Patents

Literature

42results about How to "Improves pressure uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

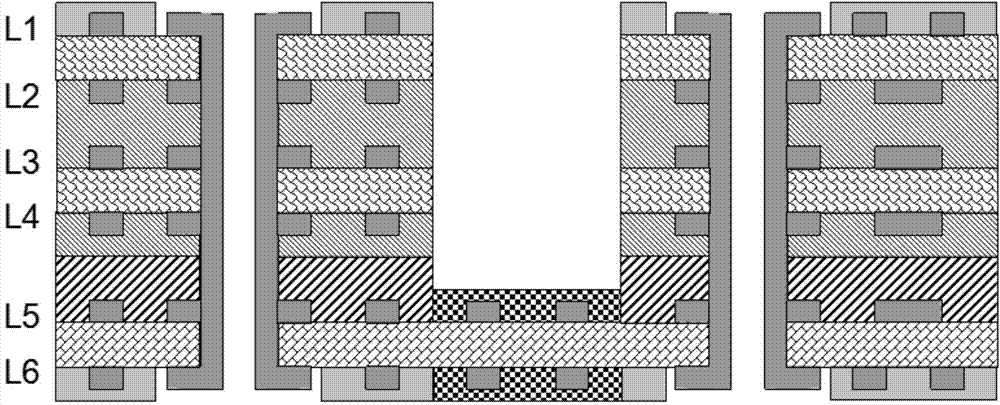

Semi-flexible circuit board and preparation method thereof

ActiveCN104519682AGuaranteed interlayer bondingReduce the degree of glue overflowPrinted circuits structural associationsMultilayer circuit manufactureFlexible circuitsEngineering

The invention belongs to the technical field of printed circuit boards and discloses a semi-flexible circuit board and a preparation method thereof. The preparation method includes manufacturing of a rigid auxiliary board, manufacturing of a semi-flexible core board, laminating of a main board, manufacturing of an outer layer of the main board and a windowing procedure. Manufacturing of the rigid auxiliary board includes: (1) manufacturing an inner-layer circuit of a rigid core board; (2) adopting a flowing type prepreg for laminating the rigid core board to make the rigid auxiliary board, and pressing the prepreg and temporary copper foils onto a surface, adjacent to the semi-flexible core board, of the inner-layer circuit; (3) removing the temporary copper foils by etching; (4) milling grooves. In the procedure of laminating of the main board, the rigid auxiliary board and the semi-flexible core board are laminated by the aid of a non-flow type prepreg. Therefore, a dielectric layer between the rigid auxiliary board and the semi-flexible core board is made by means of twice lamination, interlayer binding force between the rigid auxiliary board and the semi-flexible core board is guaranteed while glue overflowing in a semi-flexible area is reduced, and the problem of proneness to glue overflowing in the prior art is solved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

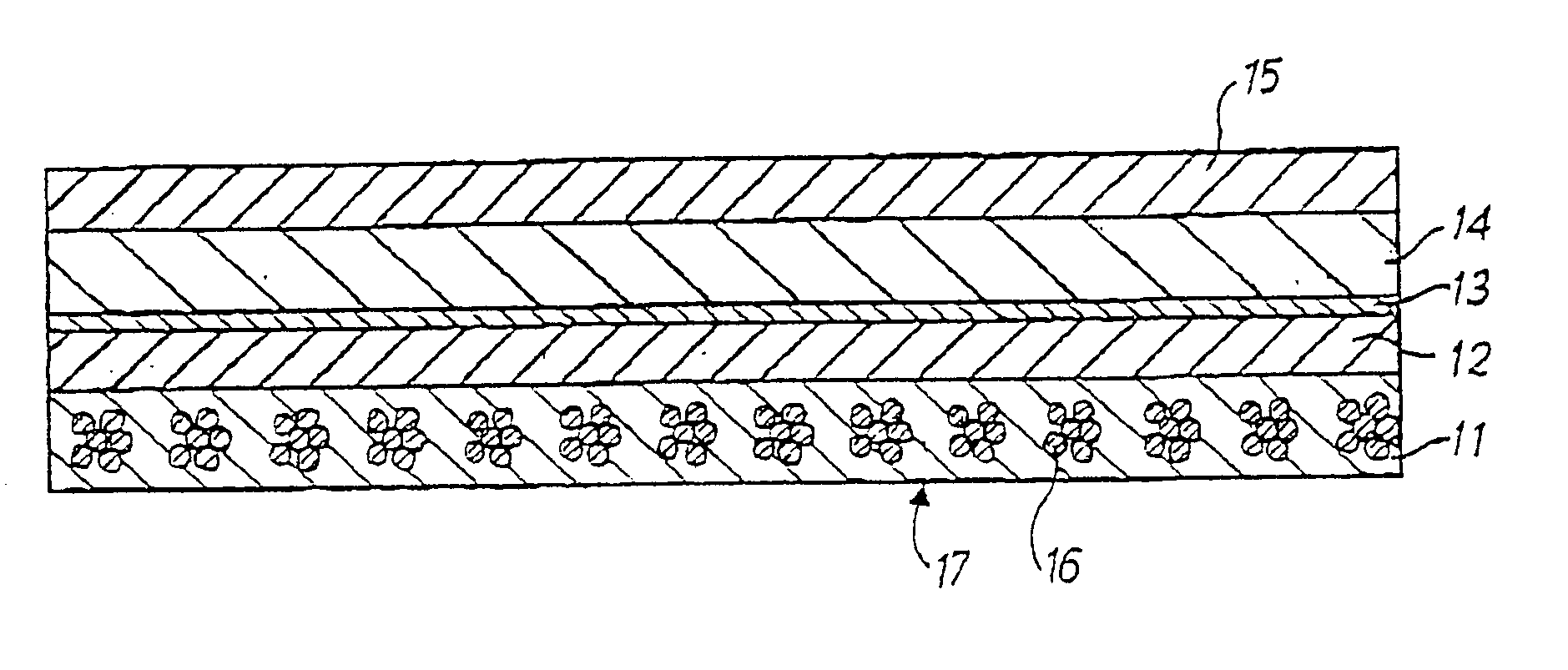

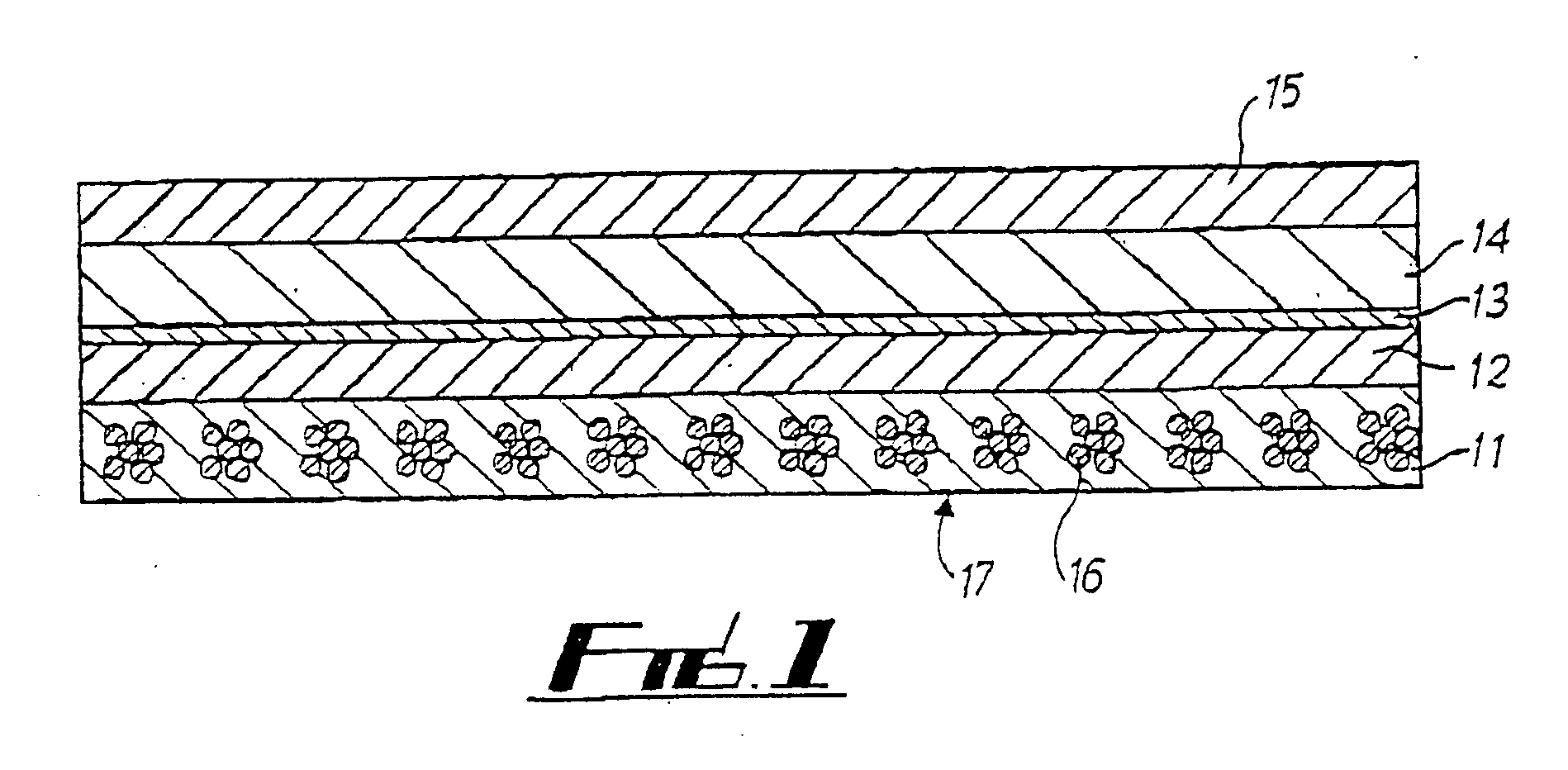

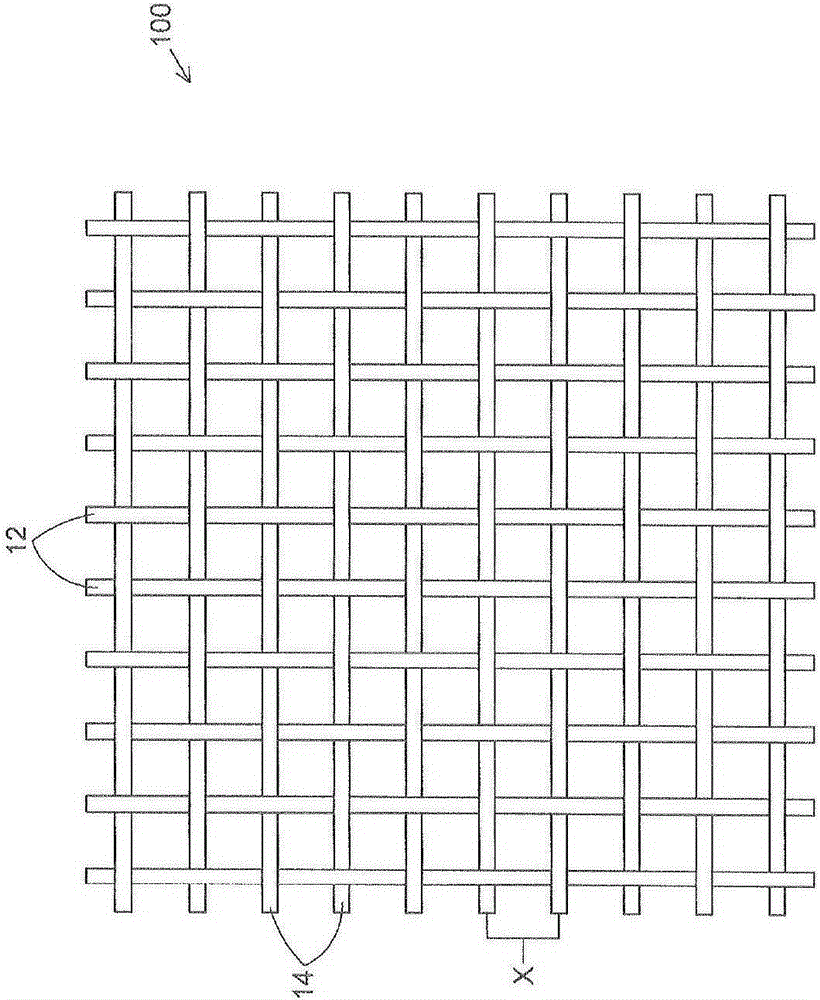

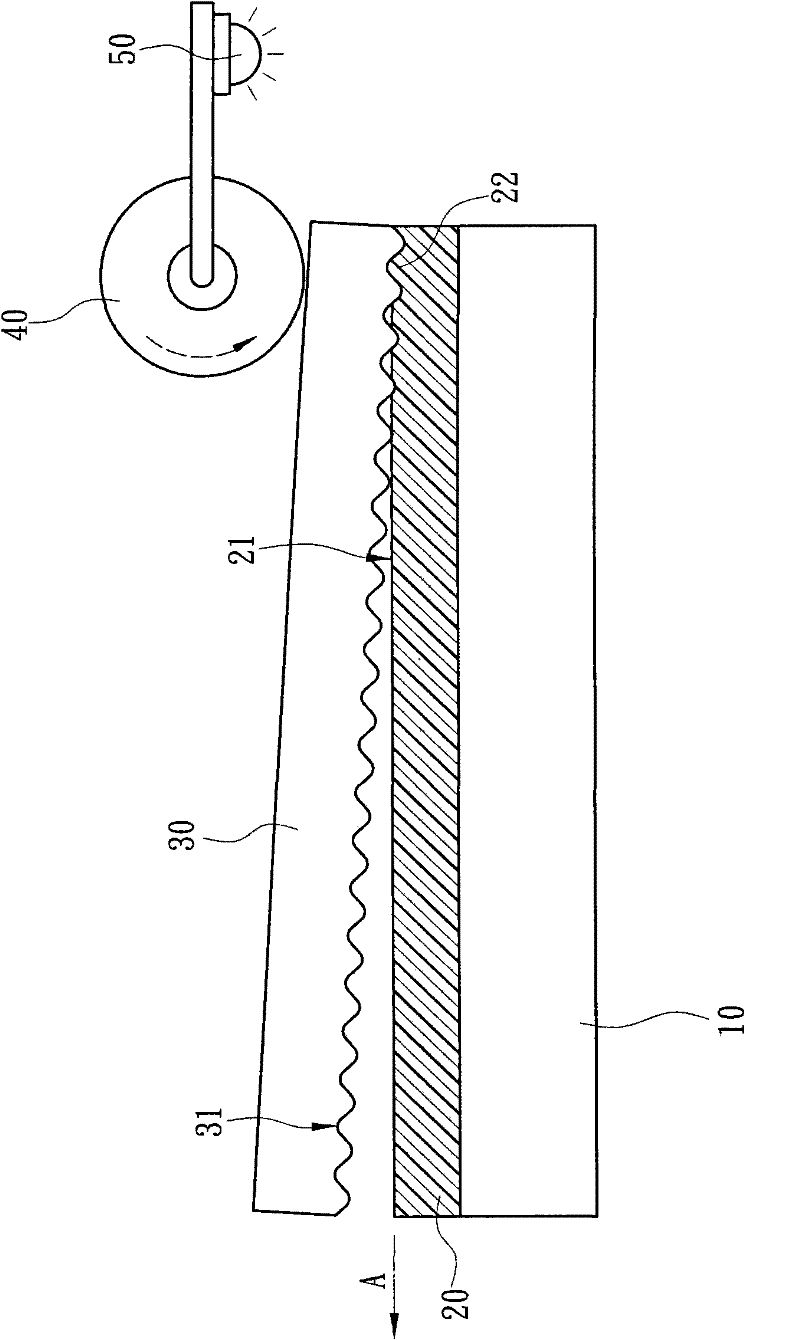

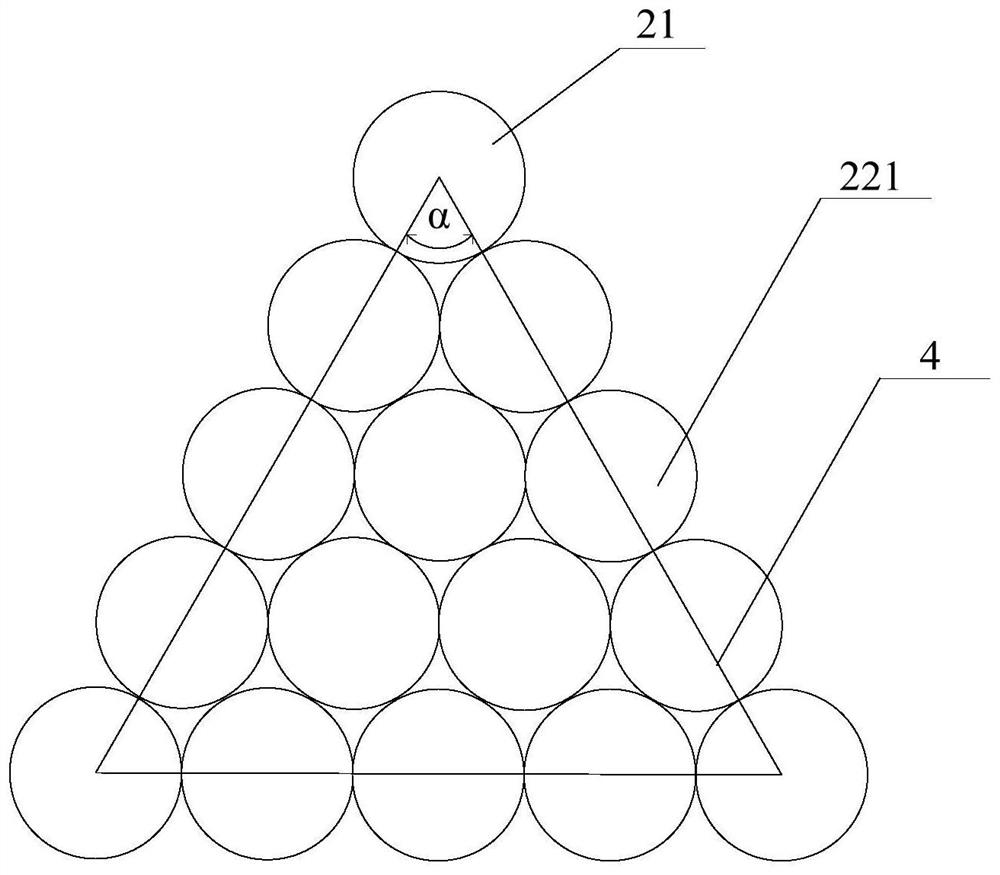

Paper machine belt

InactiveUS20050081570A1Eliminating edge curlImproves pressure uniformityMachine wet endCircular knitting machinesYarnEngineering

A paper machine belt that includes a cross-machine direction supporting layer providing strength in the cross-machine direction and at least two additional layers. The two additional layers include polymeric material and at least one of the additional layers that includes the polymeric material is positioned on one side of the cross-machine direction supporting layer and at least another of the additional layers that includes the polymeric material is positioned on an opposite side of the cross-machine direction supporting layer. The cross-machine direction supporting layer substantially includes cross-machine direction yarns loosely bound together with very fine machine-direction yarns. A ratio of mass of the cross-machine direction yarns to the machine direction yarns being at least 160:1, and mass of the polymeric material of the additional layer on the one side of the cross-machine direction supporting layer is substantially the same as a mass of the polymeric material of the additional layer that is provided on the opposite side of the cross-machine direction supporting layer.

