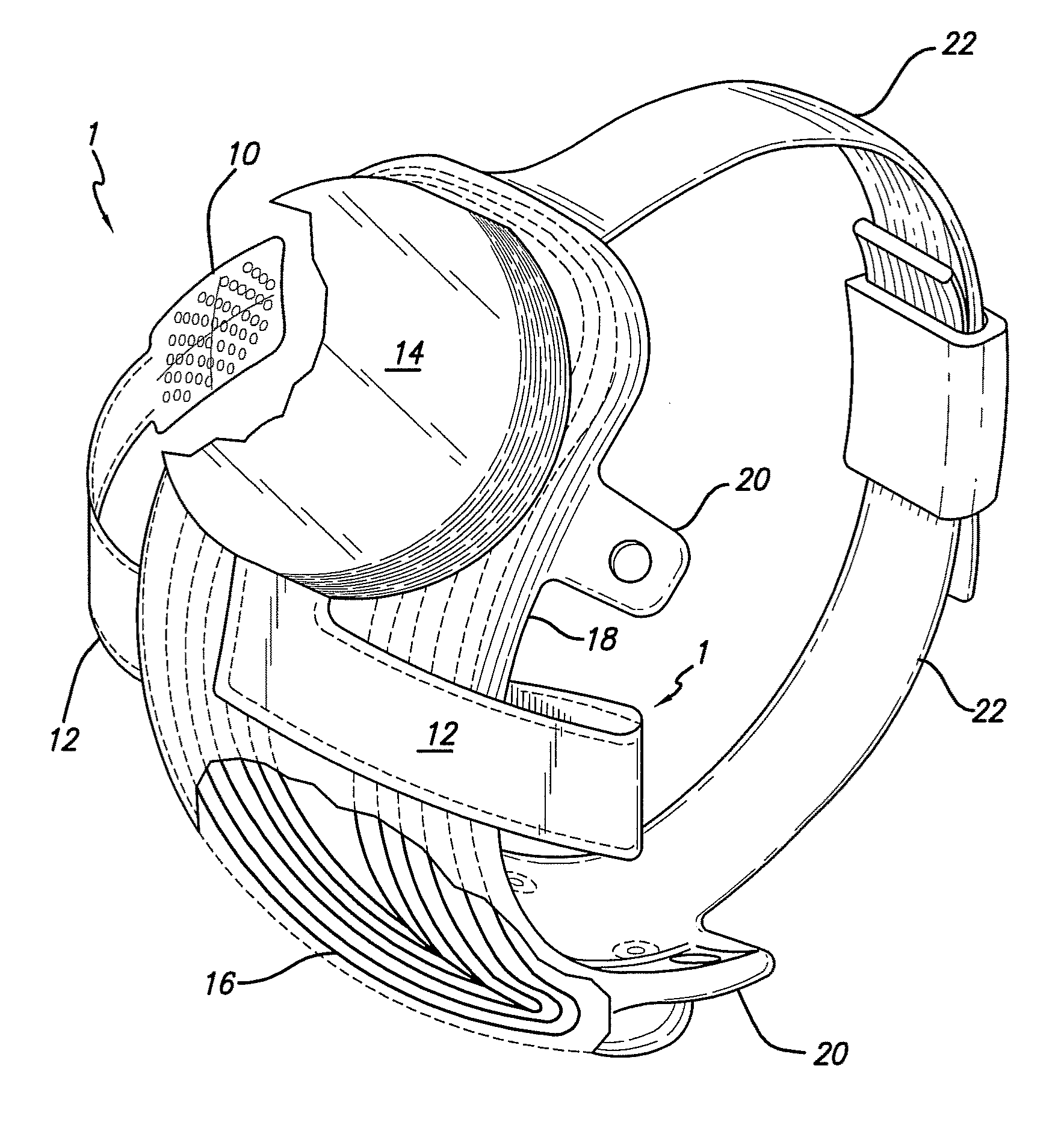

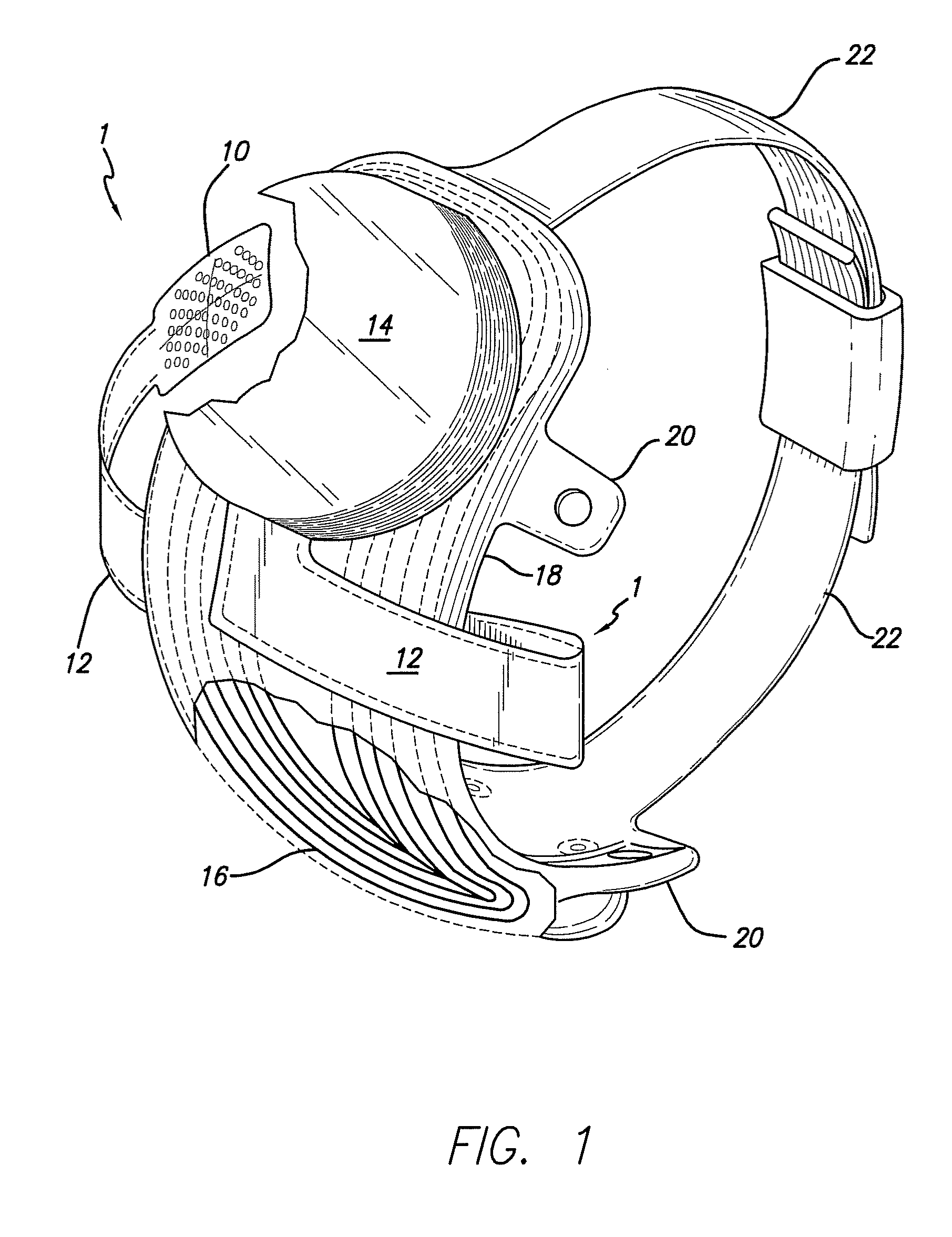

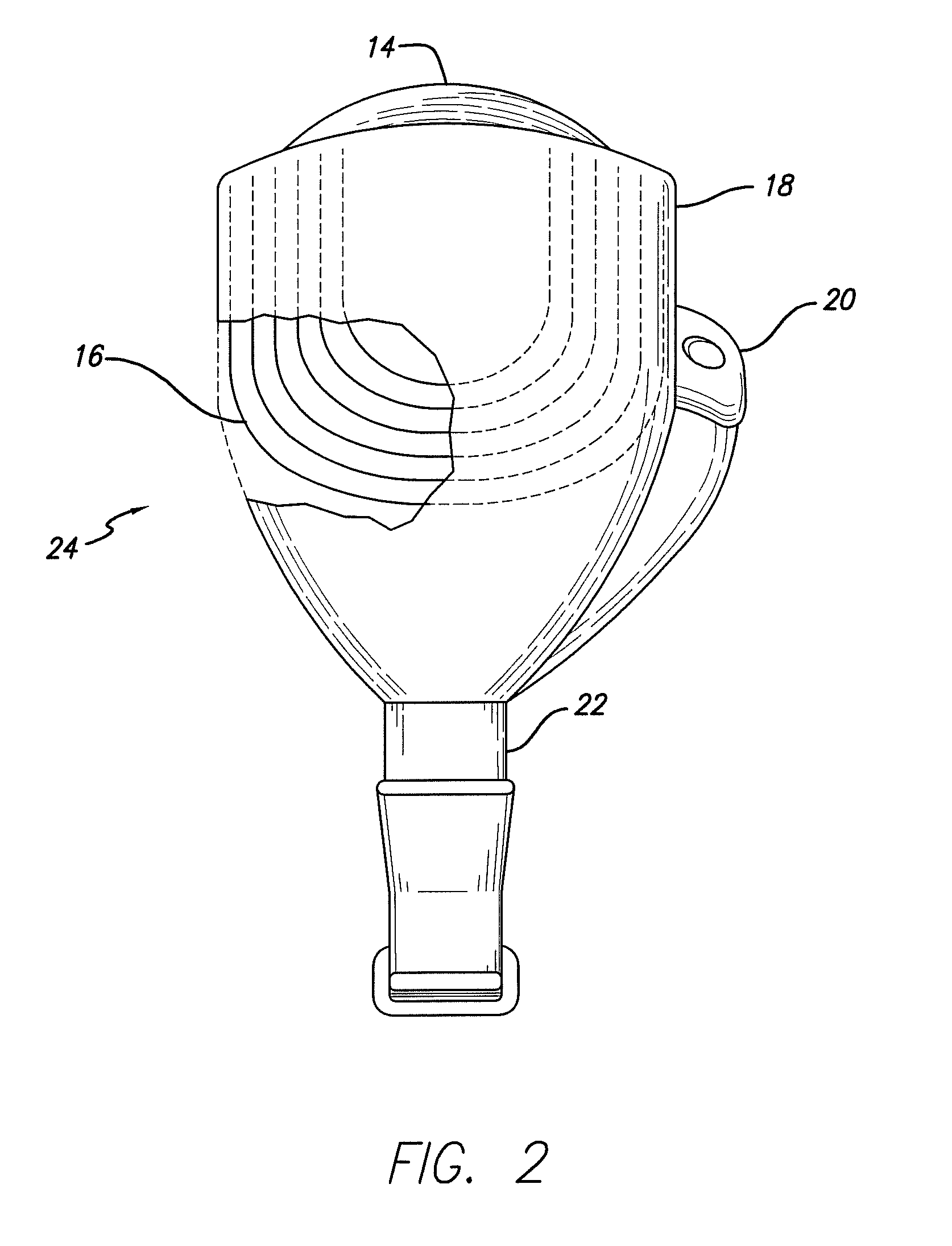

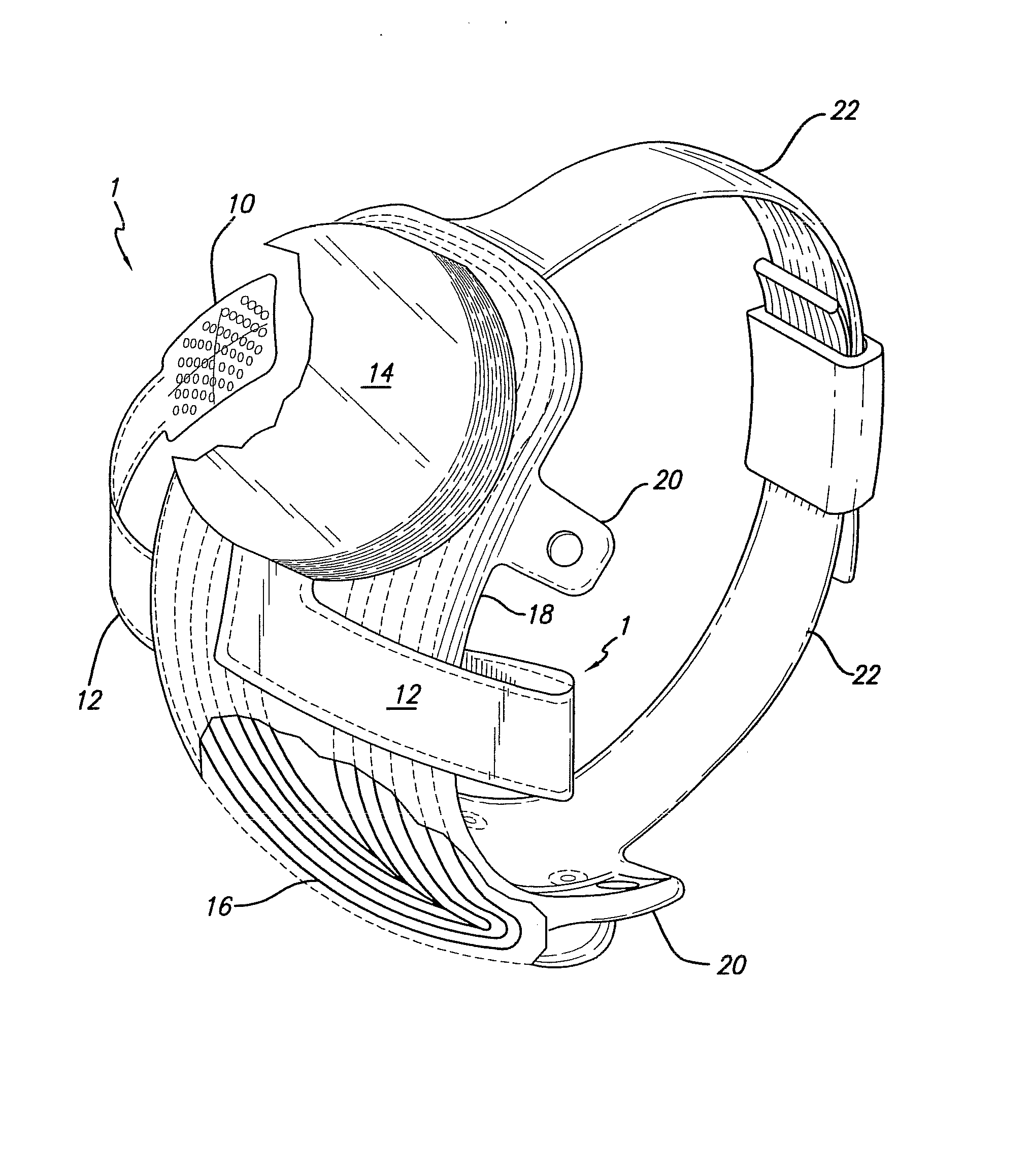

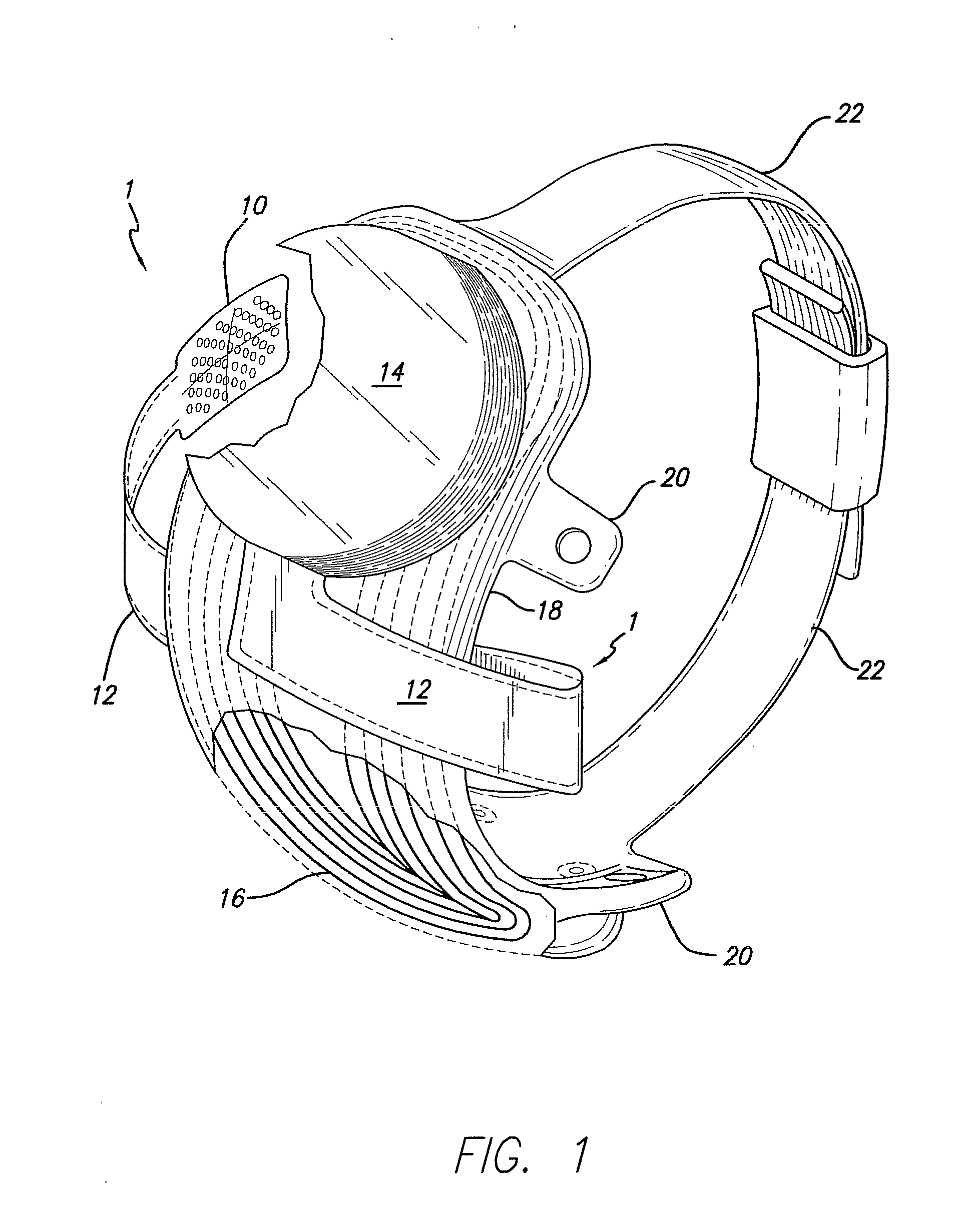

Flexible Circuit Electrode Array with Wire or Film Support

ActiveUS20080288036A1Improves pressure uniformityEasy shape controlHead electrodesPrinted circuitsFlexible circuitsThree dimensional shape

The disclosure relates to a flexible circuit electrode array comprising: a polymer base layer; metal traces deposited on said polymer base layer, including electrodes suitable to stimulate neural tissue; a polymer top layer deposited on said polymer base layer and said metal traces; and at least one support embedded in said array. The disclosure further relates to a flexible circuit electrode array comprising: a polymer base layer; metal traces deposited on said polymer base layer, including electrodes suitable to stimulate neural tissue; a polymer top layer deposited on said polymer base layer and said metal traces; and a folded flexible circuit cable connecting the electrode array with an interconnection pad. The disclosure further relates to a method of making a flexible circuit electrode array comprising: depositing a polymer base layer; depositing metal on said polymer base layer; patterning said metal to form metal traces; depositing a polymer top layer on said polymer base layer and said metal traces; heating said flexible circuit electrode array in a mold to form a three dimensional shape in said flexible circuit electrode array, embedding a support at least in the base layer, top layer or between the base and top layer, and / or folding a flexible circuit cable at least once connecting the electrode array with an interconnection pad the array.

Owner:CORTIGENT INC +1

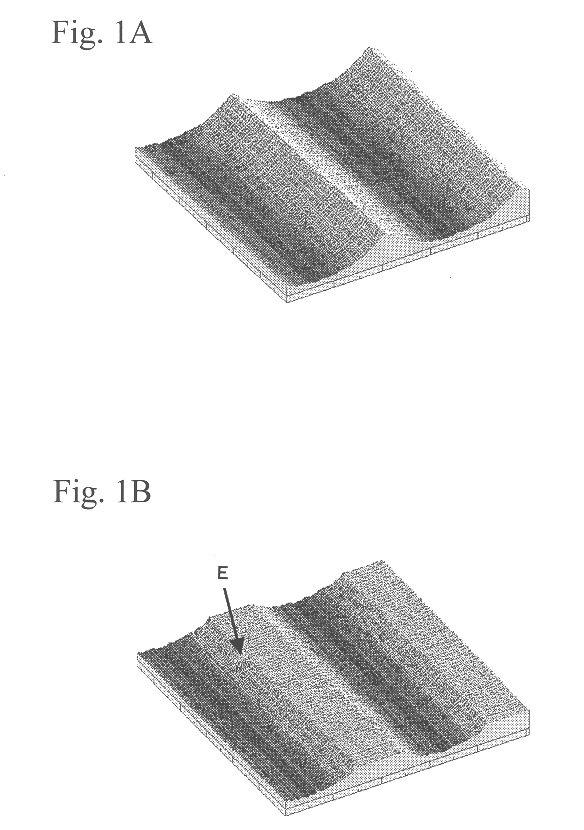

Sliding members and piston for internal combustion engine

InactiveUS6523456B1Avoid unusual noiseClearanceCylindersMachines/enginesInternal combustion enginePiston

A sliding surface of at least one of sliding members sliding with respect to each other in a sliding direction comprises a protrusion extending along a direction intersecting the sliding direction and fine dimples provided on a surface of the protrusion. In the sliding members, lubricating oil is accumulated in the dimples, and is easily extracted through a drain portion formed by dimple in a running-in operation.