Owner:VOTH FABRICS PATENT GMBH

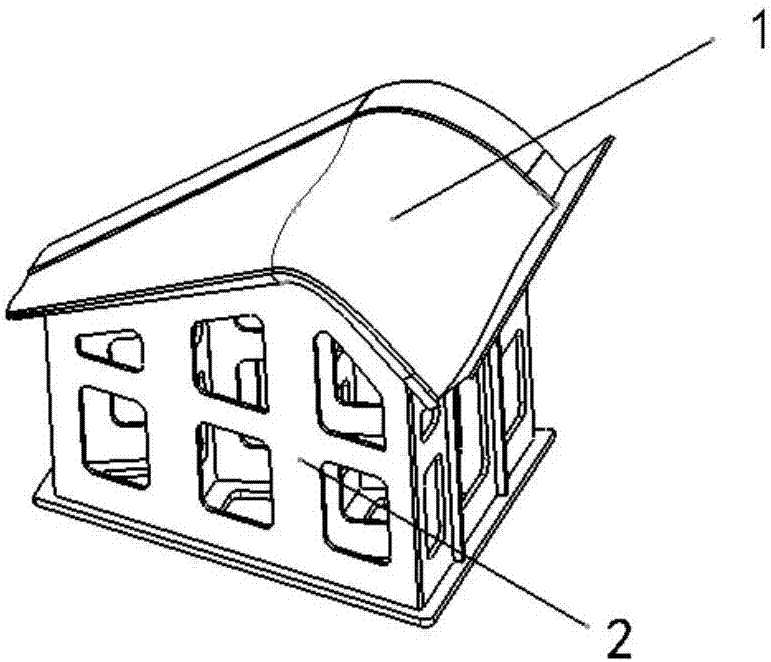

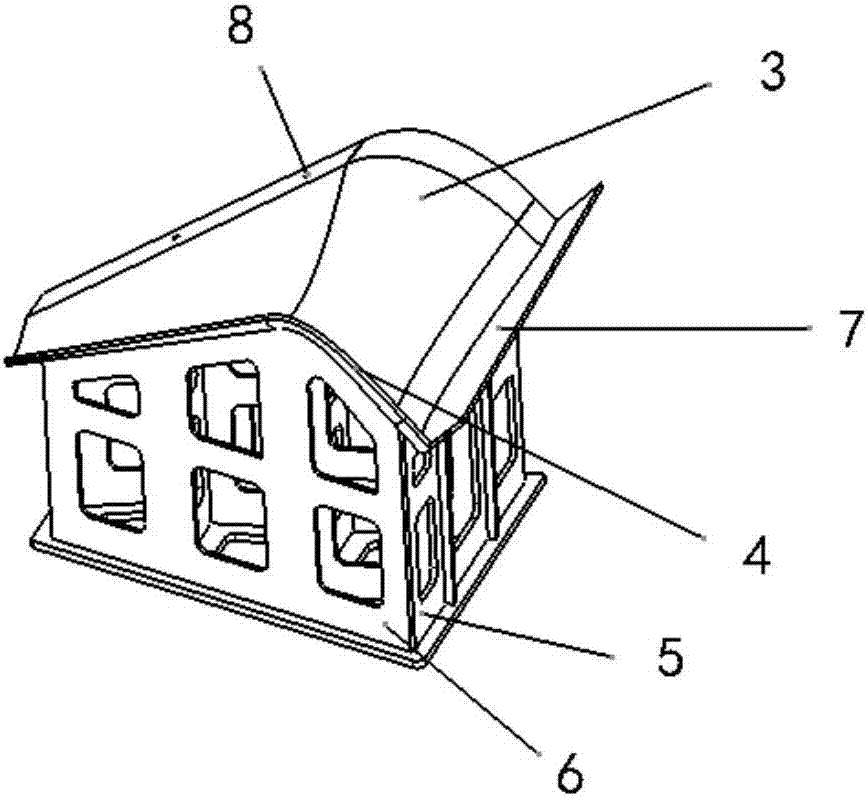

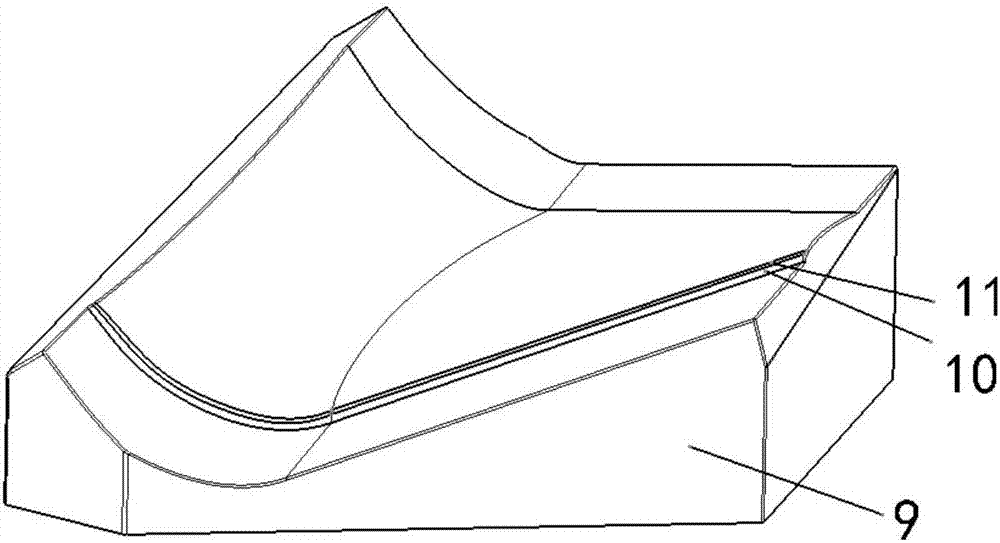

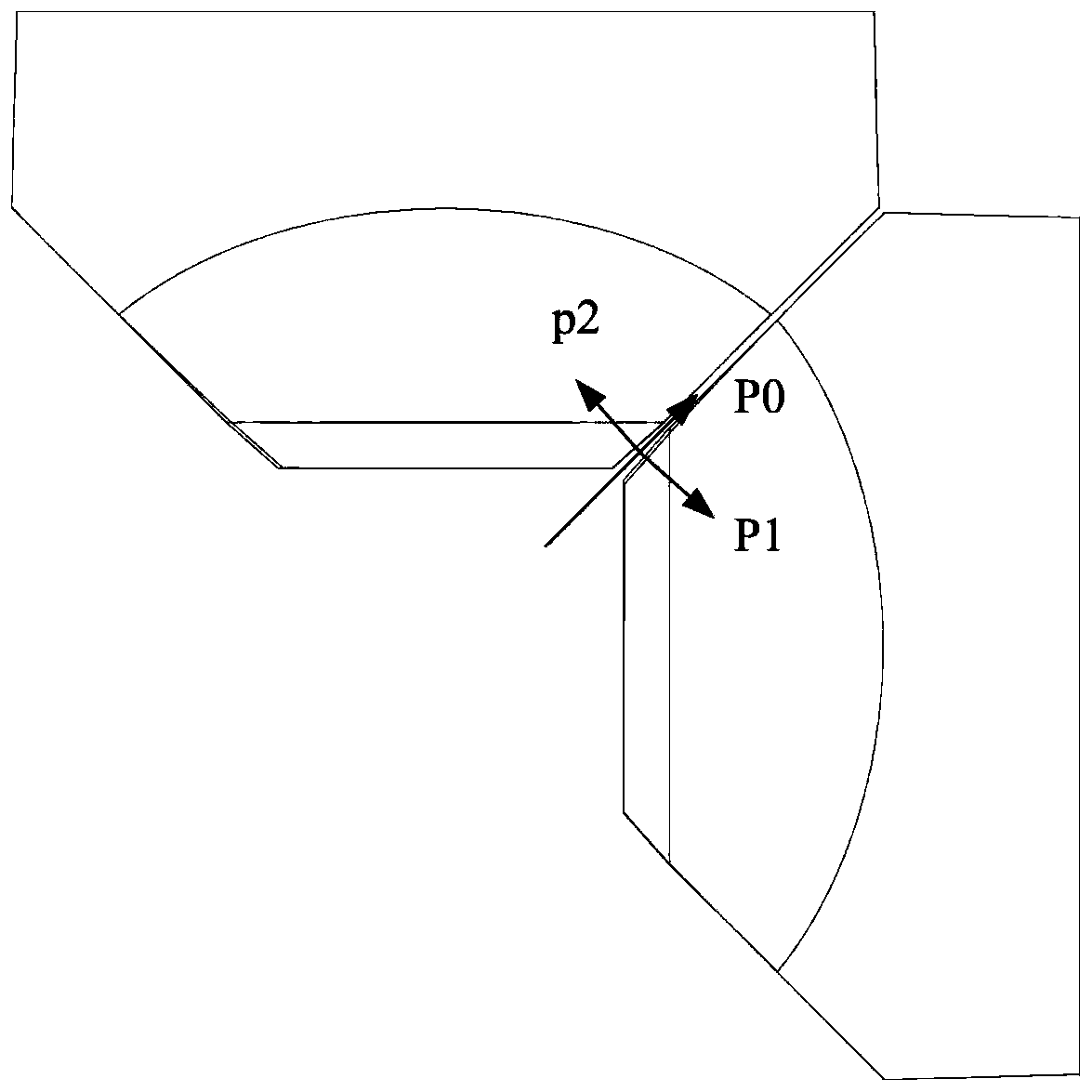

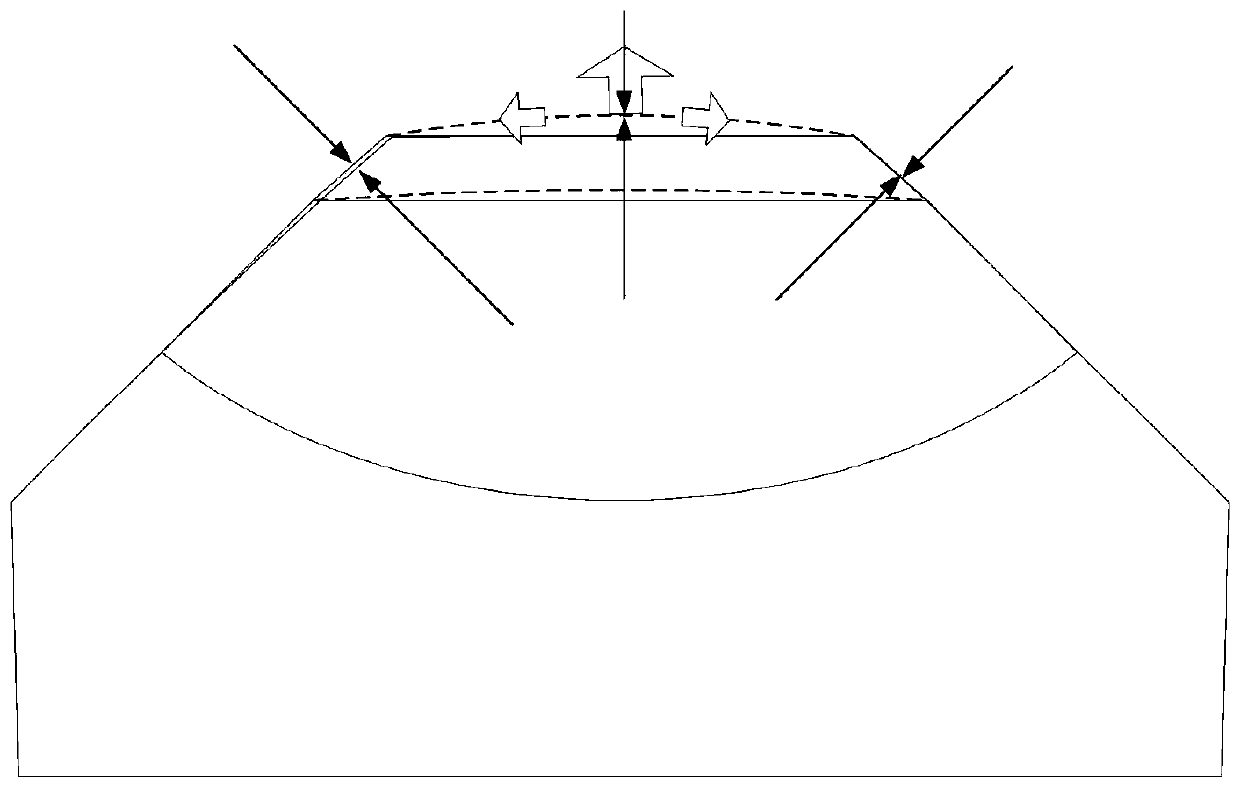

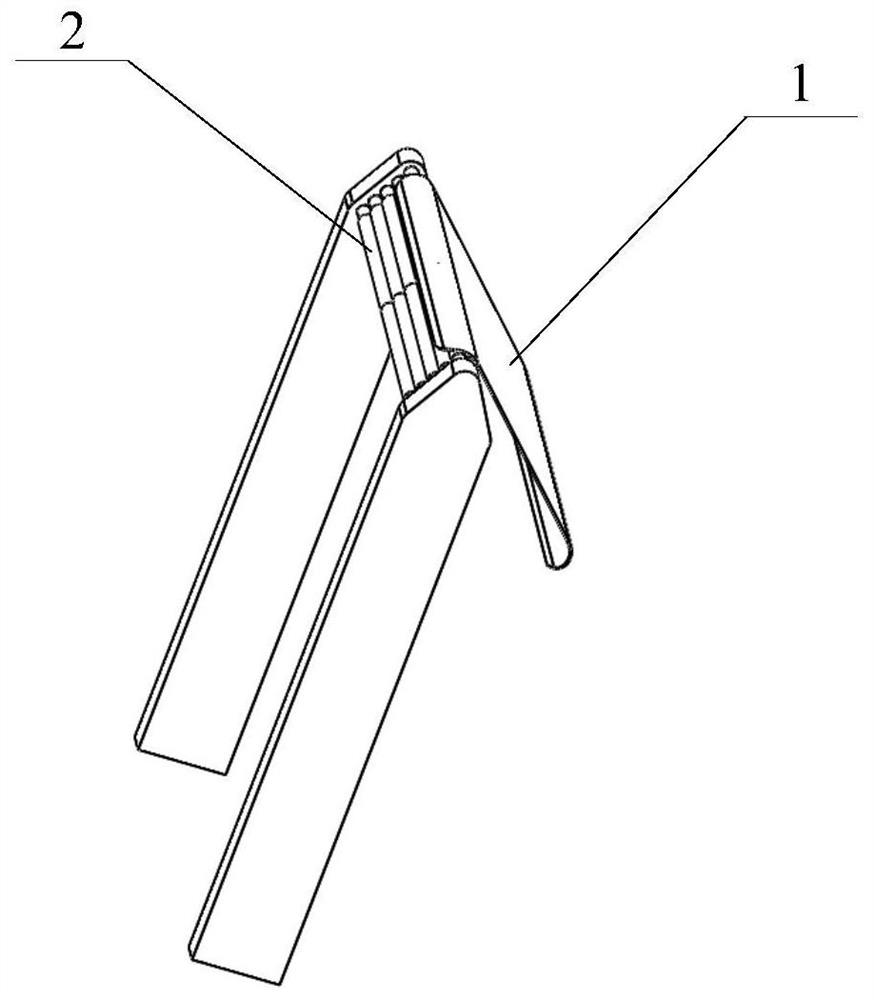

Forming tool for winglet of foam sandwich composite structure

The invention belongs to the technical field of composite aviation manufacturing and relates to a forming tool for a winglet of a foam sandwich composite structure. The forming tool is composed of an upper forming mold and a lower forming mold. The upper forming mold is a composite mold and is used for ensuring the outline dimension and the surface quality of the upper molded surface of the winglet in the winglet forming process. The lower forming mold is a composite frame mold and is used for supporting and fixing a whole part and ensuring the outline dimension and the surface quality of the lower molded surface of the winglet in the winglet forming process. The molded surface of the lower forming mold is a variable-thickness composite molded surface. The butt joint area of the front edge of the lower forming mold and the upper forming mold is provided with a thinning area to ensure the uniformity of a pressure field in the large-curvature area of the front edge of the winglet. The forming tool for the winglet of the foam sandwich composite structure is easy to operate, demolding is easy, the problem that large-curvature complex structure parts similar to the winglet are unevenly pressurized is solved, and the internal quality and the surface quality of the parts are well ensured.

Owner:AVIC COMPOSITES

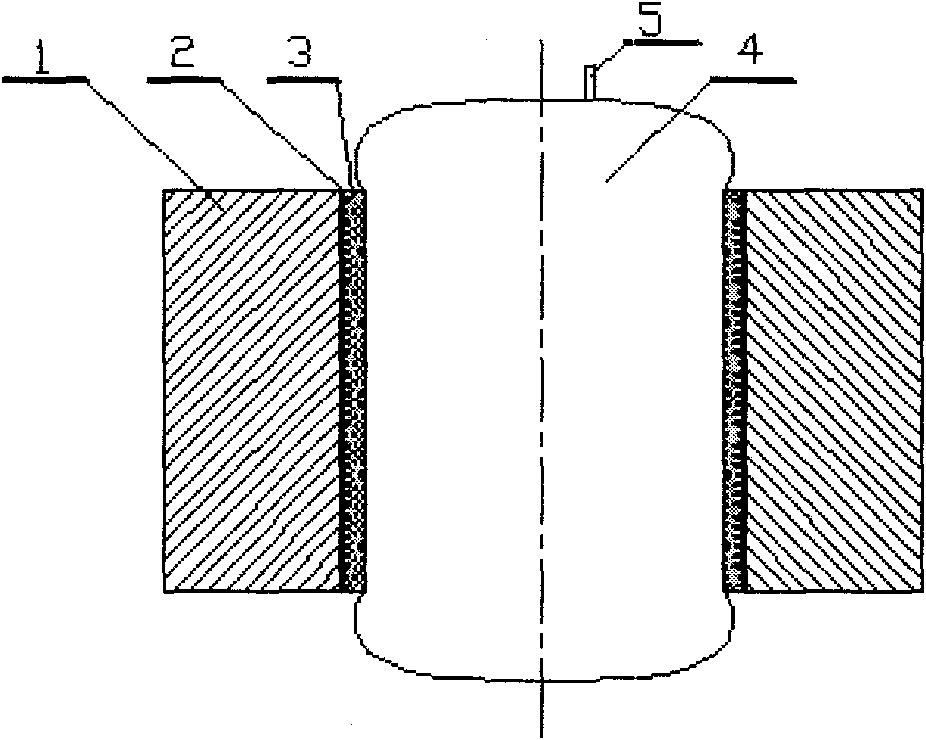

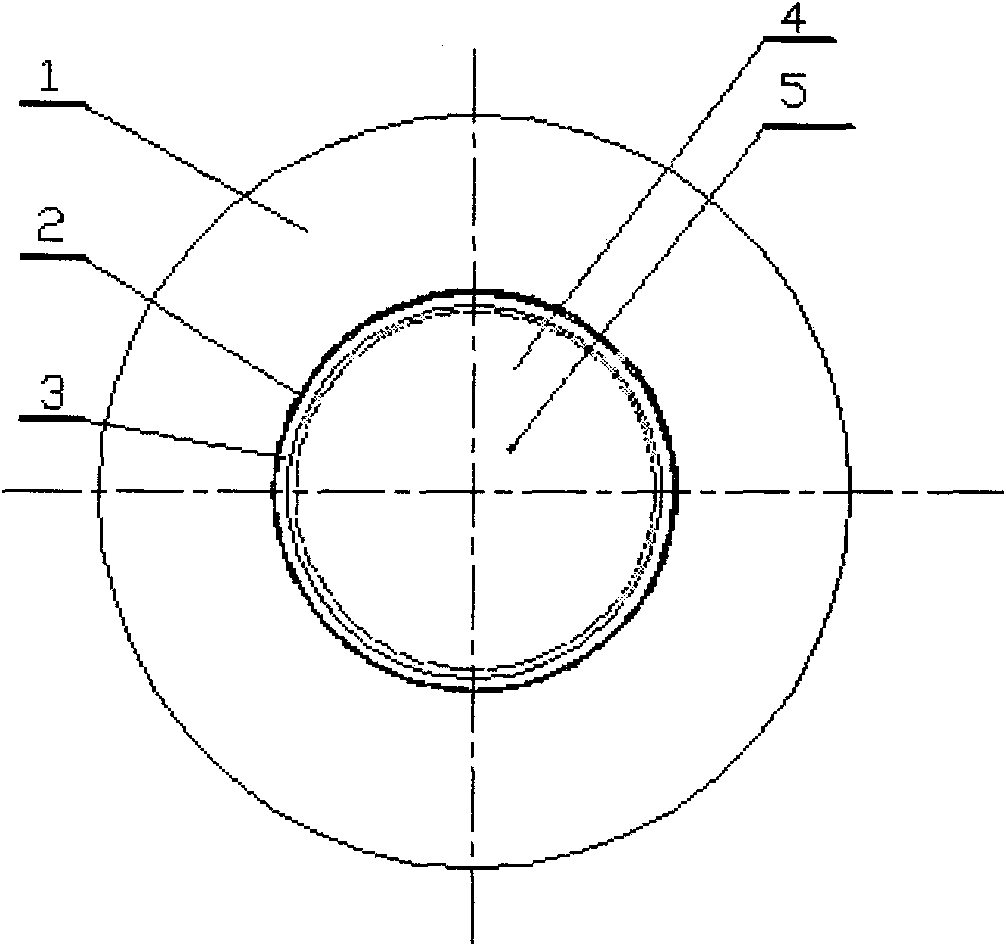

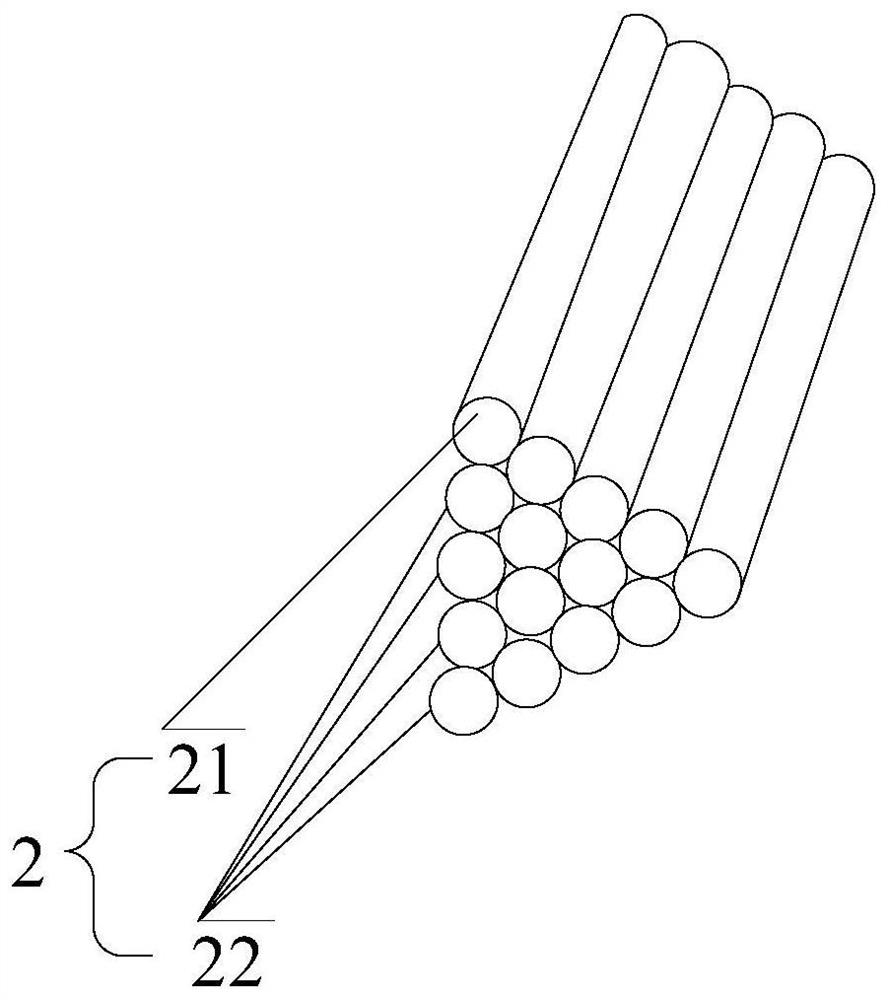

Air bag expansion pressurization method for adhering plastic radial tile faces

The invention discloses a machining method by air bag pressurization when plastic tile faces are adhered to adhered plastic radial tiles. When a metal tile substrate is adhered to and composited with a pure polytetrafluoroethylene plate or a modified polytetrafluoroethylene board by an adhesive, an air bag is put in the center of a cylindrical bore of the tile and is inflated to make the air bag expand for pressurization. The method has the advantages of uniform pressurization stress, low cost, simpleness and feasibility, and conveniently solves the problem of pressurization when large- and overlarge-diameter tile faces are adhered.

Owner:上海迈可尔轴瓦有限公司

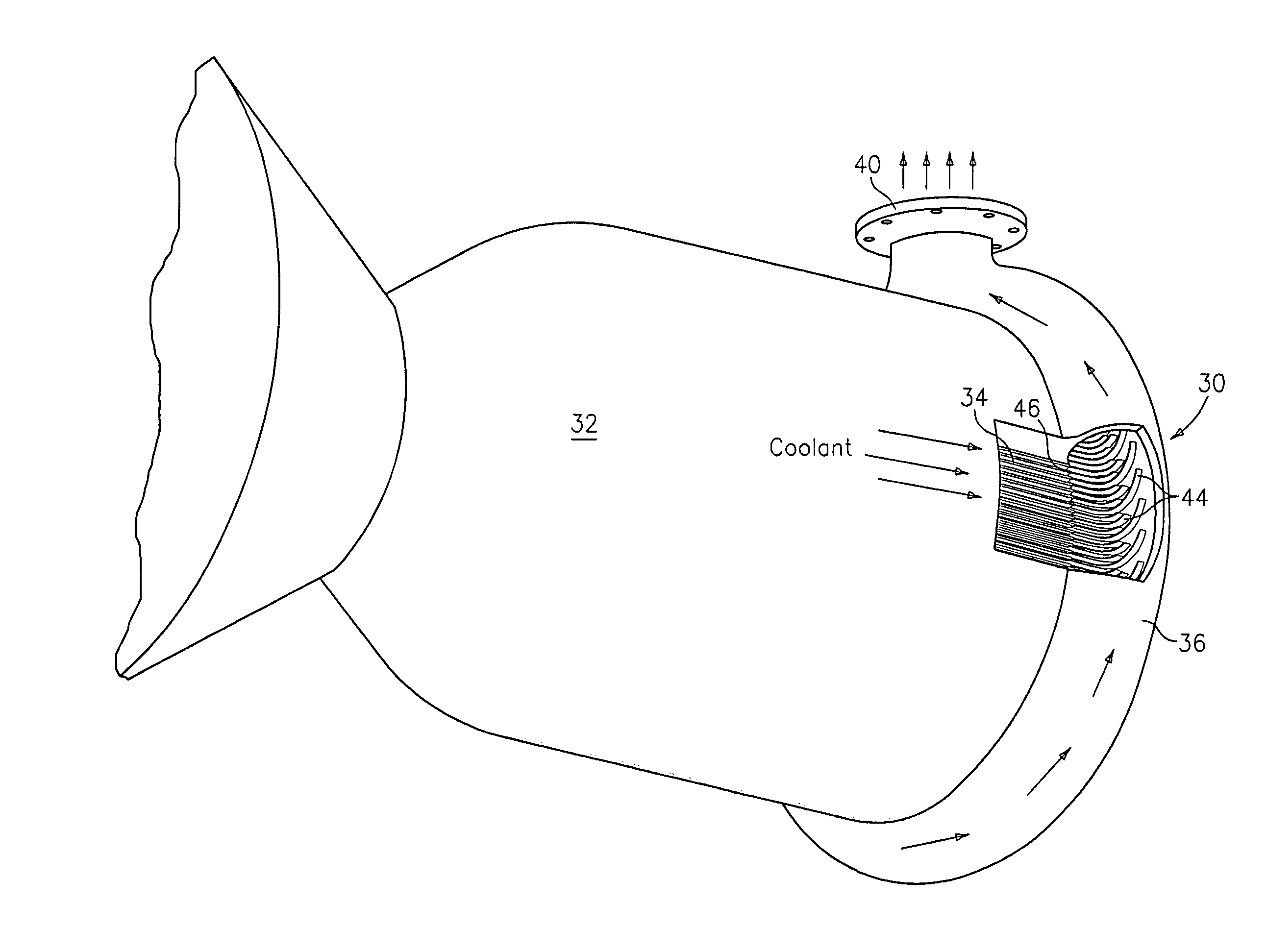

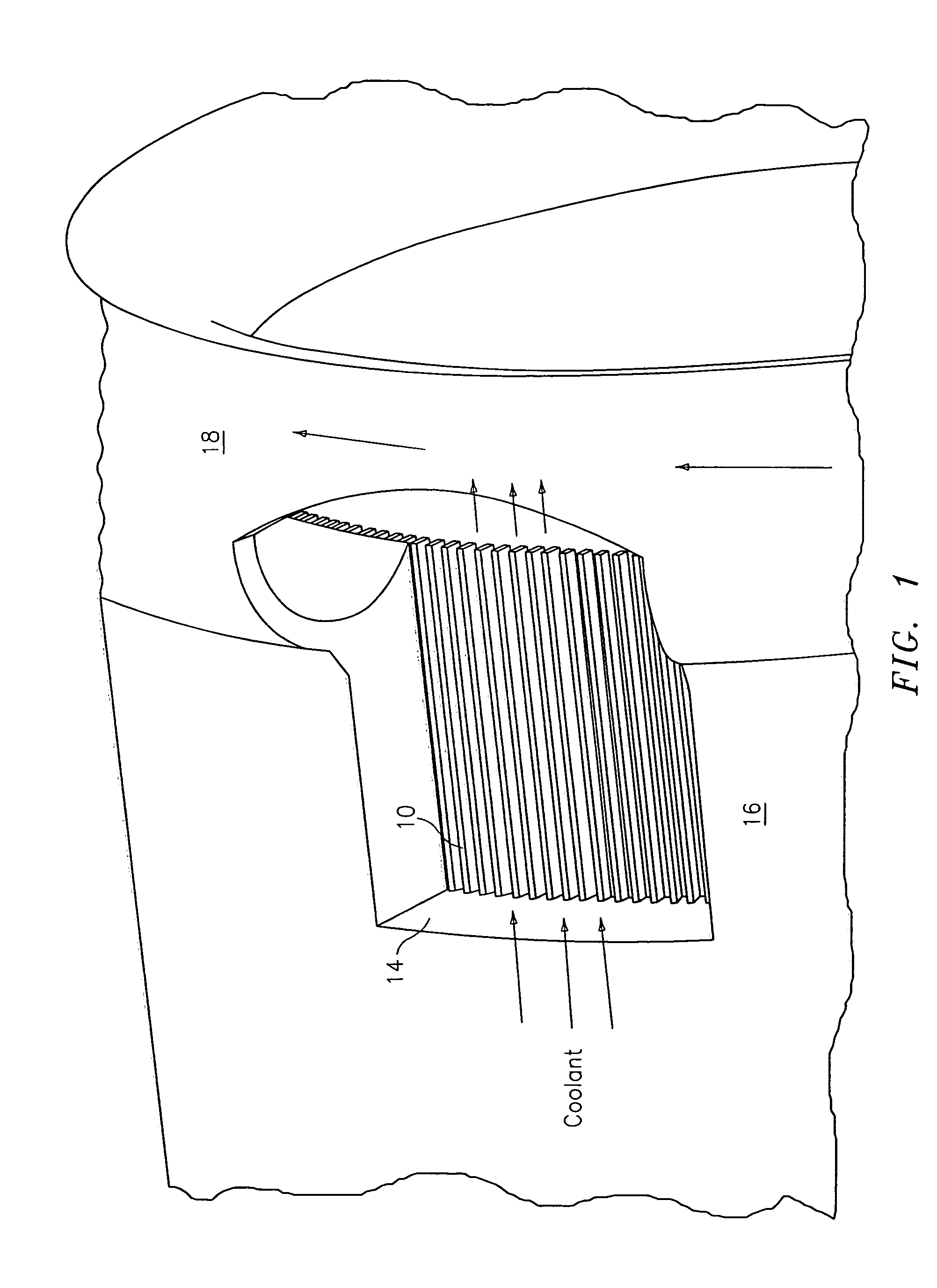

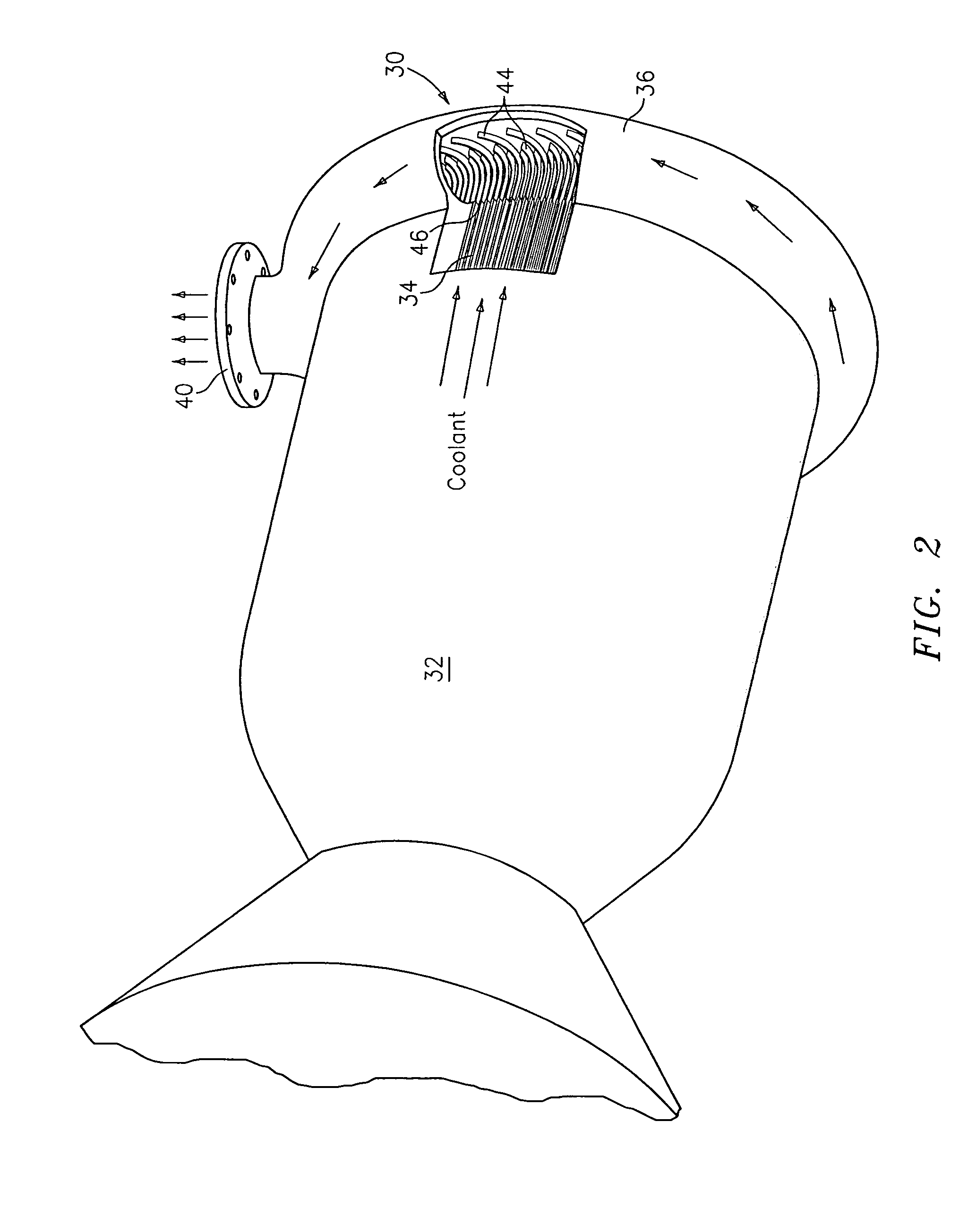

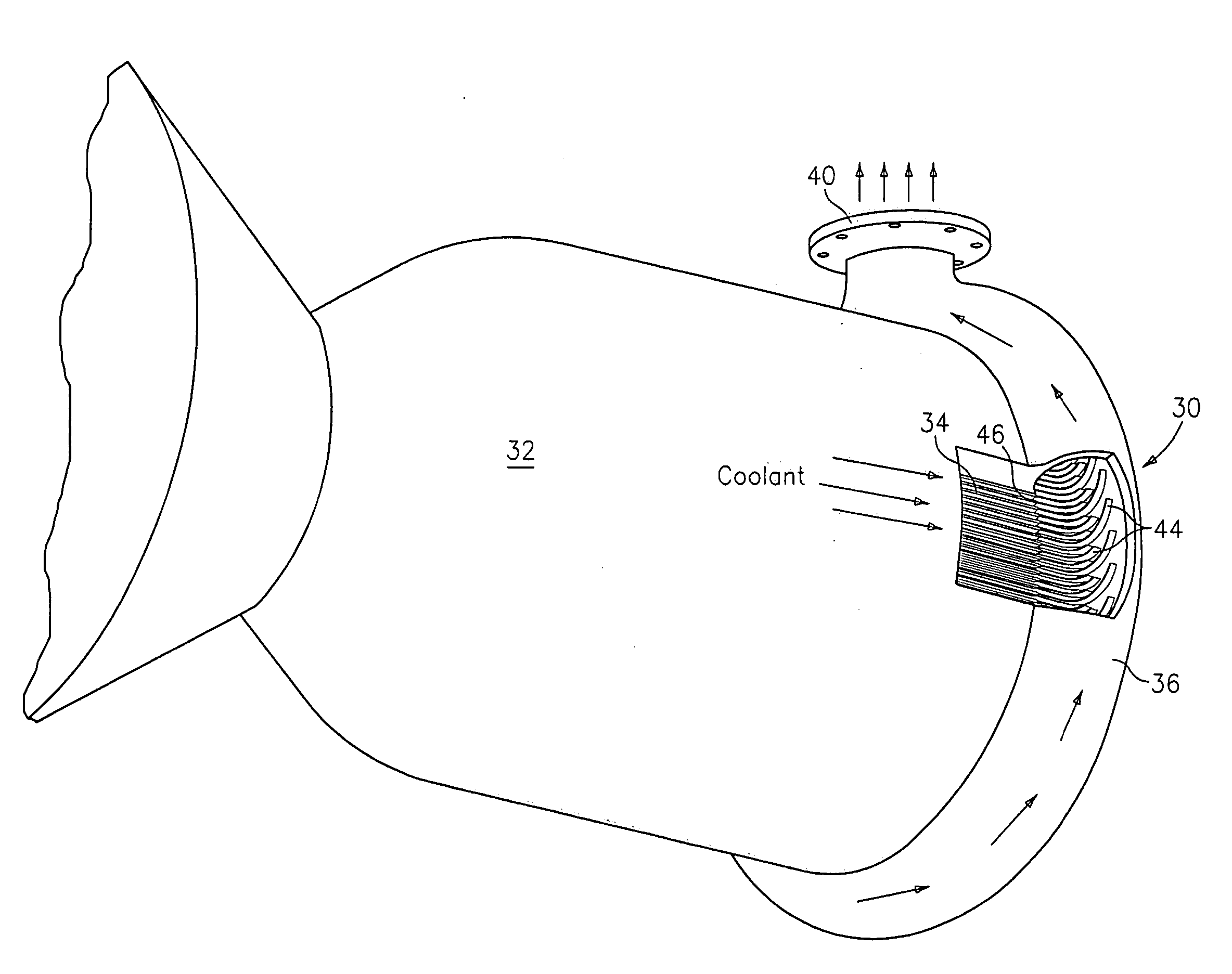

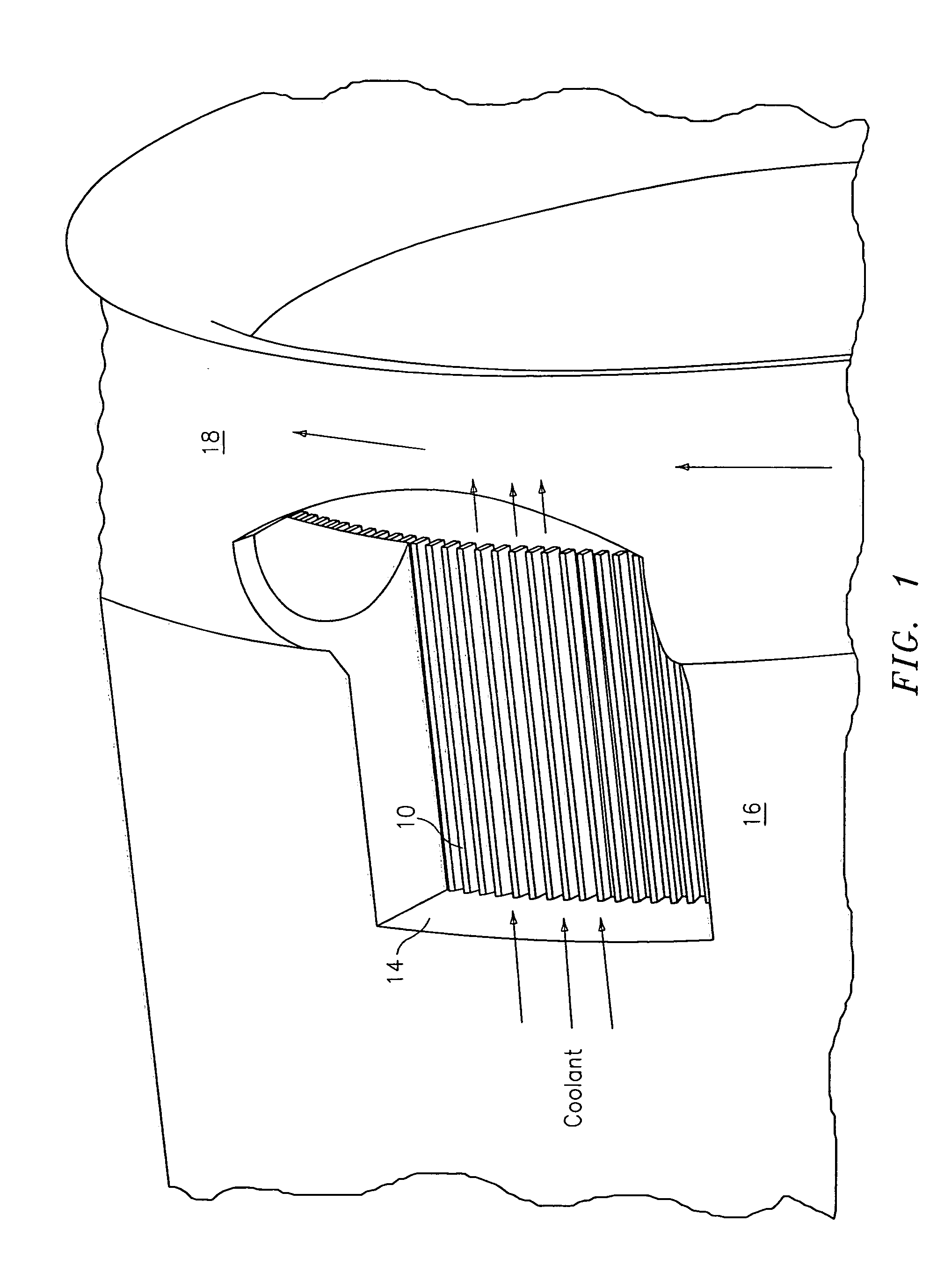

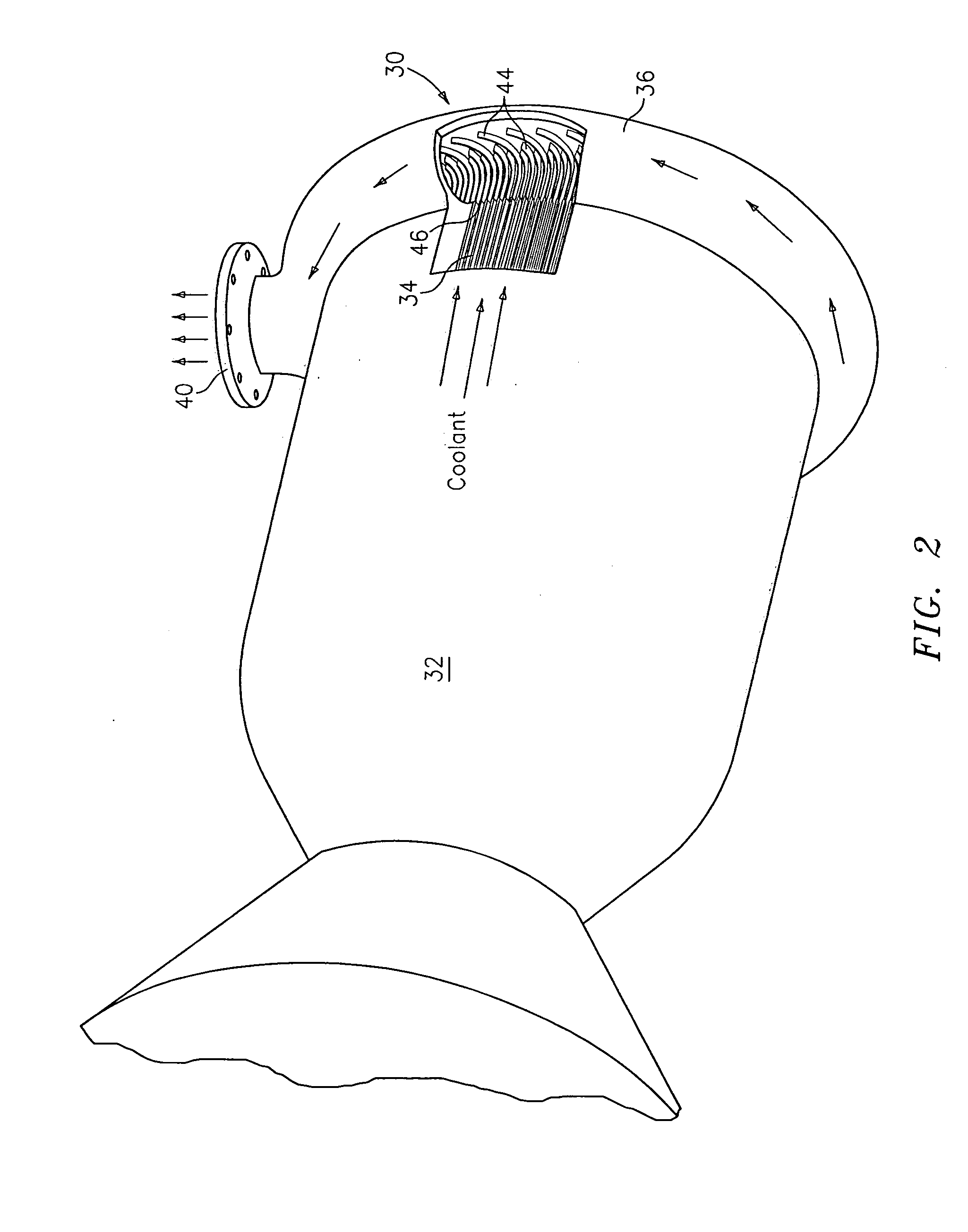

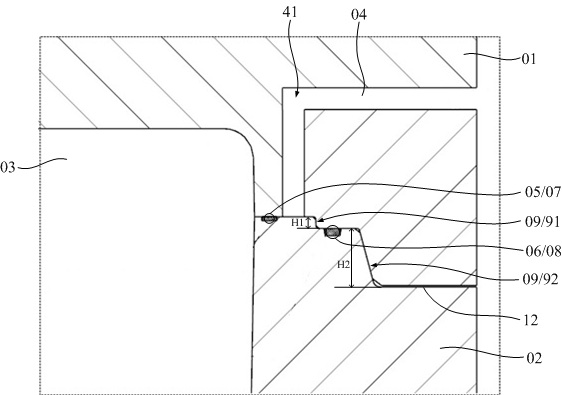

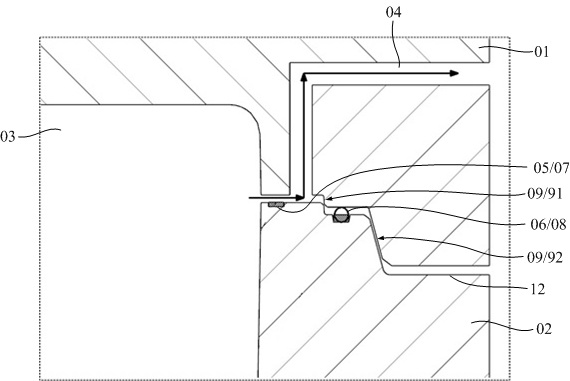

Enhanced performance torroidal coolant-collection manifold

ActiveUS7373774B2Reduce total pressure lossImproves pressure uniformityGas turbine plantsRocket engine plantsCombustion chamberEngineering

A system for cooling a combustion chamber of an engine, such as a rocket engine, is provided. The system has a plurality of coolant tubes or passages surrounding the combustion chamber, a torroidal coolant-collection manifold for receiving coolant from the coolant tubes or passages and for discharging the coolant through a discharge port, and a plurality of turning vanes within the torroidal manifold for reducing pressure loss and improving pressure uniformity associated with the torroidal coolant-collection manifold.

Owner:AEROJET ROCKETDYNE INC

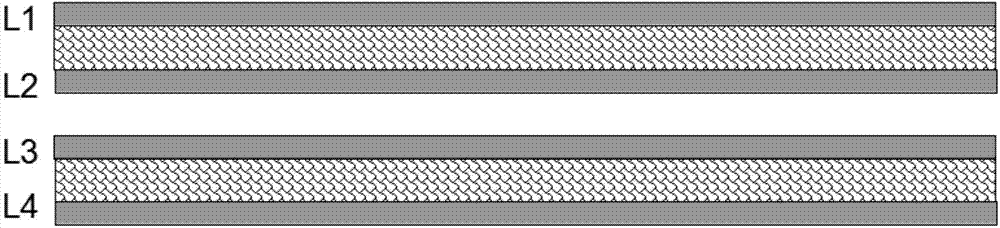

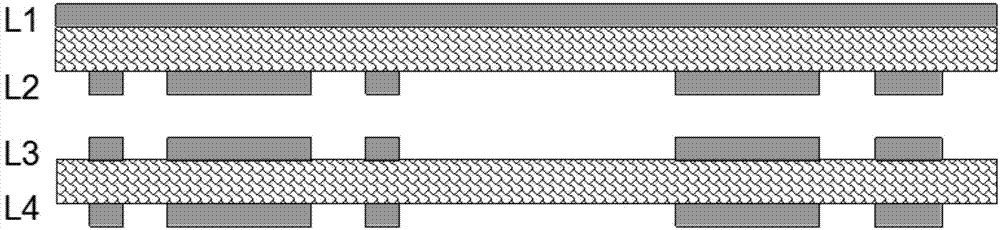

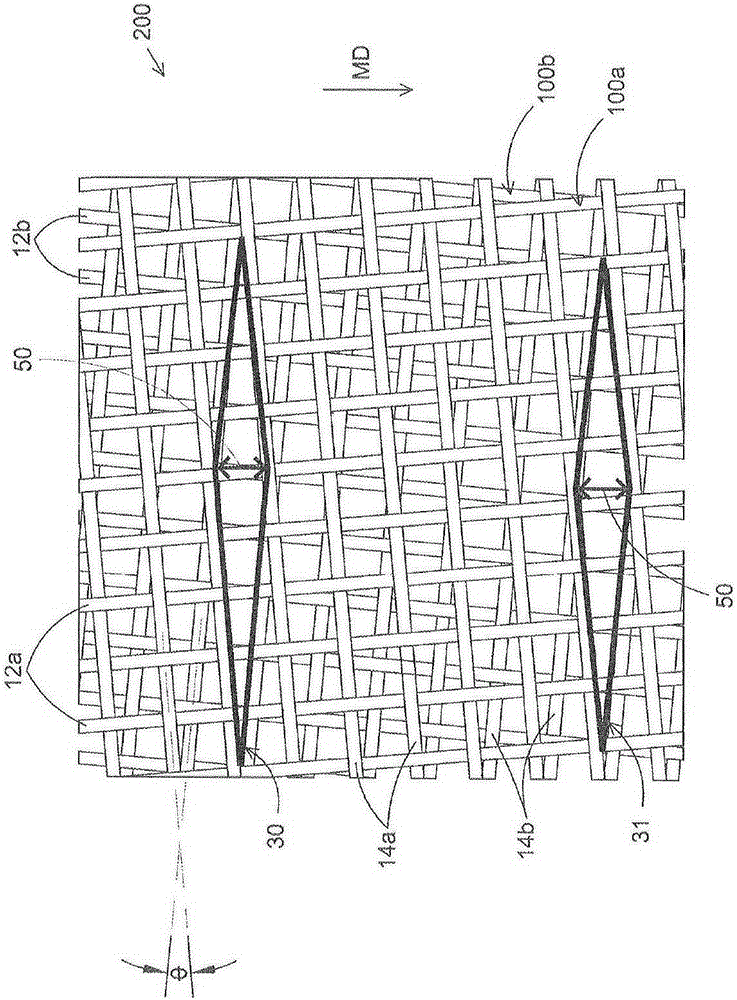

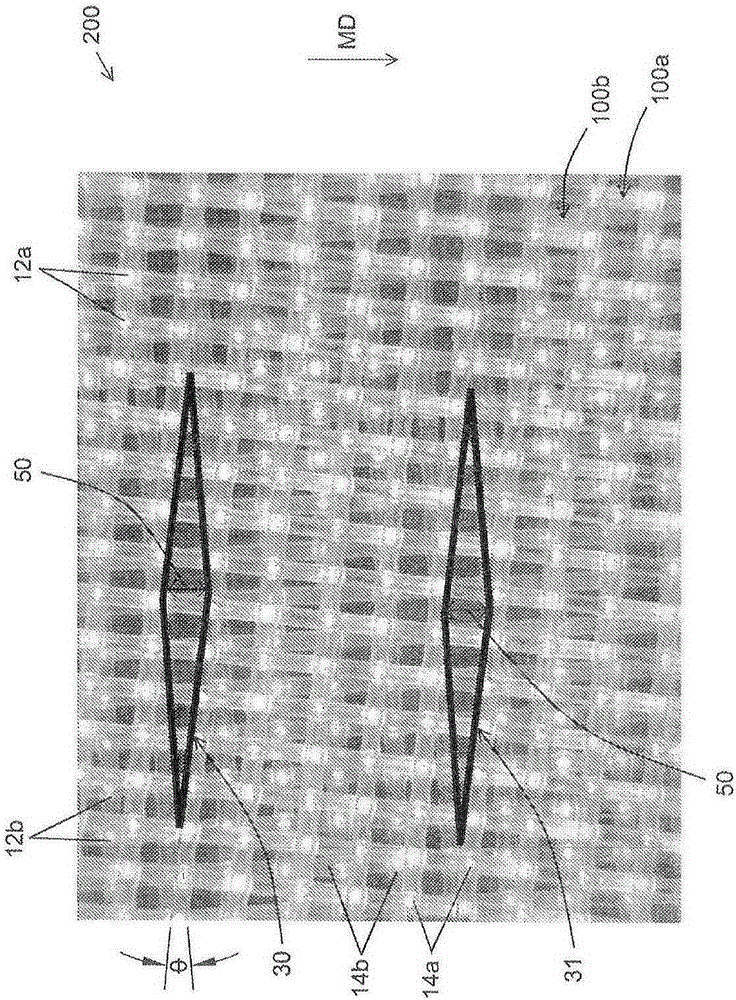

Press felt base fabric exhibiting reduced interference

ActiveCN105121719ALong felt lifeQuick run-inLayered productsMachine wet endPolymer sciencePolymer chemistry

A press felt formed of two stacked layers of woven single layer base fabric, each layer being formed by warp yarns interwoven with two systems of weft yarns according to a single layer weave pattern. The layers are needled with a batt layer. In the woven single layer base fabric: a) the warp yarns are polymeric monofilaments arranged as a single layer and there are two systems of weft yarns; b) the first system of weft yarns are formed by cabled polymeric monofilaments and the second system of weft yarns are single polymeric monofilaments; c) the cabled polymeric monofilaments are 50% to 85% in one repeat; d) the cabled monofilaments are each formed of at least two monofilaments which are cabled together; and e) at least two of the cabled weft yarns in each repeat are adjacent to each other.

Owner:ASTENJOHNSON

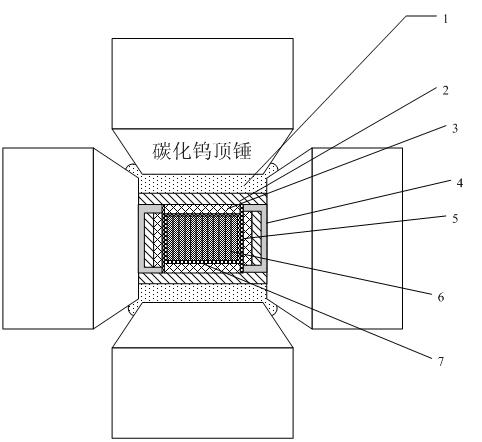

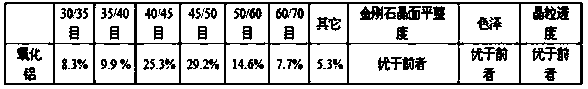

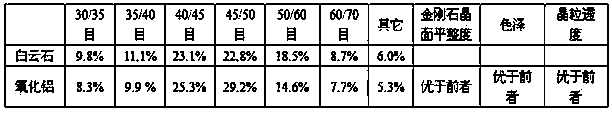

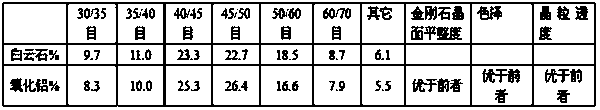

Indirect heating-type synthesis assembly for high-temperature and high-pressure artificial single crystal synthesis by using cubic press

InactiveCN102600768AImprove stabilityIncrease temperatureUltra-high pressure processesPyrophylliteNiobium

The invention relates to an indirect heating-type synthesis assembly for single crystal synthesis by using a cubic press. The indirect heating-type synthesis assembly comprises pyrophyllite powder pressing block which is internally lined with a dolomite casing. The indirect heating-type synthesis assembly is characterized in that a cylindrical metal cup made of metal niobium, tantalum, molybdenum or tungsten is arranged in the dolomite casing, an aluminum oxide ceramic high-temperature pipe is wrapped outside the cylindrical metal cup and the aluminum oxide ceramic high-temperature pipe is made of alpha-aluminum oxide and talc through high-temperature sintering; metal conducting strips are respectively arranged on the two sides of the metal cup and are connected with the metal cup; and the two ends of the dolomite casing are respectively sealed by composite conducting plugs and the composite conducting plugs are connected with the metal conducting strips. The indirect heating-type synthesis assembly uses high-melting-point metals to make the metal cup which is also used as an electric heating element, aluminum oxide ceramic materials are additionally used for making the high-temperature protection pipe, the indirect heating-type synthesis assembly is suitable for synthesizing artificial single crystals such as diamonds by using the cubic press, the requirements of higher temperature and longer heating time are satisfied, the stability of single crystal synthesis technology and equipment is improved, the losses of anvils are reduced and favorable conditions are provided for the synthesis of gem grade diamonds.