Owner:HONDA MOTOR CO LTD

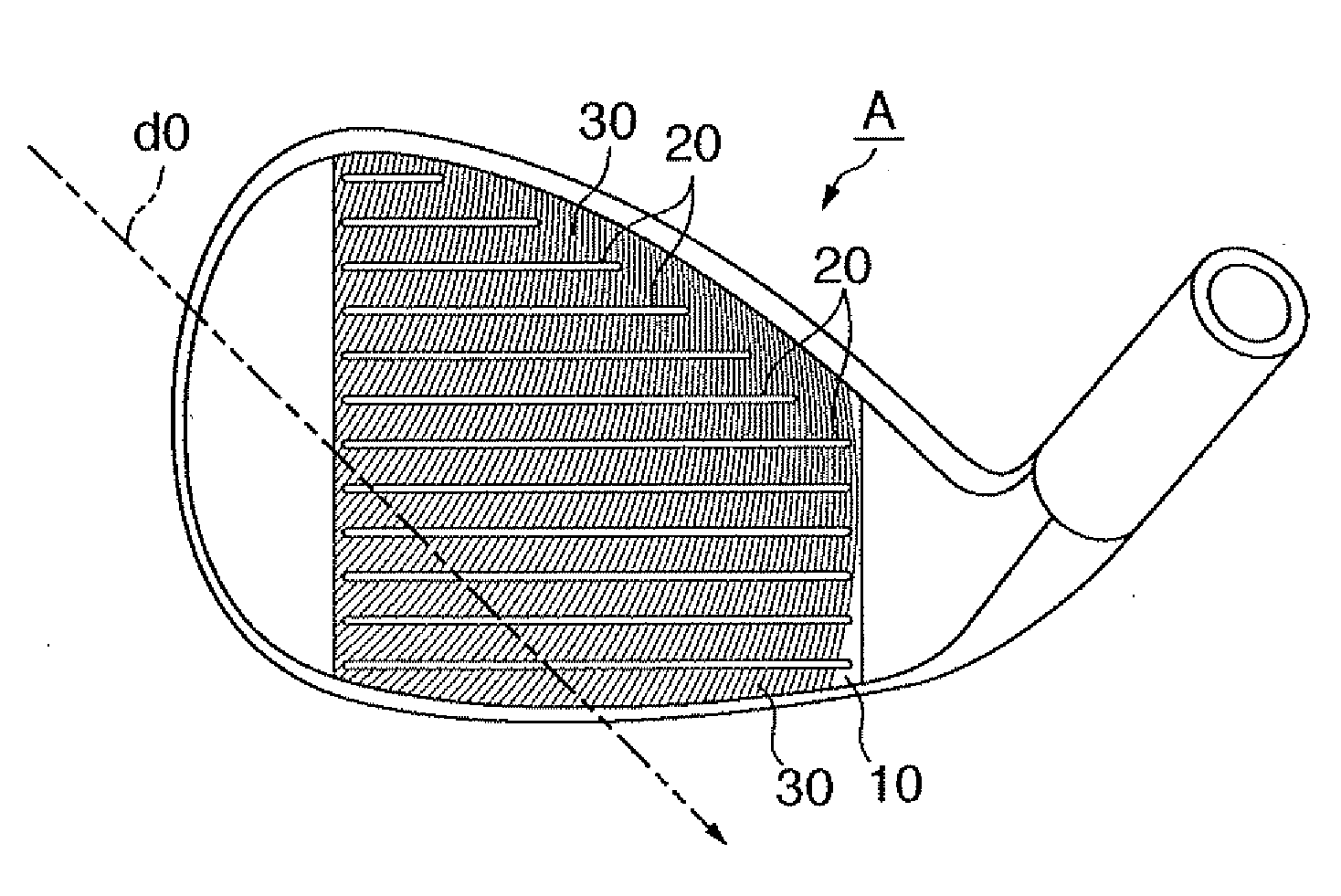

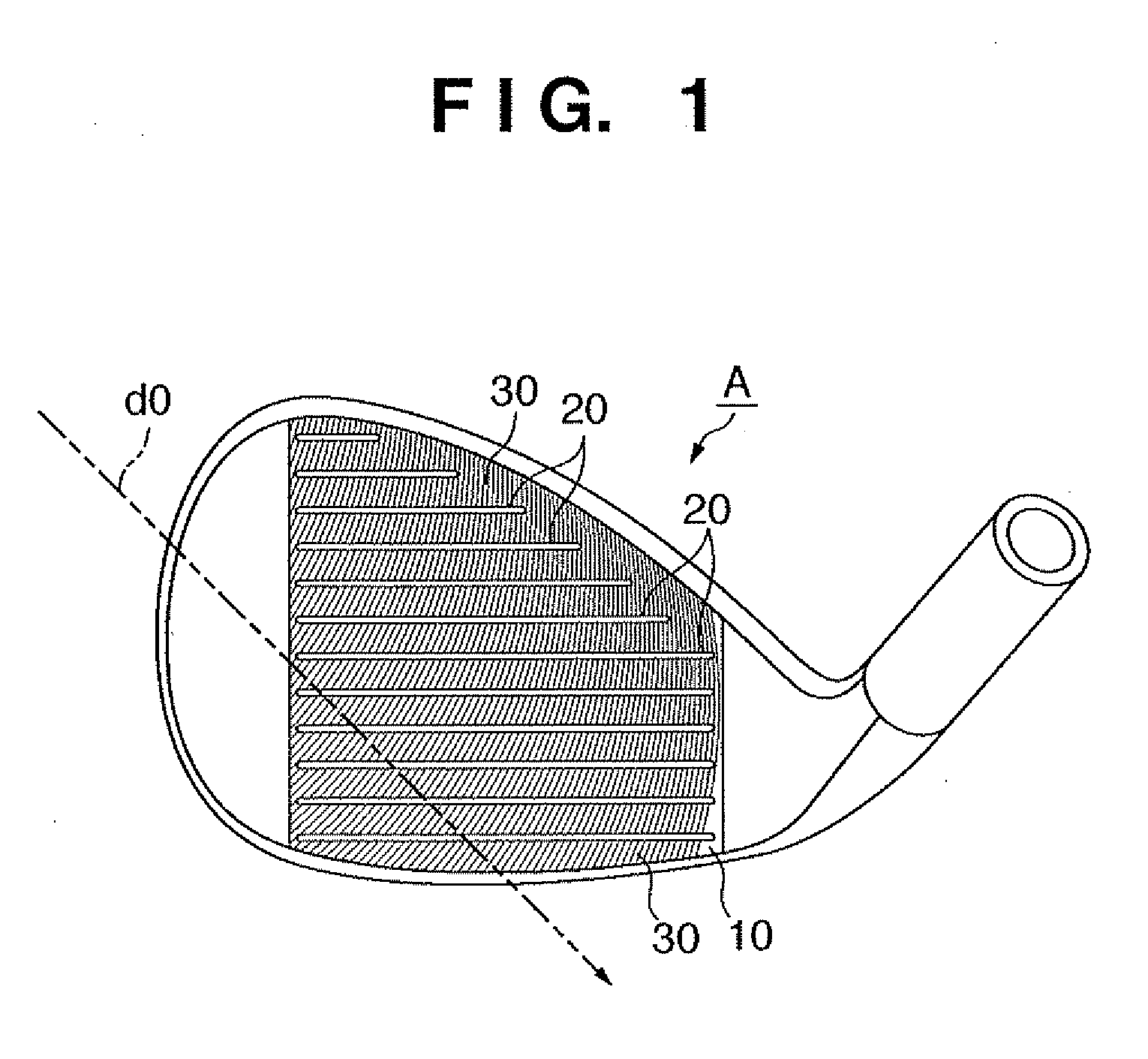

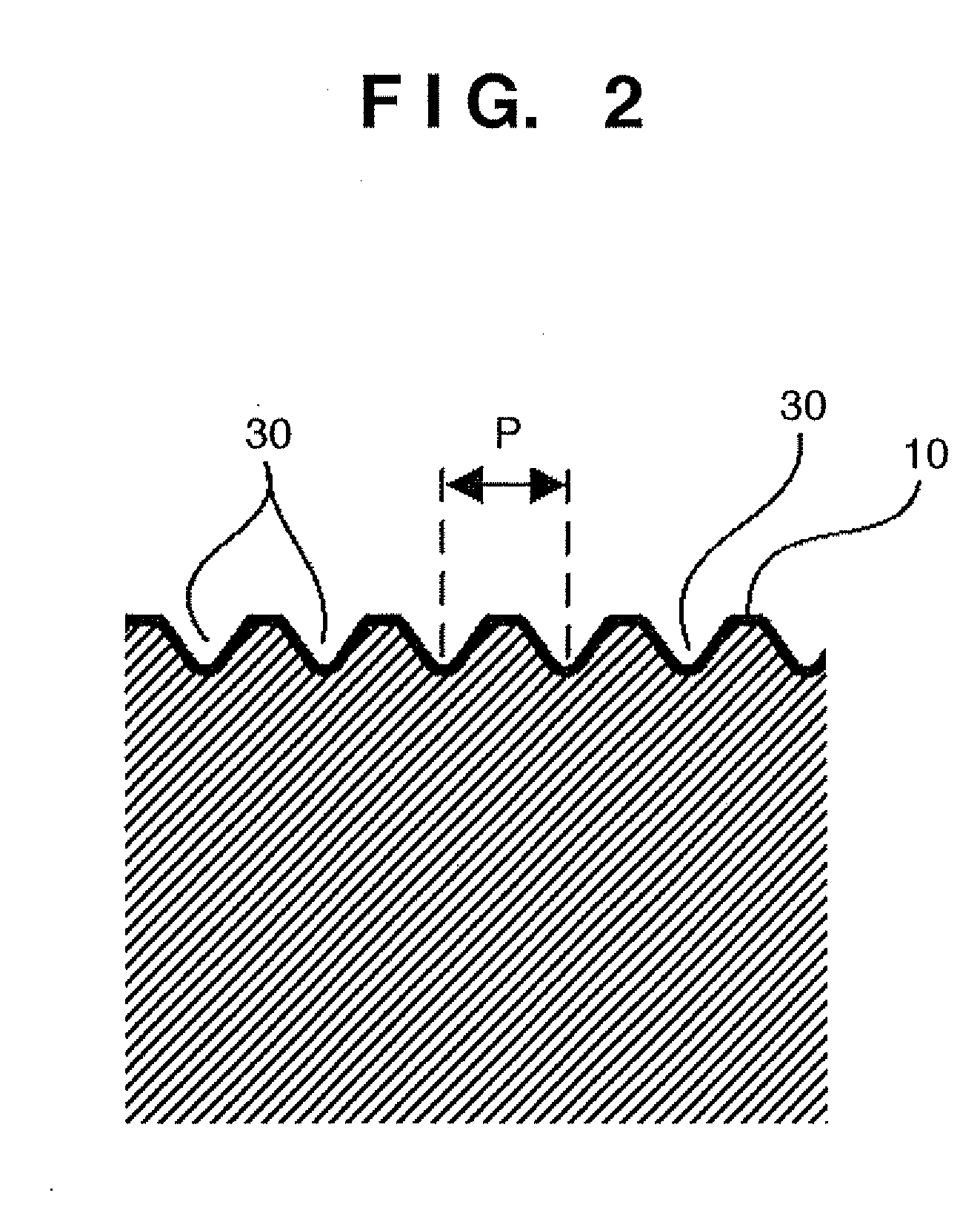

Golf club head

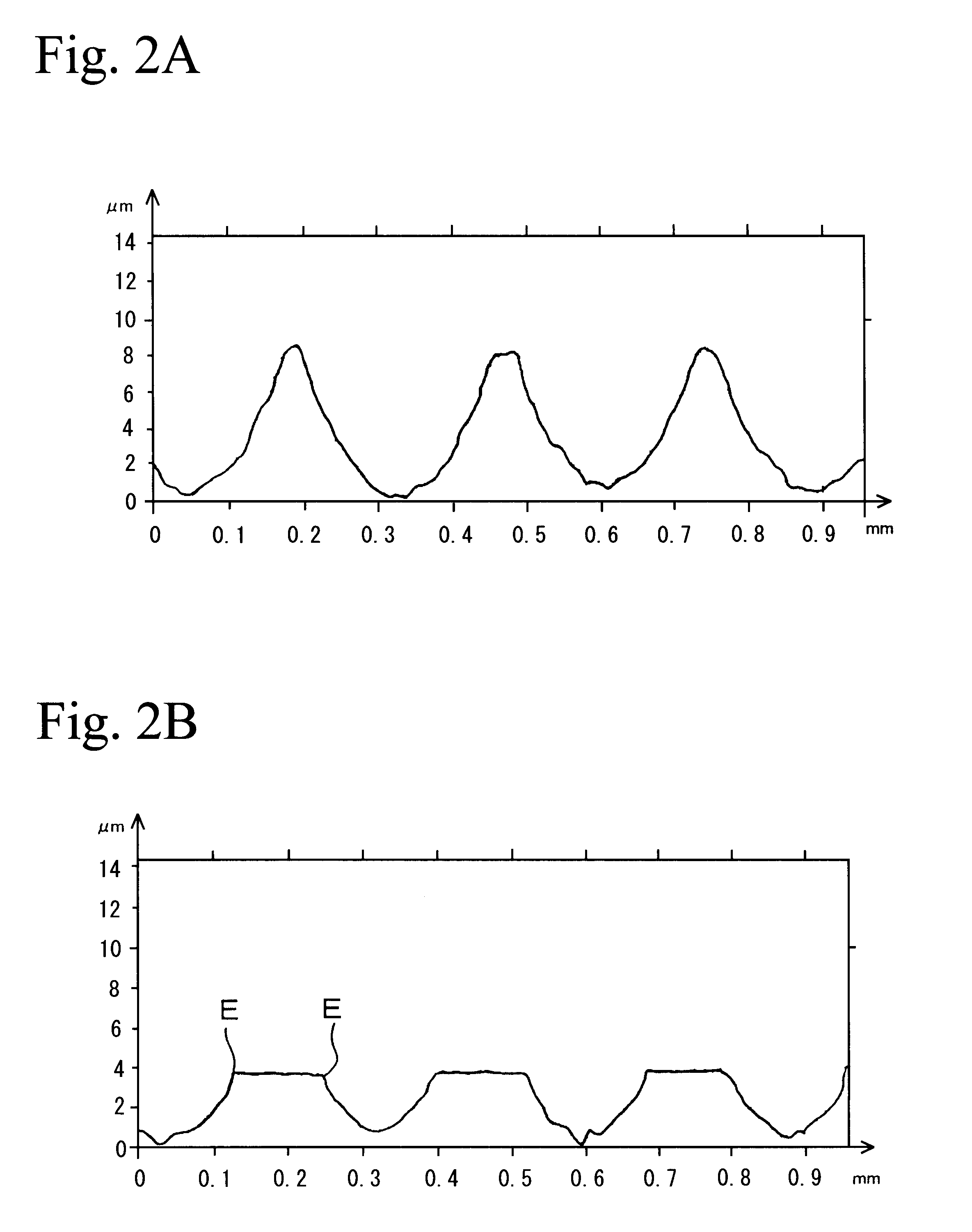

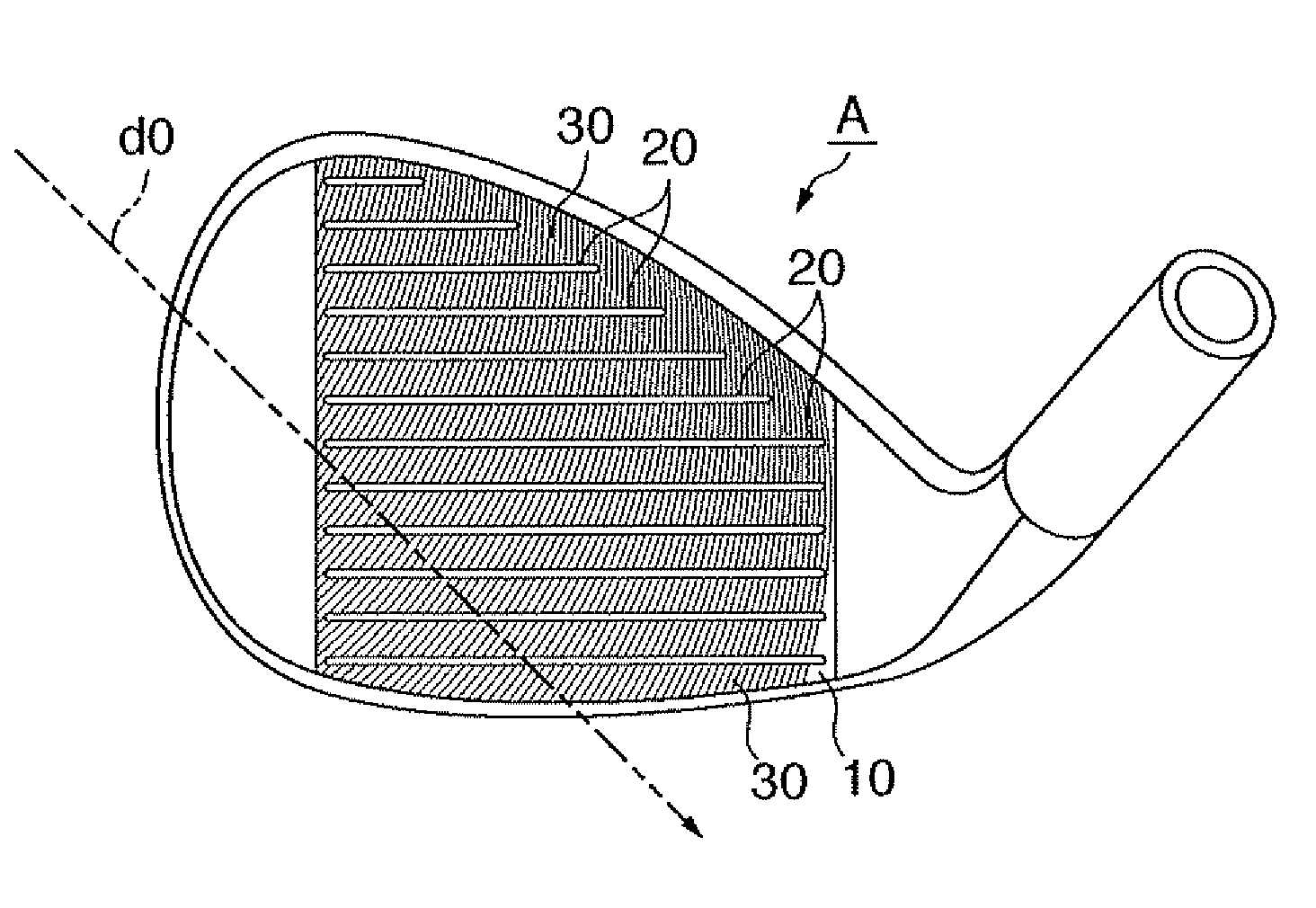

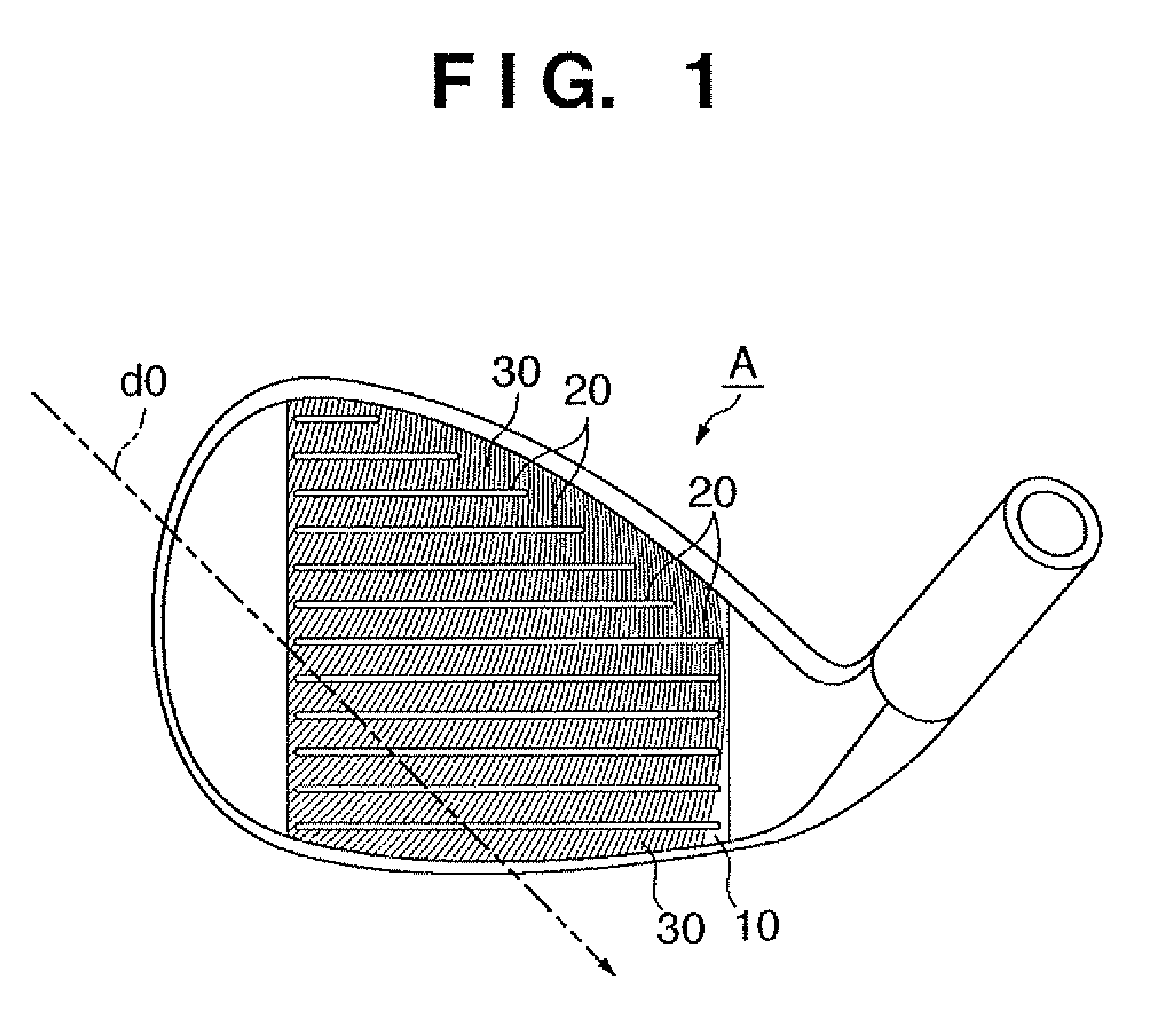

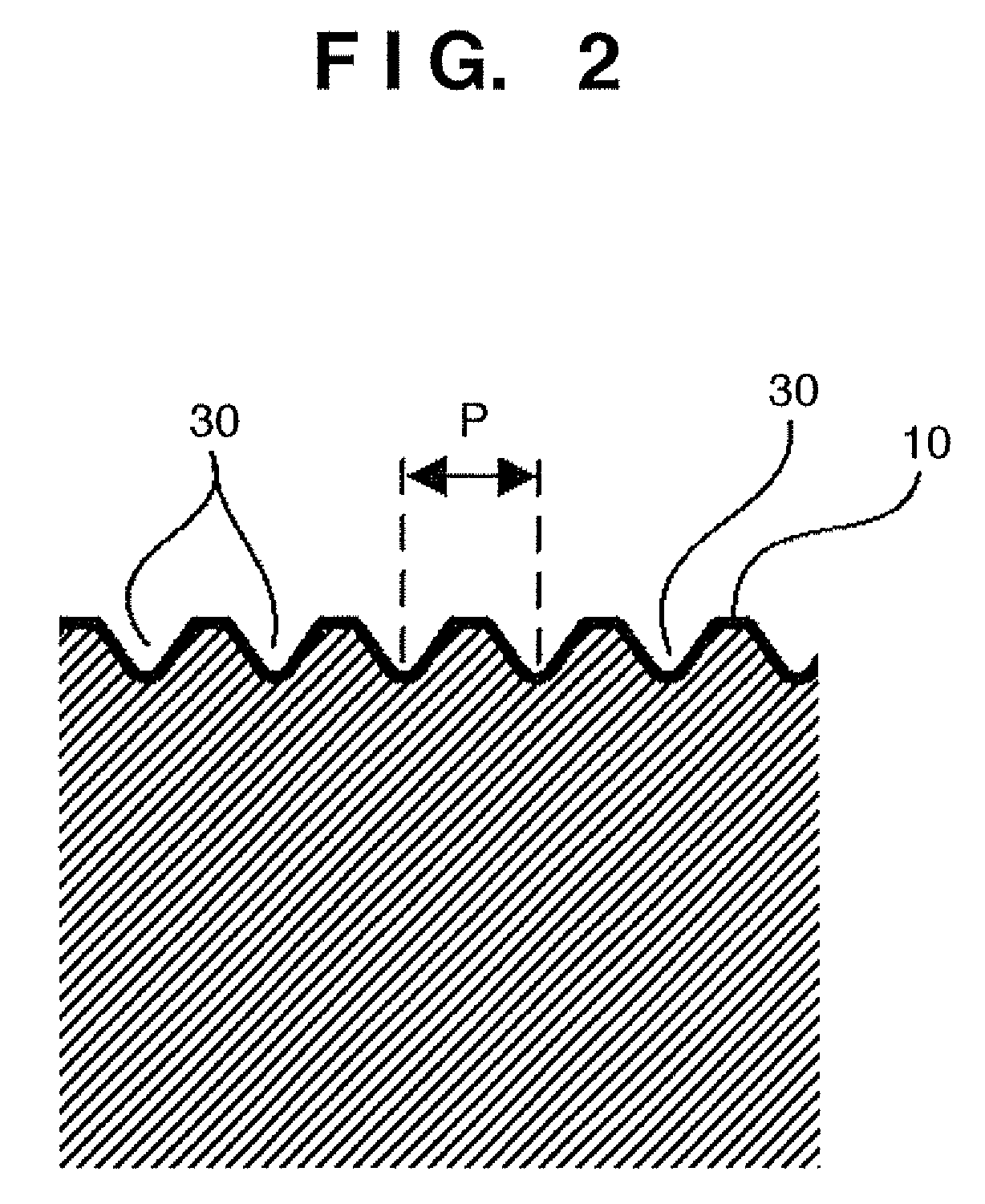

InactiveUS7677990B2A large amountImprove the rotation effectGolf clubsRacket sportsSurface roughnessGolf Ball

A golf club head of this invention includes a face and a plurality of striations formed on the face by milling. A pitch P in the arrangement direction of the plurality of striations satisfies 300 μm≦P≦600 μm. The surface roughness of a region in the face with the striations satisfies in the maximum height of the profile Ry, 15 μm≦Ry≦0.005×P+15.7 μm.