Owner:常熟市怡华金刚石有限公司 +1

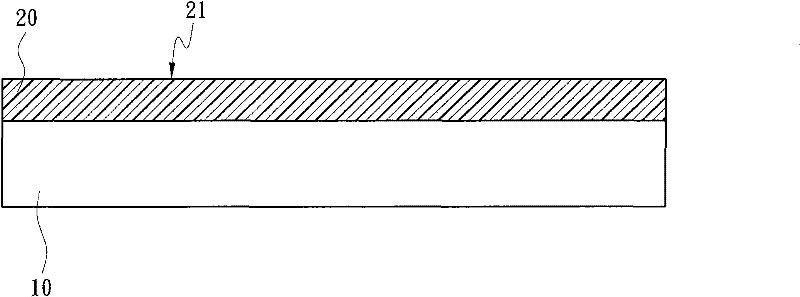

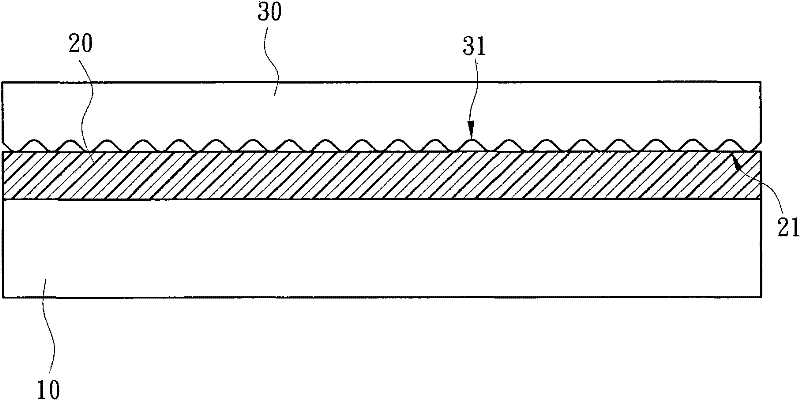

Light guide plate manufacturing method

InactiveCN102455460AGood brightness performanceReduce the number of bubblesOptical light guidesLight guideOptoelectronics

The light guide plate manufacturing method comprises the following steps of: using a rolling depression device comprising an imprinter, wherein the surface of the imprinter comprises a first structure; rolling a resin layer arranged on a substrate by the imprinter, or forming the resin layer on the imprinter to roll the substrate, enabling the resin layer to continuously form a second structure complementary to the first structure, and attaching the second structure on the substrate. The rolling depression area formed by the rolling depression mode is smaller, so the uniformity of pressure application is easy to control, the light guide plate can have high transcription rate, and defects are reduced.

Owner:WIN OPTICAL

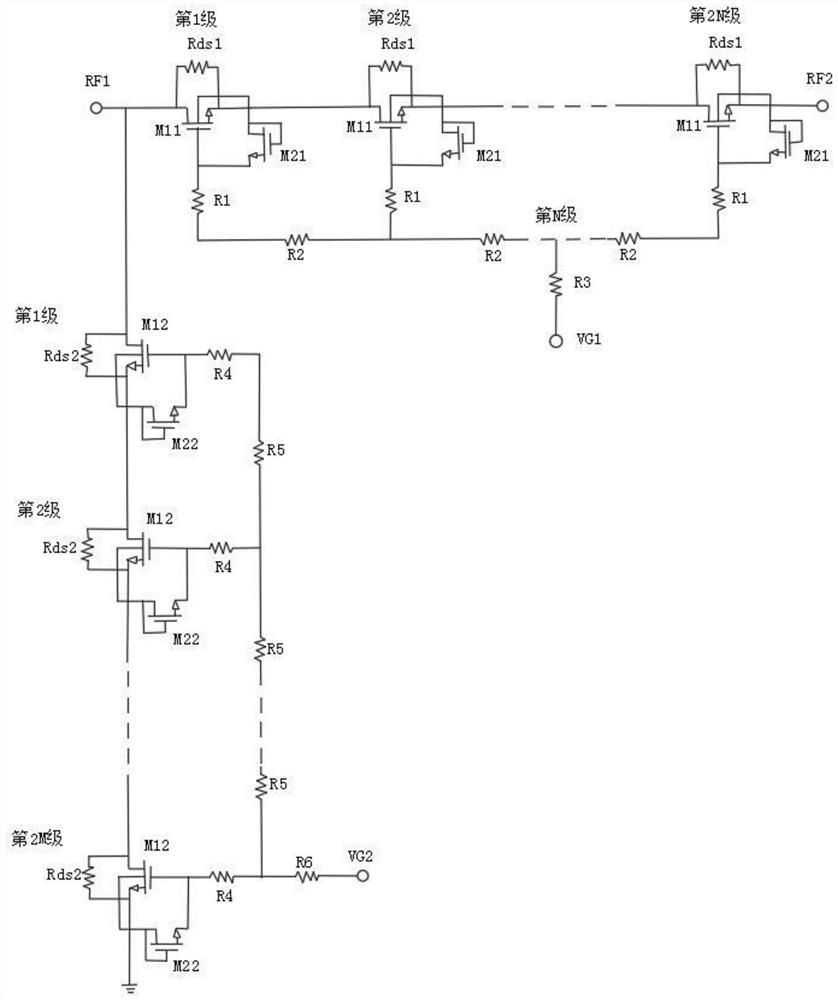

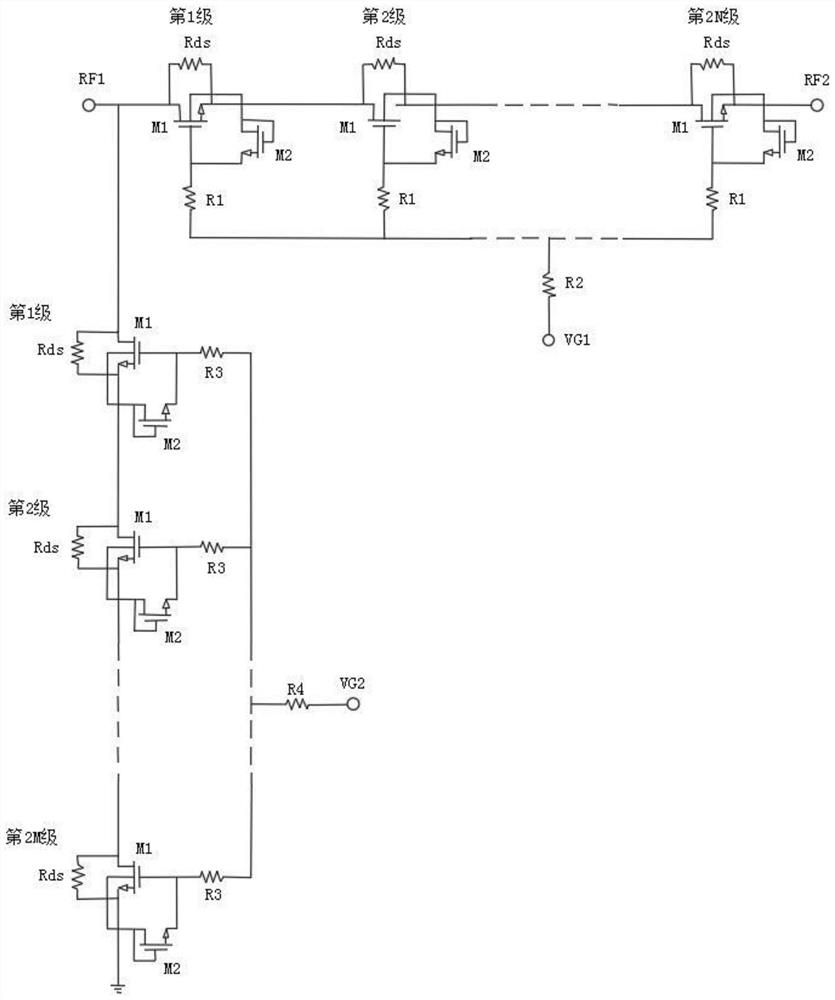

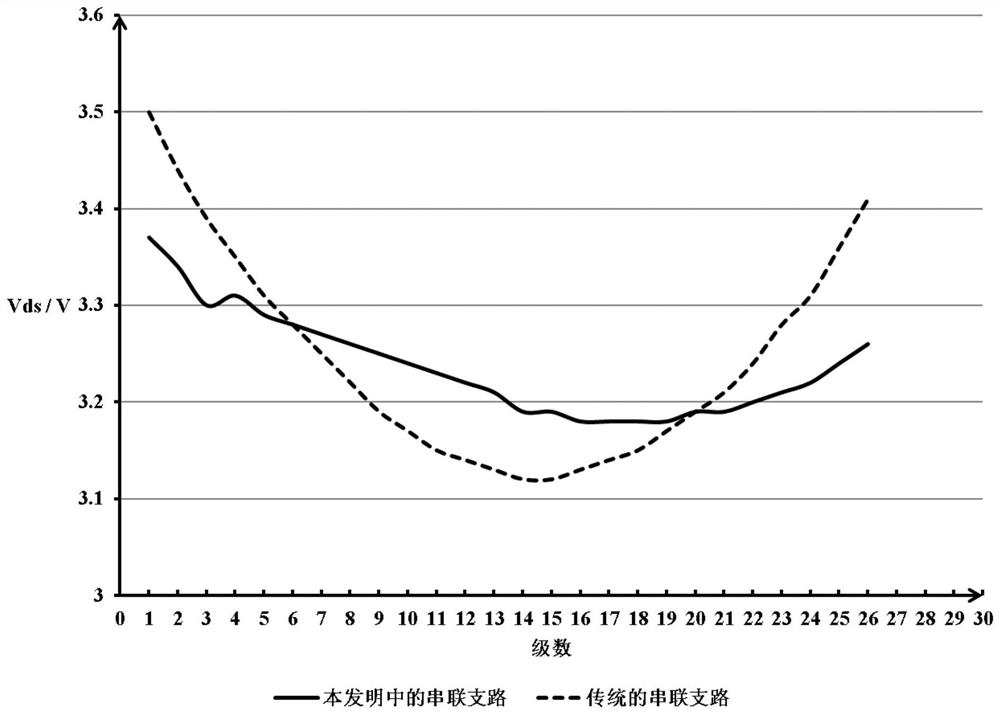

Radio frequency switch circuit for optimizing voltage withstanding uniformity of stacked switch tubes

PendingCN113472329AImproves pressure uniformityIncrease the maximum input powerElectronic switchingControl theoryRadio frequency

The invention discloses a radio frequency switch circuit for optimizing voltage withstanding uniformity of stacked switch tubes, and relates to the technical field of radio frequency integrated circuits. The circuit comprises a series branch module composed of 2N first switch transistors, a first bias transistor, a first source drain resistor, a first grid bias resistor, 2N-1 first grid series resistors and a first grid common end resistor; a parallel branch module composed of 2M second switch transistors, a second bias transistor, a second source drain resistor, a second grid bias resistor, 2M-1 second grid series resistors and a second grid common end resistor; according to the structure, the maximum peak voltage borne by the switch transistors of the previous stages and the later stages of the radio frequency switch can be reduced, the withstand voltage uniformity of each stage of switch transistor of the radio frequency switch and the maximum input power of the radio frequency switch are improved, and particularly, the withstand voltage uniformity of each stage of switch transistor of a parallel branch module is improved.

Owner:上海迦美信芯通讯技术有限公司

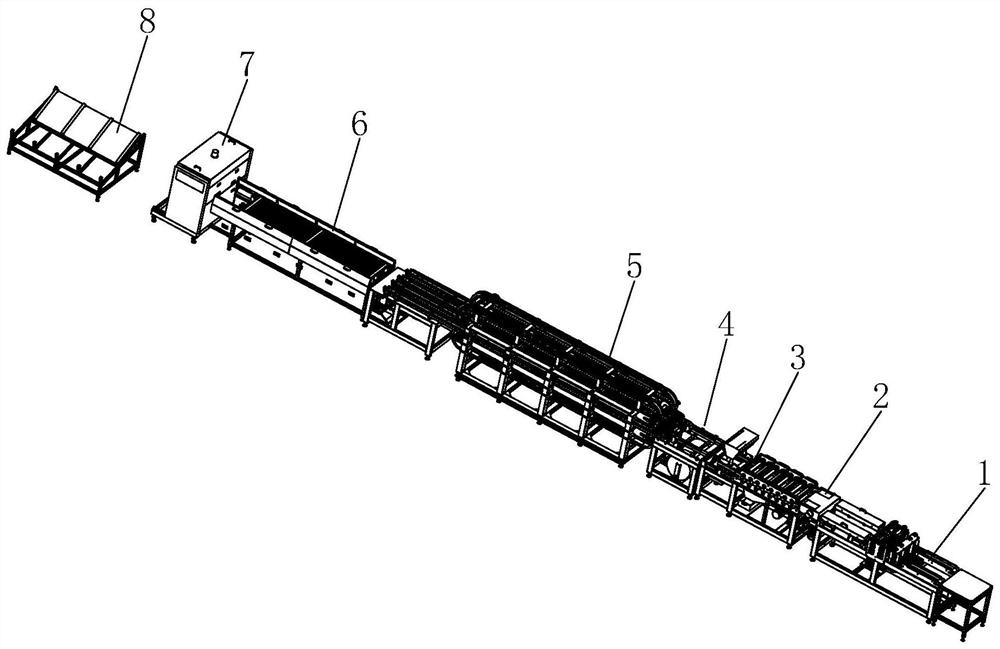

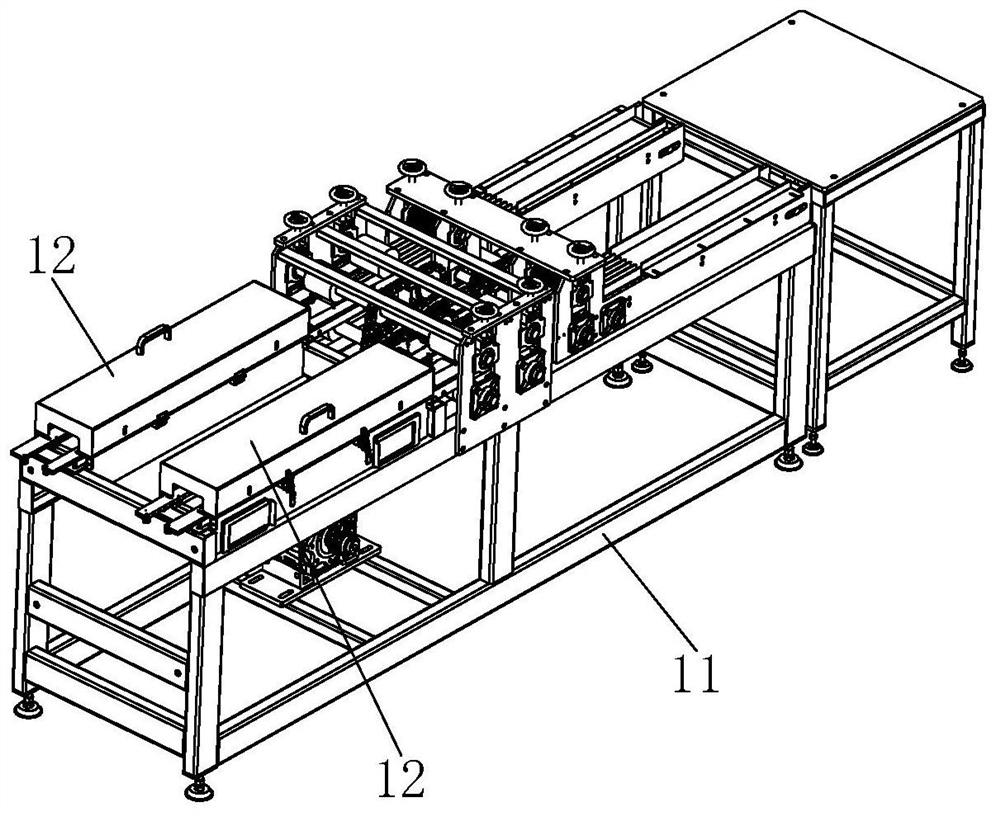

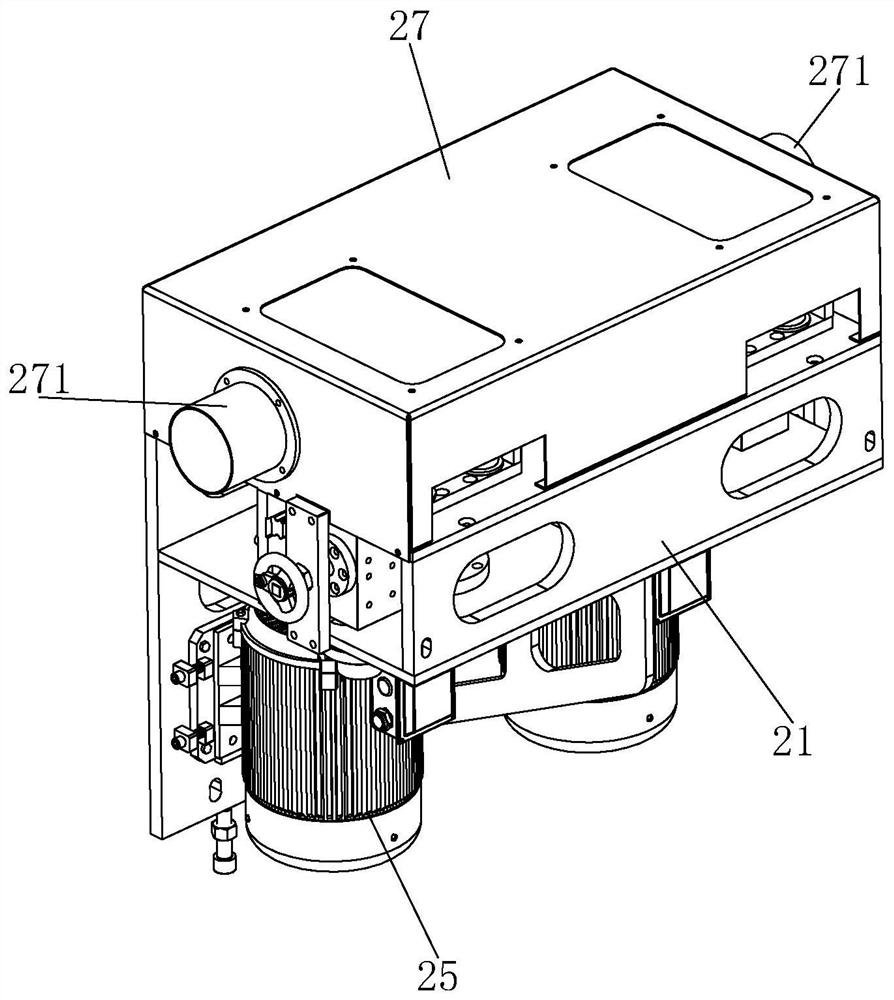

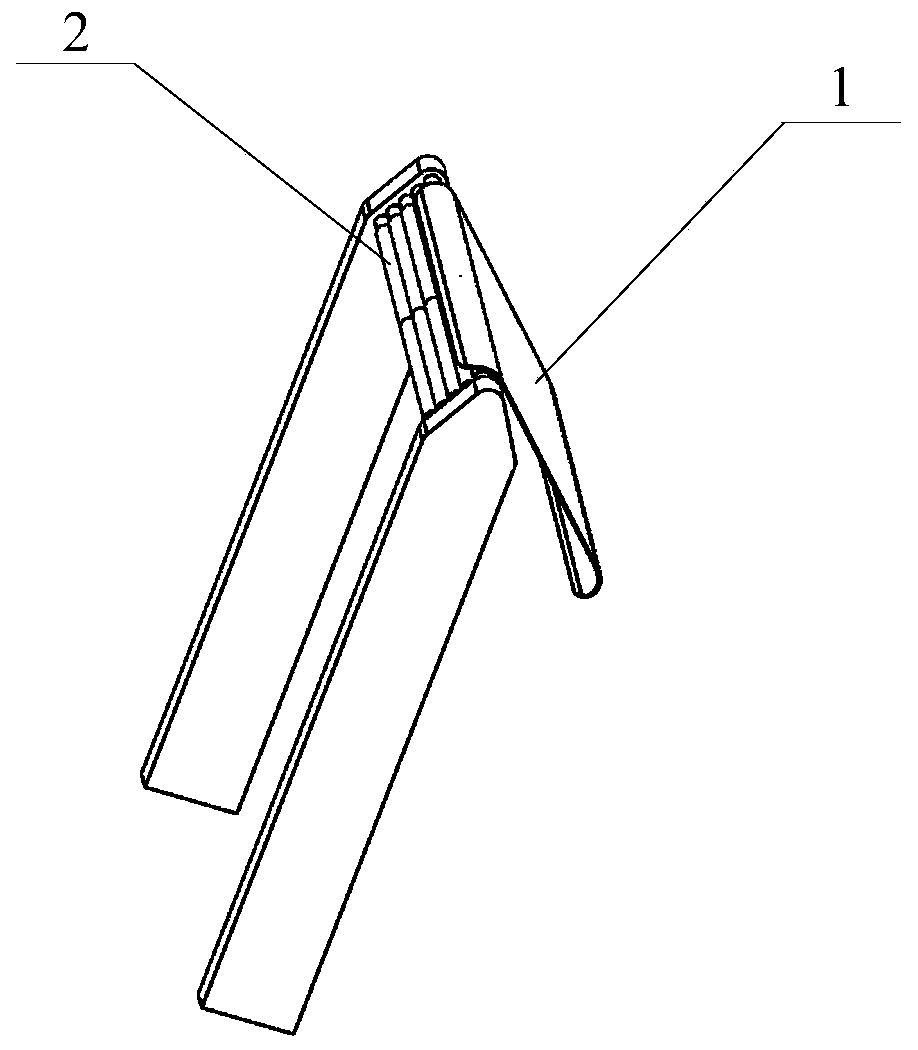

Composite batten production line

PendingCN112060233AImprove tightnessImprove structural strengthWood veneer joiningAuxillary members of forms/shuttering/falseworksGlass fiberBatten

The invention discloses a composite batten production line. The composite batten production line comprises a feeding and conveying device, an online planing device, a pressure feed gluing device, a glass fiber cloth compounding device, an under-pressure thermal forming device, a cooling device, a cutting device and a discharging device; the online planing device is used for planing the two sides of a batten body so as to control the width; the glass fiber cloth compounding device is used for wrapping glass fiber cloth on the peripheral side of the batten body so as to form a composite batten;the under-pressure thermal forming device is used for conveying the glass fiber cloth and tightly adhering the glass fiber cloth to the peripheral side of the batten body; and the discharging device is used for receiving cut composite battens and discharging the cut composite battens. The composite batten production line has the following advantages and effects that the under-pressure thermal forming device is used for conveying the glass fiber cloth and tightly adhering the glass fiber cloth to the peripheral side of the batten body, and the under-pressure thermal forming device has a thermalforming function, such that thermal forming is achieved while the peripheral side of the composite batten is tightly pressed, and the tightness of the composite batten can be improved; and the glassfiber cloth cannot be tightly bonded on the batten body, so that the structural strength of the composite batten can be improved.

Owner:浙江衡昶科技有限公司

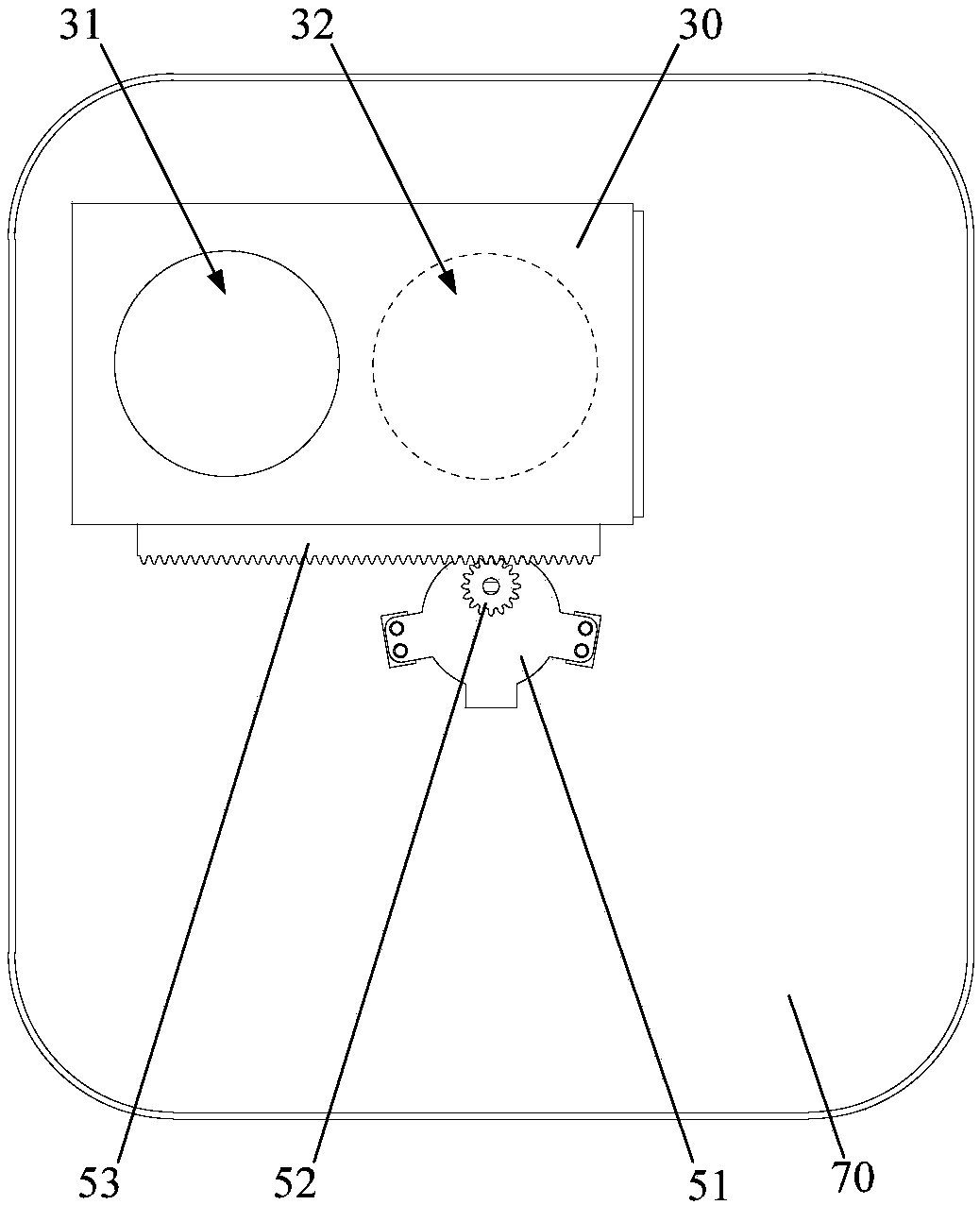

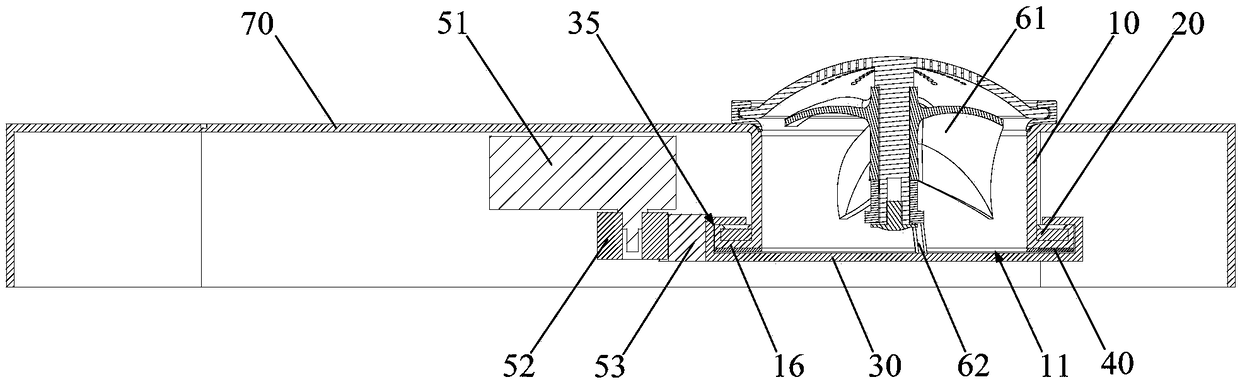

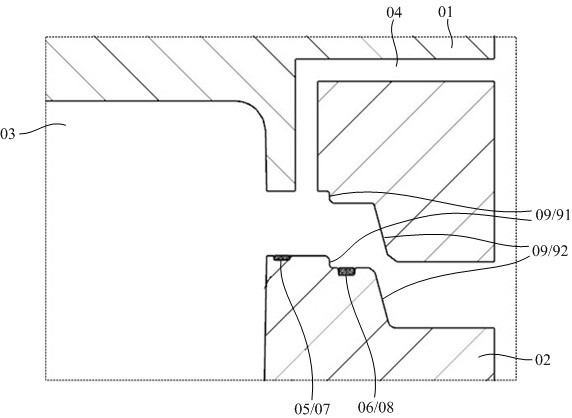

Laminating device for curved surface display panel

ActiveCN110264883AAvoid display effectsLarge fitting pressureIdentification meansSurface displayBlack spot

The embodiment of the invention provides a laminating device for a curved surface display panel. The laminating device solves the technical problems that black spots or other undesirable display appear on display screen bodies due to uneven distribution of curved surface laminating pressure. Laminating can be achieved by using a laminating roller and at least one layer of support roller group to roll and press a display substrate and a curved surface cover plate, when the curved surface cover plate and the display substrate are laminated, the at least one layer of support roller group and the laminating roller can bear a larger laminating pressure to avoid curving, so that the laminating pressure in the laminating process can be increased; even if the diameter of the laminating roller is smaller, the greater laminating pressure in the laminating process can also be ensured; and the laminating device not only can ensure that the laminating pressure in the laminating process is greater, but also can ensure that the diameter of the laminating roller is smaller, improves the pressure uniformity in the lamination process, and solves the problems that the black spots or other undesirable display appear on the display screen bodies due to uneven distribution of the curved surface laminating pressure.

Owner:YUNGU GUAN TECH CO LTD

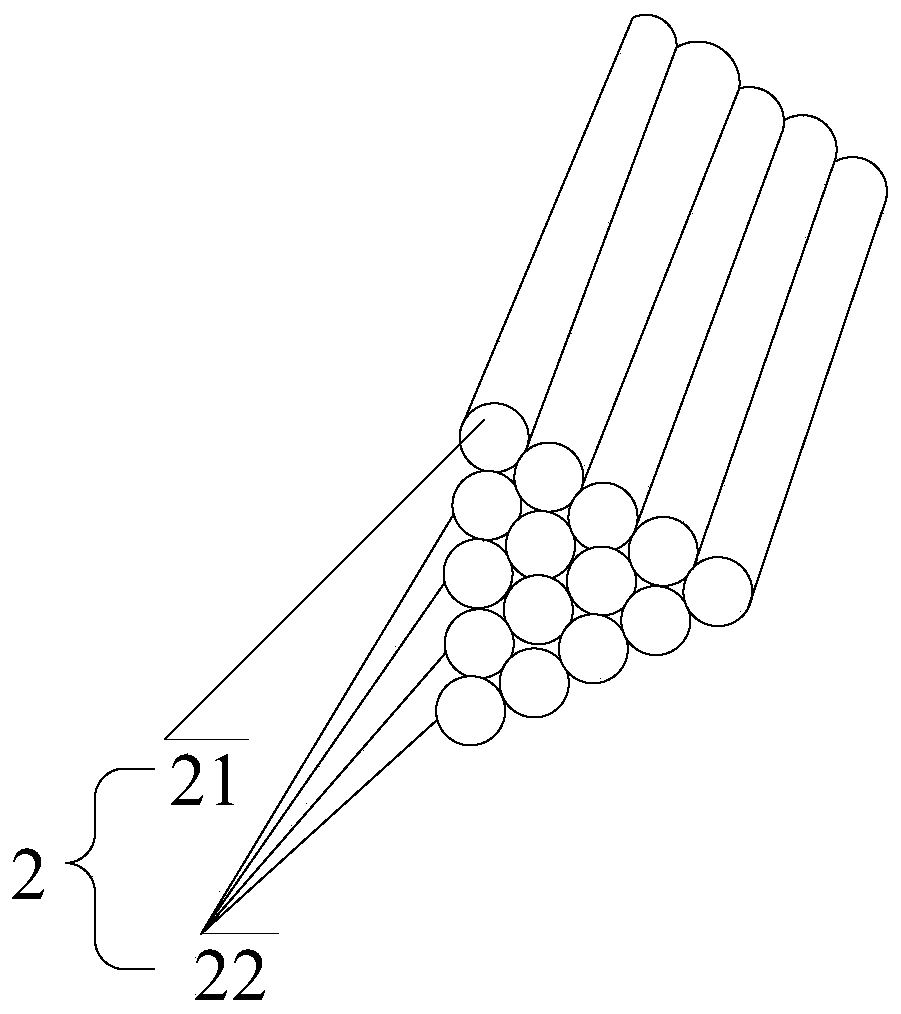

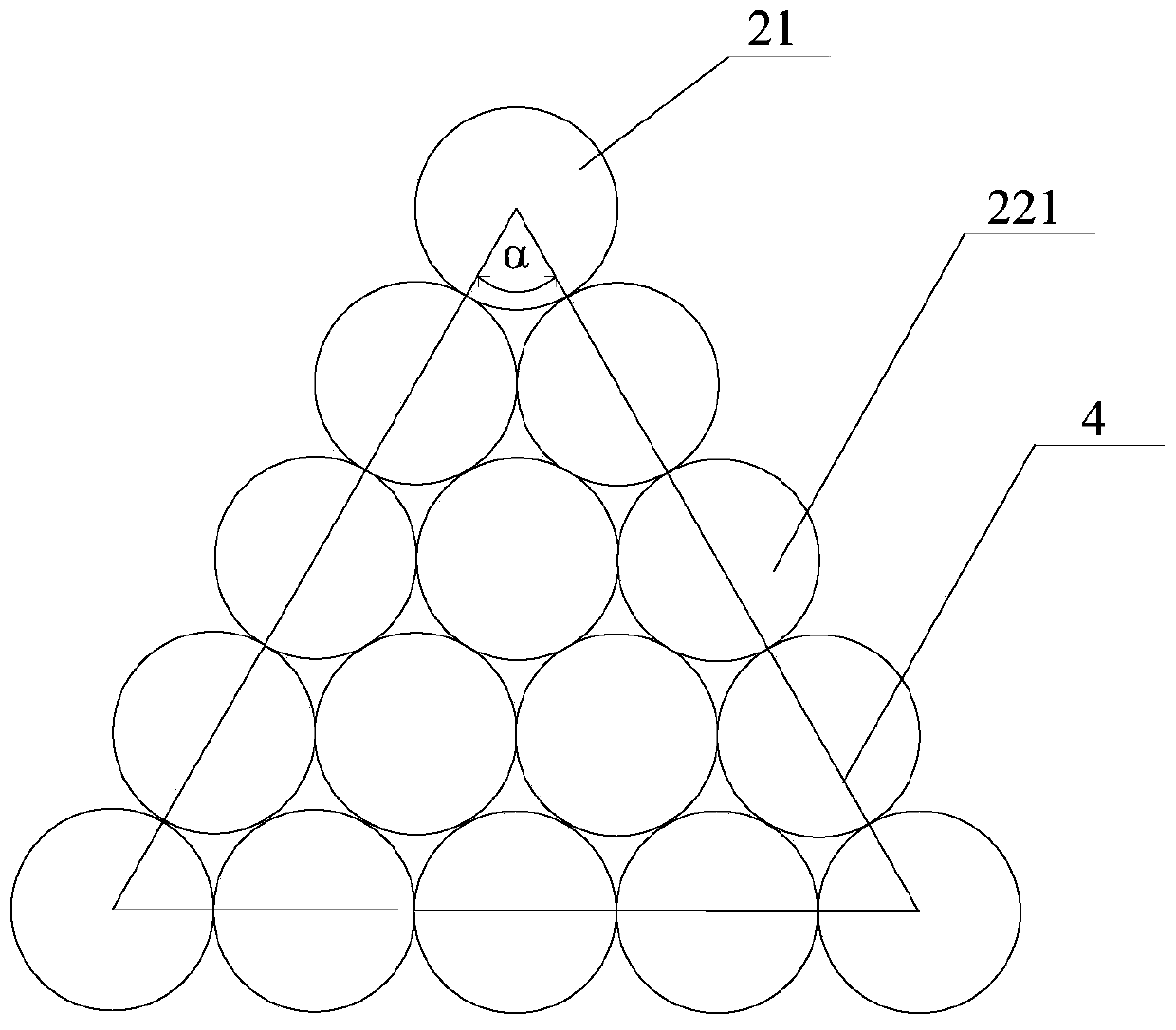

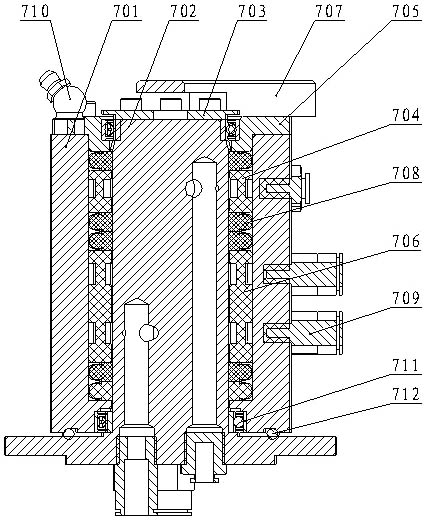

Crawler follower mechanism for thin steel material quenching and leveling process

InactiveCN104120243AIncrease stiffnessIncreased contact areaFurnace typesHeat treatment furnacesRolling-element bearingFuel tank

The invention discloses a crawler follower mechanism for a thin steel material quenching and leveling process. The crawler follower mechanism comprises chain-plate crawler units, an oil tank assembly and a motor transmission system, wherein the chain-plate crawler units are arranged surrounding tank bodies, each chain-plate crawler unit comprises chain wheels, a chain wheel shaft and a closed-ring crawler which is formed through connecting a plurality of chain-plate assemblies in series, and thus, the closed-ring crawlers cyclically revolve around the face of an oil tank under the drive of the chain wheels; each chain-plate assembly comprises a chain plate, chain plate pin shafts, rollers, embedded shafts and rolling bearings; the motor transmission system is connected with the chain wheel shafts and is used for transferring motor power, so that the closed-ring crawlers are driven to cyclically revolve, and meanwhile, relative-sliding-free follow-up with a quenched thin material is realized. Through the crawler follower mechanism, the phenomena that folds appear after the thin material is quenched, the thin material is stuck due to the fact that the rolling bearings are burnt out due to too high temperature of the thin material, and the like can be effectively avoided; meanwhile, the surface quality of the quenched thin material is remarkably improved, and the leveling efficiency of the quenched thin material is remarkably increased.

Owner:WUHAN UNIV OF SCI & TECH

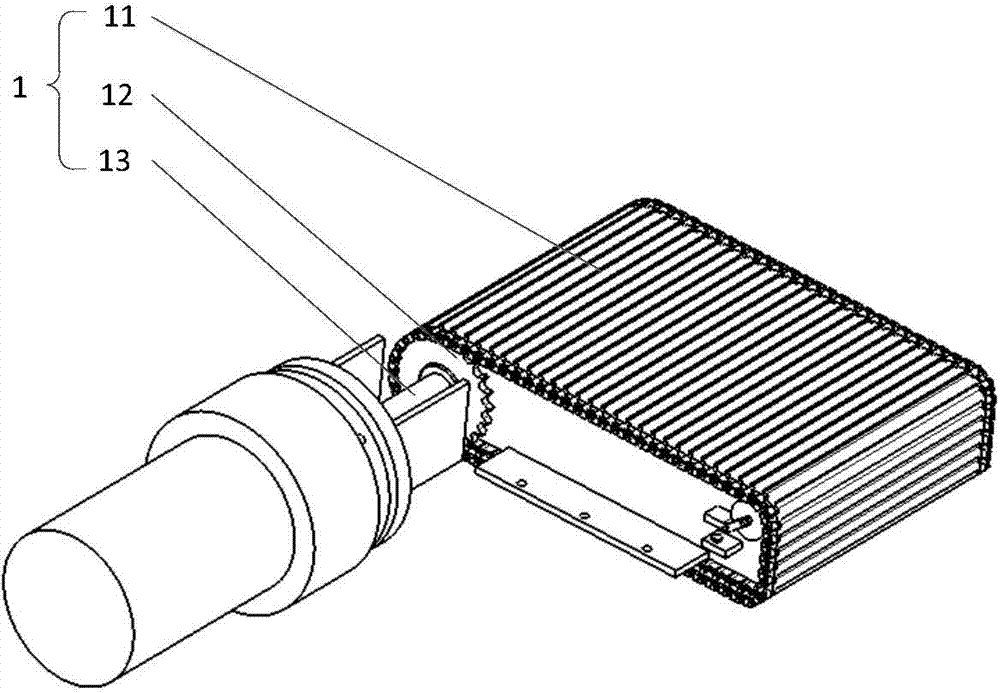

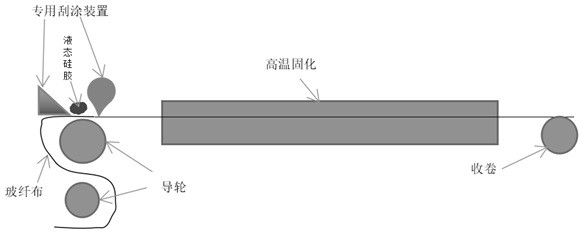

Silica gel glass fabric hot-pressing buffer material and preparation method thereof

PendingCN112622370AWon't hurtAvoid compromising flatnessLaminationLamination apparatusGlass fiberElastomer

The invention belongs to the technical field of hot-pressing buffer materials, and particularly relates to a silica gel glass fiber cloth hot-pressing buffer material and a preparation method thereof.The silica gel glass fiber cloth hot-pressing buffer material comprises a liquid silica gel layer, a heat conduction silica gel layer and glass fiber cloth with the two faces coated with silane coupling agents, the heat-conductive silica gel layer is calendered and compounded on the other surface; the liquid silica gel layer is a mixture of liquid silica gel, a heat-resisting agent and heat conduction powder; the heat-conductive silica gel layer is obtained by filling solid silica gel with heat-conductive powder; the buffer material prepared by the invention is a unique synthetic elastomer prepared from a silica gel polymer and high-strength glass fibers, perfectly combines the thermal performance and elasticity of silica gel molecules and the unique toughness of a fiber material, and has extremely high tear resistance and very high compression resistance and resilience; The excellent insulativity, high-speed heat transfer performance and high-temperature resistance of the cable can be embedded in extremely harsh application occasions.

Owner:镇江中垒新材料科技有限公司

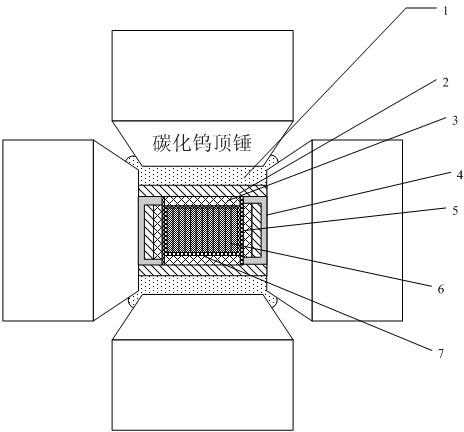

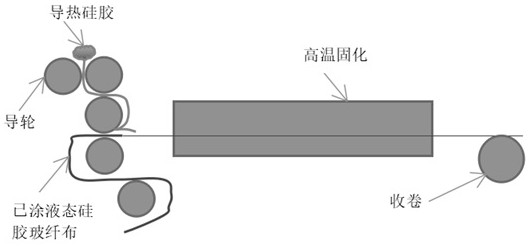

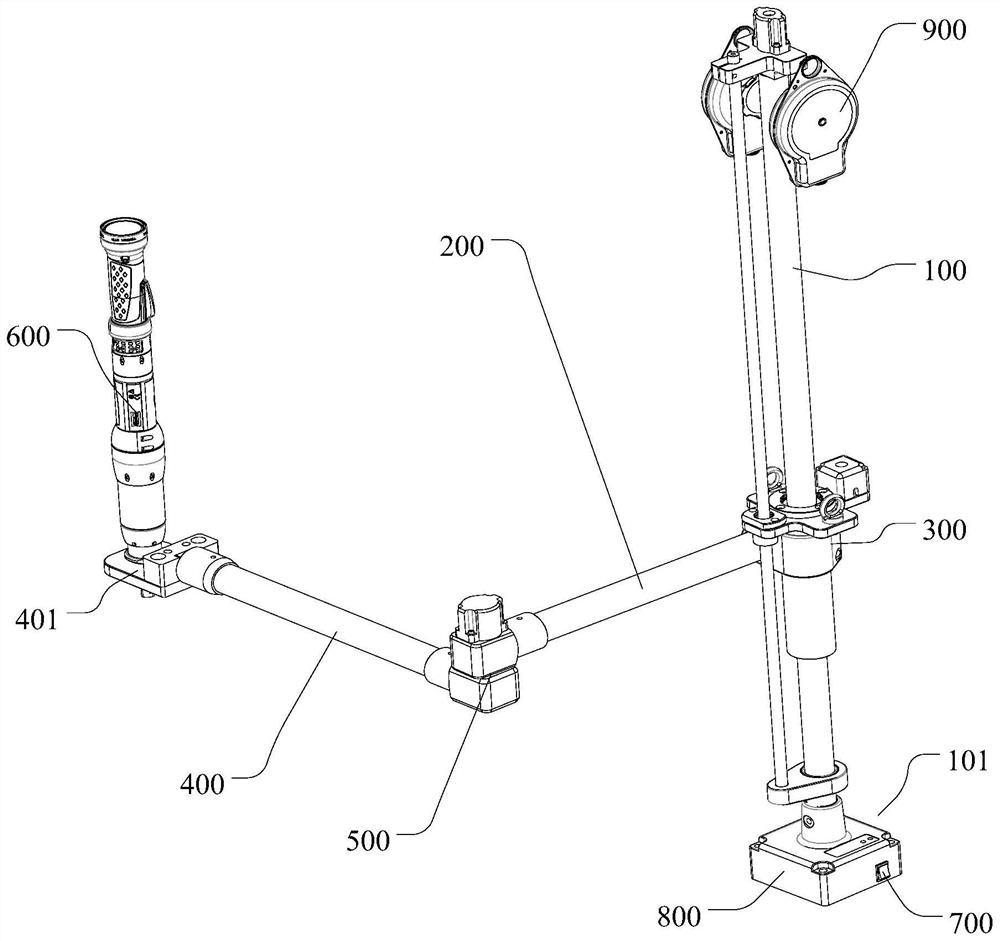

Operation and sealing method of large cubic press based on two-sided jacking mode

ActiveCN111203153AImproves pressure uniformityIncrease the proportionEngine sealsUltra-high pressure processesMechanical engineeringOil pressure

The invention relates to an operation and sealing method of a large cubic press based on a two-sided jacking mode. The top surfaces of four transverse non-heating hammers of the cubic press are designed into rectangles and are first fitted to form a square cavity during operation, and the oil ways of oil cylinders corresponding to two vertical heating hammers are separated from those of the otherfour oil cylinders and independently controlled; square columns with proper heights are designed at the top ends of the two heating hammers, the pressurizing process is realized by pushing the squarecolumns in the square cavity, and an inner sealing form is adopted between the heating hammers and the cavity; and inner sealing edges with proper widths and angles are designed on the four sides of the square columns. According to the invention, a traditional pressurizing mode is changed, the four non-heating hammers form a square cavity in advance under proper pressure, the pressure of the non-heating hammers is gradually increased and is matched with the pressure of the heating hammers while the heating hammers are pushed forwards, the utilization rate of oil pressure is increased, and theproblem that the pressure of a top hammer plane and the pressure of the sealing edges are uneven due to volume shrinkage in the diamond synthesis process is solved.

Owner:CHANGZHOU UNIV

Enhanced performance torroidal coolant-collection manifold

ActiveUS20050178106A1Reduce total pressure lossImproves pressure uniformityGas turbine plantsRocket engine plantsCombustion chamberEngineering

A system for cooling a combustion chamber of an engine, such as a rocket engine, is provided. The system has a plurality of coolant tubes or passages surrounding the combustion chamber, a torroidal coolant-collection manifold for receiving coolant from the coolant tubes or passages and for discharging the coolant through a discharge port, and a plurality of turning vanes within the torroidal manifold for reducing pressure loss and improving pressure uniformity associated with the torroidal coolant-collection manifold.