Owner:BRIDGESTONE SPORTS

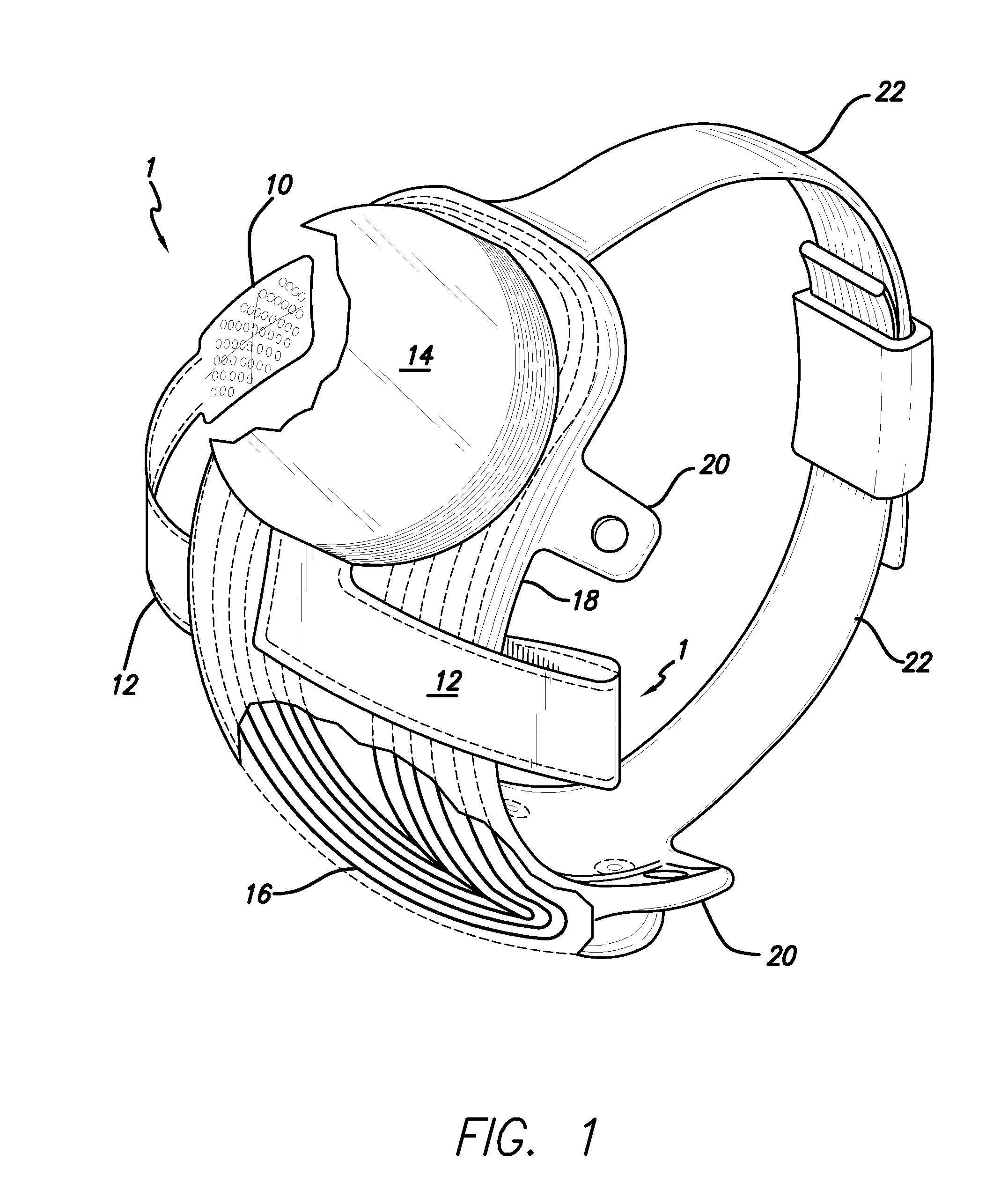

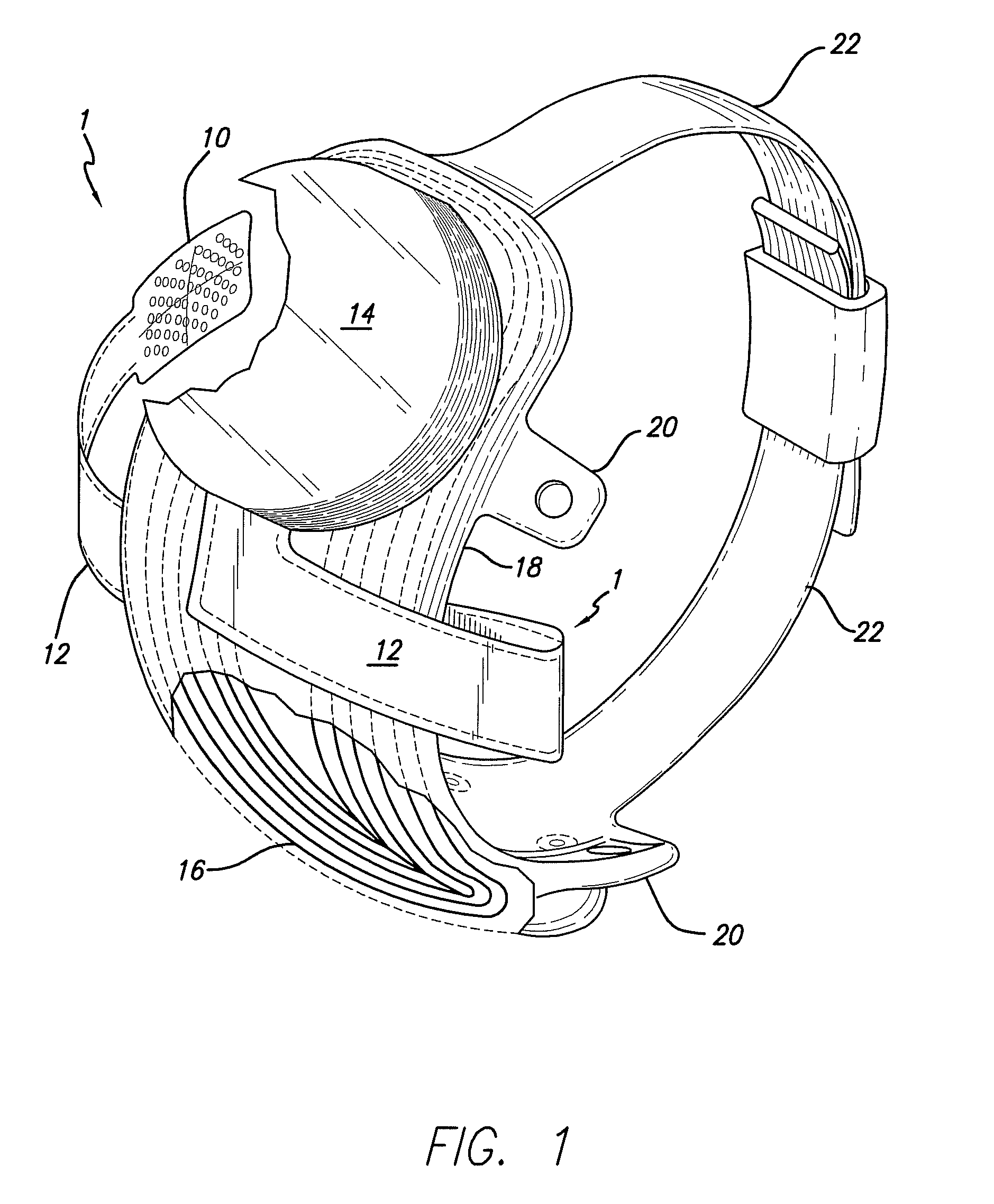

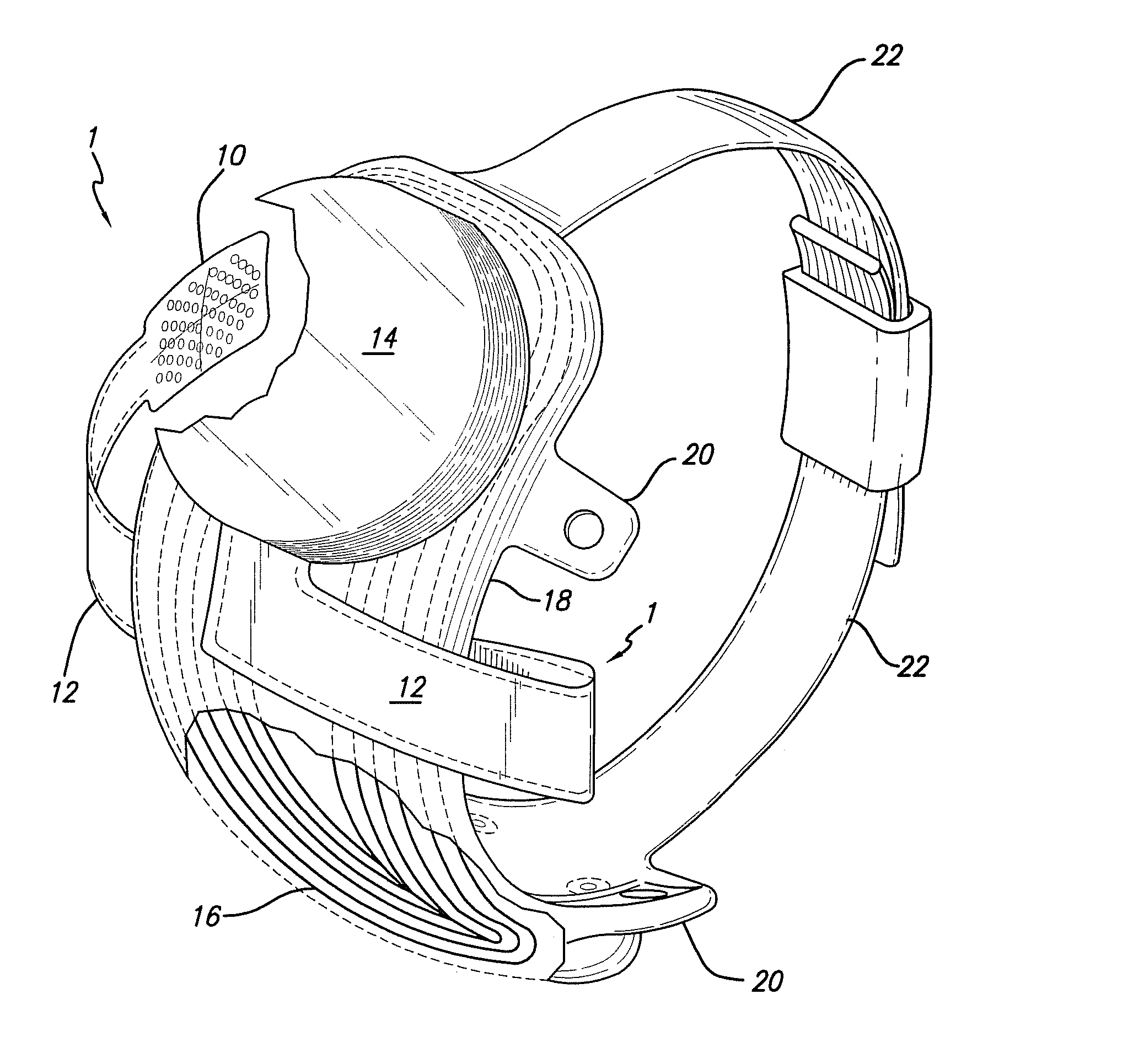

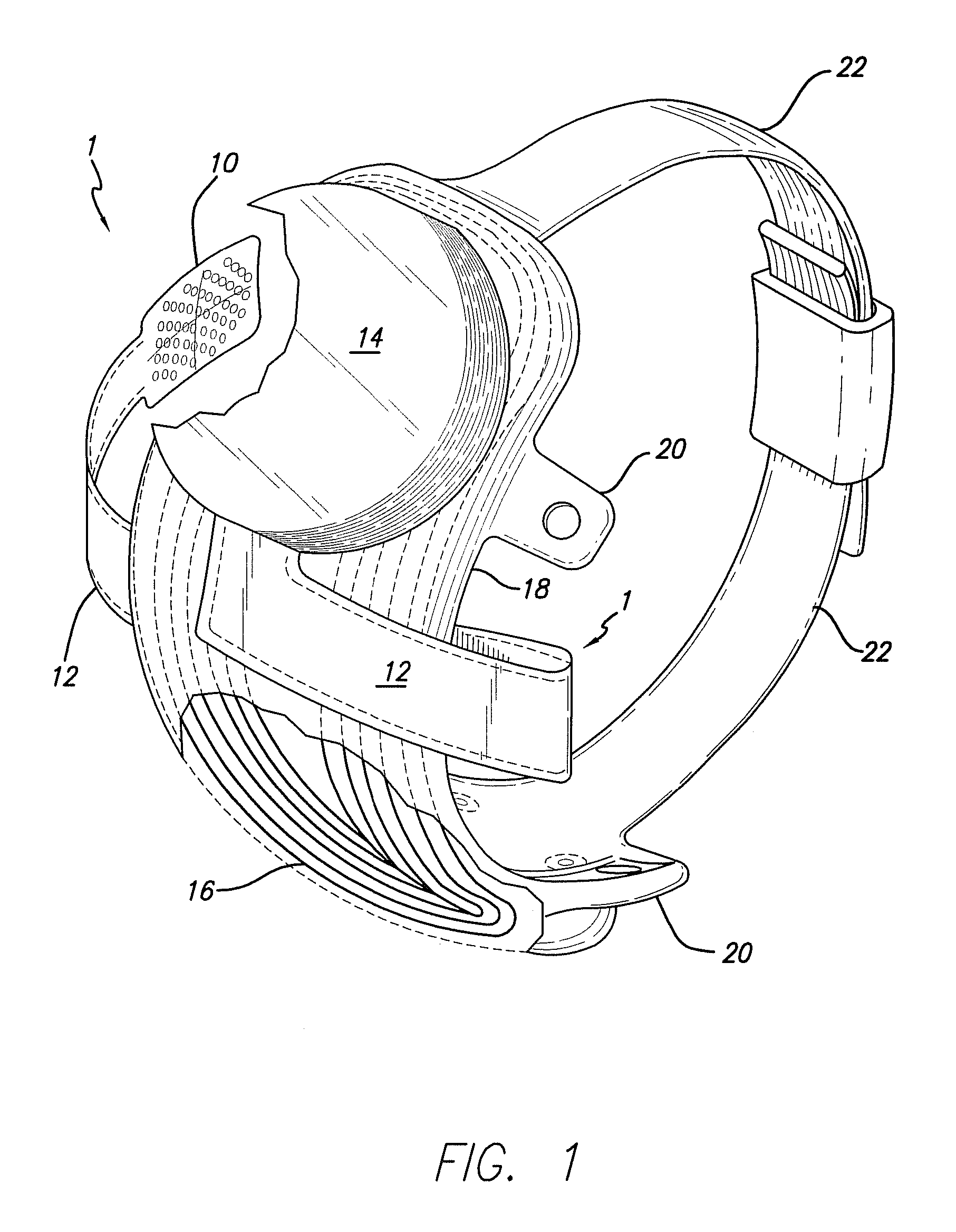

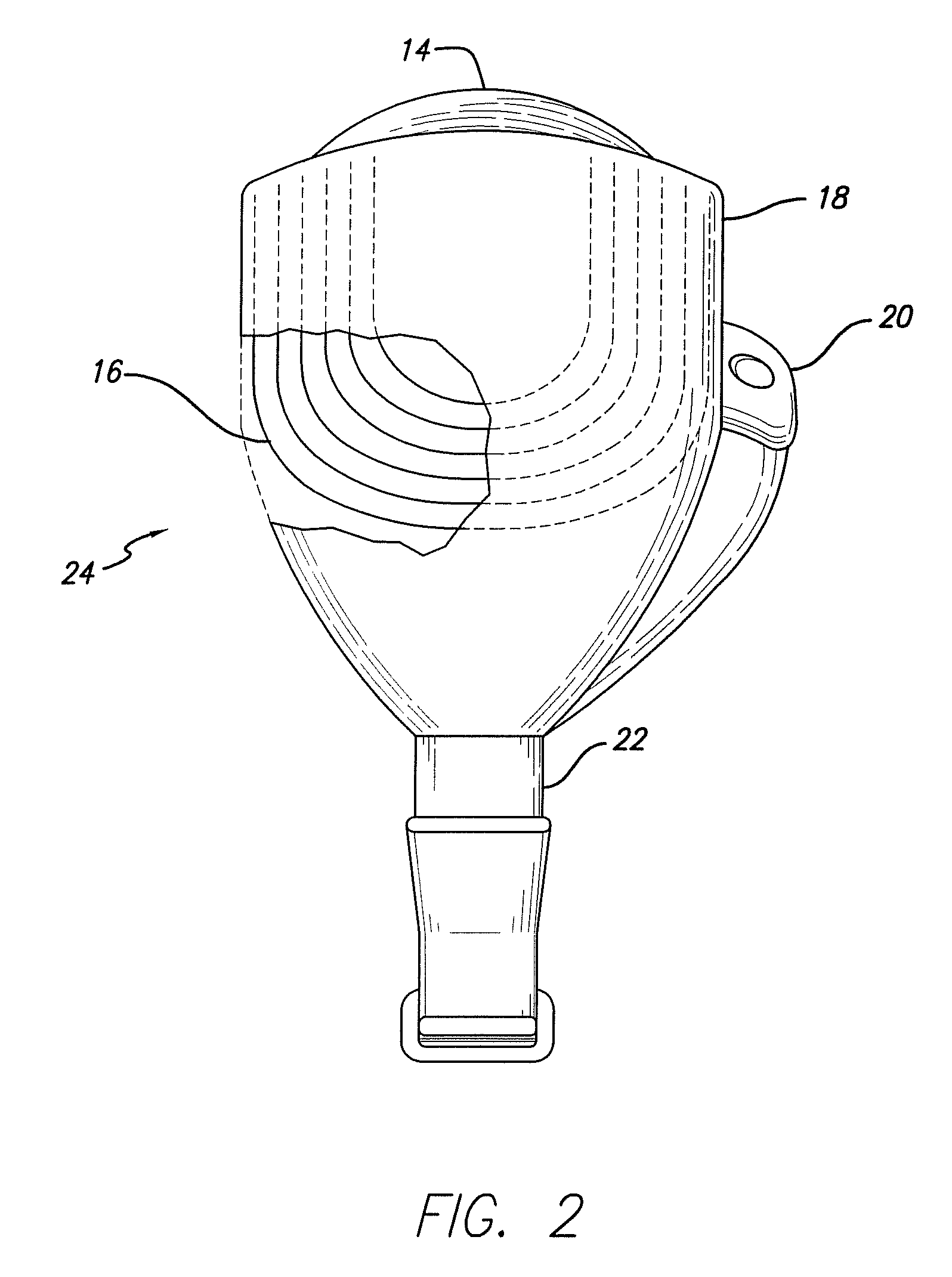

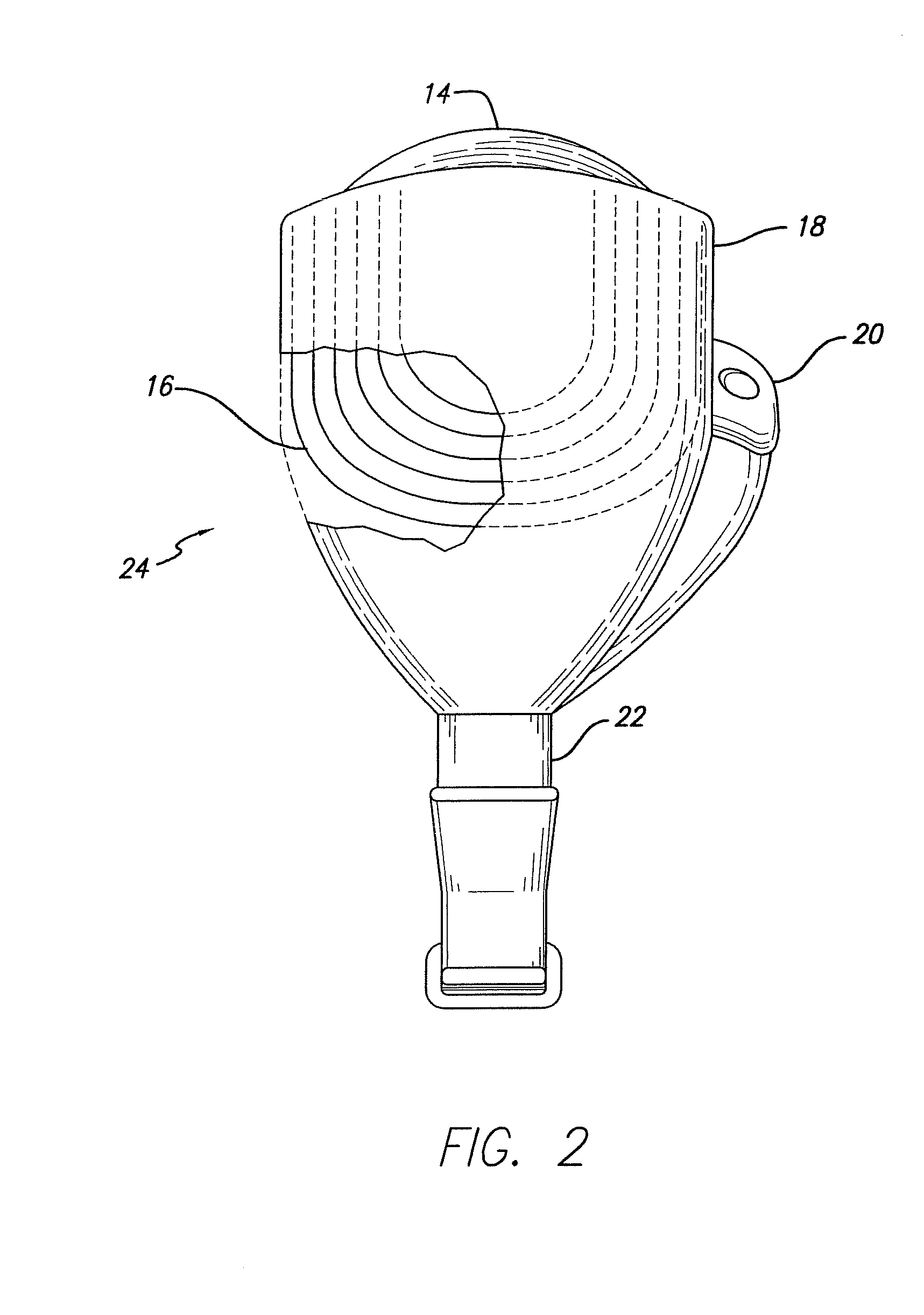

Retinal Prosthesis with a New Configuration

ActiveUS20080275527A1Improve the immunityCut the delicate retinal tissueCircuit bendability/stretchabilityHead electrodesFlexible circuitsRetinal Prosthesis

Polymer materials are useful as electrode array bodies for neural stimulation. They are particularly useful for retinal stimulation to create artificial vision, cochlear stimulation to create artificial hearing, and cortical stimulation, and many related purposes. The pressure applied against the retina, or other neural tissue, by an electrode array is critical. Too little pressure causes increased electrical resistance, along with electric field dispersion. Too much pressure may block blood flow. Common flexible circuit fabrication techniques generally require that a flexible circuit electrode array be made flat. Since neural tissue is almost never flat, a flat array will necessarily apply uneven pressure. Further, the edges of a flexible circuit polymer array may be sharp and cut the delicate neural tissue. By applying the right amount of heat to a completed array, a curve can be induced. With a thermoplastic polymer it may be further advantageous to repeatedly heat the flexible circuit in multiple molds, each with a decreasing radius. Further, it is advantageous to add material along the edges. It is further advantageous to provide a fold or twist in the flexible circuit array. Additional material may be added inside and outside the fold to promote a good seal with tissue.

Owner:SECOND SIGHT MEDICAL PRODS +1

Flexible circuit electrode array

ActiveUS20060259112A1Improve the immunityCut the delicate retinal tissueHead electrodesPrinted circuit manufactureFlexible circuitsHearing perception

Owner:SECOND SIGHT MEDICAL PRODS +2

Golf club head

InactiveUS20080132352A1Large spin amountA large amountGolf clubsRacket sportsSurface roughnessGolf Ball

A golf club head of this invention includes a face and a plurality of striations formed on the face by milling. A pitch P in the arrangement direction of the plurality of striations satisfies 300 μm≦P≦600 μm. The surface roughness of a region in the face with the striations satisfies in the maximum height of the profile Ry, 15 μm≦Ry≦0.005×P+15.7 μm.