Owner:AEROJET ROCKETDYNE INC

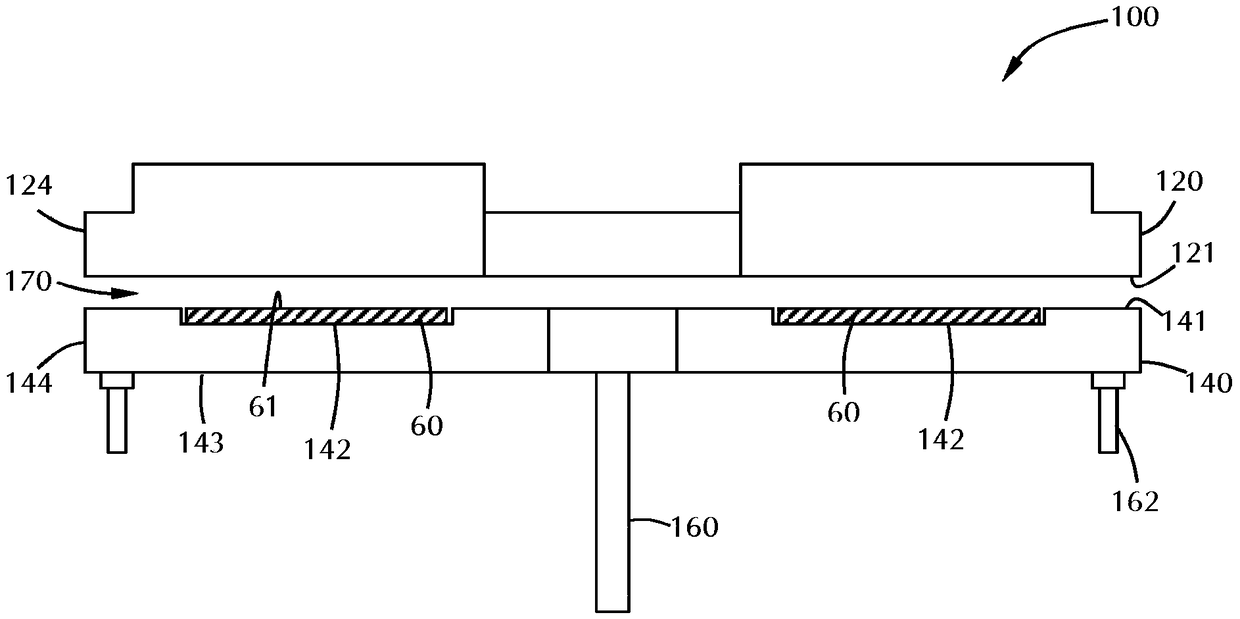

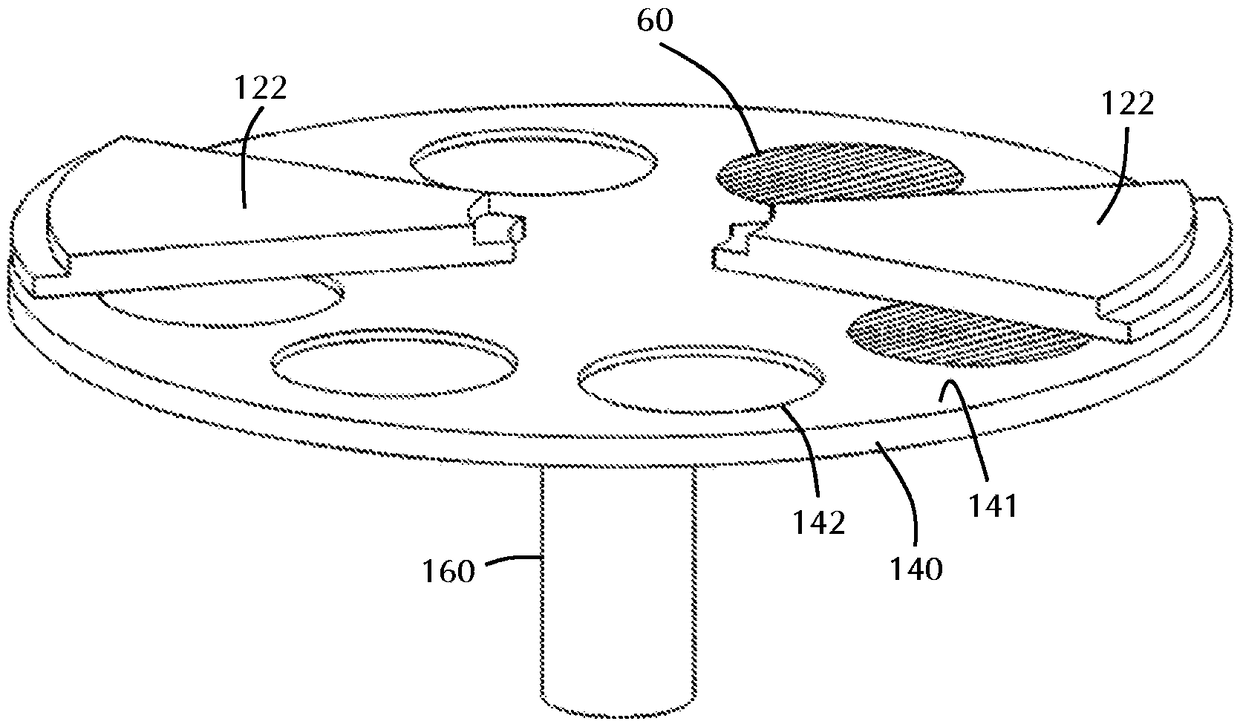

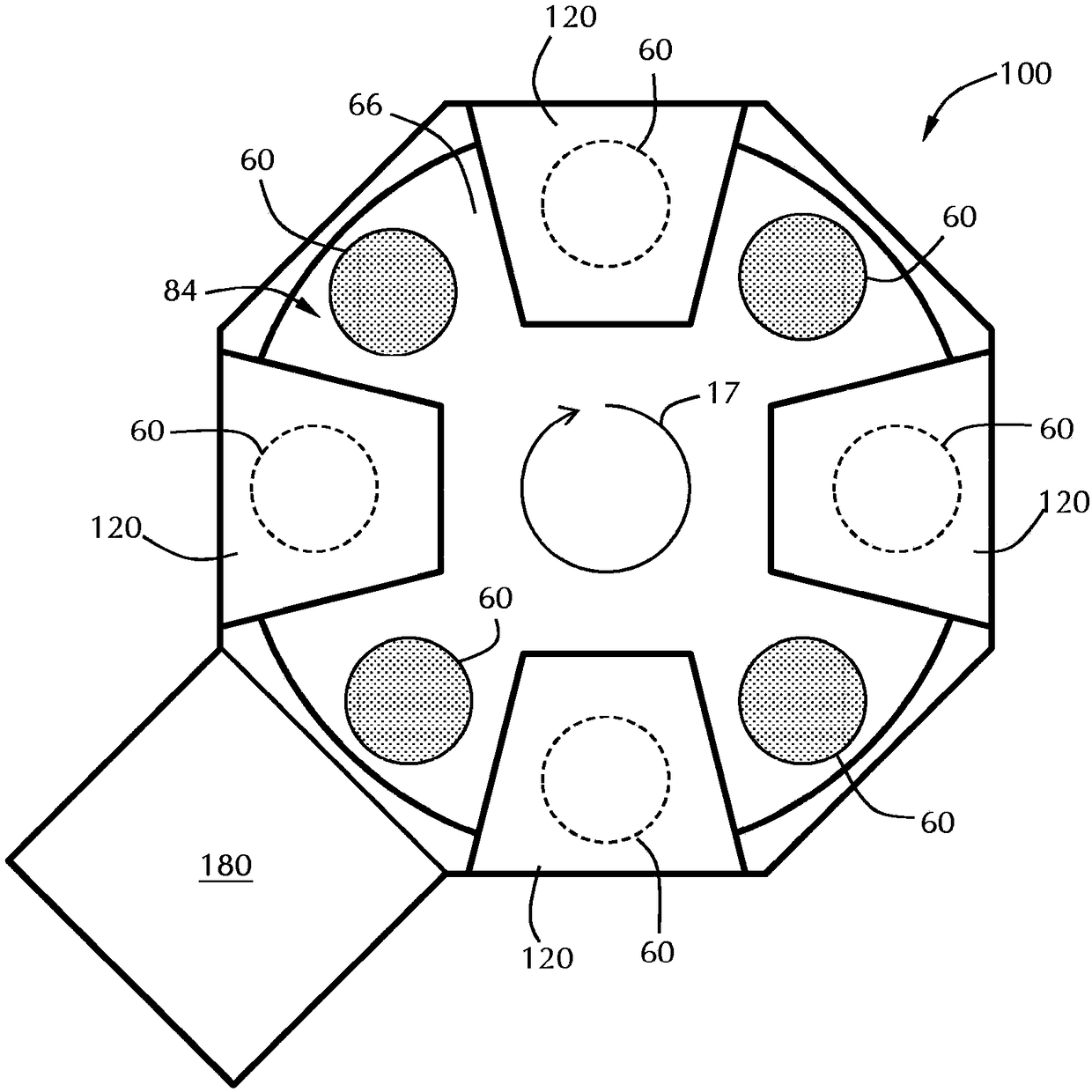

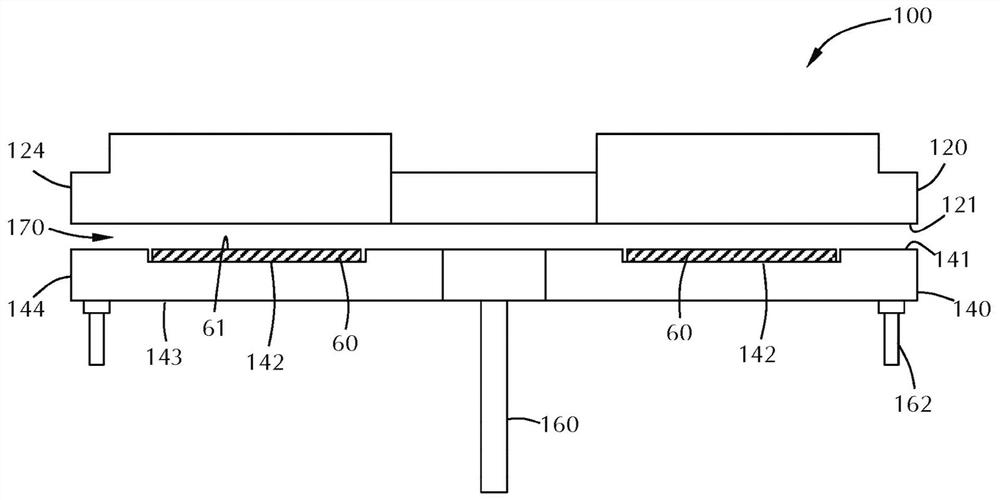

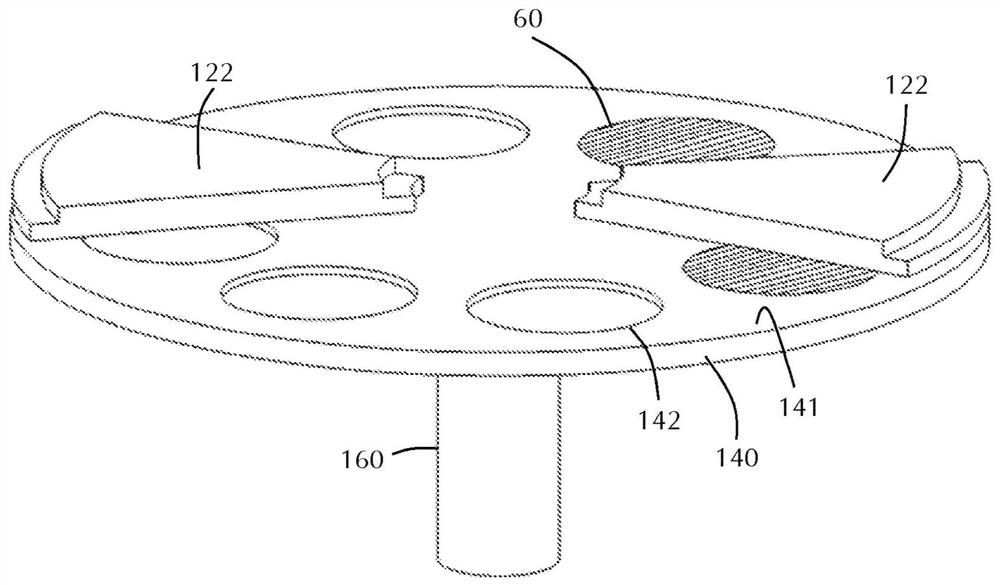

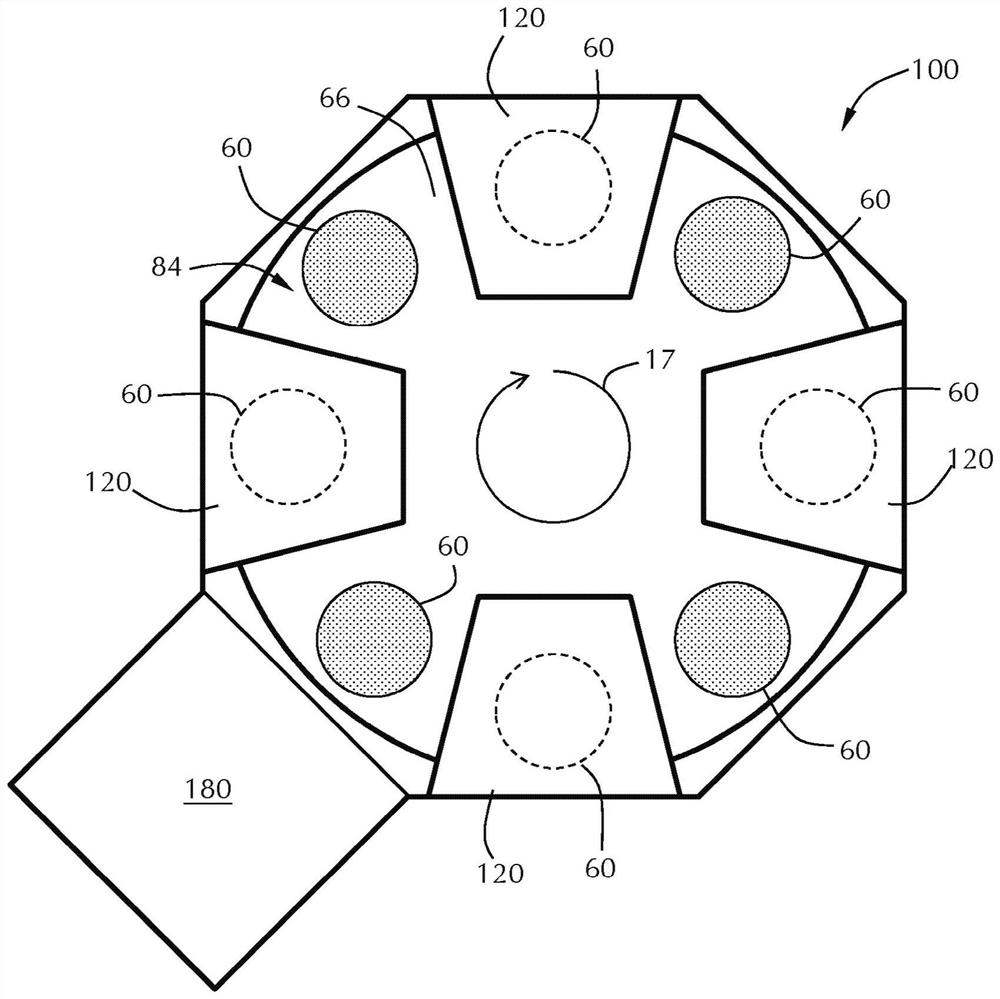

Apparatus for prevention of backside deposition in a spatial ald process chamber

ActiveCN109072433AImproves pressure uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

Susceptor assemblies comprising a susceptor with a support post are described. The susceptor has a body with a top surface and a bottom surface. The top surface has a plurality of recesses therein. The support post is connected to the bottom surface of the susceptor to rotate the susceptor assembly. The support post includes support post vacuum plenum in fluid communication with a susceptor vacuumplenum in the body of the susceptor. The support post also includes a purge gas line extending through the support post to a purge gas plenum in the body of the susceptor.

Owner:APPLIED MATERIALS INC

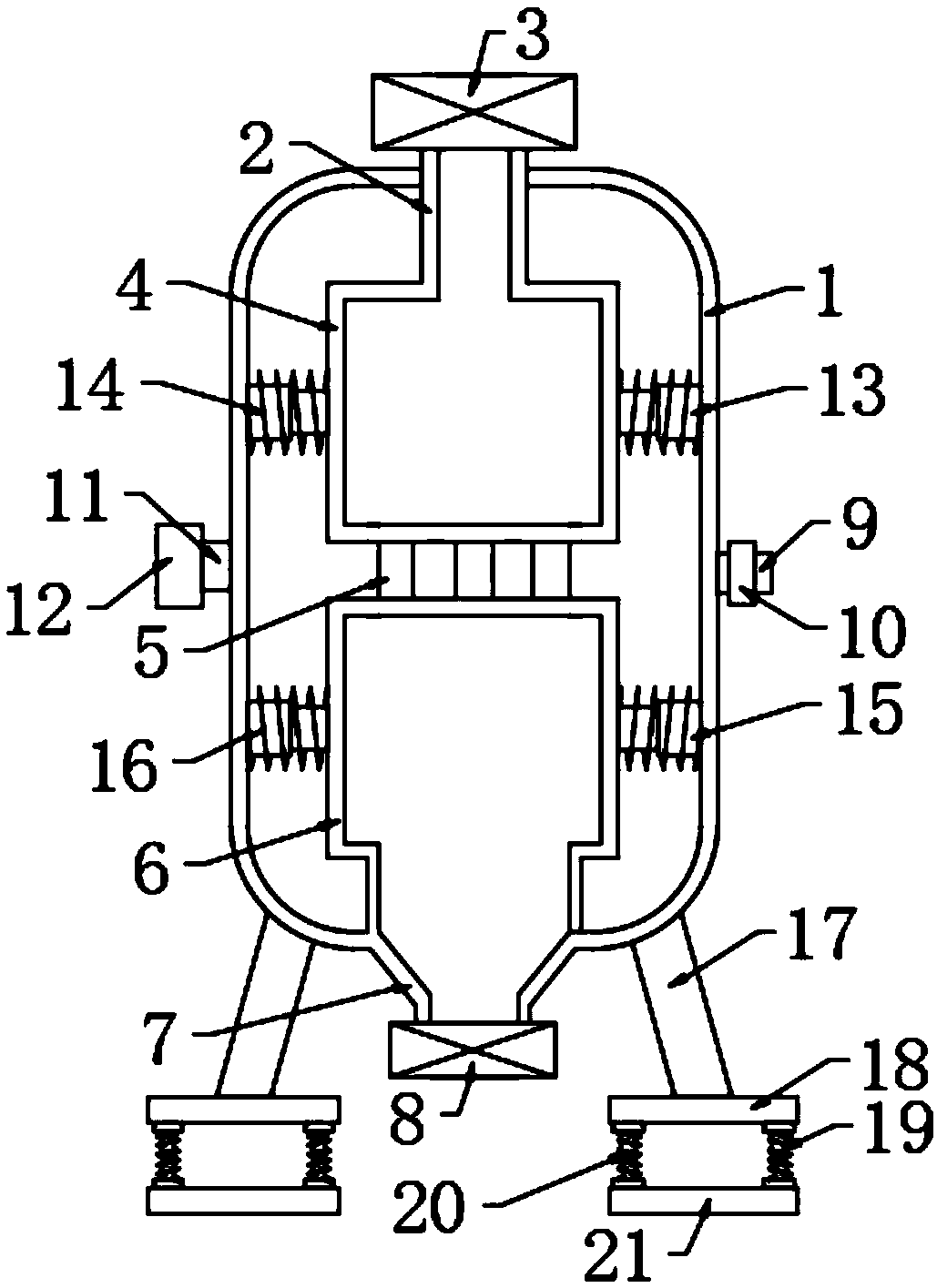

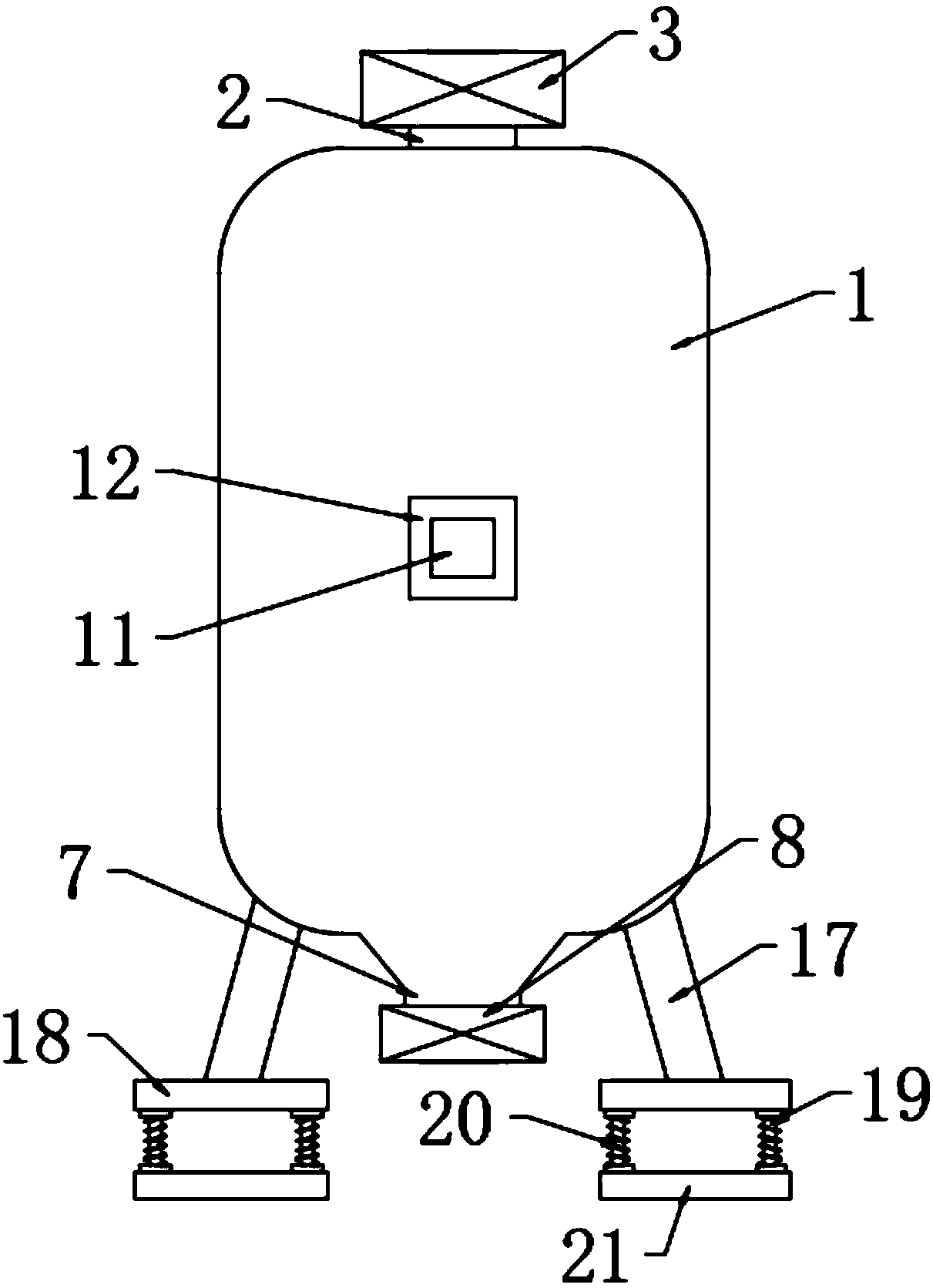

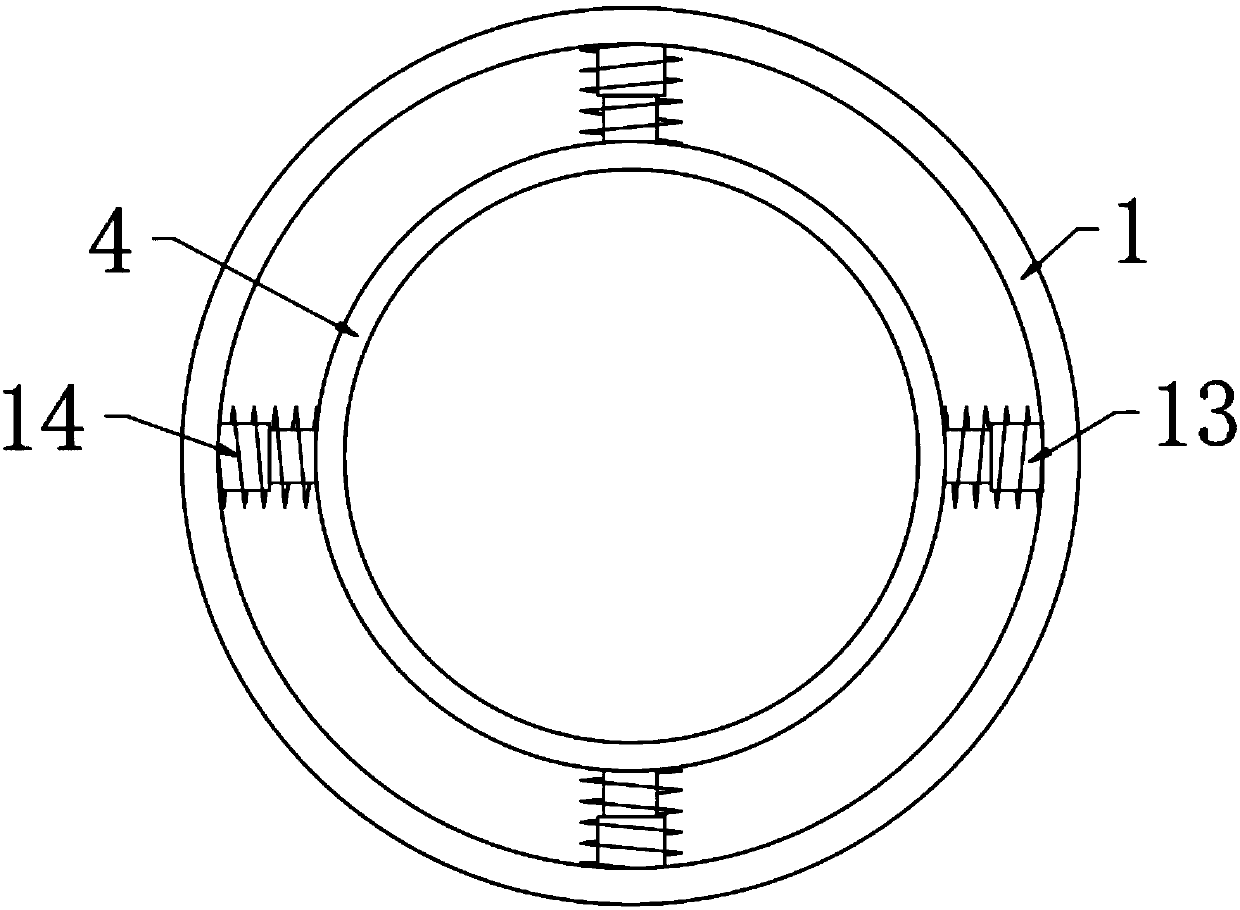

Expansion tank for water supply system of plate type heat exchanger unit

InactiveCN111270731AIncrease contact areaIncrease the uniformity of pressureService pipe systemsWater mainsExpansion tankWater supply network

The invention discloses an expansion tank for a water supply system of a plate type heat exchanger unit. The expansion tank comprises a tank body, wherein a water inlet pipe is fixedly mounted at thetop of the tank body, a first electromagnetic valve is fixed to the end, away from the tank body, of the water inlet pipe, a first skin bag chamber is formed in the position, located below the water inlet pipe, in the tank body, a plurality of water delivery skin bag pipes are uniformly arranged at the bottom of the first skin bag chamber, a second skin bag chamber is fixed to the ends, away fromthe first skin bag chamber, of the water delivery skin bag pipes, and is located in the tank body, a drain pipe is fixed to the bottom of the second skin bag chamber, and a second electromagnetic valve is fixed to the end, away from the tank body, of the drain pipe. By means of the first skin bag chamber and the second skin bag chamber, the contact area of gas and water can be increased, water canbe subjected to relatively uniform pressure bearing during draining, so that pressing uniformity of water in the first skin bag chamber and the second skin bag chamber is increased, and the drainingeffect of the expansion tank is improved.

Owner:乐沃(天津)新能源技术有限公司

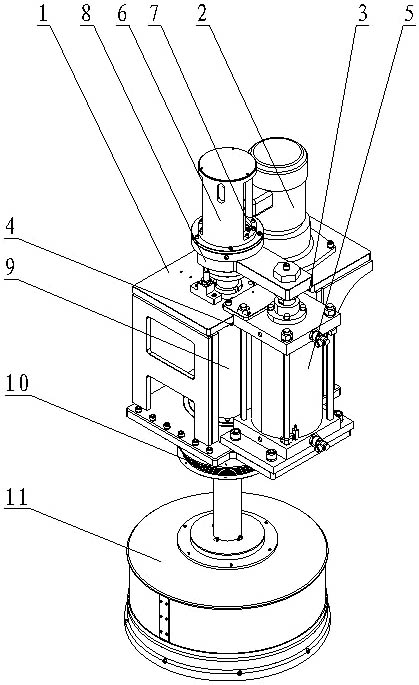

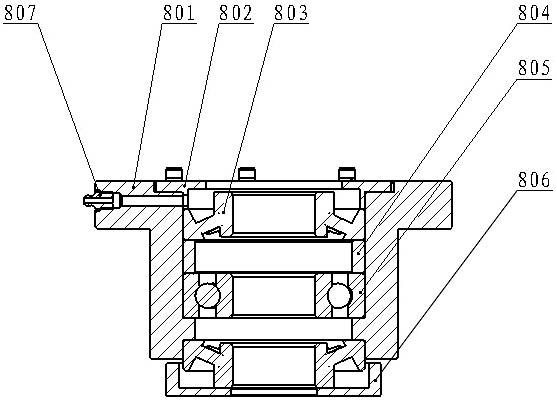

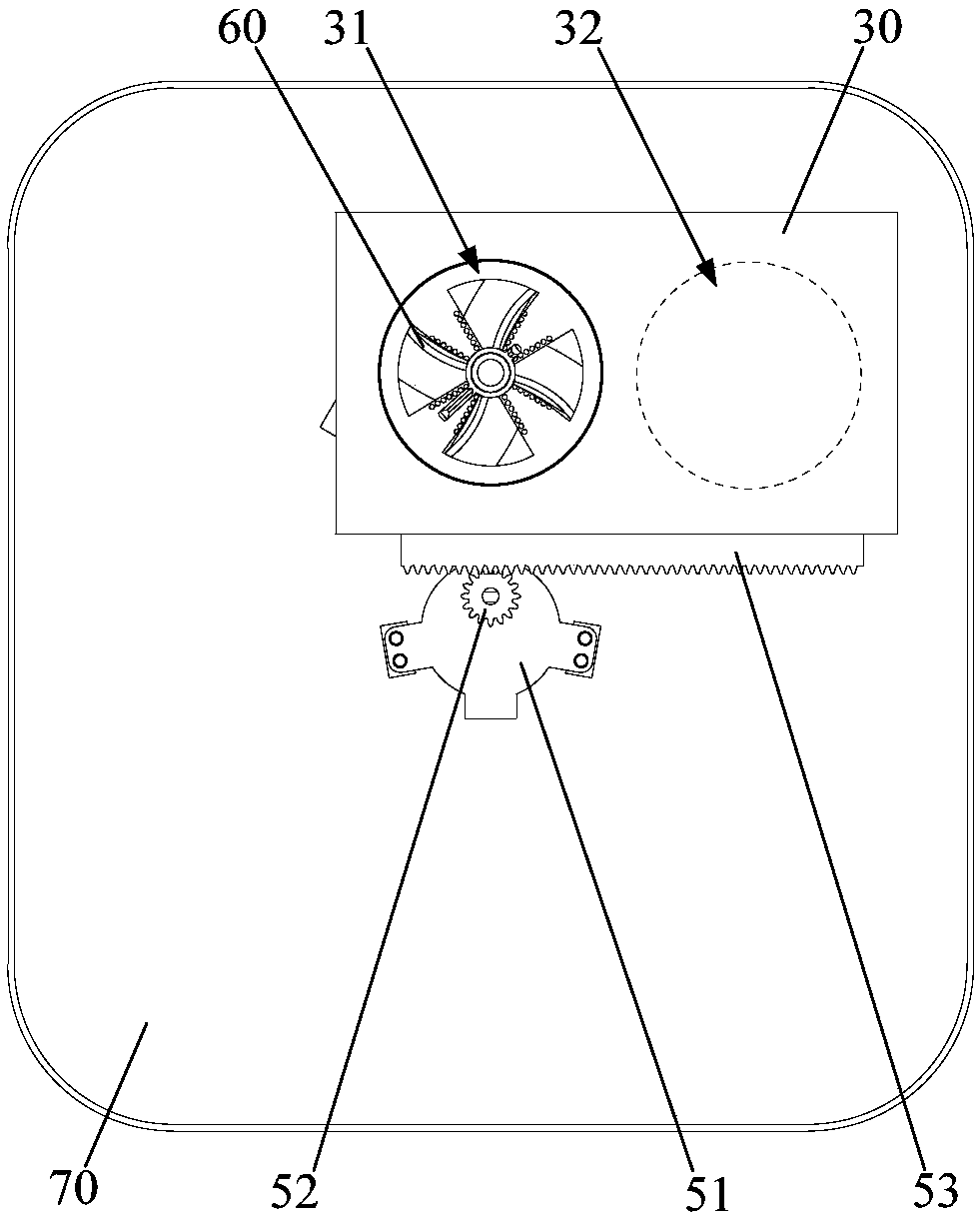

Polishing head structure of polishing machine

PendingCN112139988AImproves pressure uniformityPressurized and stableGrinding headsGear wheelPolishing

The invention discloses a polishing head structure of a polishing machine. The polishing head structure comprises a support, a vertical motor, a driving gear, a driven gear and an air cylinder assembly, wherein the vertical motor is fixed to the support; the driving gear is located in the support and fixedly connected with the output end of the vertical motor; the driven gear is fixedly connectedto an upper disc shaft assembly and is in engaged transmission with the driving gear; a cylinder rod of the air cylinder assembly is connected with a transition shaft sleeve assembly; an anti-rotationsleeve is arranged at the upper end of the transition shaft sleeve assembly; a rotary connector assembly is arranged in the anti-rotation sleeve and connected with the upper disc shaft assembly; theupper disc shaft assembly is rotationally arranged in the support; the lower end of the upper disc shaft assembly is connected with an upper disc assembly; the upper disc assembly is located below thesupport; and an organ cover is arranged between the support and the upper disc assembly and connected to the upper disc shaft assembly. According to the polishing head structure, a balancing weight adjusting and pressurizing manner is adopted for replacing a traditional air cylinder pressurizing manner, pressurizing is more stable, and the pressurizing uniformity of a polishing head is better through a center auxiliary air cylinder pressurizing manner.

Owner:SUZHOU HRT ELECTRONICS EQUIP TECH

Material cleaning device and cooking utensil

PendingCN108065819AGuaranteed accuracyImprove reliabilitySteam cooking vesselsPressure-cookersMechanical engineering

The invention provides a material cleaning device and a cooking utensil. The material cleaning device comprises a cleaning cavity which is provided with a sliding assembly part and a material discharging port, an absorbing component which is arranged on the cleaning cavity and a movable plate which is provided with a sliding part, wherein the sliding part can be slidably connected with the slidingassembly part, the material discharging port is blocked by the movable plate when the movable plate slides to a sealing position, and the movable plate is matched with the absorbing component at thesealing position in a magnetic attraction mode, so that the material discharging port is sealed by the movable plate, the material discharging port is avoided by the movable plate when the movable plate slides to a material discharging position, and therefore the material discharging port is opened to allow discharging of materials in the cleaning cavity. According to the material cleaning device,tightly sealing and covering of the material discharging port can be achieved under the premise that a powering device is not relied on, and accuracy of moving of the movable plate in a long-term useof a product can be ensured to avoid the occurrence of the problem that the material discharging port cannot be tightly sealed and covered by the movable plate.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Apparatus for preventing backside deposition in a space ald processing chamber

ActiveCN109072433BImproves pressure uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringVacuum chamber

Owner:APPLIED MATERIALS INC

High-temperature insulation ceramic tube for synthesizing diamond with large cavity and manufacturing method thereof

InactiveCN102600767BInhibition releaseReduce loss rateUltra-high pressure processesPolyvinyl alcoholSlurry

The invention discloses a high-temperature insulation ceramic tube for synthesizing diamond with a large cavity and a manufacturing method of the high-temperature insulation ceramic tube. The insulation ceramic tube is manufactured by pressing, molding and sintering dry ceramic powder, the ingredients of the dry powder comprises a-aluminum oxide or magnesium oxide with the purity higher than or equal to 99%, soapstone and / or kaolinite (being taken as sintering aids), magnesium stearate (being taken as a releasing agent) and polyvinyl alcohol (being taken as a binder), wherein the proportion of a-aluminum oxide or magnesium oxide, the sintering aids, the binder to magnesium stearate is (75-90):(10-25):(1-2):(1-2). The manufacturing method of the high-temperature insulation ceramic tube comprises the steps of preparing slurry by wet ball-milling process according to the proportion, conducting spray granulation on the slurry to prepare the dry ceramic powder; and pressing, molding and sintering the dry ceramic powder to prepare the high-temperature insulation ceramic tube. The high-temperature ceramic tube replaces dolomite to be used for the production of the diamond synthesized by a cubic press with the diameter of a cavity being more than or equal to 40mm, can avoid the gas release in the diamond synthesizing process so as to reduce the hammer explosion risk, and effectively reduces the loss rate of a tungsten carbide anvil.

Owner:常熟市怡华金刚石有限公司 +1

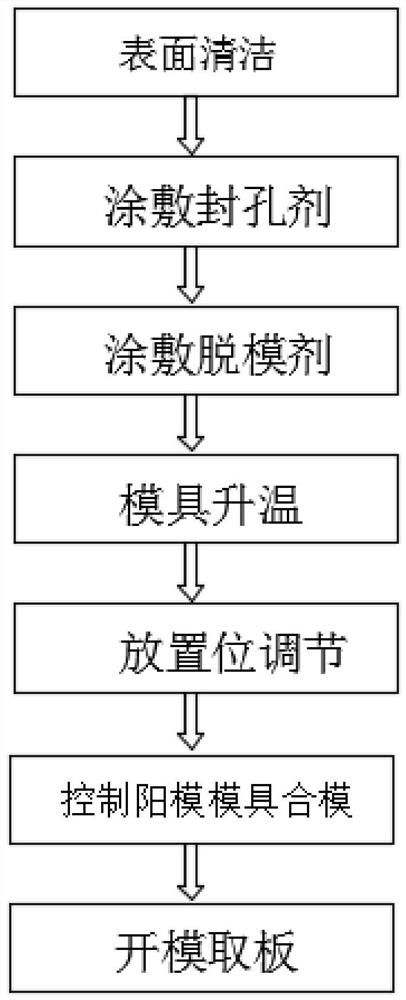

Processing method of flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate

PendingCN114211772AGood and effective adhesionGuaranteed absorptionFlat articlesFiberCompression molding

The invention discloses a flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate and a processing method thereof. Comprising the following contents: (1) the laying mode of the flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate, (2) the processing technological parameters of the flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate, (3) the processing method of the flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate, (4) the mold surface structure design of the flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate, and (5) the mold surface structure design of the flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate. The paving mode of the flat plate type thermoplastic PEKK carbon fiber one-way belt laminated plate in the step 1 is as follows: the thickness of a thermoplastic PEKK carbon fiber one-way belt is 0.1-0.2 mm. And the laying direction of the 20 layers of materials is [45 / -45 / 0 / 0 / 90 / 0 / 0 / 45 / -45 / 0] S. All layers of thermoplastic PEKK carbon fiber one-way belts are prevented from sliding during compression molding in a spot welding mode or a mode that the peripheries of the thermoplastic PEKK carbon fiber one-way belts are fixed through high-temperature adhesive tapes, the effect on the angle between fibers is avoided, and it is guaranteed that a hole sealing agent and a release agent can be better and effectively attached to the surface of a mold through control over the construction temperature of the hole sealing agent and the release agent; and the effects of hole sealing and demolding are achieved.

Owner:浙江抟原复合材料有限公司

A bonding device for curved display panels

ActiveCN110264883BAvoid display effectsLarge fitting pressureIdentification meansBlack spotDark spot

The embodiment of the present invention provides a curved display panel bonding device, which solves the technical problem of uneven distribution of curved surface bonding pressure, resulting in black spots on the display body or other poor display. The curved surface bonding device provided by the embodiment of the present invention adopts bonding rollers and at least one layer of supporting rollers to roll the display substrate and the curved surface cover to achieve bonding. When the curved surface cover is bonded to the display substrate, the supporting rollers The set and fitting rollers can carry greater fitting pressure without bending, thereby increasing the fitting pressure during the fitting process, so even if the diameter of the fitting roller is small, it can also ensure the tightness during the fitting process Fitting pressure is high. It can not only ensure a large bonding pressure during the bonding process, but also ensure that the diameter of the bonding roller is small, which improves the uniformity of pressure during the bonding process and avoids the display caused by uneven distribution of bonding pressure There are black spots or other poor display problems on the screen.

Owner:YUNGU GUAN TECH CO LTD

Flush valve for public washroom

PendingCN113700887AExtended service lifeImproves pressure uniformityWater resource protectionPlug valvesRatchetDrive shaft

The invention relates to the technical field of water valves, and discloses a flush valve for a public washroom. A pull rod is fixedly connected to the outer side of a gear shaft, a rack in engaged transmission with the gear shaft is movably connected with a sleeve hole in a sleeved manner, a notch is formed in the middle of the rack, an end of a driving shaft is of a ratchet wheel structure and movably connected with a one-way gear in a sleeved manner, power gears are fixedly connected to two ends of a valve element, axial sliding grooves are uniformly formed in the outer ring of the valve element, radial sliding grooves are formed in the positions, located at two ends of the axial sliding grooves, of the valve element, sliding plates are symmetrically and movably connected to two ends of the axial sliding grooves in a sleeved mode, a baffle is movably connected to the top of a hydraulic cavity in a sleeved mode, a rotating wheel in engaged transmission with the power gears is movably arranged in a transmission cavity, and top blocks are uniformly arranged at the outer ring of the front surface of the rotating wheel at intervals. Through the arrangement of the valve element structure, the cooperation with the transmission part, the baffle and other structures, and the arrangement of the rack with the notch, the overall service lifetime of a valve body is prolonged, and water is saved.