Owner:BRIDGESTONE SPORTS

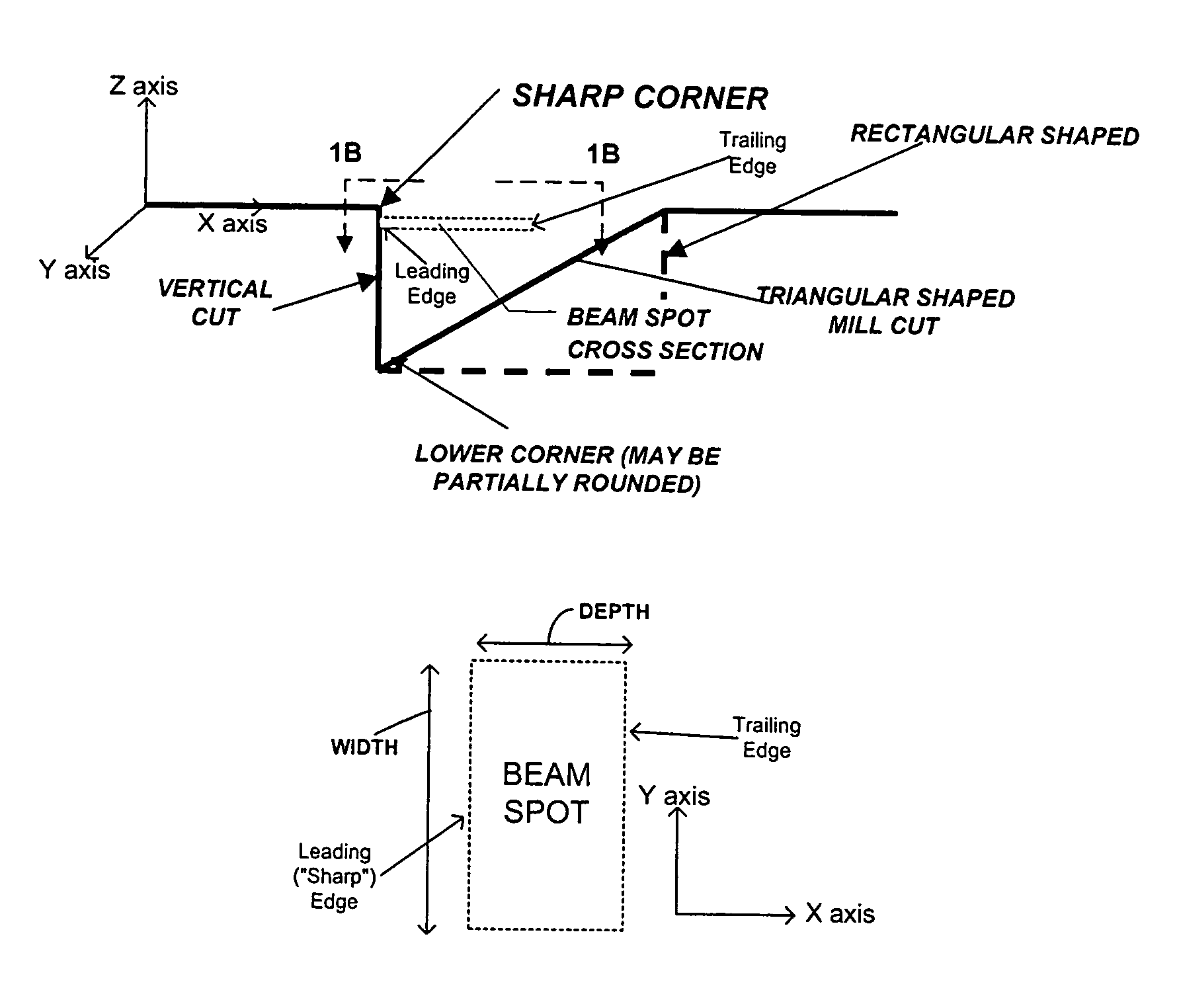

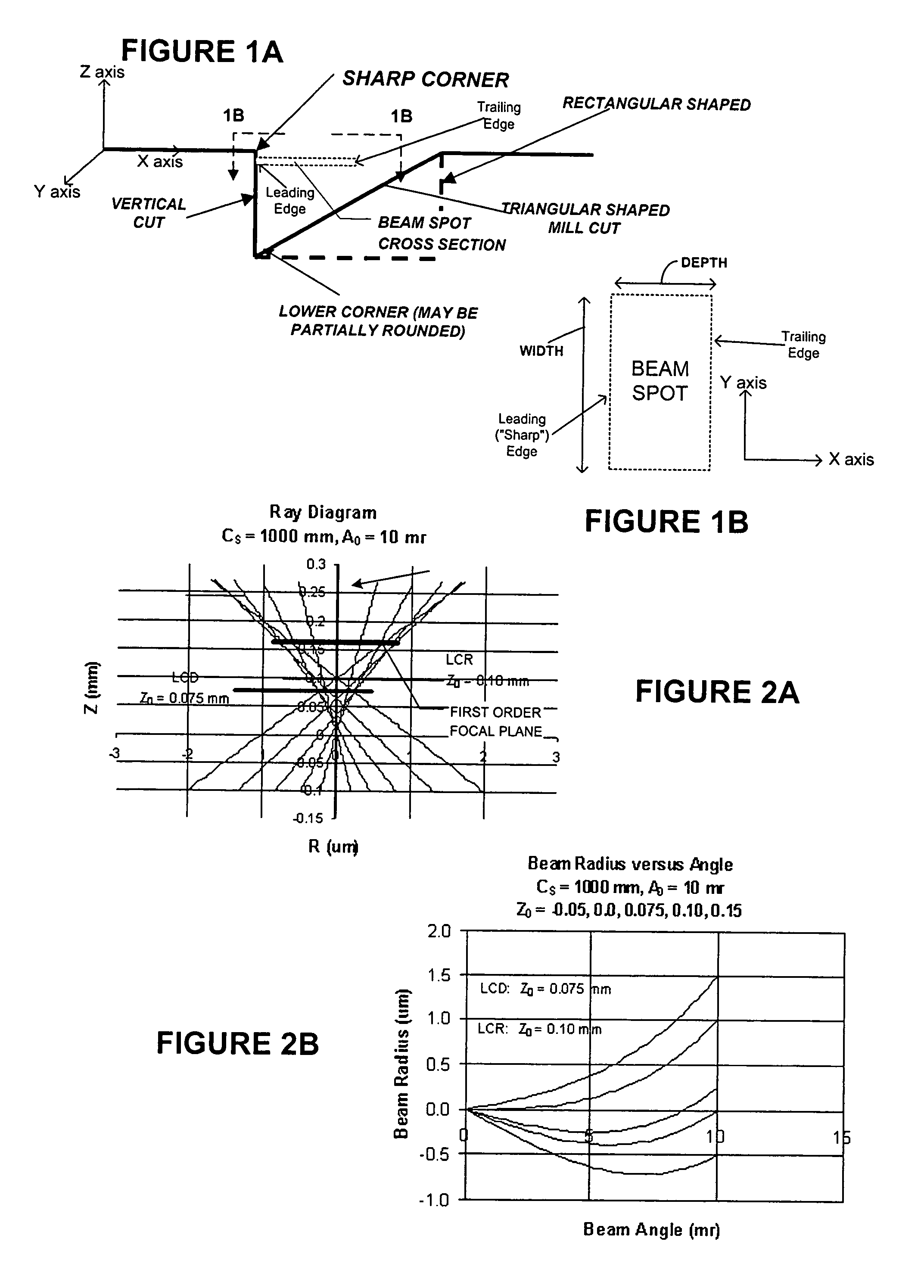

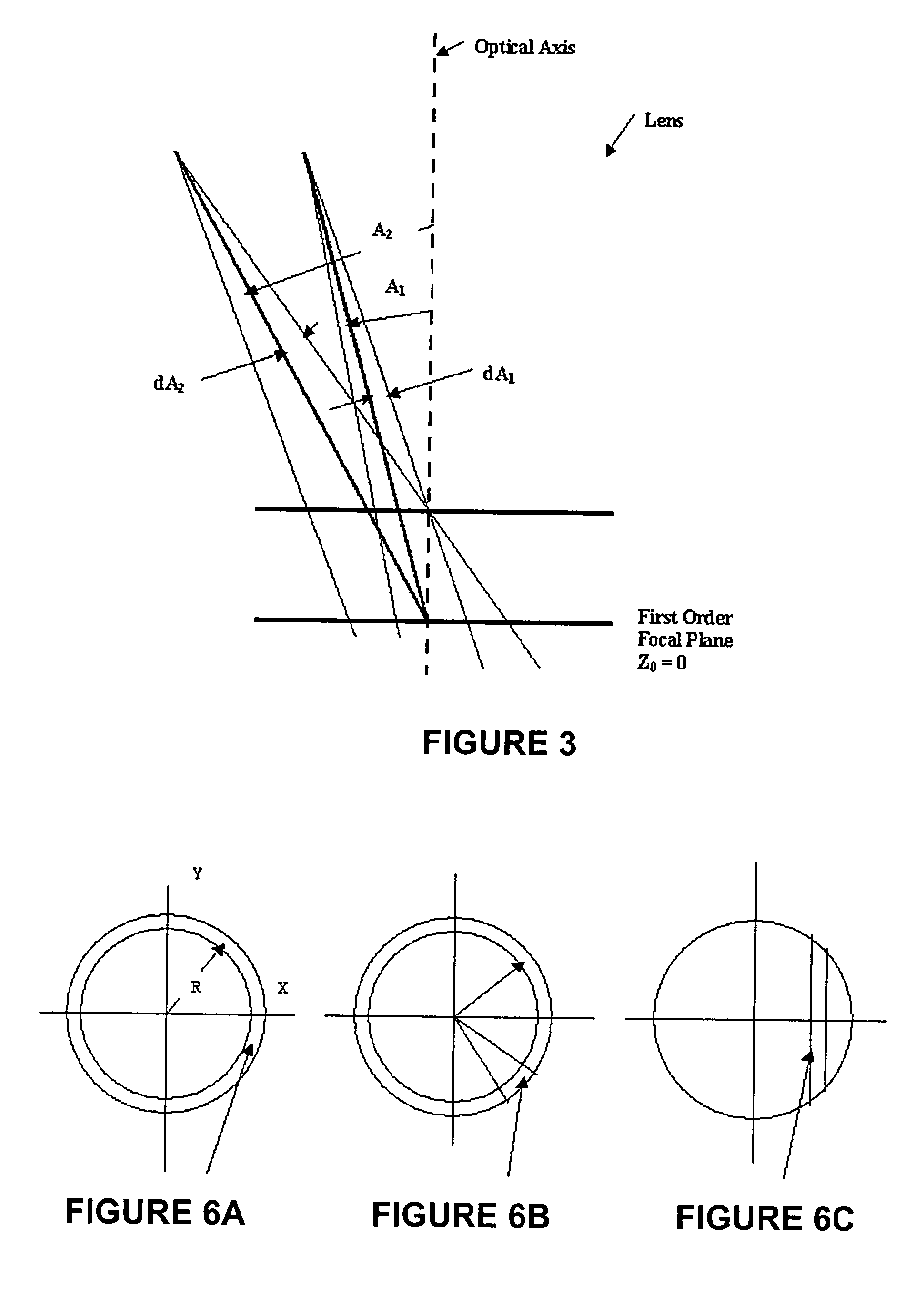

Angular aperture shaped beam system and method

InactiveUS6977386B2More currentSharp edgeMaterial analysis using wave/particle radiationElectric discharge tubesShaped beamSEMI-CIRCLE

The present invention provides improved angular aperture schemes for generating shaped beam spots having a desired geometric shape from rectangular, elliptical, and semi-elliptical apertures having one sharp edge. A sharper beam edge can be generated by offsetting the rectangular or elliptical aperture in combination with under or over focus. In the spherical aberration limit, under-focused semi-circle apertures provide a sharp, flat edge. The sharp edge can be made resolute enough for precision milling applications, and at the same time, the spot can be made large enough with enough overall current and current density to efficiently mill away material in either a production or laboratory environment. Depending on the particular beam spot that is desired, combinations of techniques including defocusing, aperture offsetting, and stigmation adjustment, can be used in both spherical aberration dominant and chromatic aberration dominant environments to achieve a desired beam for a desired application.

Owner:FEI CO

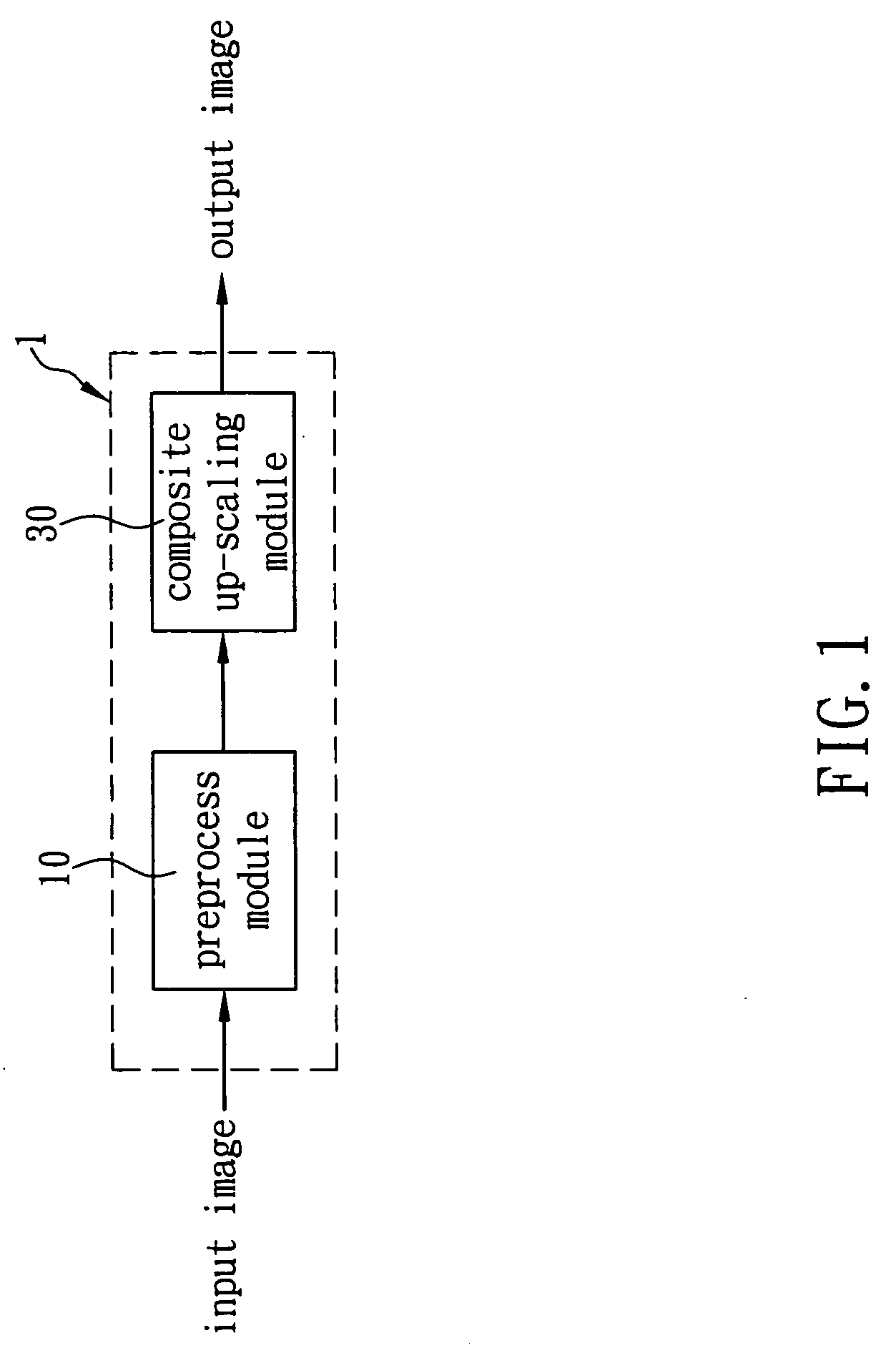

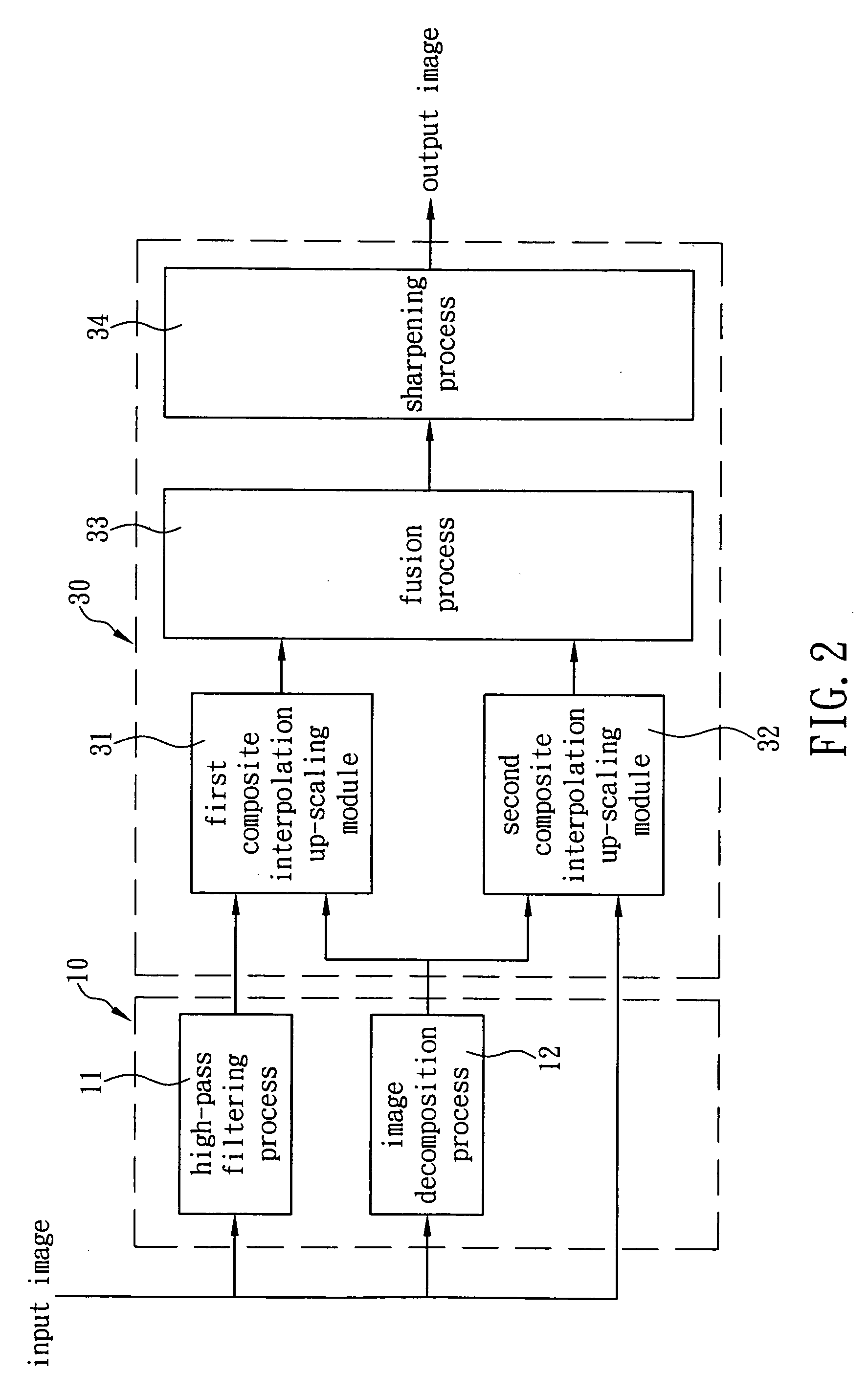

Method for magnifying images and videos

ActiveUS20100166334A1Improve robustnessAvoid it happening againTelevision system detailsColor signal processing circuitsImaging processingMagnification

This invention is a method applicable to an image processing device, which includes the steps of providing a preprocess module for extracting a high-frequency portion of an image inputted into the device, extracting a gradient of the image and decomposing the image into plane and edge regions according to a predetermined fixed threshold, and providing a composite up-scaling module for executing the magnification processes on the image and the high-frequency portion thereof respectively, wherein the magnification process of plane regions of the image and the high-frequency portion is based on a simple interpolation while the edge regions of the image and the high-frequency portion is based on both a smart interpolation and the simple interpolation. The magnification results of the image and the high-frequency portion are then processed by a fusion process, so as to output an image having sharp but not blocky edges, rich details and strong contrast.

Owner:ARCSOFT CORP LTD

Hot rolling process of wide flat bar steel

InactiveCN1857807AImprove cleanlinessExact widthWork treatment devicesRoll mill control devicesHeating furnaceWater cooling

The hot rolling process of wide flat bar steel includes the following steps: heating continuously cast rectangular steel billet at 1050-1150 deg.c inside heating furnace, coarse edge rolling in an edger, descaling in a descaling unit, repeated rolling in a two-roller reversing mill, cutting ends in a hot shearing machine, finish rolling in a finishing mil group, chilling to 475-525 deg.c in a water cooler, cooling to below 200 deg.c in a cooling bed, cutting ends in a cold shearing machine, lengthing in a shear gauge, shearing to certain length in a cold shearing machine, collecting and baling. The present invention provides wide flat bar steel in certain sizes for building and bridge.

Owner:江阴博丰钢铁有限公司

Flexible circuit electrode array

ActiveUS8209023B2Improve the immunityCut the delicate retinal tissuePretreated surfacesCeramic shaping apparatusFlexible circuitsElectrode array

A flexible circuit electrode array and method of fabrication having a polymer base layer; metal traces deposited on the polymer base layer, including electrodes to stimulate tissue; a polymer top layer deposited on the polymer base layer and metal traces; and a coating of the base and top layer by a soft polymer. A method of preparing a flexible circuit electrode array, comprising: providing a first soft polymer layer; depositing a first a base layer on the first soft polymer layer; providing a metal thin film on the base layer; depositing a top polymer layer on the metal thin film; providing holes in the top polymer layer; depositing a second soft polymer layer on the top polymer layer; providing holes in the second soft polymer layer for bond pads and electrodes; and preparing electrodes in the provided holes.

Owner:CORTIGENT INC +1

Method for preparing leather sample observed by metallurgical microscope

InactiveCN102305736AFast penetrationFully infiltratedPreparing sample for investigationFiberMicroscopic observation

The invention relates to a method for preparing a leather sample observed by a metallurgical microscope, and belongs to the technical field of leather inspection. The method comprises the following steps of: (1) adding a promoter into an unsaturated polyester resin, stirring, adding a curing agent, stirring, standing, and discharging the mixed air to obtain an immobilized resin; (2) immersing a sample into the immobilized resin, and curing to obtain a cured sample; (3) grinding both ends of the cured sample until the ends are flat, fixing in a mould, injecting the immobilized resin into the mould, curing, demoulding, and post-curing to obtain a post-cured sample block; and (4) grinding and polishing the post-cured sample block by using abrasive paper to obtain the leather sample observed by the metallurgical microscope. In the method, the unsaturated polyester resin is used as a main ingredient of the immobilized resin, and operation steps are designed according to a capillary action principle to ensure that the immobilized resin can be quickly and fully permeated into the leather sample, so the adhesion and deformation of section fiber of leather are furthest avoided.

Owner:QILU UNIV OF TECH

Flexible circuit electrode array with at least one tack opening

ActiveUS20070265665A1CutImprove the immunityHead electrodesWave amplification devicesPolymer scienceFlexible circuits

The present invention provides a flexible circuit electrode array adapted for neural stimulation, comprising: a polymer base layer; metal traces deposited on said polymer base layer, including electrodes suitable to stimulate neural tissue; a polymer top layer deposited on said polymer base layer and said metal traces at least one tack opening; wherein said polymer base layer, said metal traces and said polymer top layer are thermoformed in a three dimensional shape. The present invention provides further a method of making a flexible circuit electrode array comprising depositing a polymer base layer; depositing metal on said polymer base layer; patterning said metal to form metal traces; depositing a polymer top layer on said polymer base layer and said metal traces; preparing at least one tack opening; and heating said flexible circuit electrode array in a mold to form a three dimensional shape in said flexible circuit electrode array.

Owner:CORTIGENT INC +1

Flexible Circuit Electrode Array with at Least one Tack Opening

ActiveUS20080058875A1Improve the immunityCut the delicate retinal tissueLine/current collector detailsHead electrodesPolymer scienceFlexible circuits

The present invention provides a flexible circuit electrode array adapted for neural stimulation, comprising: a polymer base layer; metal traces deposited on said polymer base layer, including electrodes suitable to stimulate neural tissue; a polymer top layer deposited on said polymer base layer and said metal traces at least one tack opening; wherein said polymer base layer, said metal traces and said polymer top layer are thermoformed in a three dimensional shape. The present invention provides further a method of making a flexible circuit electrode array comprising depositing a polymer base layer; depositing metal on said polymer base layer; patterning said metal to form metal traces; depositing a polymer top layer on said polymer base layer and said metal traces; preparing at least one tack opening; and heating said flexible circuit electrode array in a mold to form a three dimensional shape in said flexible circuit electrode array.

Owner:CORTIGENT INC

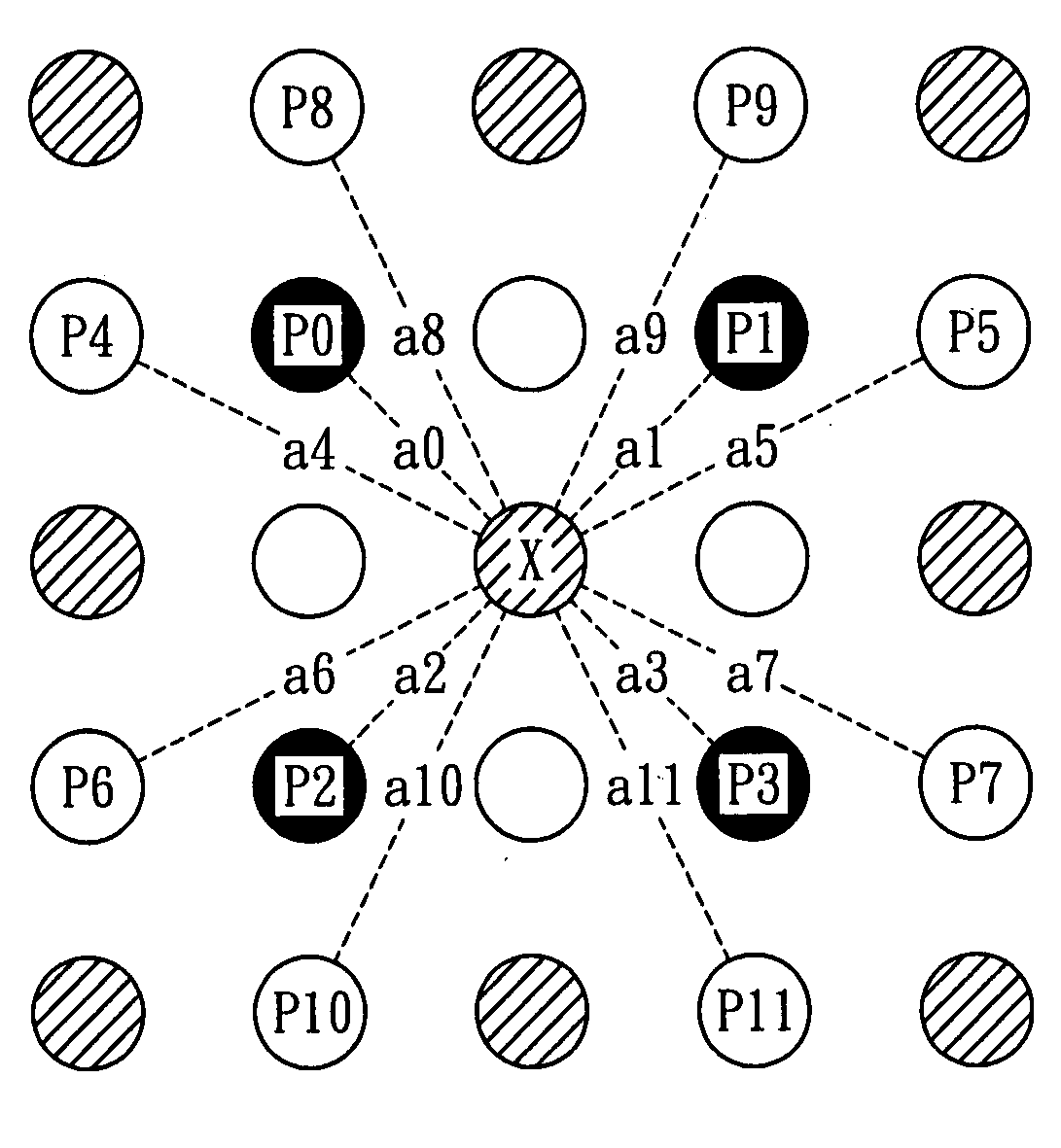

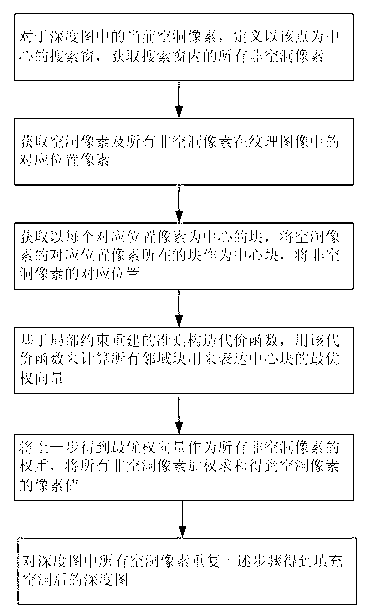

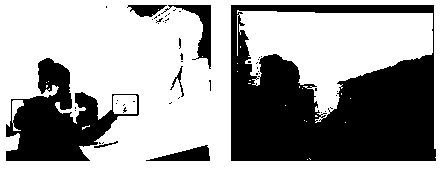

KINECT depth map cavity filling method based on local restriction reconstruction

InactiveCN103136775AAvoid mappingHigh precisionFilling planer surface with attributesOptimal weightDepth map

The invention discloses a KINECT depth map cavity filling method based on local restriction reconstruction. The KINECT depth map cavity filling method based on the local restriction reconstruction comprises the steps of taking a cavity pixel in a depth map as a center to construct a search window, obtaining all non-cavity pixels in the search window, obtaining corresponding position pixels of the cavity pixel and the non-cavity pixels in a texture map, taking the corresponding position pixels as centers to build blocks, taking a bock where the corresponding position pixel of the cavity pixel is located as a central block, taking blocks where the corresponding position pixels of the non-cavity pixels as neighborhood blocks, constructing a cost function based on a local restriction reconstruction standard and obtaining the neighborhood blocks to be used for expressing the optimal weight vector of the central block, achieving a weighted sum pixel value of all the non-cavity pixels in the search window based on the optimal weight vector of the neighborhood blocks to obtain a target pixel value, and taking the target pixel value as the pixel value of the cavity pixel in the depth map. The KINECT depth map cavity filling method based on the local restriction reconstruction can accurately fill up cavities in an edge area and a smooth area of the depth map.

Owner:WUHAN UNIV

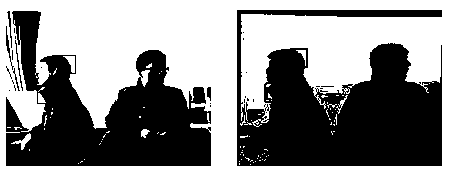

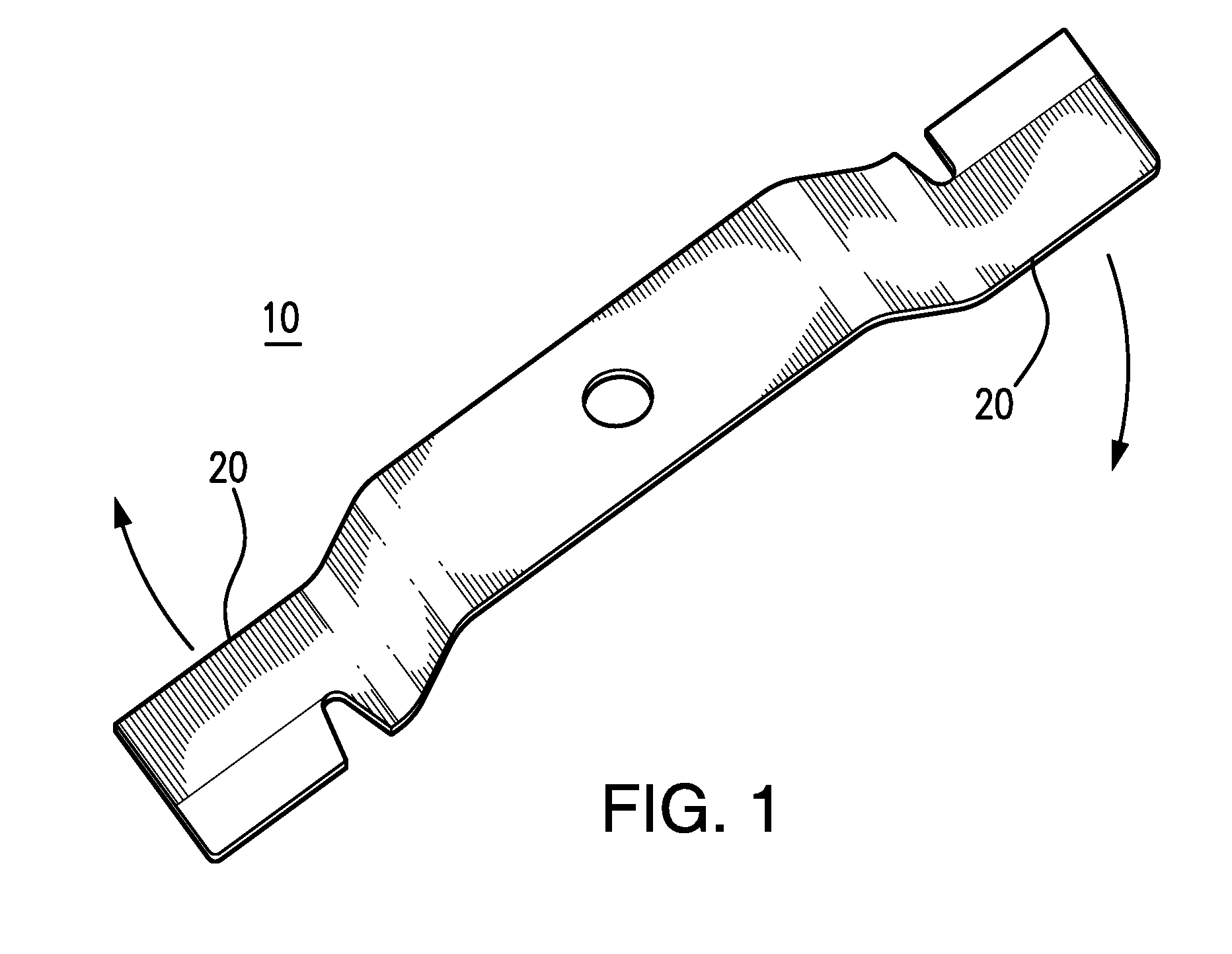

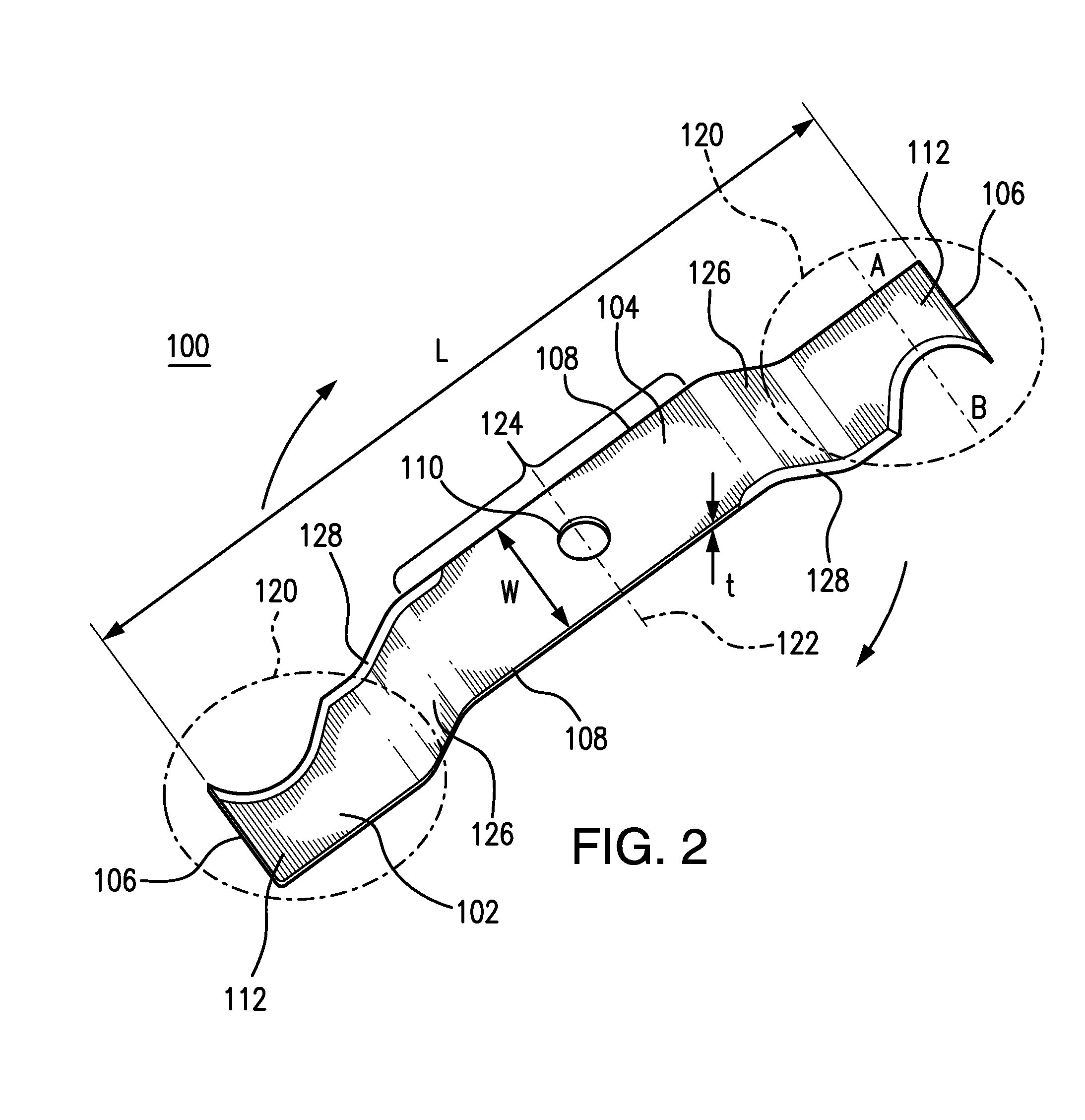

Cutting Blade

InactiveUS20140182257A1Improved cutting edgeReduce power consumptionMowersEngineeringRotational symmetry

An improved blade is disclosed. The blade has an elongated member having rotational symmetry about a center axis. The elongated member further has two ends each having a sharpened edge, wherein at least a portion of each sharpened edge comprises a slicing edge configured to intersect a stalk of grass in non-perpendicular relation. The blade is configured so that rotation of the blade causes the slicing edges to come into non-perpendicular contact with the grass, thereby slicing the grass to be mowed.

Owner:VON RENTZELL WILLIAM E

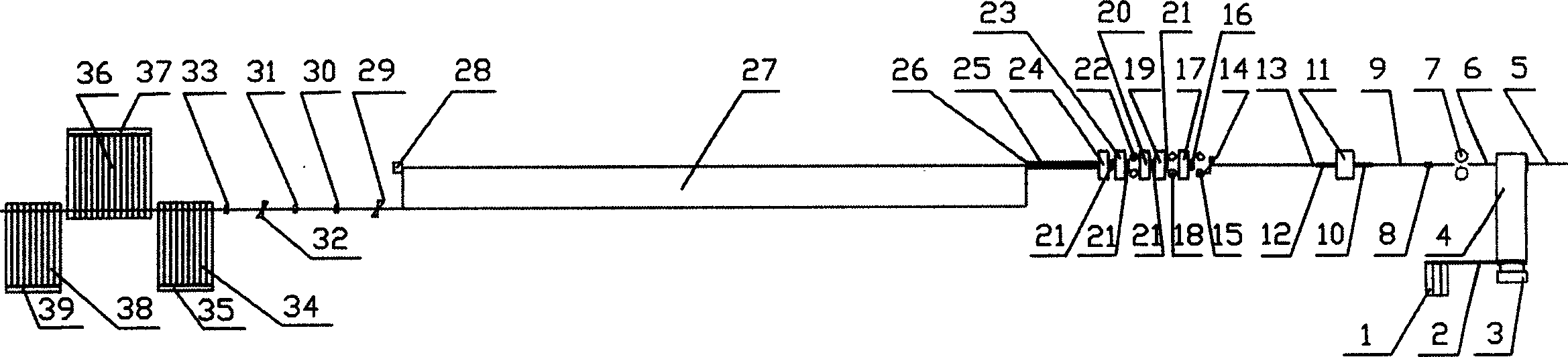

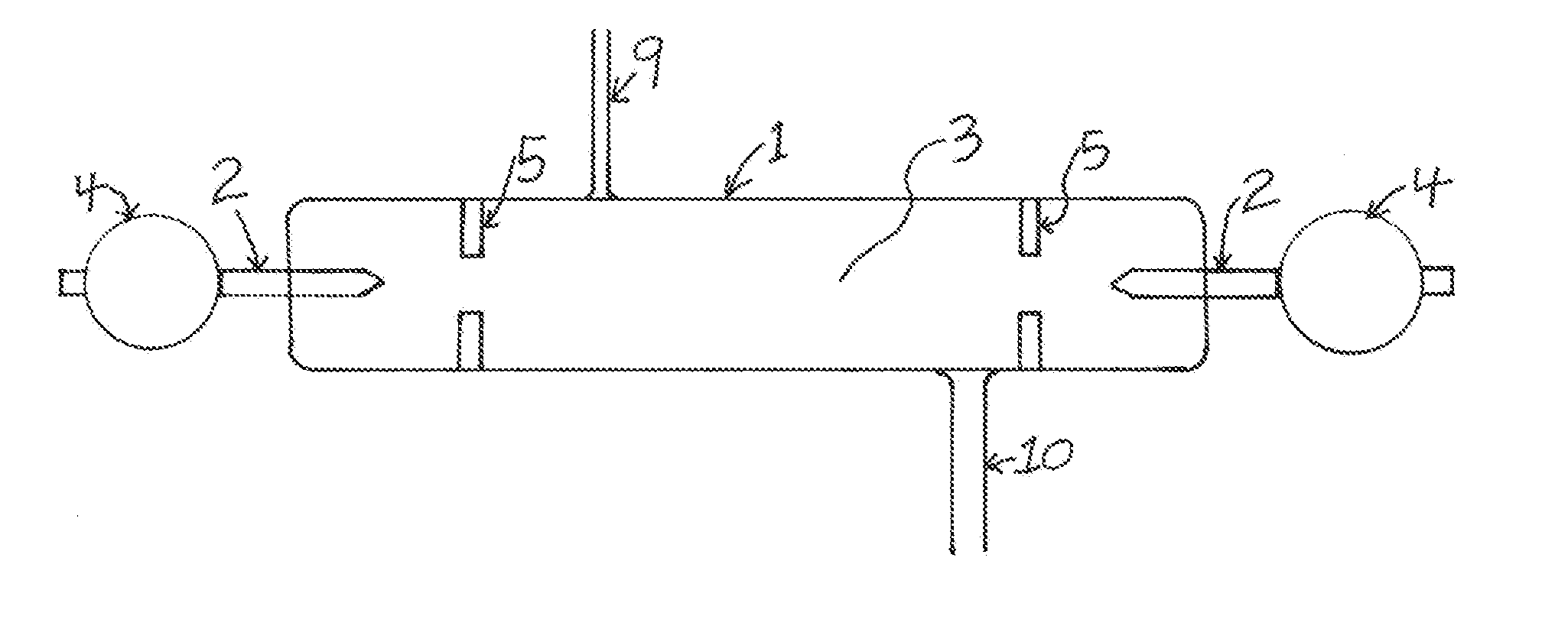

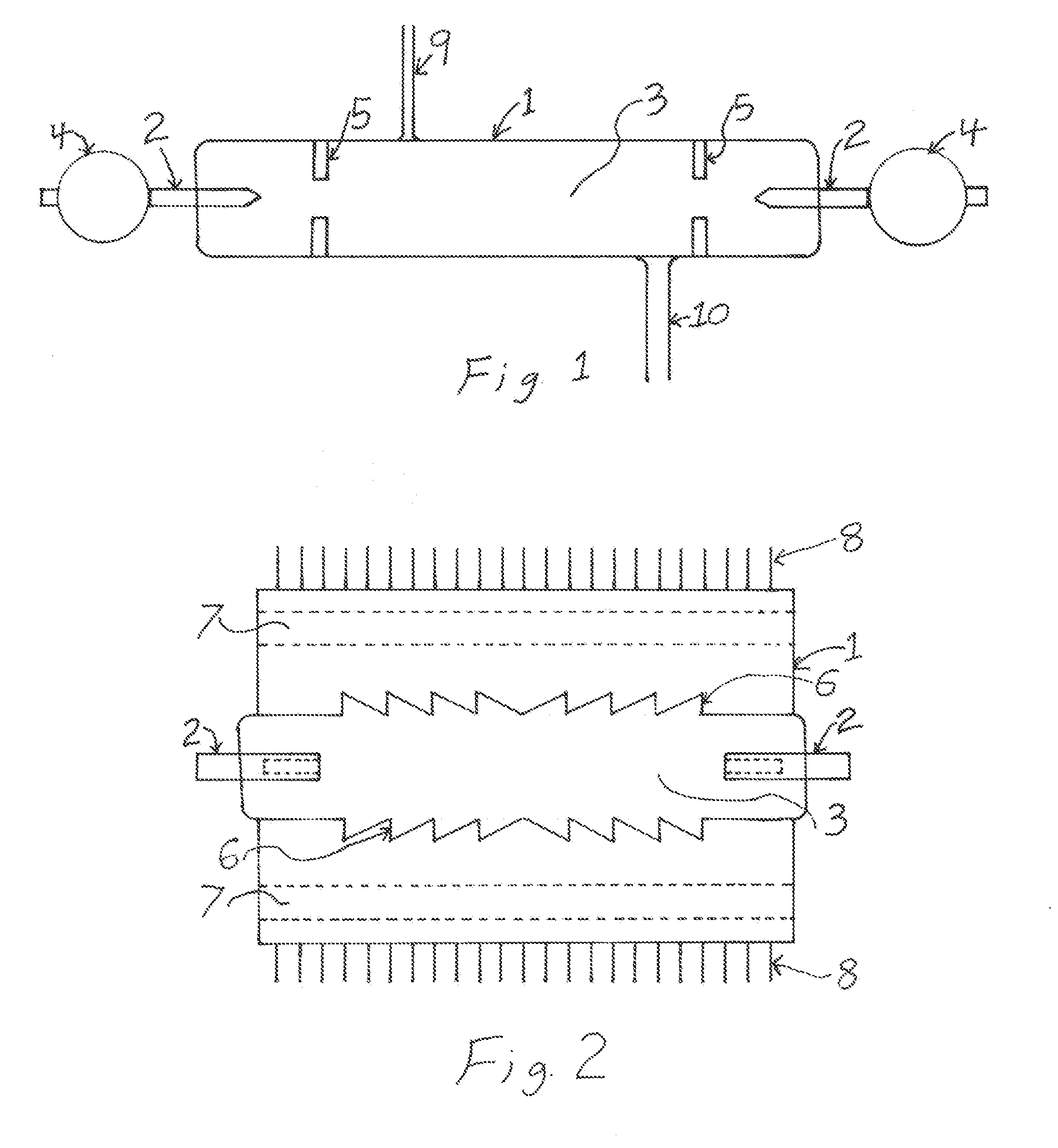

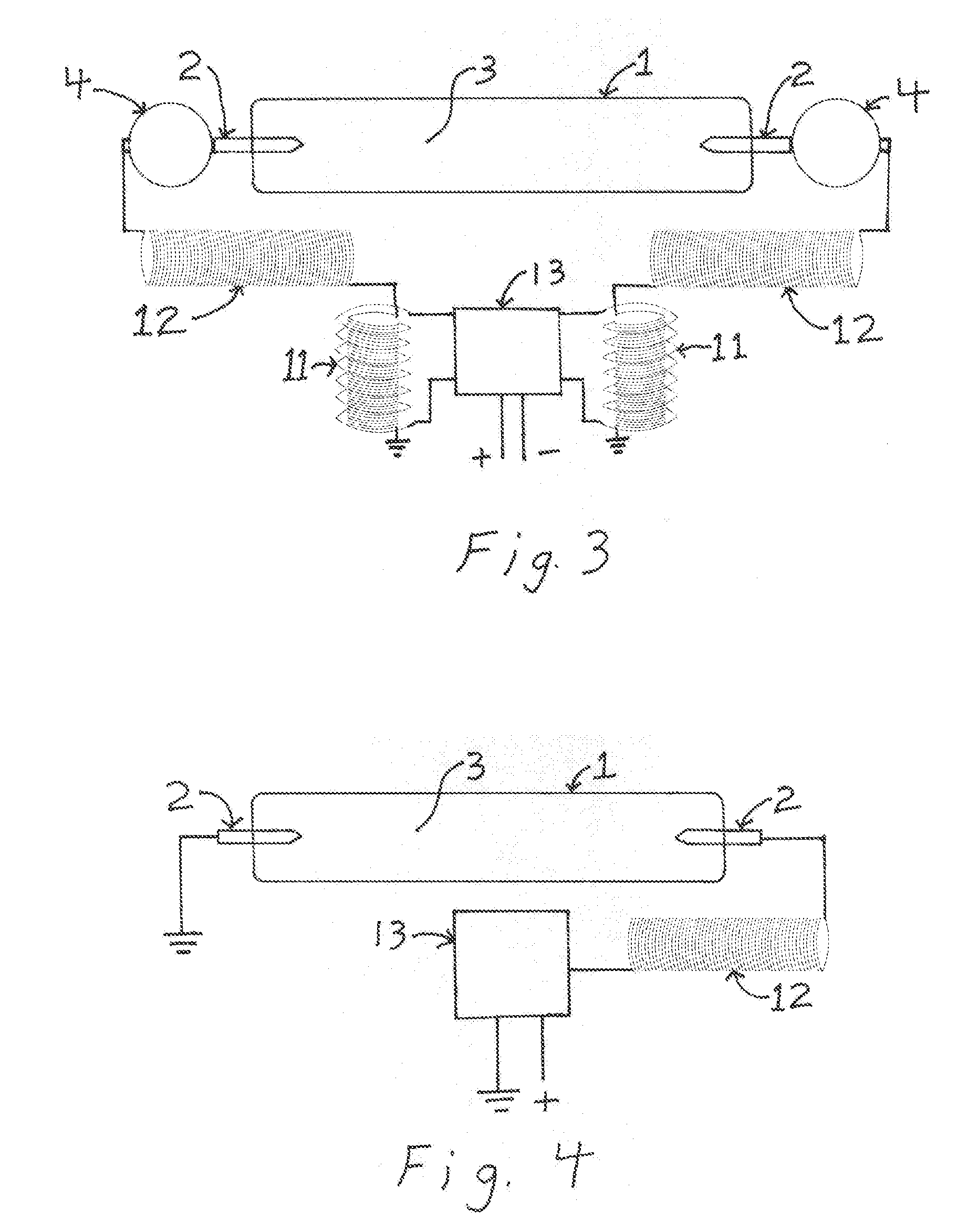

Resonant Vacuum Arc Discharge Apparatus for Nuclear Fusion

InactiveUS20120008728A1Improve efficiencyImprove fusion efficiencyNuclear energy generationDirect voltage acceleratorsWell loggingNuclear fusion

The present invention relates to a resonant vacuum arc discharge apparatus for producing nuclear fusion. A resonant high-frequency high-voltage alternating current (AC) power supply is used to efficiently power a fusion tube normally containing deuterium, tritium and / or helium-3 vapor. Metals that can hold large amounts of hydrogen isotopes such as palladium and titanium can be used to increase the target density. The nuclear fusion device can be used for energy production, well logging, uranium mining, neutron activation analysis, isotope production or other applications that require a neutron source.

Owner:FLEMING RAY R

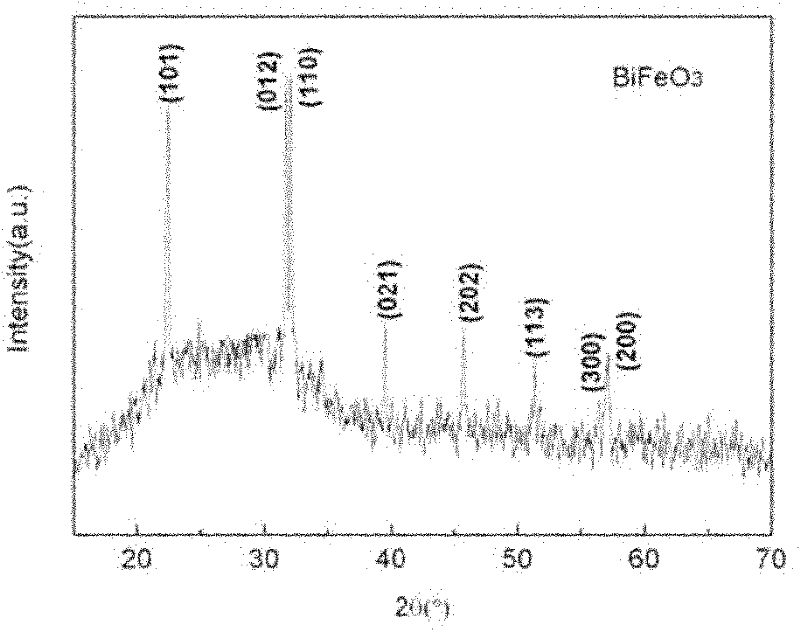

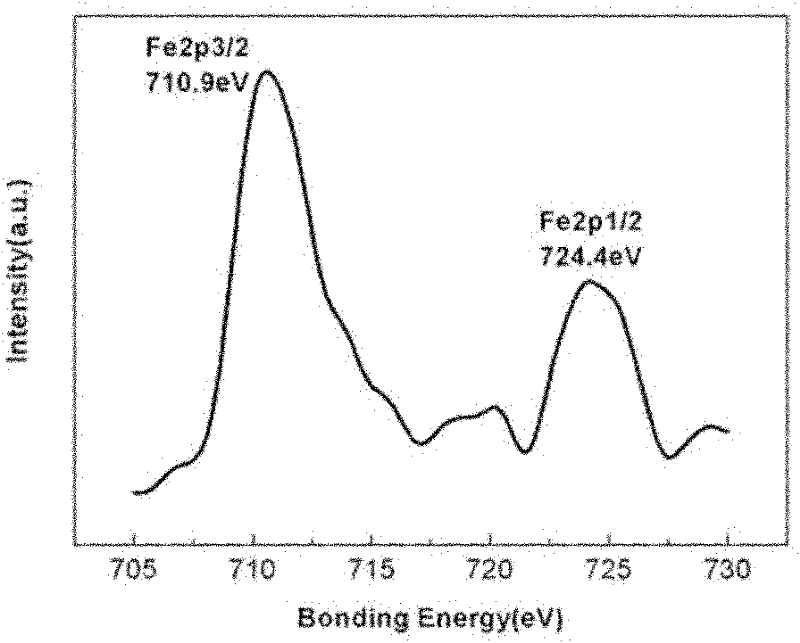

Photoethcing self assembly preparation method of patterned BiFeO3 film

InactiveCN102163486ASharp edgeSimple preparation processNanotechnologySubstrate/intermediate layersSelf-assembled monolayerUltraviolet lights

The invention discloses a photoethcing self assembly preparation method of a patterned BiFeO3 film. The method comprises the following steps: (1) selecting a common slide glass as a substrate, cutting the glass substrate, performing ultrasonic cleaning, drying, and irradiation in an ultraviolet light irradiation instrument, respectively; (2) immersing the glass substrate irradiated by ultravioletlight in OTS-toluene solution to form an OTS monomolecular film on the surface of the substrate, after the immersing, cleaning the substrate with acetone, blow-drying, stoving, irradiating the substrate, with a photomask covering thereon, under ultraviolet light to obtain a patterned functional self-assembled film; (3) preparing BiFeO3 precursor solution, placing an OTS-SAMs matrix of the patterned functional self-assembled film in the prepared precursor solution, performing deposition, supersonic wave concussion cleaning and annealing to obtain the photoetching self-assembled patterned BiFeO3 film. The method provided by the invention combines liquid phase deposition method and photoetching self-assembled monolayers technology to obtain the patterned BiFeO3 film. The film has the following advantages: the edge contour is clear, and the film is firmly bonded to the substrate.

Owner:SHAANXI UNIV OF SCI & TECH

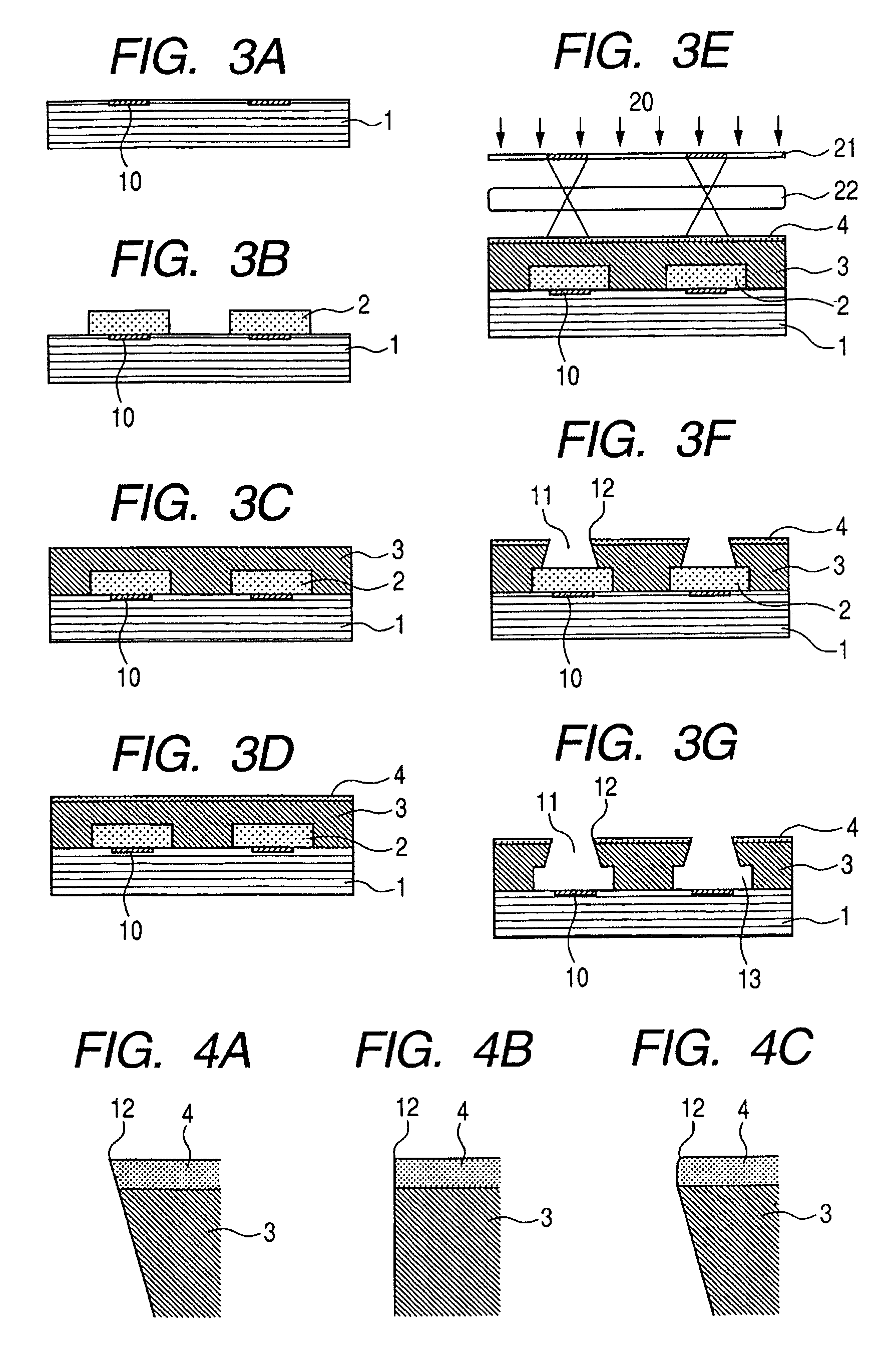

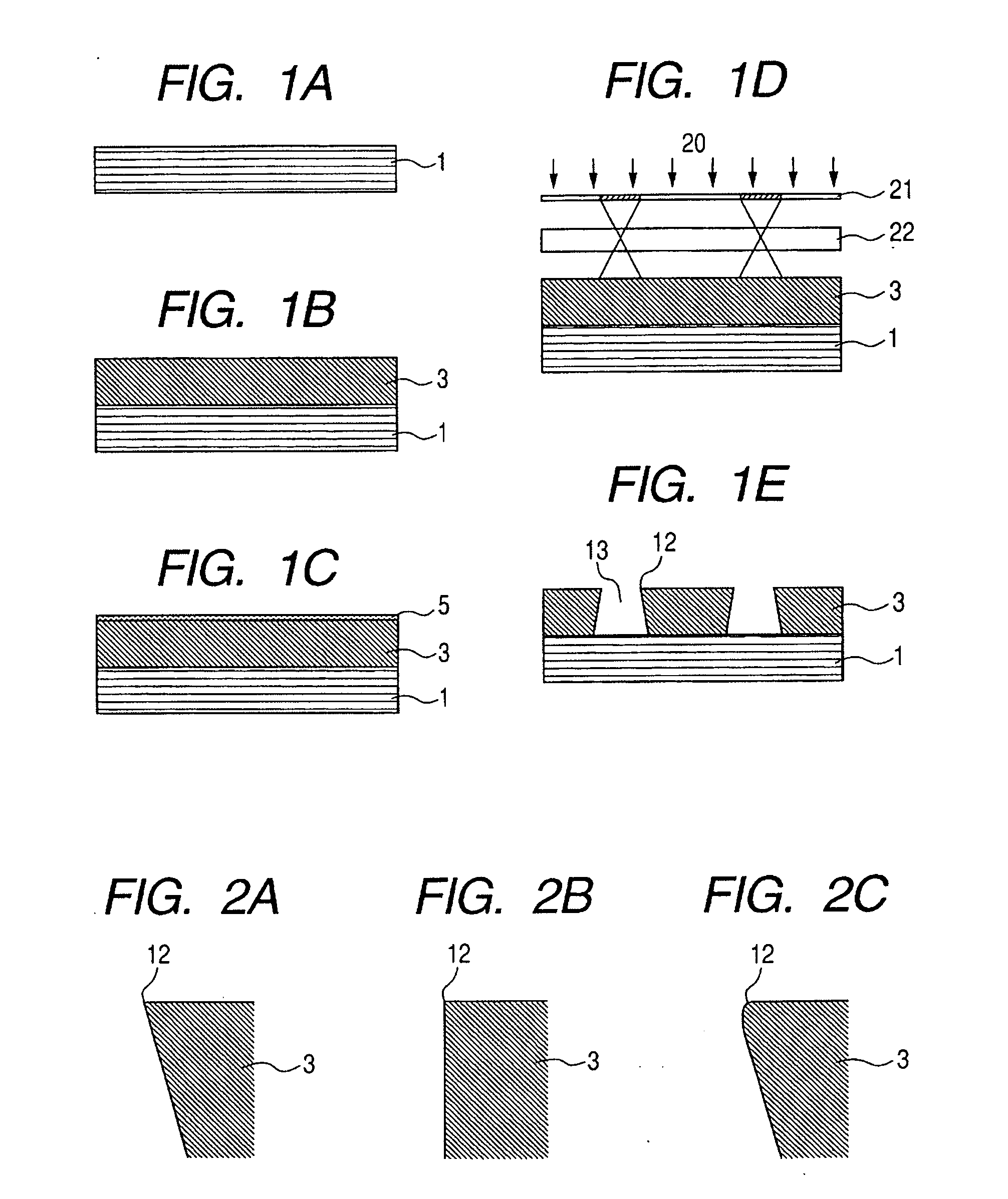

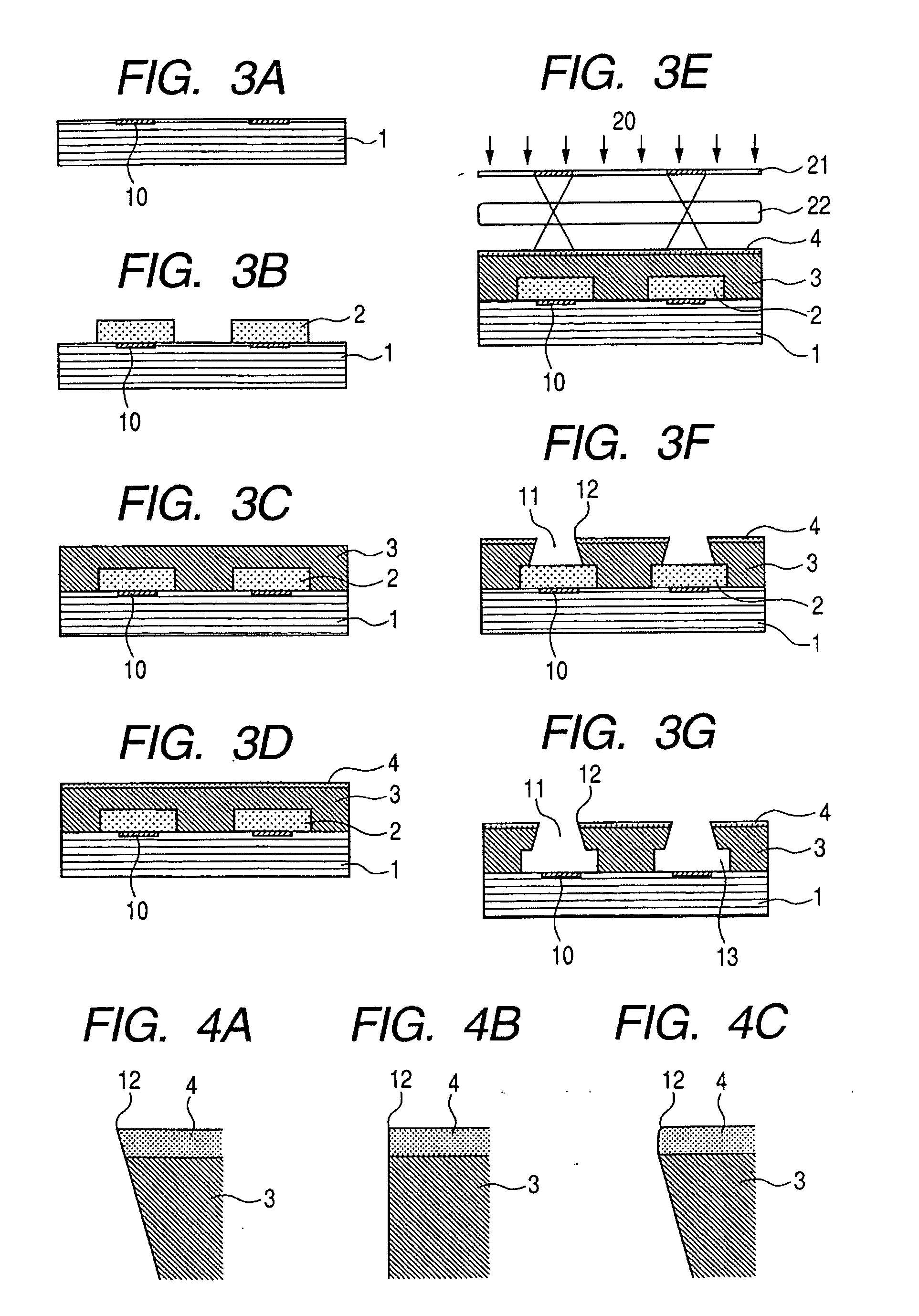

Pattern forming method and method of manufacturing ink jet recording head

InactiveUS7282243B2Quality improvementSharp edgePhotoprinting processesPhotomechanical apparatusEngineeringPhotolithography

Owner:CANON KK

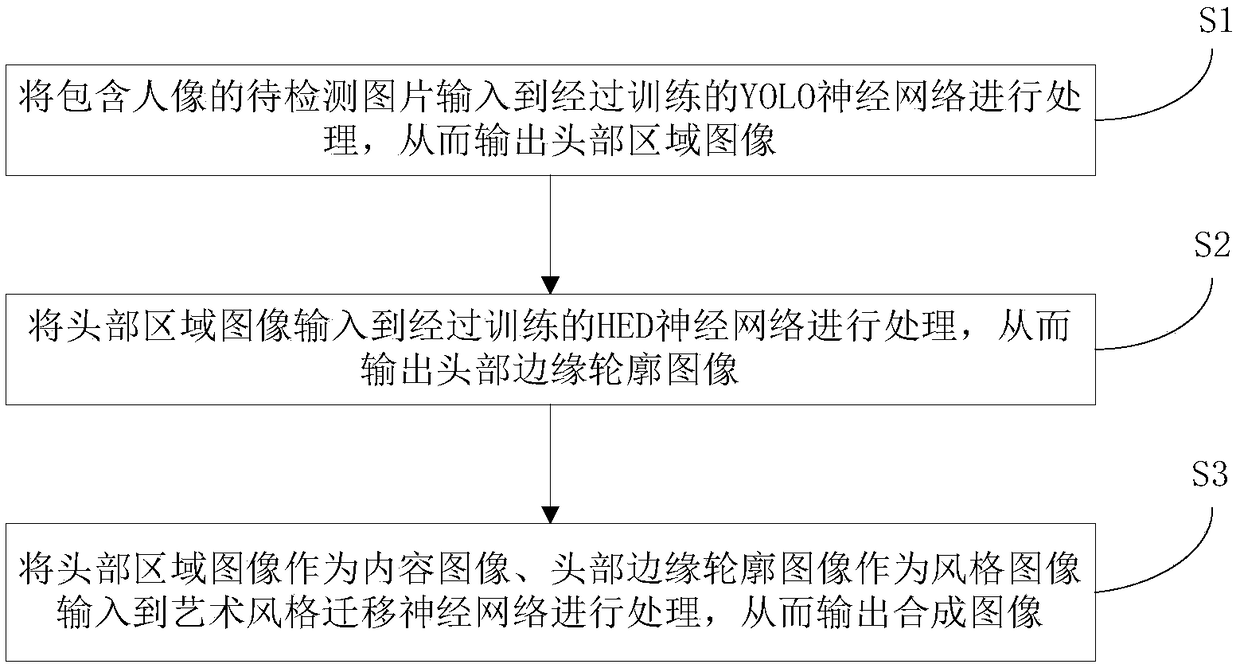

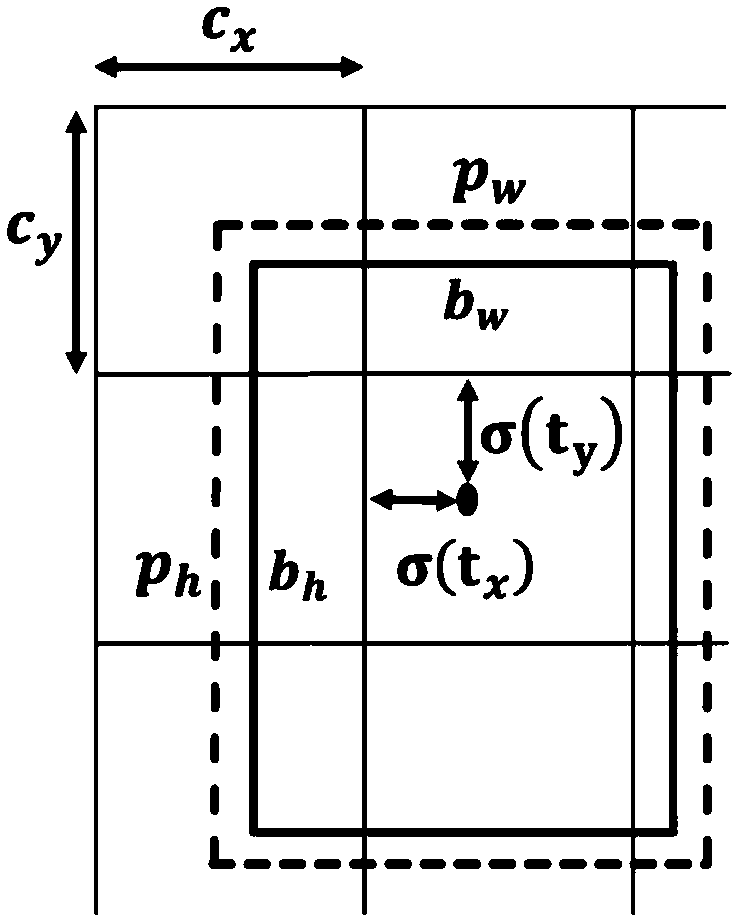

Method and device for extracting human head image based on deep learning

InactiveCN108614994AReduce data processingImprove work efficiencyBiometric pattern recognitionNeural architecturesImage basedImage extraction

The invention discloses a method and device for extracting a human head image based on deep learning. The method comprises the steps of inputting a to-be-extracted picture including a portrait into apre-trained YOLO neural network for processing and outputting a head region image, inputting the head region image into a trained HED neural network for processing and outputting a head edge contour image, inputting the head region image serving as a content image and the head edge contour image serving as a style image into an artistic style transfer neural network for processing, and thus outputting a synthetic image. The device comprises a memory and a processor. The head edge contour image can be extracted from the head region image, and the style of the head edge contour image is transferred to the head region image, thereby realizing the integration of the details such as the head edge contour, the five sense organs and the hairs, and enabling the synthetic image to have rich facialfeatures and clear edge contour. The method and device disclosed by the invention are applied to the technical field of image recognition and processing.

Owner:深圳市智能机器人研究院

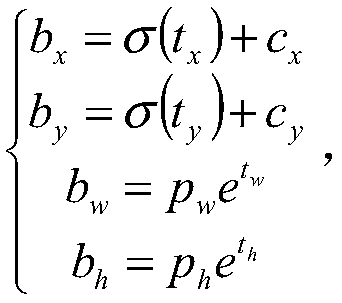

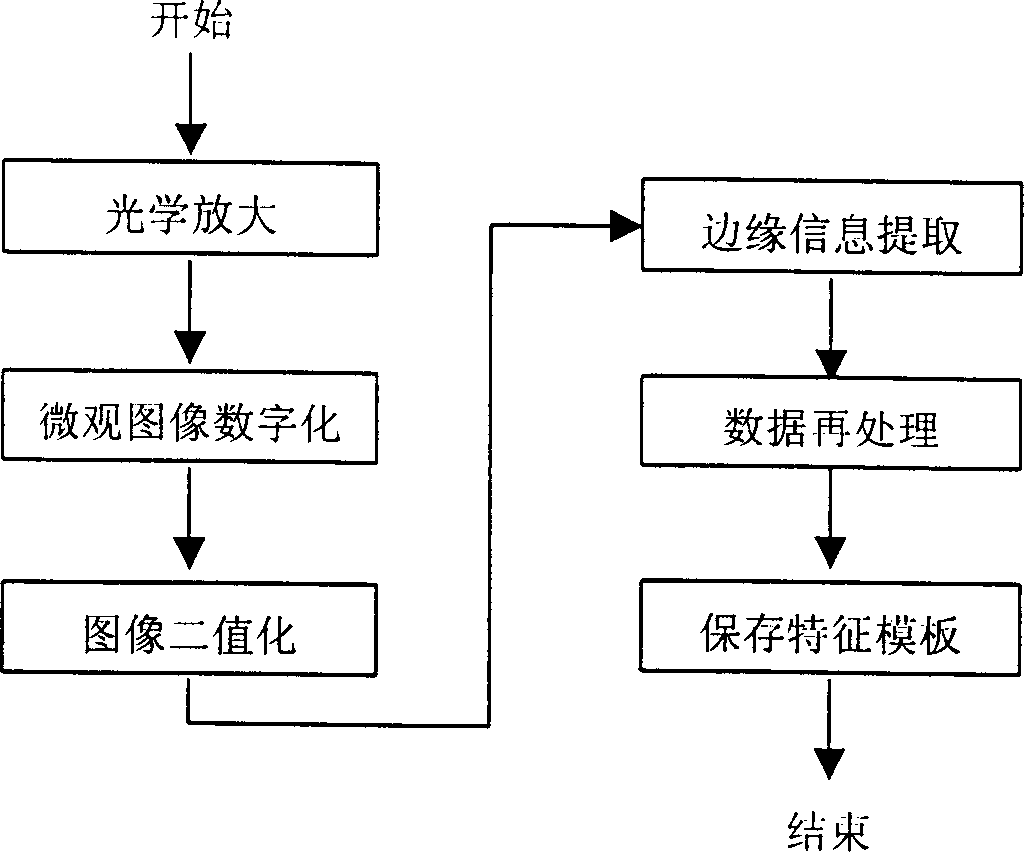

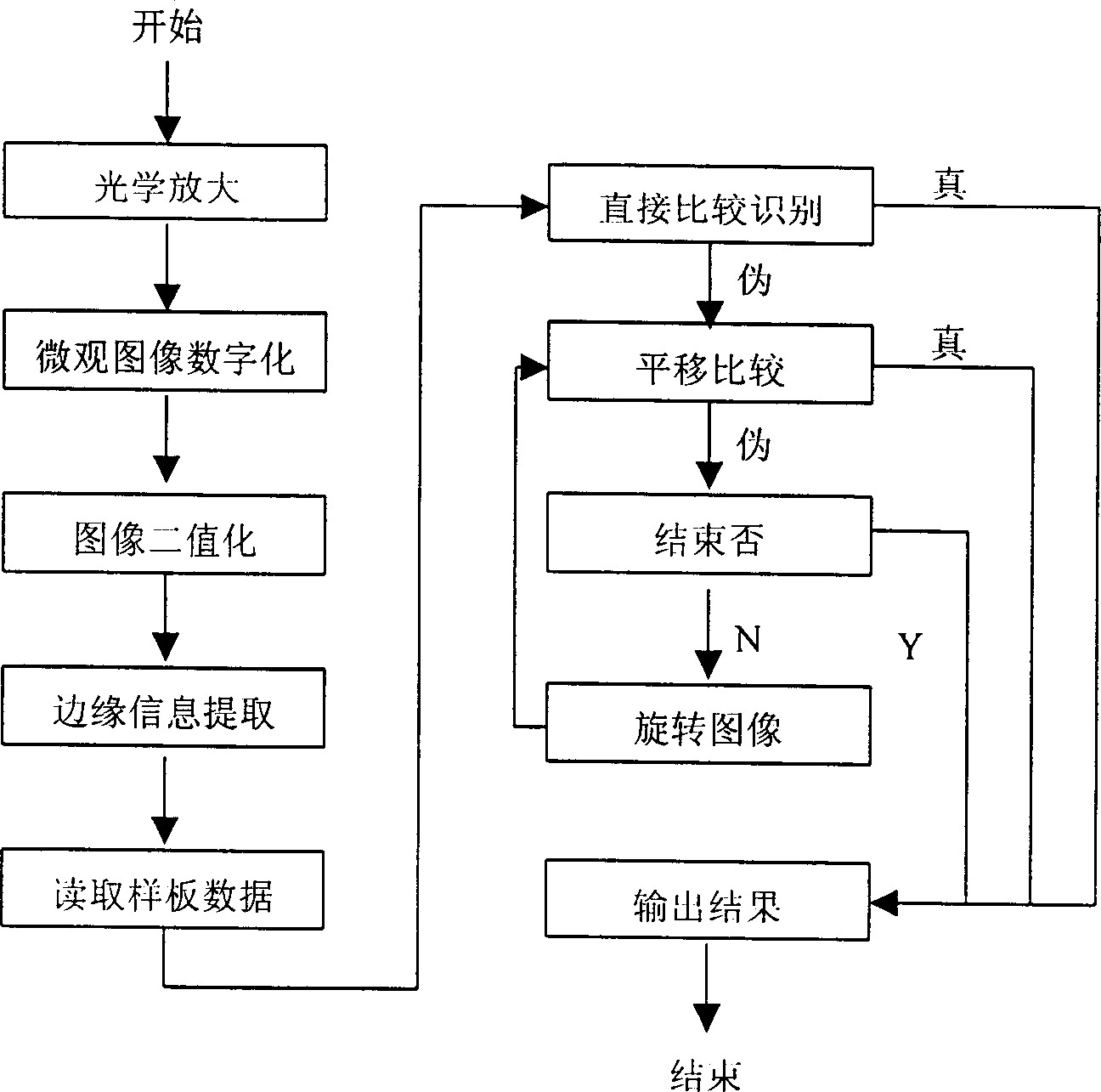

Micro image characteristic extracting and recognizing method

InactiveCN1384467AEasy to implementSharp edgeCharacter and pattern recognitionMaximum errorImaging processing

The present invention relates to image processing technology, and the micro image characteristic extracting and recognizing method includes two parts, the extraction of micro image characteristic andthe recognition of characteristics. The extraction includes the micro enlargement of image, digitizing the analog micro image, binarization processing, characterizing the position information of digital image with normalized coordinates and information re-processing and template preserving. The recognition includes micro enlargement of the image to be recognized, digitizing the image, edge information extraction of the digitized image and the comparison between the edge information and the stored characteristic template. Maximum error limit criterion is used in judging the truth of image. Thepresent invention is especially suitable for recognition and anti-fake of volualbe security and document.

Owner:TSINGHUA UNIV

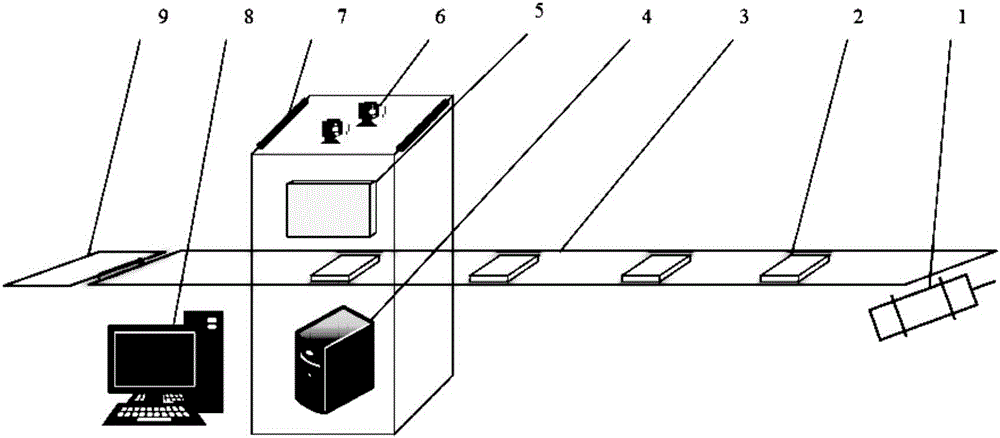

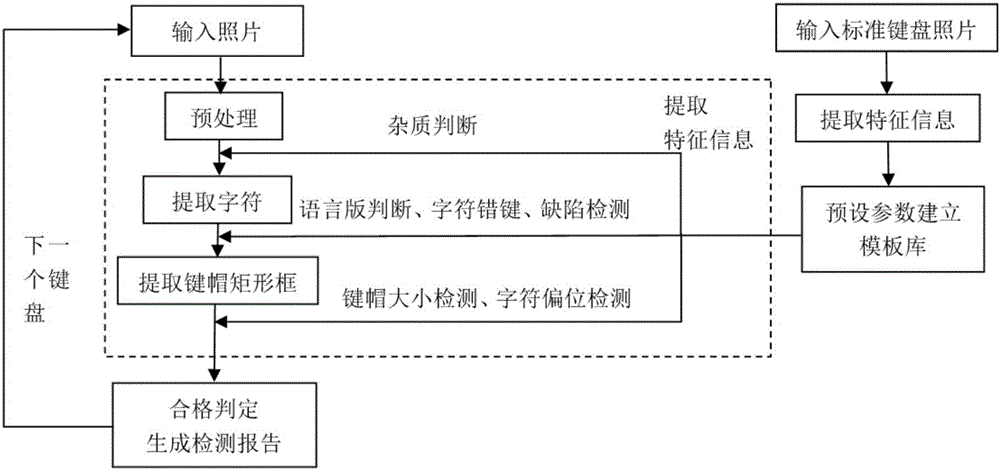

Dynamic optical detection device and detection method for laptop keyboards

The invention provides a dynamic optical detection device and detection method for laptop keyboards. The dynamic optical detection device comprises a camera, a touch screen displayer, an industrial personal computer, a stepping motor, a sorter, an assembly line testing table for storing the keyboards to be detected, and an illuminating device. The stepping motor drives the assembly line testing table to move. The camera and the illuminating device are arranged above the assembly line testing table. The camera is used for photographing the keyboards to be detected and generating to-be-detected photos. The touch screen displayer, the camera and the illuminating device are electrically connected with the industrial personal computer. The sorter is arranged at the discharging end of the assembly line testing table and used for discharging of the keyboards after detection is completed.

Owner:SHANGHAI JIAO TONG UNIV

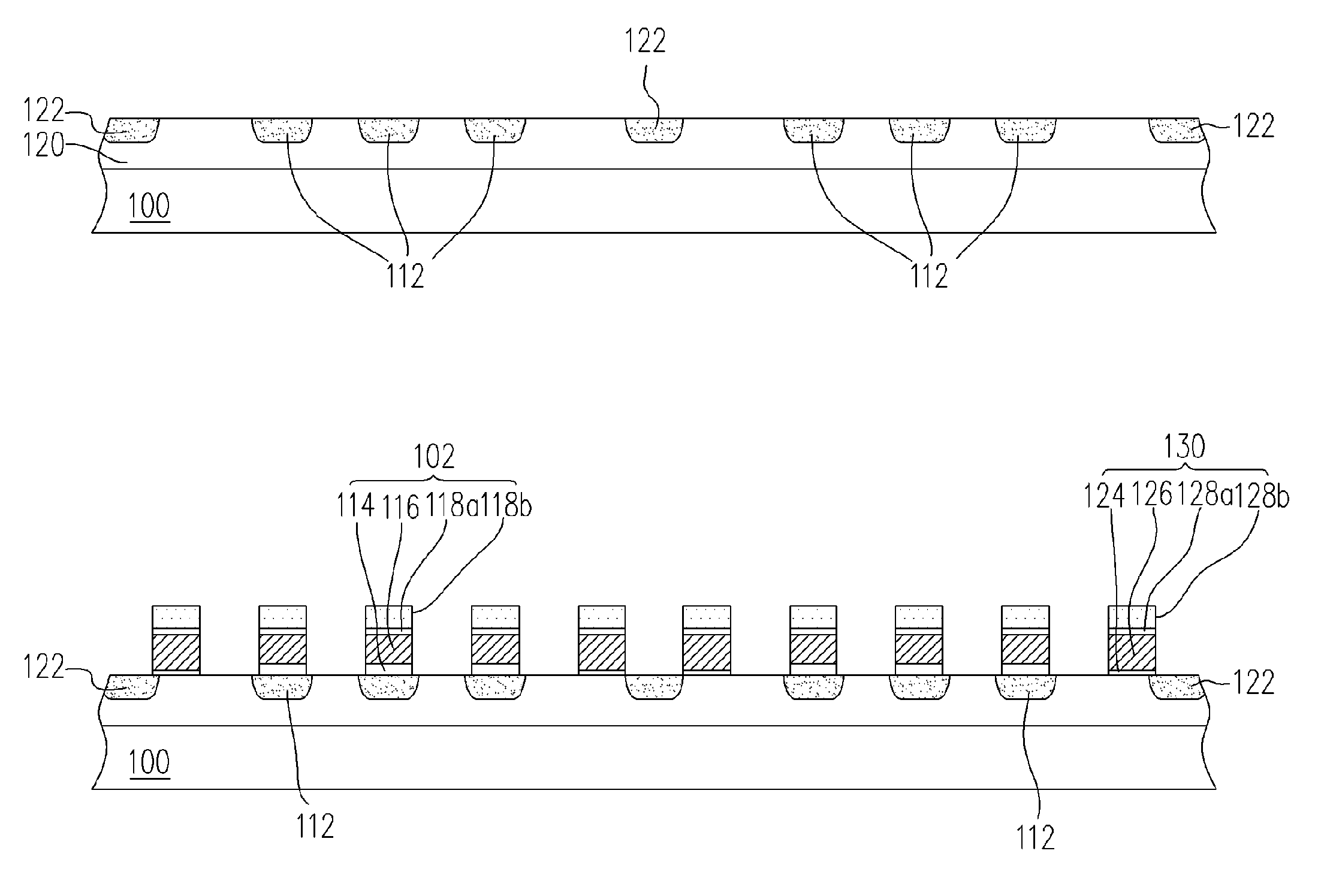

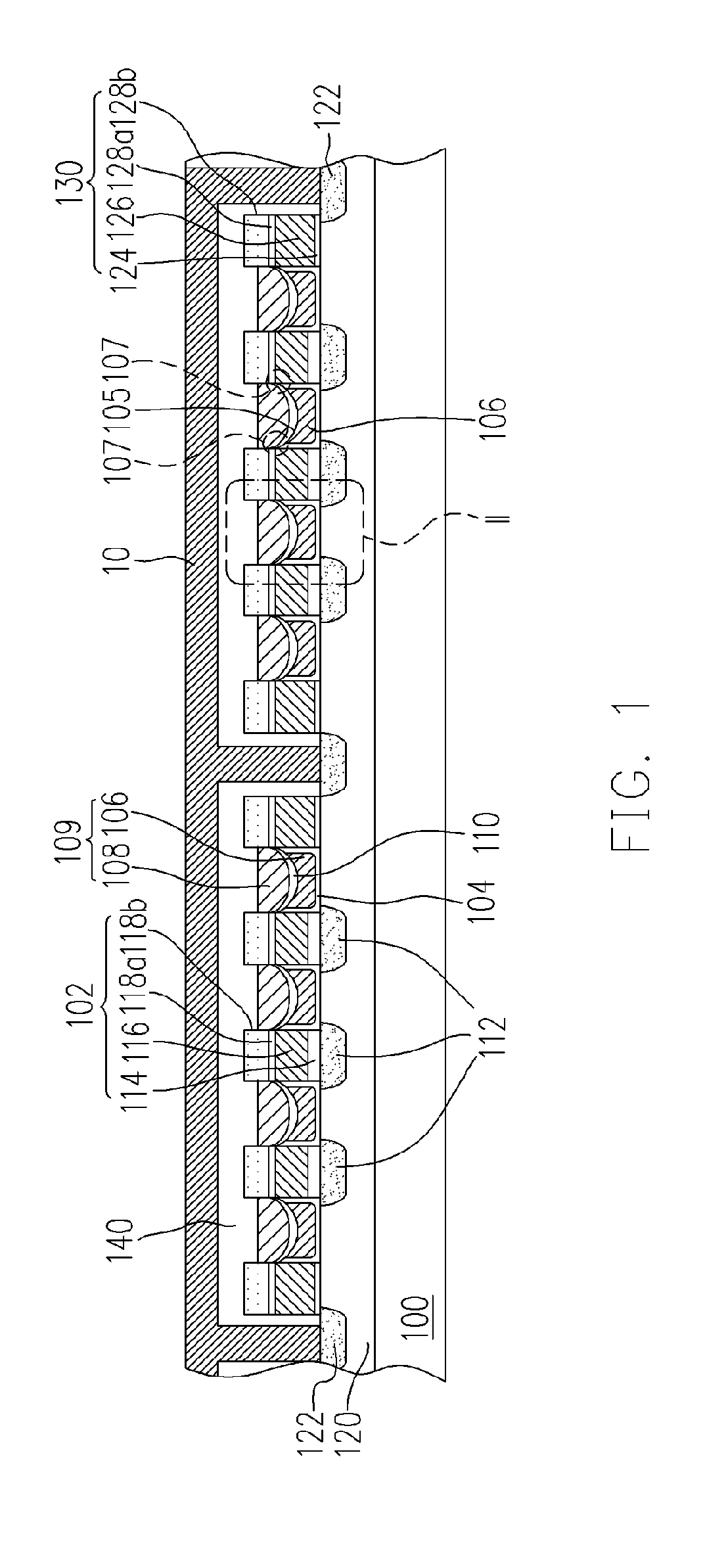

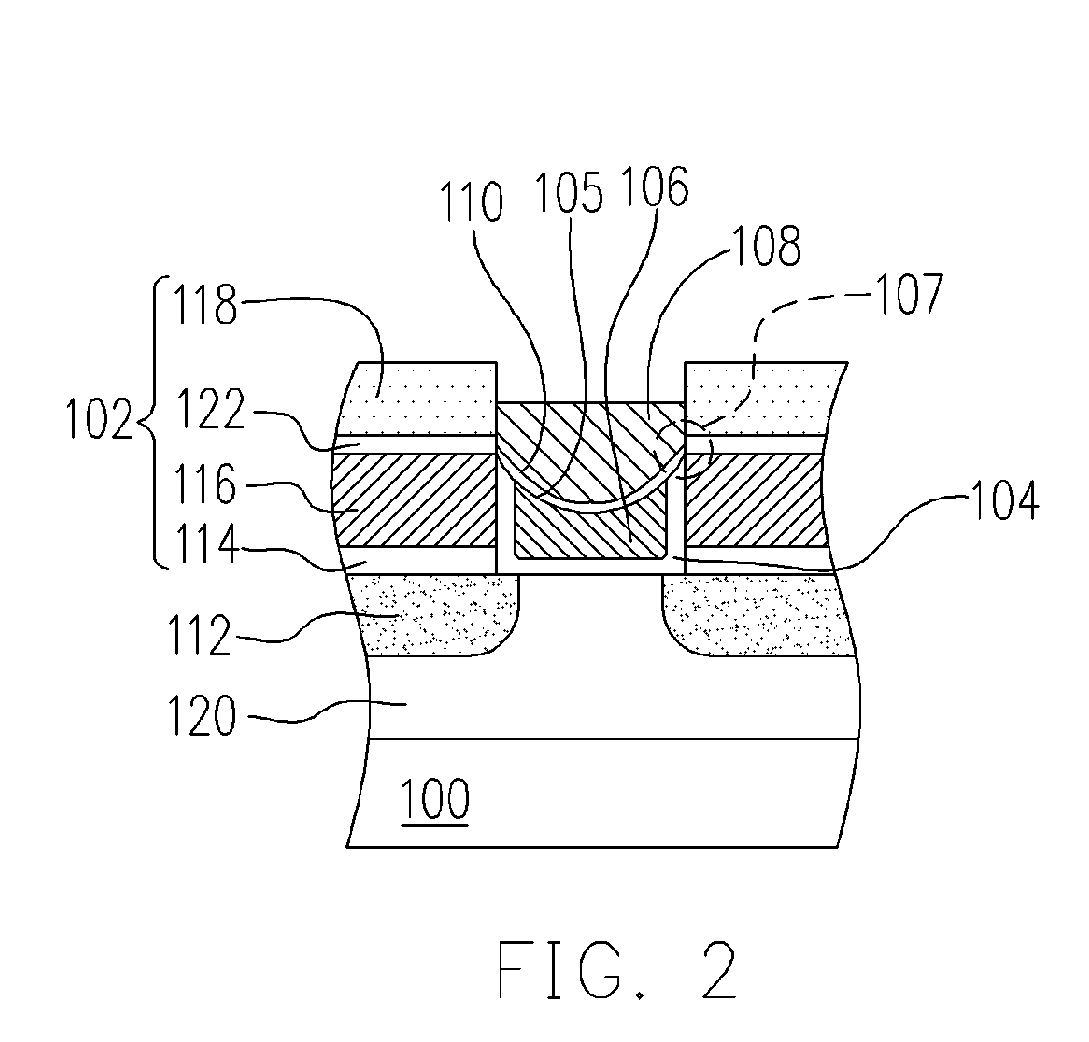

NAND flash memory cell row and manufacturing method thereof

ActiveUS20060040440A1Improve memory performanceIncrease erasing speedSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricEngineering

A NAND flash memory cell row includes first and second stacked gate structures, control and floating gates, inter-gate dielectric layer, a tunnel oxide layer, doping regions and source / drain regions. The first stacked gate structures has an erase gate dielectric layer, an erase gate and a first cap layer. Each of the second stacked gate structure has a select gate dielectric layer, a select gate and a second cap layer. The control gate is between each of the first stacked gate structures, and between each of the second stacked gate structures and the adjacent first stacked gate structure. The floating gate is between the control gate and substrate. The inter-gate dielectric layer is disposed between the control and floating gates. The tunnel oxide is between the floating gate and substrate. The doping regions are disposed under the first stacked gate structure, and the source / drain regions are in the exposed substrate.

Owner:POWERCHIP SEMICON MFG CORP

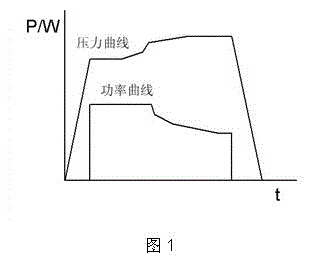

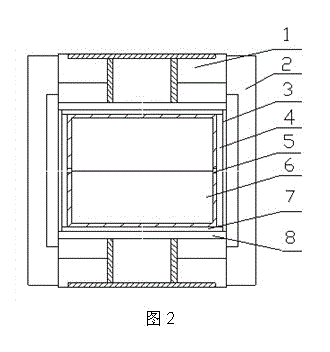

Synthetic process of high self-sharpening diamond

ActiveCN102941038AExtended service lifeInhibit sheddingUltra-high pressure processesCompression moldingPressure curve

The invention provides a synthetic process of a high self-sharpening diamond. The synthetic process includes that graphite powders and Mn based alloy catalyst powders are mixed according to a weight ratio of 6: (4-9) to obtain a mixture, the mixture is subjected to isostatic pressing and vacuum treatment, the mixture is subjected to compression molding in a four-column press machine, a core column is placed in a diamond synthetic block, the diamond synthetic block is placed in a 6-surface diamond press machine for synthesis, the actual synthesis pressure is in a range from 6.2-6.8 GPa, the synthesis temperature is in a range from 1210 DEG C to 1250 DEG C, and the actual synthesis pressure and the synthesis temperature are completed by a control pressure curve and a power curve respectively. According to the synthetic process of the high self-sharpening diamond, the synthesized high self-sharpening diamond accords with the national synthetic diamond inspection standard, the yield per unit reaches to above 100catars, the crystal forms are not regular, the needle flake shaped crystal forms account for above 75%, the impact toughness (TI) detection is in a range between 15% and 25%, the intensity is low, and the edge tip and the grinding are sharp.

Owner:山东昌润钻石股份有限公司

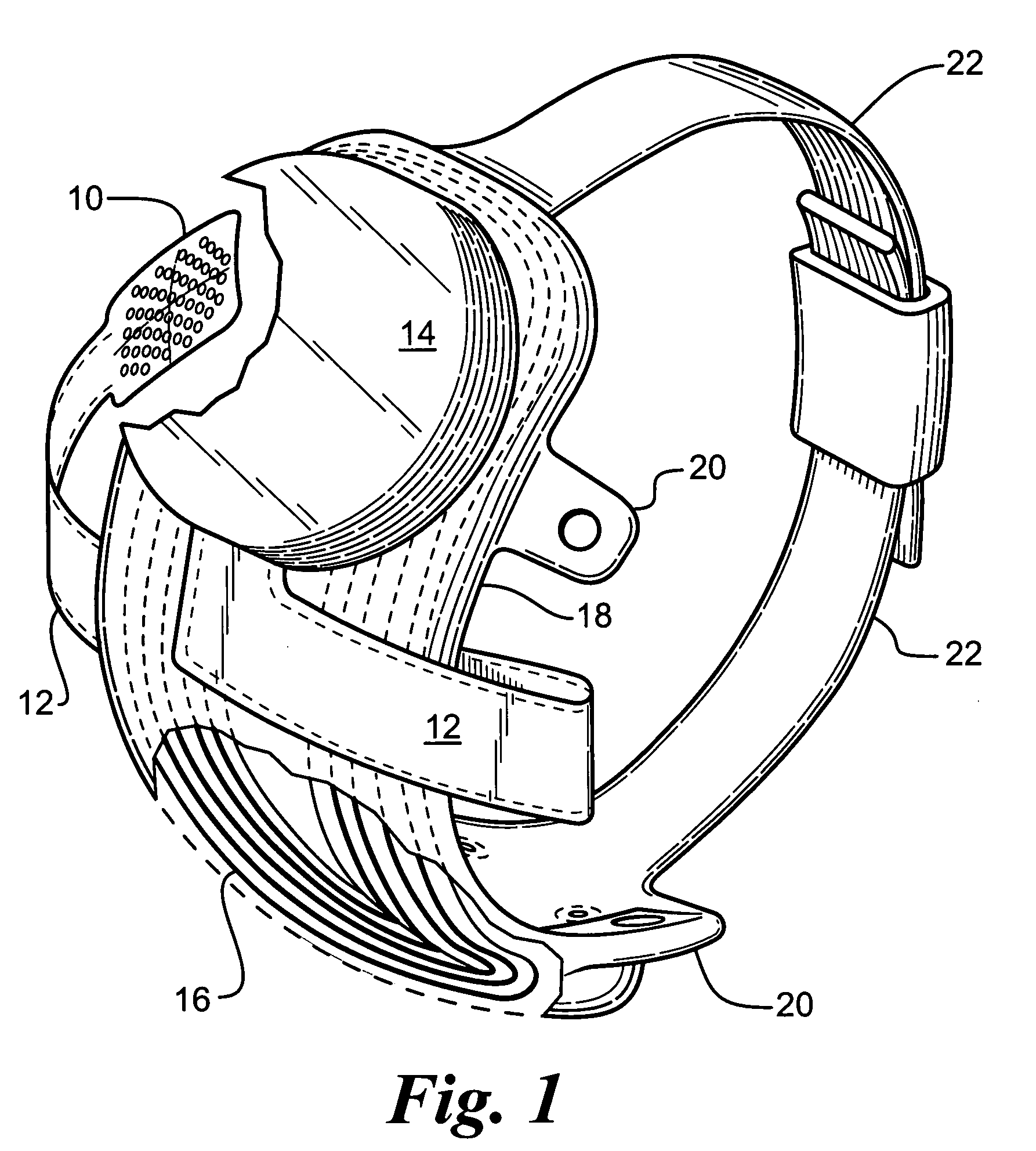

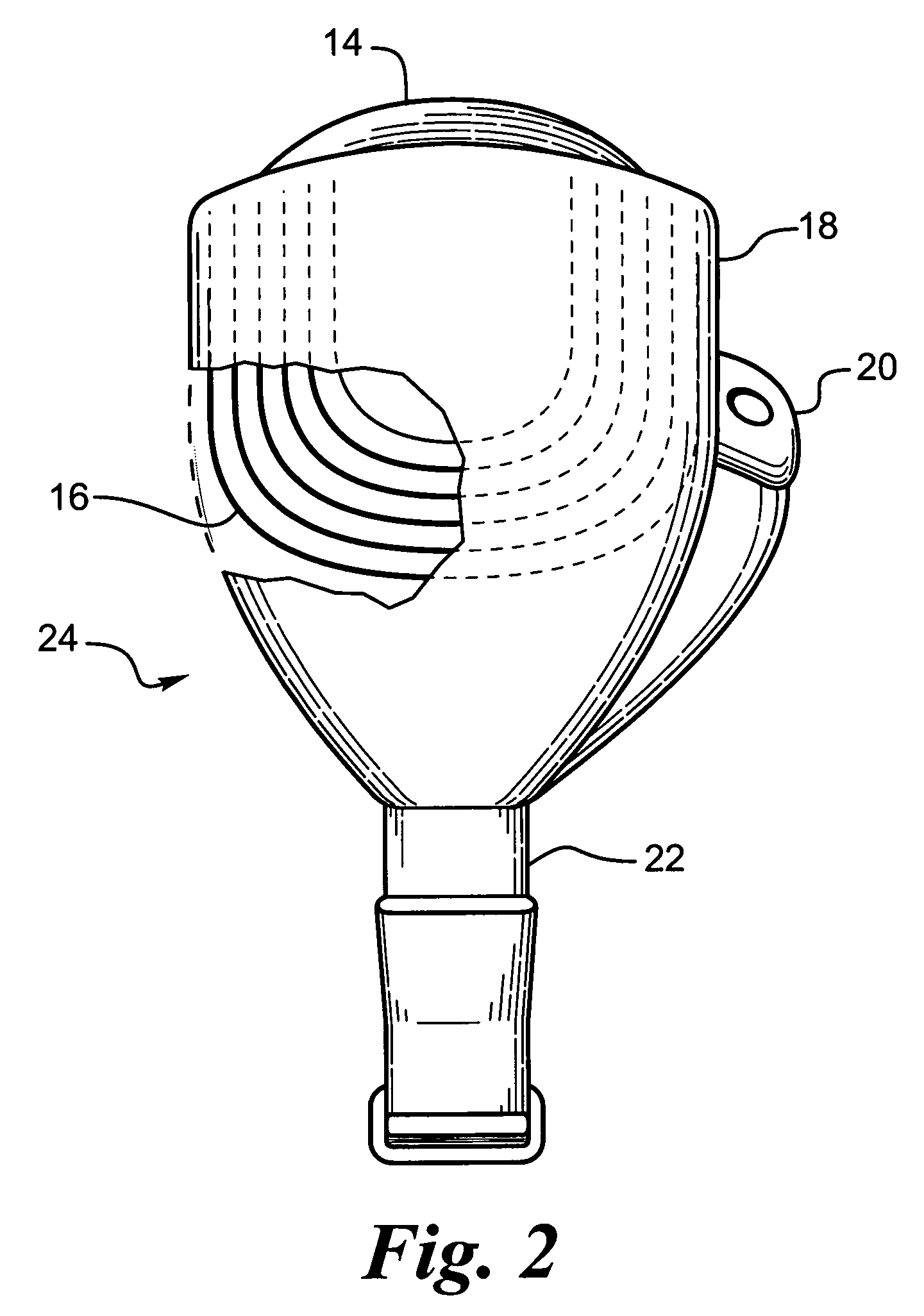

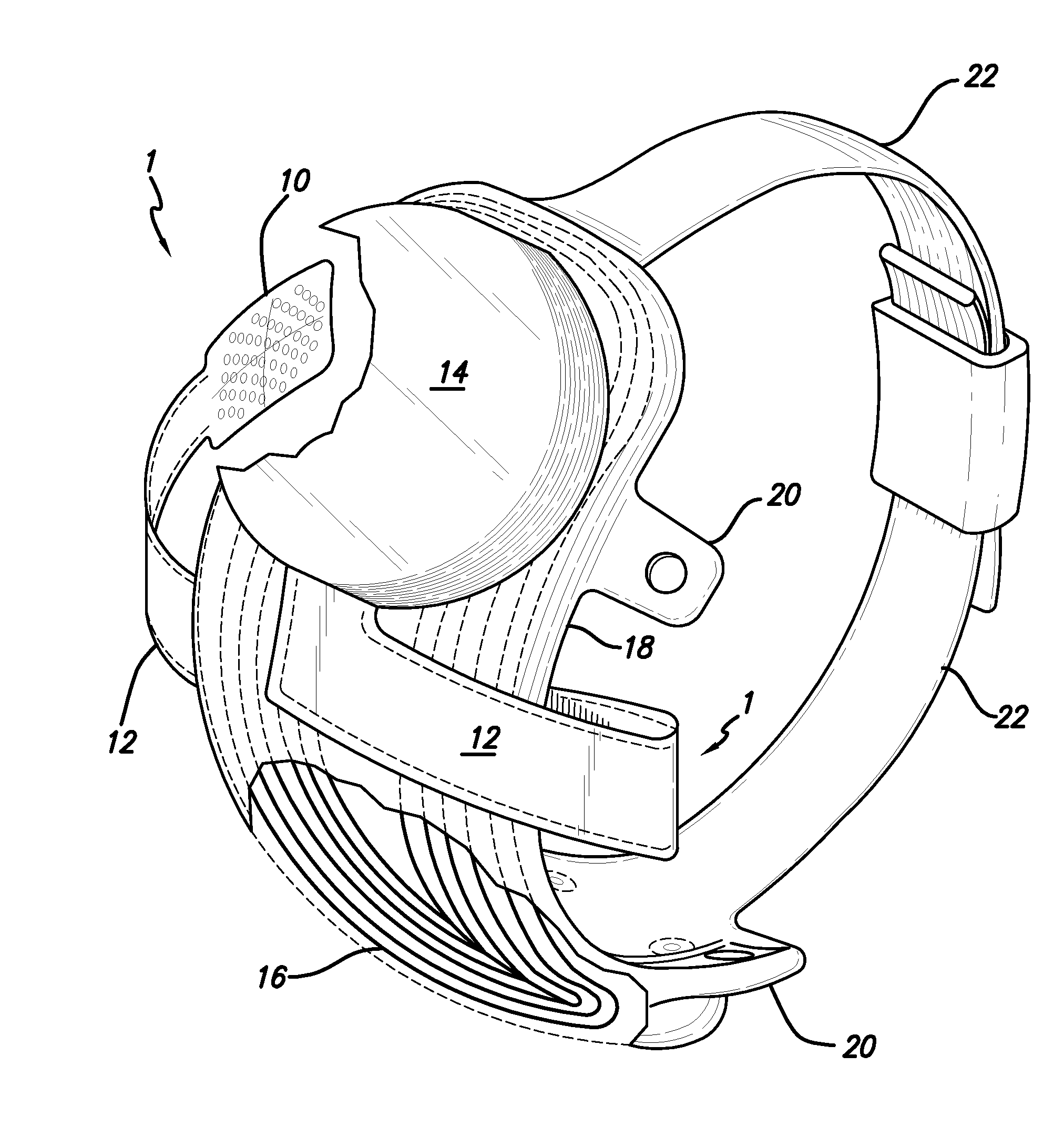

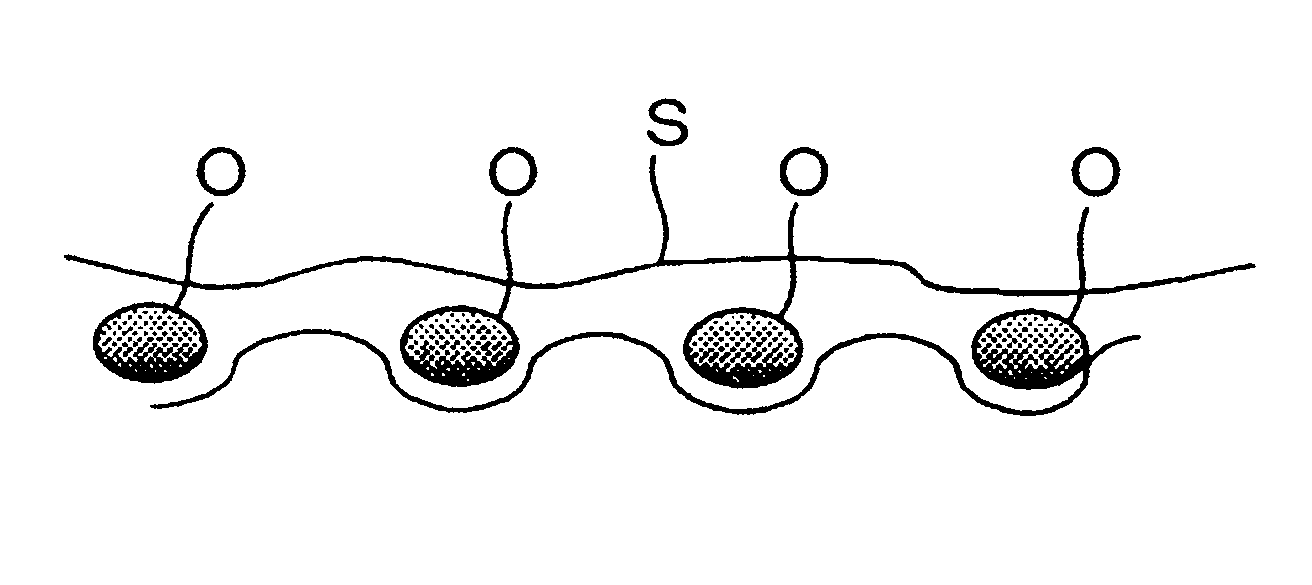

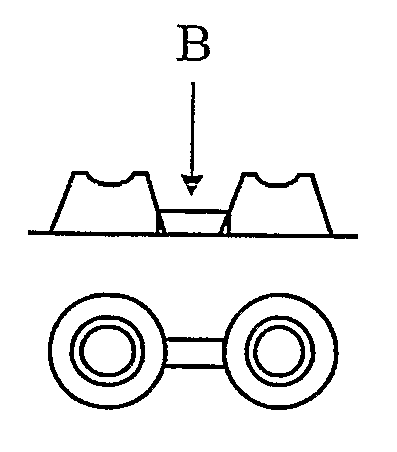

Motorcycle Grip Pad, System, Motorcycle and Riding Apparel therefor

InactiveUS20100007115A1Good thicknessStop scratchesGarment special featuresTrousersEngineeringPlastic film

A motorcycle grip pad comprises a base layer of elastomeric material having spaced bumps on a top surface. An adhesive layer is on a bottom surface. The area of the pad is between 1000 and 4000 mm2. A motorcycle grip system also includes a reaction patch of relatively rigid material having apertures spaced and arranged in the same way as the bumps on the pad. The patch is adapted for connection to a motorcycle rider's suit (74,88) or other apparel. A wear pad for a motor cycle comprises a base sheet in the form of a flexible plastics sheet; an adhesive layer on the underside side of the flexible sheet; a release layer under the adhesive layer and protecting it during handling and storage; a top layer of soft, flexible elastomeric resin, which is poured onto the top surface prior to curing so that it spreads over the pad to its edges; and bumps of elastomeric material arranged on said base sheet prior to pouring of the polyurethane entrapping said bumps on said sheet, said bumps protruding above the level of said top layer.

Owner:MOTO COMP

Cutting tool insert

InactiveUS7736734B2Prolong lifeSharp edgePigmenting treatmentVacuum evaporation coatingMetal machiningEngineering

The present invention relates to a cutting tool insert for metal machining comprising a substrate with a first coating and an outermost PVD-layer. The insert further comprises clearance faces and rake faces intersecting to form cutting edges having essentially no edge radius. The first coating has been removed so that the outermost PVD-layer is the only layer on the clearance face at least close to the cutting edge. The present invention also relates to a method of making such an insert. The inserts according to the present invention gives an increased tool life.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Femtosecond heterodyne optical Kerr gate and imaging device and method based on optical Kerr gate

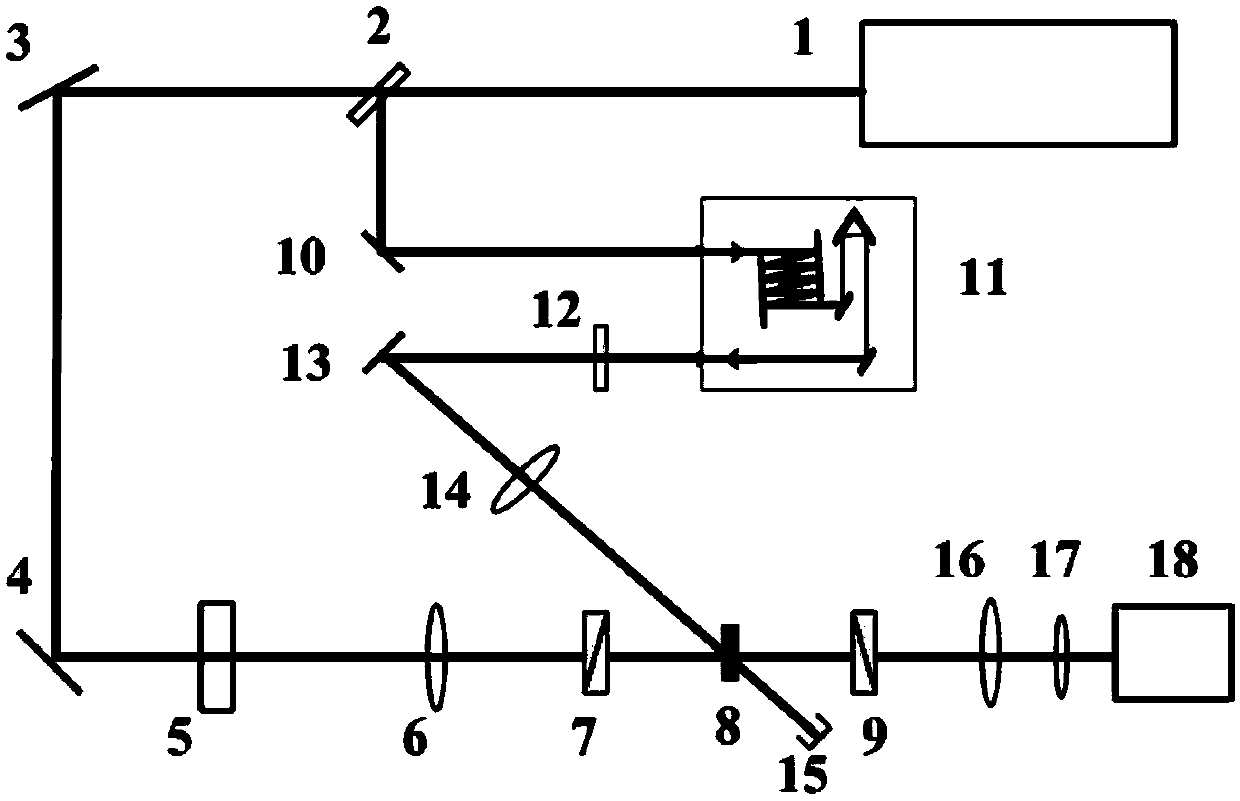

ActiveCN103728811ASharp edgeIncrease system resolutionHigh-speed photographyNon-linear opticsPolarizerOptical path

The invention provides a femtosecond heterodyne optical Kerr gate and an imaging device and method based on the optical Kerr gate. A target to be detected, the femtosecond heterodyne optical Kerr gate and a CCD are sequentially arranged on a detection light path of the imaging device, wherein the femtosecond heterodyne optical Kerr gate is composed of a polarizer, an optical Kerr medium and an analyzer, and the heterodyne angle between the polarization direction of the analyzer and the polarization perpendicular direction of a detection pulse ranges from 3 degrees to 5 degrees. An optical delay line and a half wave plate are sequentially arranged on a switch light path, and a switching pulse and the detection pulse coincide inside the Kerr medium. The imaging method includes the steps of dividing a femtosecond pulse into two paths, enabling the detection pulse to enter a sample to be detected and enter the femtosecond heterodyne optical Kerr gate after being reflected and transmitted, opening the femtosecond heterodyne optical Kerr gate through the switching pulse, instantly gating components carrying sample morphology information in the detection pulse, enabling the gated detection pulse to enter the CCD, and obtaining a morphology image of the sample to be detected, wherein the morphology image has ultrahigh time resolution. The femtosecond heterodyne optical Kerr gate and the imaging device and method have the advantages of being simple in light path and extremely short in gating time, enabling the imaging space resolution to be close to the system diffraction limit, and the like.

Owner:XI AN JIAOTONG UNIV

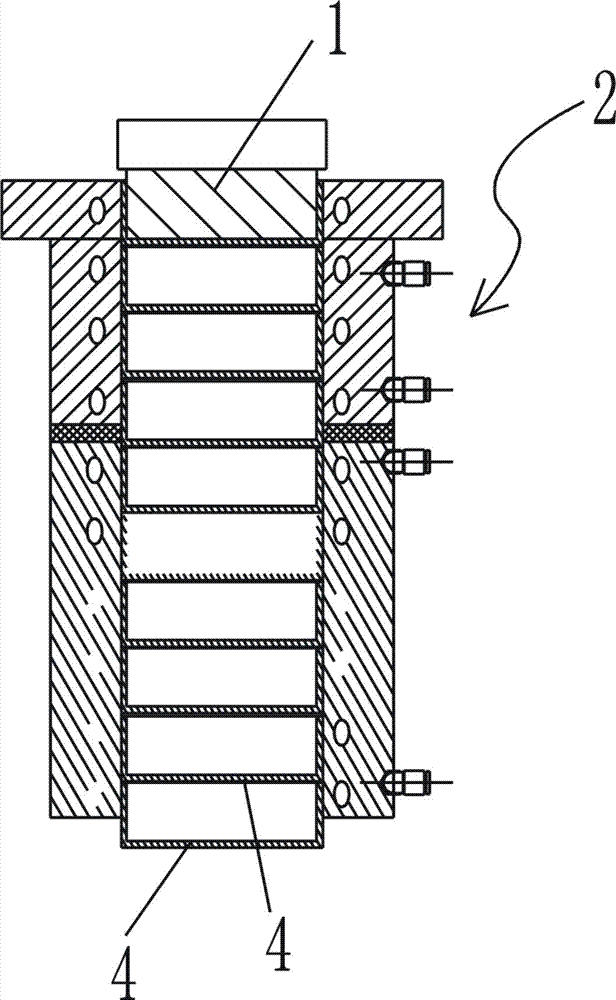

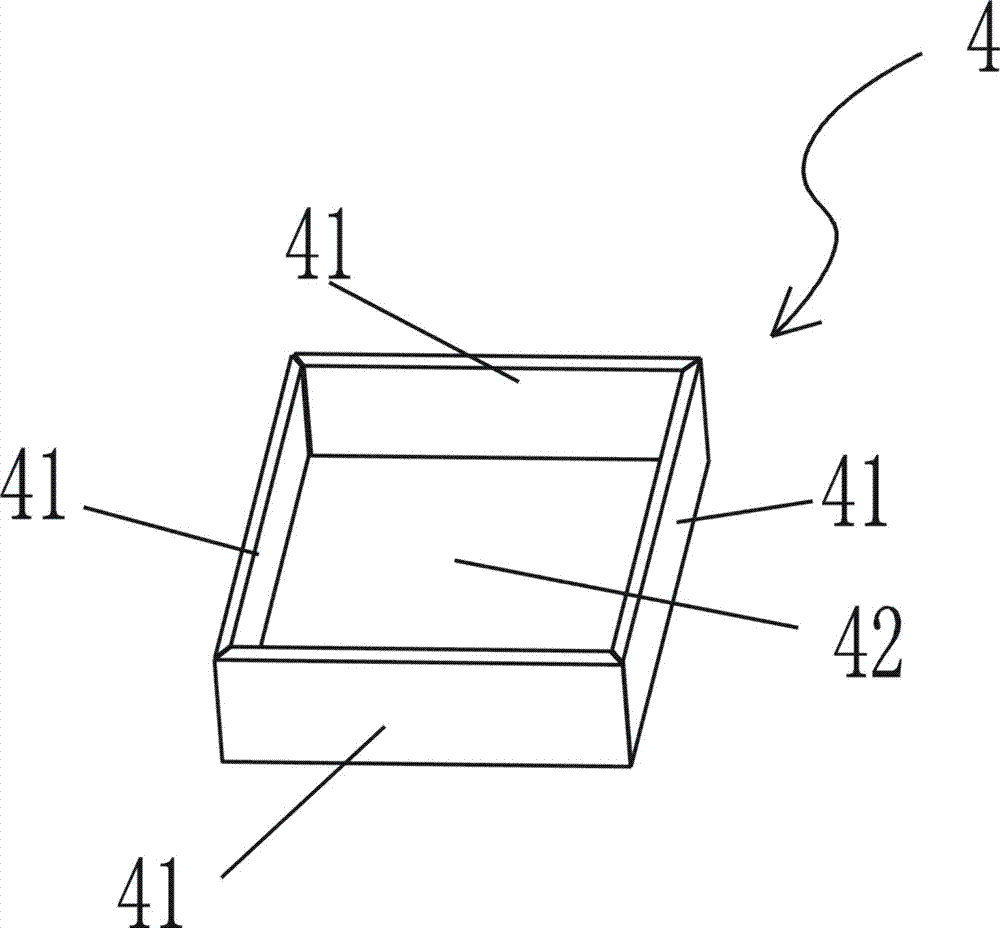

Punch forming device and punch forming process of square paper box component

ActiveCN103786368ASmooth edges and cornersAngularPaper-makingBox making operationsPaperboardForming processes

The invention relates to a punch forming device of a square paper box component. The punch forming device comprises an outer mold and an inner mold. The inner mold and the outer mold can relatively and vertically move, the inner mold is in a cuboid shape, and a cavity where the inner mold is downwards embedded is formed in the outer mold. The inner mold and the outer mold are both made of metal. The punch forming device is characterized in that the bottom of the cavity of the outer mold is hollowed; the cavity of the outer mold is divided into an upper section and a lower section; the portion, corresponding to the periphery of the upper section of the cavity of the outer mold, on a mold body is an upper section of the mold body of the outer mold, and the portion, corresponding to the periphery of the lower section of the cavity of the outer mold, on the mold body is a lower section of the mold body of the outer mold; the upper section of the mold body of the outer mold is provided with a heating component, and the lower section of the mold body of the outer mold is provided with a cooling flowing way; the depth of the upper section of the cavity of the outer mold is more than two times larger than the maximum embedding depth of the inner mold; the depth of the lower section of the cavity of the outer mold is also more than two times larger than the maximum embedding depth of the inner mold. The square paper box component manufactured by the punch forming device is square, clear and sharp in parison corner angle, each paper board top is smooth, upright and straight, and the production speed is high. The invention further provides a punch forming process of the square paper box component.

Owner:GUANGDONG MAGNOLIA PACKING MACHINERY

Pattern forming method and method of manufacturing ink jet recording head

InactiveUS20060127813A1Quality improvementSharp edgePhotoprinting processesPhotomechanical apparatusEngineeringVolumetric Mass Density

The present invention has as its object to provide a pattern forming method which, even if a pattern is formed by photolithography, can keep the edge of the opening portion of the pattern in a sharp state and yet, can make the wall surface of the recess of the pattern into a tapered shape, and a method of manufacturing an ink jet recording head to which the aforedescribed method is applied. The pattern forming method is a pattern forming method having the step of forming on a substrate a coat resin layer containing a photopolymerizable resin, the step of applying a solution containing a photopolymerization starting agent onto the coat resin layer, and forming the distribution of the density of the photopolymerization starting agent in the direction of film thickness of the coat resin layer, and the step of applying light from above the coat resin layer through a mask having a pattern depicted thereon, and the step of developing the coat resin layer to which the light has been applied to thereby make it into a coat resin layer having the pattern, and this method is applied to the manufacture of an ink jet recording head.

Owner:CANON KK

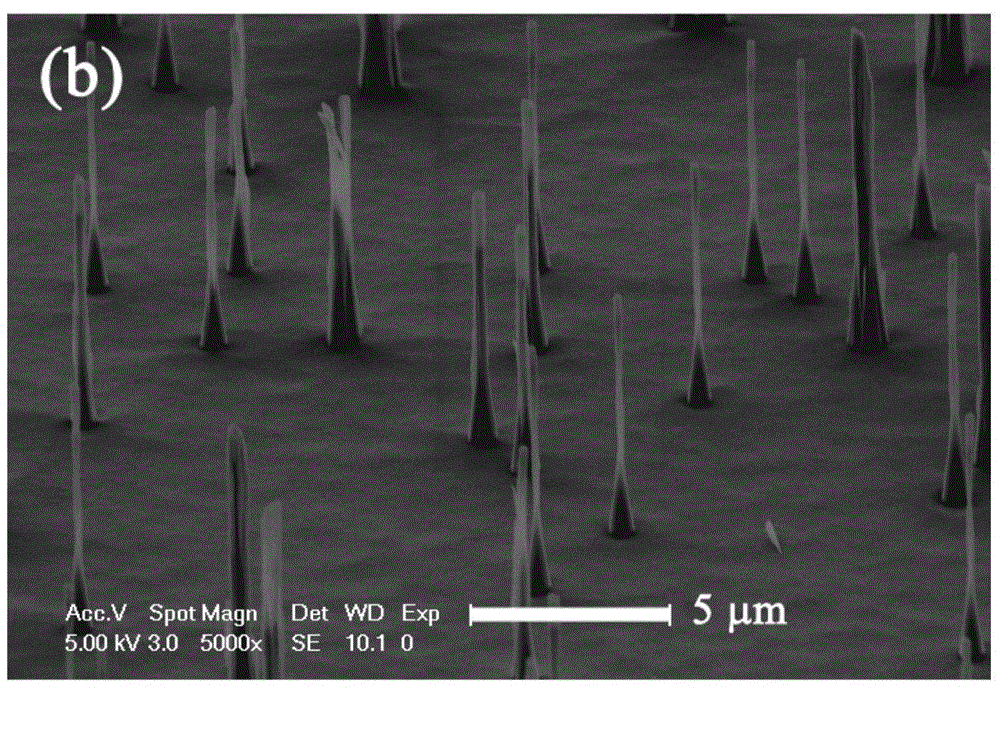

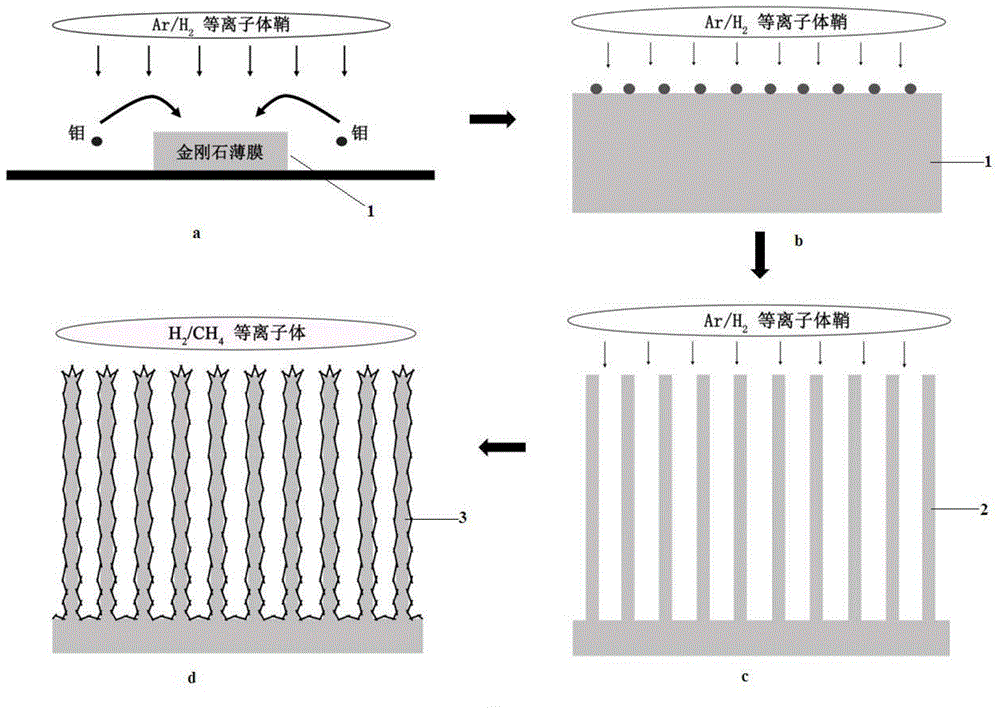

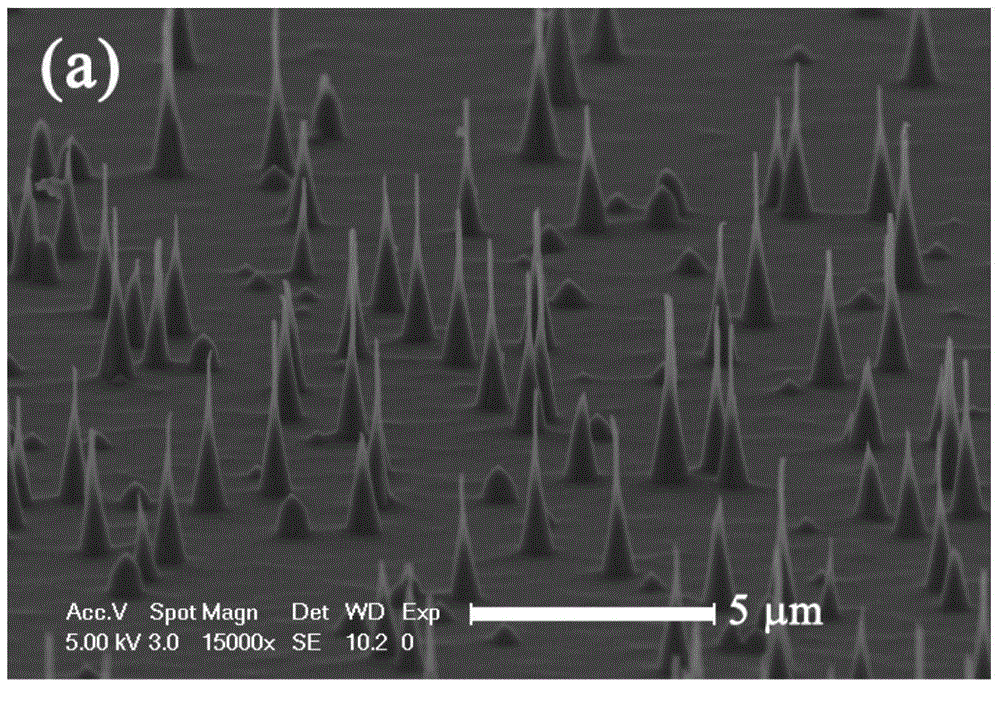

Diamond nano needle array composite material and preparation method and application thereof

ActiveCN104553124AImprove thermal conductivityImprove stabilityMaterial nanotechnologyLaminationHeat conductingGraphene

The invention provides a diamond nano needle array composite material and a preparation method and an application thereof. The diamond nano needle array composite material provided by the invention comprises a substrate layer and a diamond nano needle array which is formed on the surface of the substrate layer, wherein a three-dimensional graphene layer grows on the surface of a diamond nano needle in the diamond nano needle array. The preparation method of the diamond nano needle array composite material, disclosed by the invention, comprises the following steps: depositing a diamond film layer on the surface of a base body; etching the diamond film layer into a diamond nano needle array; and enabling the three-dimensional graphene layer to grow on the surface of the diamond nano needle array. The diamond nano needle array composite material disclosed by the invention is excellent in heat-conducting property, high in property field emission property and stability, simple in preparation process, and good in condition controllability, and can be applied to gas sensors, biosensors and electrochemical fields.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com