Owner:丁海燕

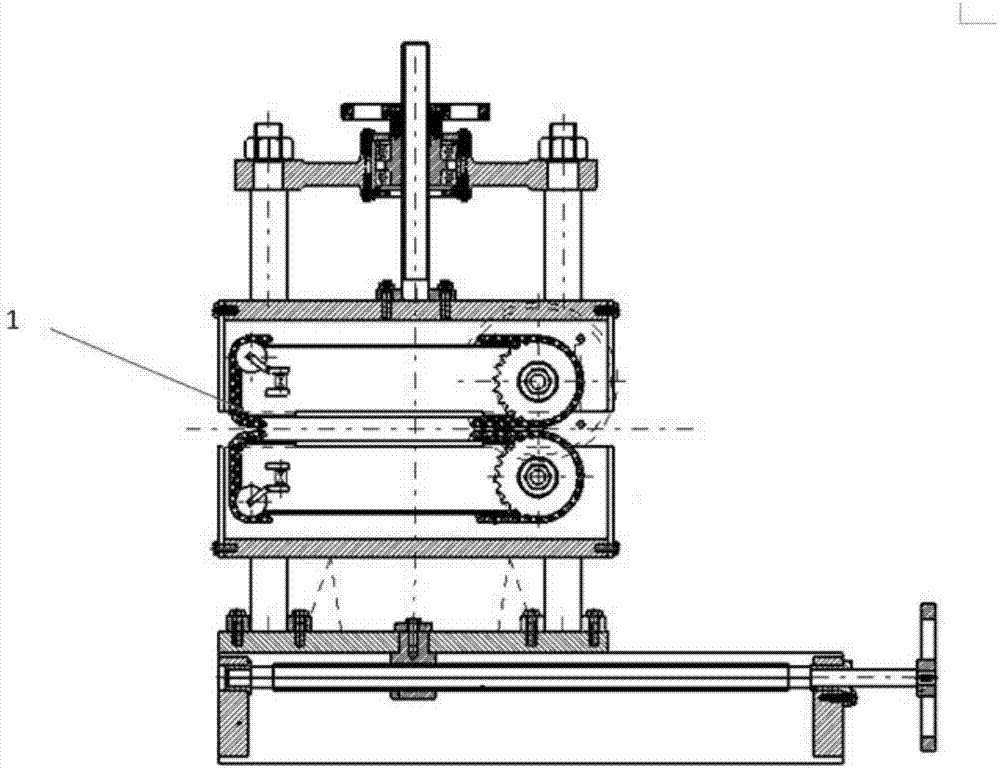

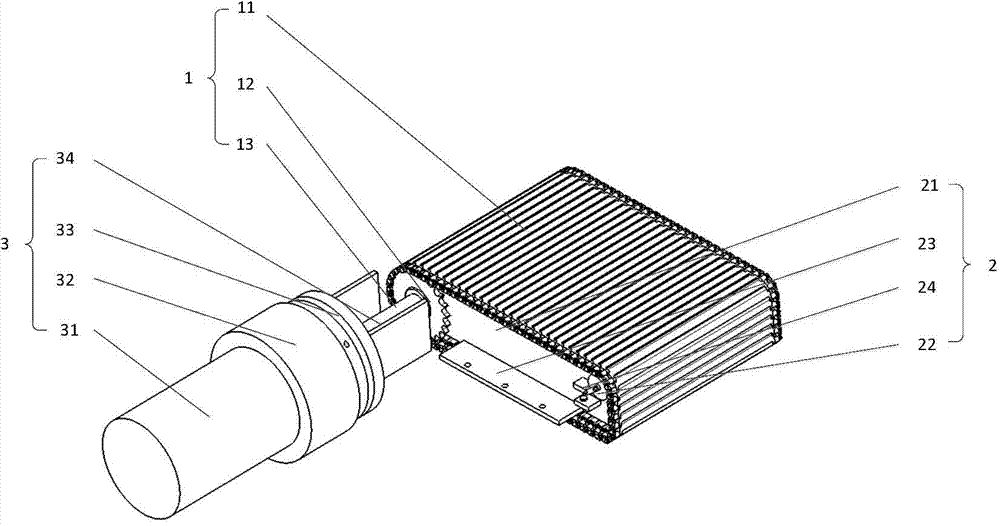

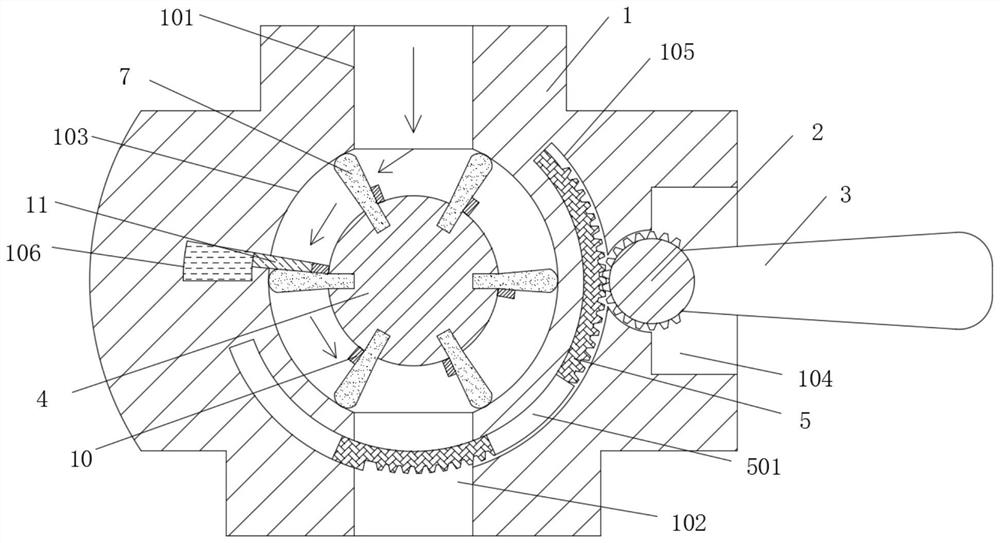

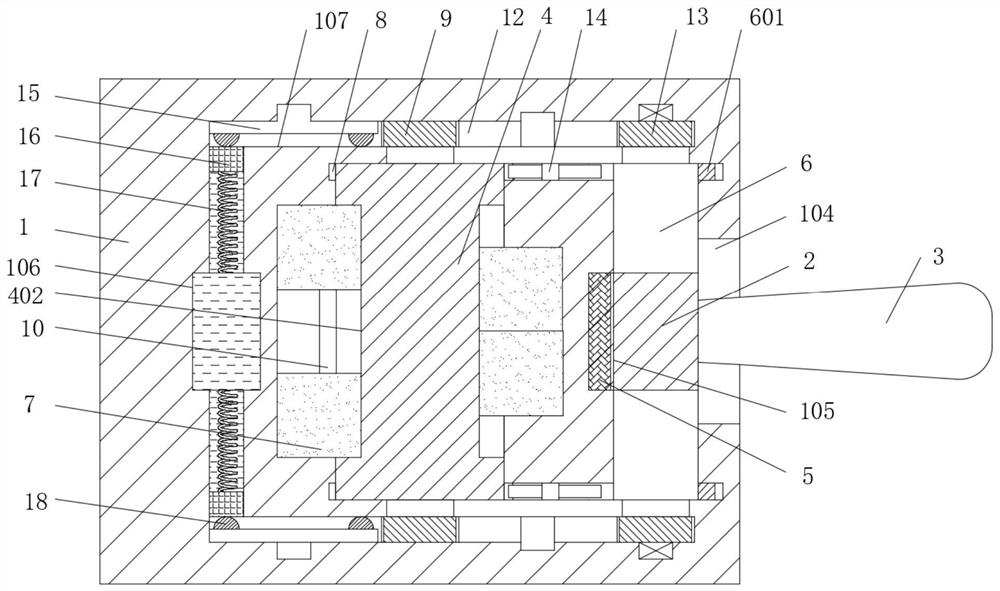

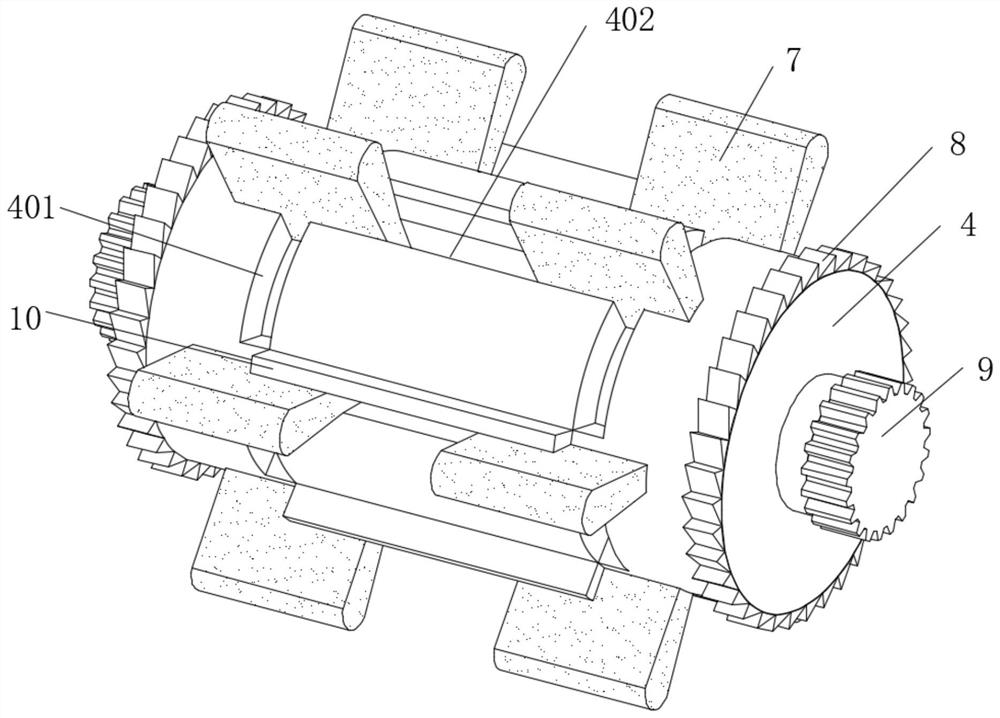

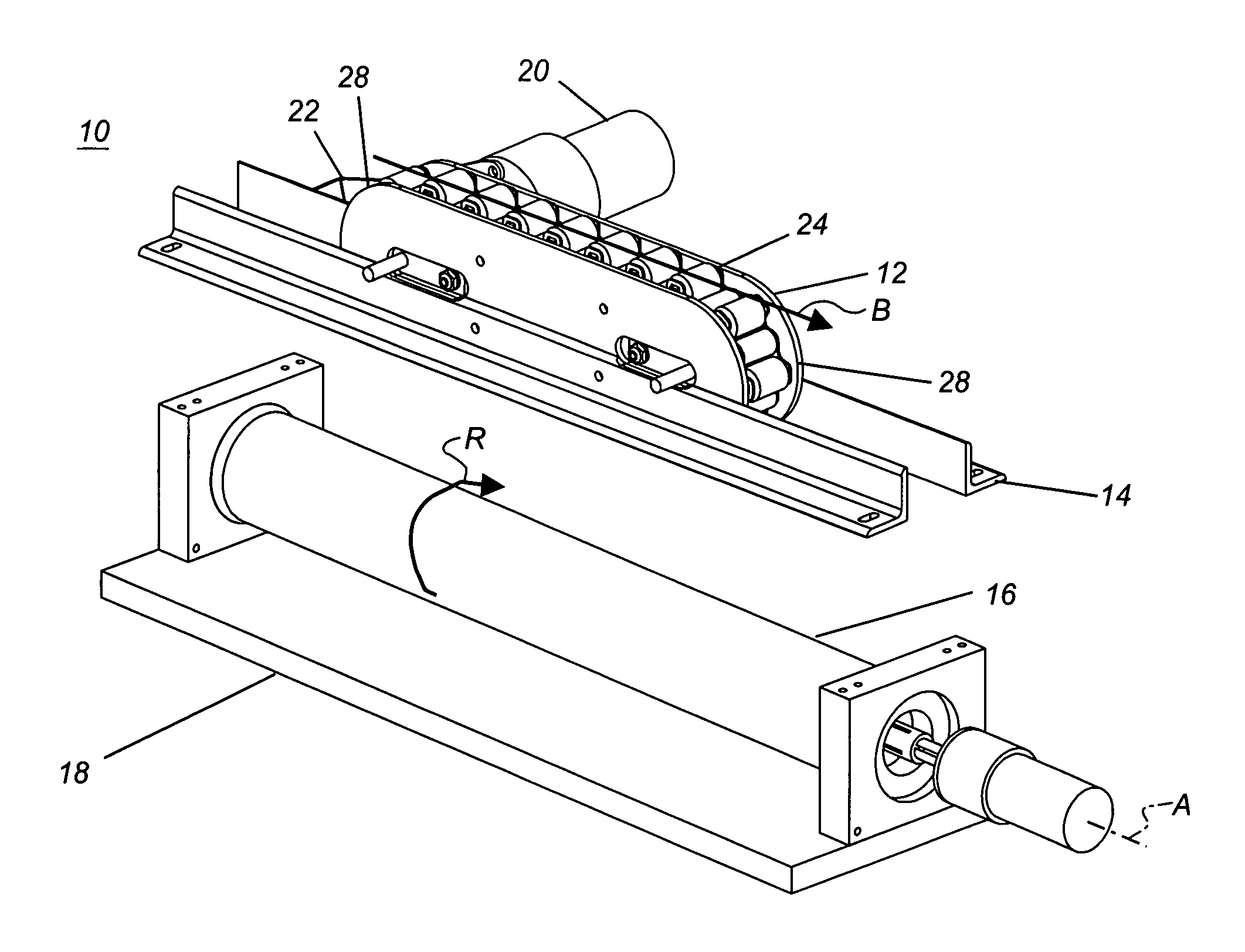

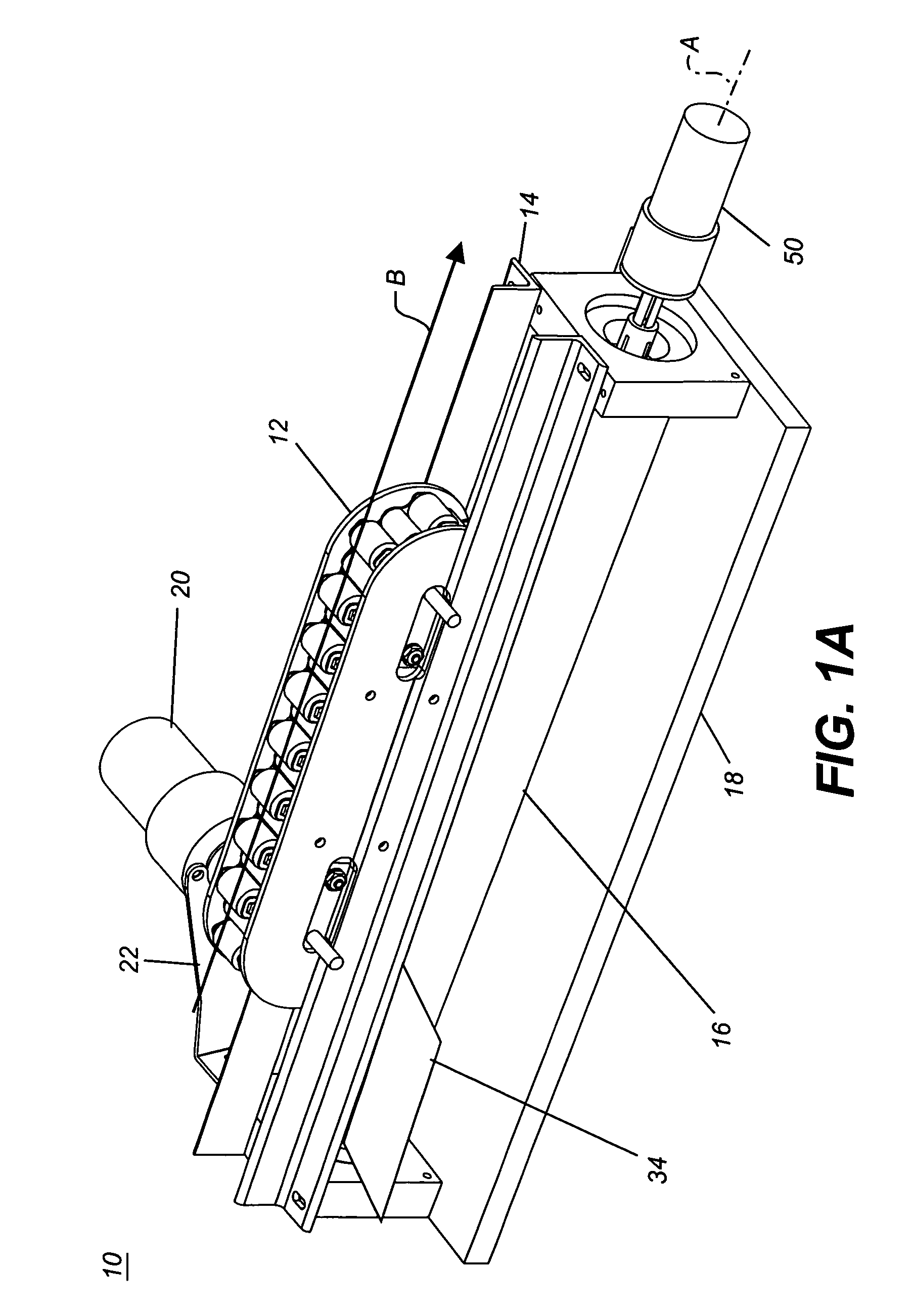

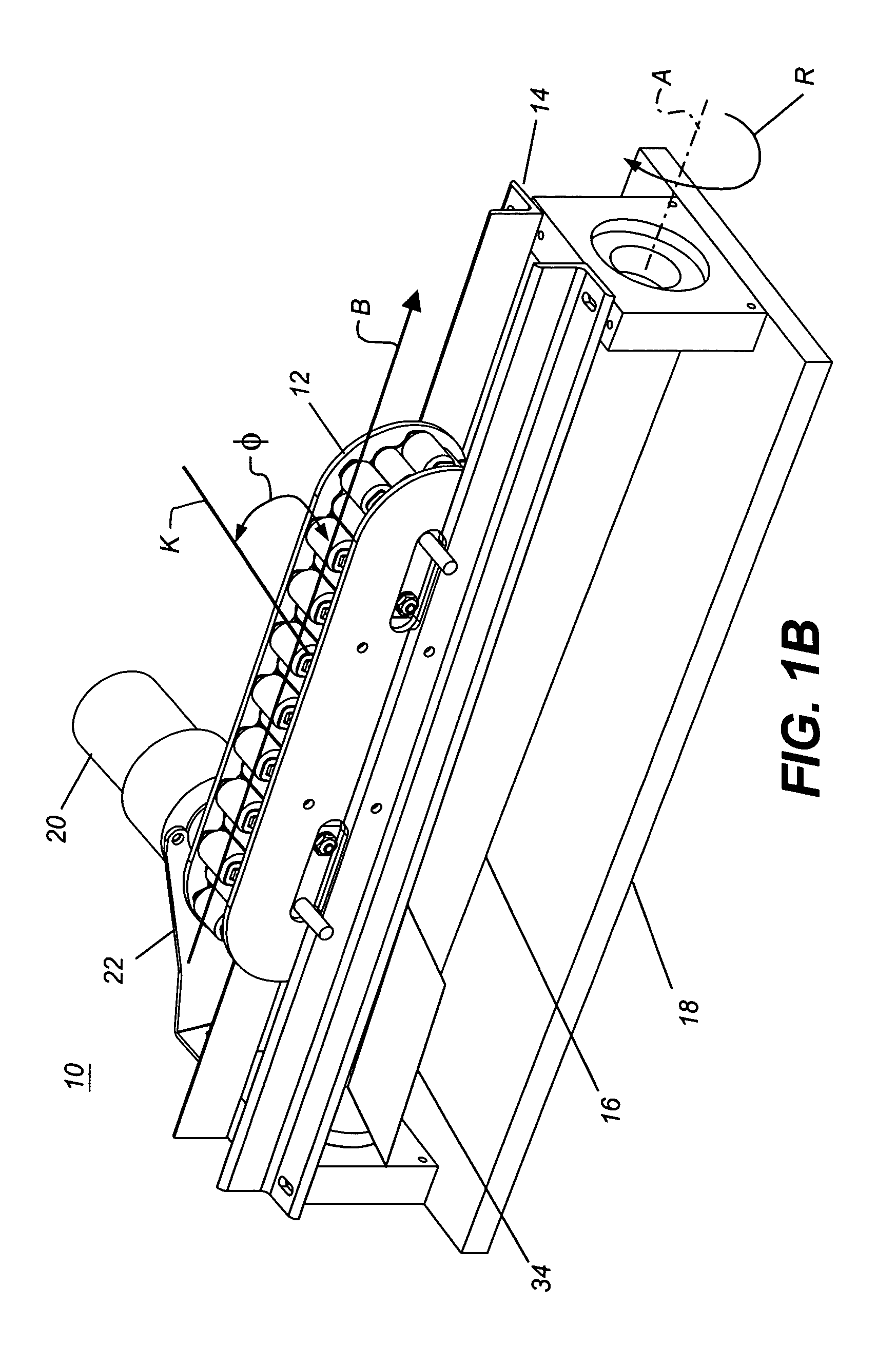

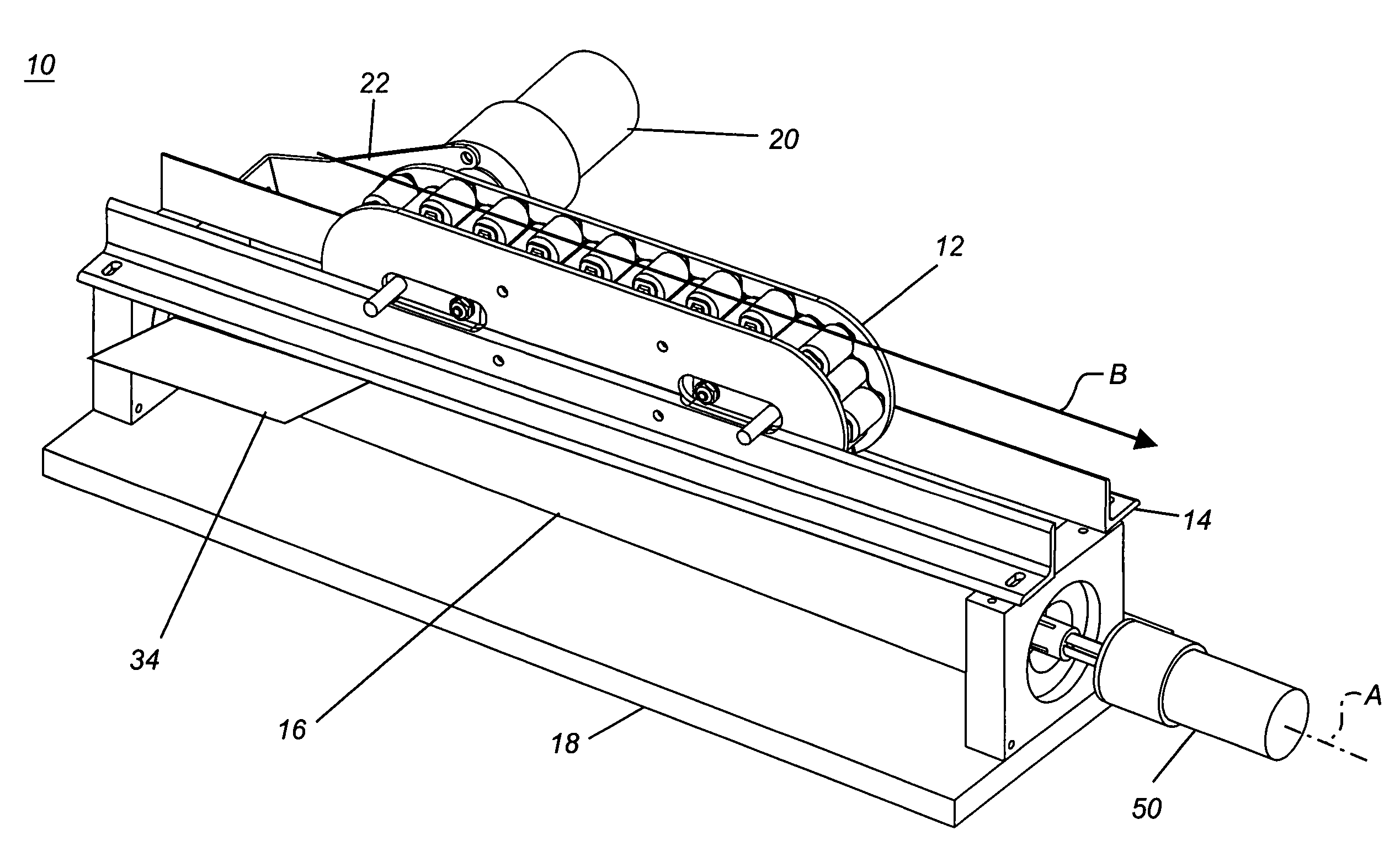

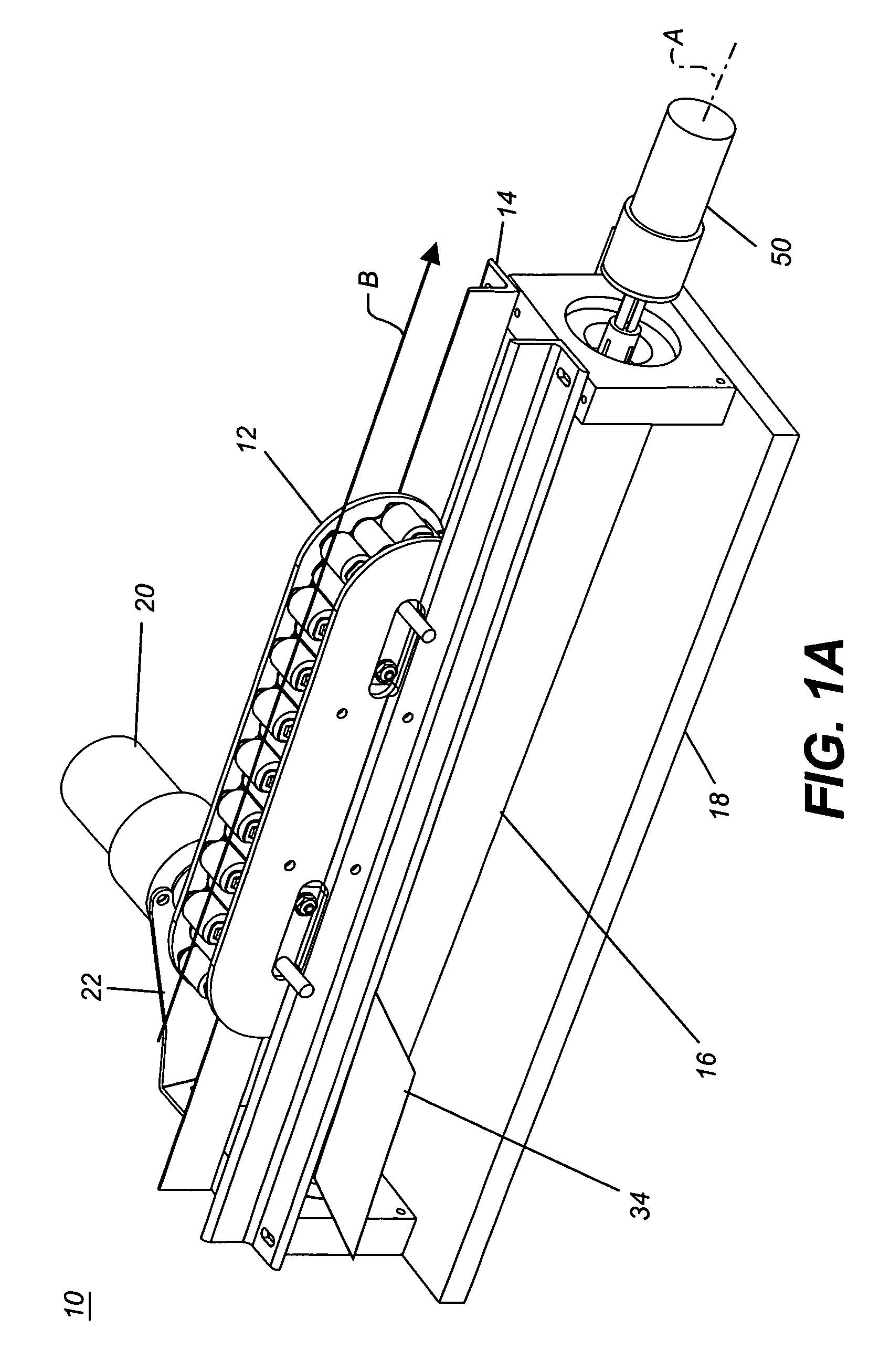

Roller chain for applying pressure

InactiveUS6989068B2Suitable for processingSmall sizeMechanical working/deformationWelding/cutting auxillary devicesClosed loopRoller chain

An apparatus (10) applies pressure against a platen (16) using a linked series of contact members arranged in a closed loop. A drive apparatus rotates the loop about a support mechanism, thereby imparting movement to the linked series of contact members. The support mechanism is disposed to force a plurality of the moving contact members simultaneously into compressive contact against the platen (16).

Owner:EASTMAN KODAK CO

Roller chain for applying pressure

InactiveUS20050236095A1Suitable for processingImproves pressure uniformityMechanical working/deformationWelding/cutting auxillary devicesClosed loopRoller chain

An apparatus (10) applies pressure against a platen (16) using a linked series of contact members arranged in a closed loop. A drive apparatus rotates the loop about a support mechanism, thereby imparting movement to the linked series of contact members. The support mechanism is disposed to force a plurality of the moving contact members simultaneously into compressive contact against the platen (16).

Owner:EASTMAN KODAK CO

Novel silica gel hot-pressing buffer material for module lamination and preparation method thereof

PendingCN114276685AImprove stress resistanceIncrease elasticitySynthetic resin layered productsLaminationPolyesterTear resistance

The invention provides a novel silica gel hot-pressing buffer material for module pressing and a preparation method, and belongs to the technical field of hot-pressing buffer materials, the novel silica gel hot-pressing buffer material for module pressing is formed by pressing a modified silica gel polymer added with a nanoscale heat conduction material and a thermoplastic polyester bottom film; the preparation method comprises the following steps: S1, mixing to obtain silica gel base rubber; S2, mixing to obtain heat-conducting base rubber; S3, preserving heat to obtain a modified silica gel material; S4, coloring the modified silica gel material; the hot-pressing buffer material has the characteristics of extremely high compression resistance, compression uniformity, rebound capability, recovery capability, buffer performance, tear resistance, high temperature resistance, high-speed heat transfer performance, heat stability, no powder on the surface, no oil leakage, no damage to hot-pressing products and the like; and the production efficiency of the bonding process of the liquid crystal module and the quality of the liquid crystal module can be indirectly improved.

Owner:镇江中垒新材料科技有限公司

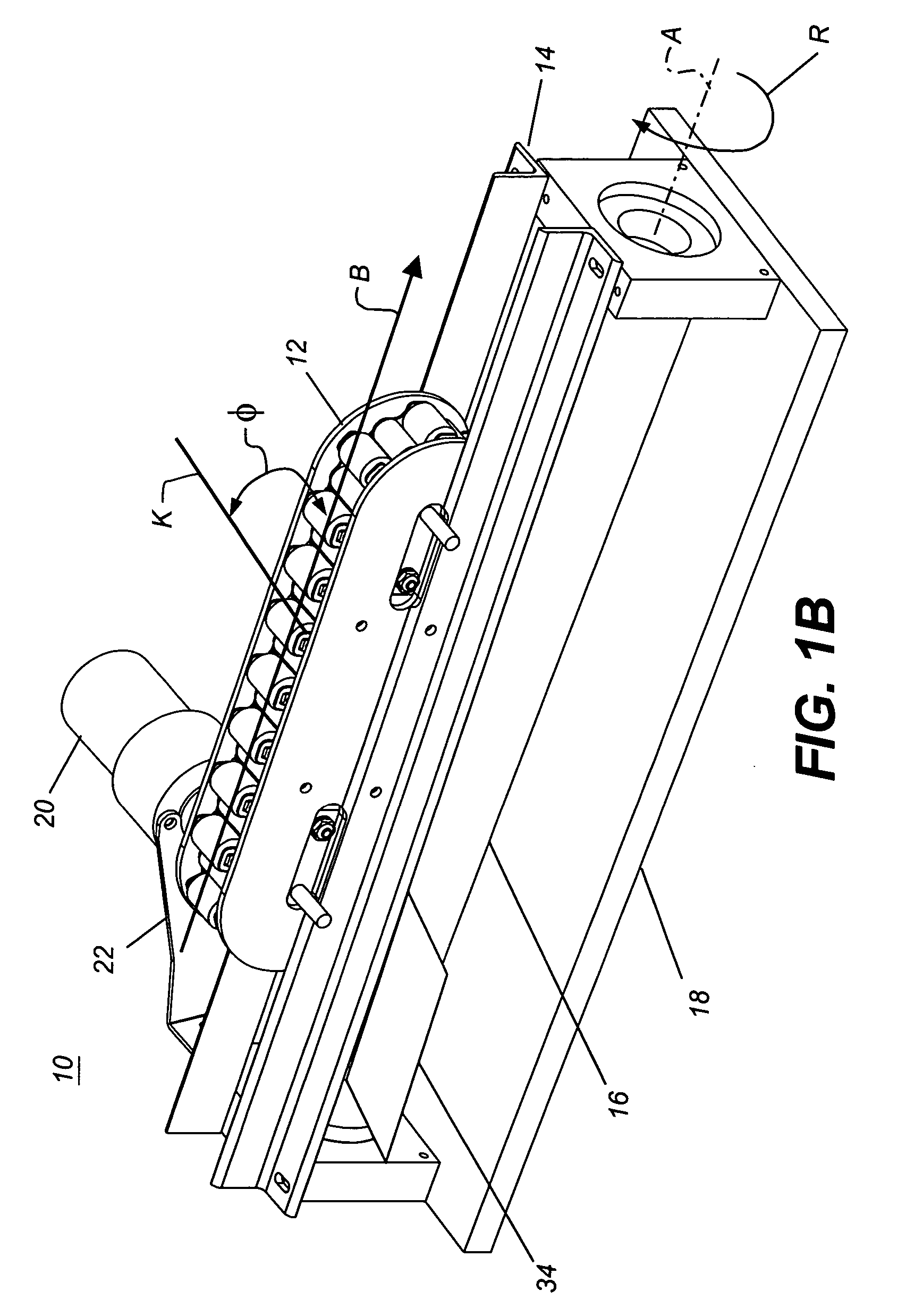

Bolt fastening device and assembly system

PendingCN113245829AAchieving torque resistanceReduce labor intensityMetal working apparatusControl engineeringBolt connection

The invention discloses a bolt fastening device and an assembly system. The bolt fastening device comprises a stand column; a first anti-torque arm rotatably connected to the stand column; a first angle encoder used for collecting first rotation angle information of the first anti-torque arm; a second anti-torque arm rotatably connected to the end, away from the stand column, of the first anti-torque arm; a second angle encoder used for collecting second rotation angle information of the second anti-torque arm; a torque wrench arranged on the second anti-torque arm; and a central guide controller which can receive and store the preset fastening sequence and the preset fastening position in advance. By means of the bolt fastening device of the invention, the actual fastening position can be consistent with the preset fastening position, the actual fastening sequence is consistent with the preset fastening sequence, the error rate of the bolt fastening sequence and the bolt fastening position is reduced, the pressure uniformity between parts is improved, the rigidity of a bolt connection assembly is enhanced, and the service life of the bolt connection assembly is prolonged.

Owner:CSR CHENGDU

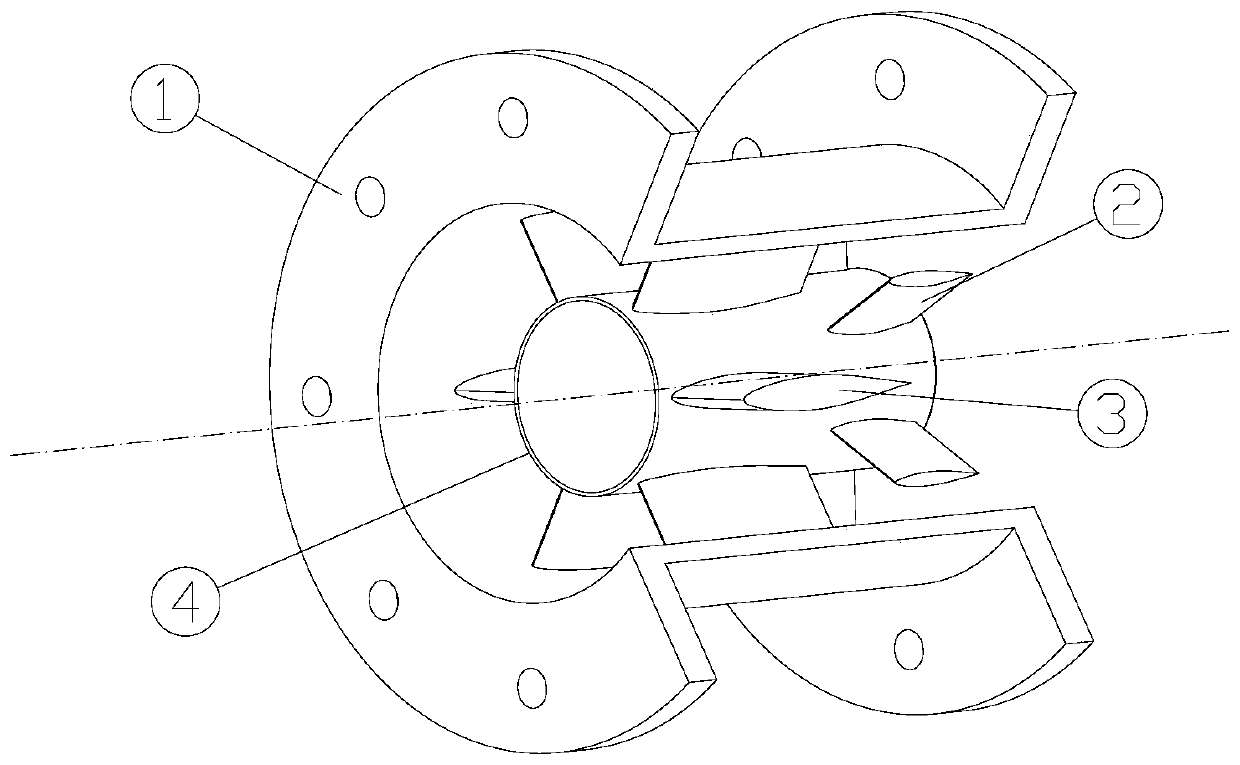

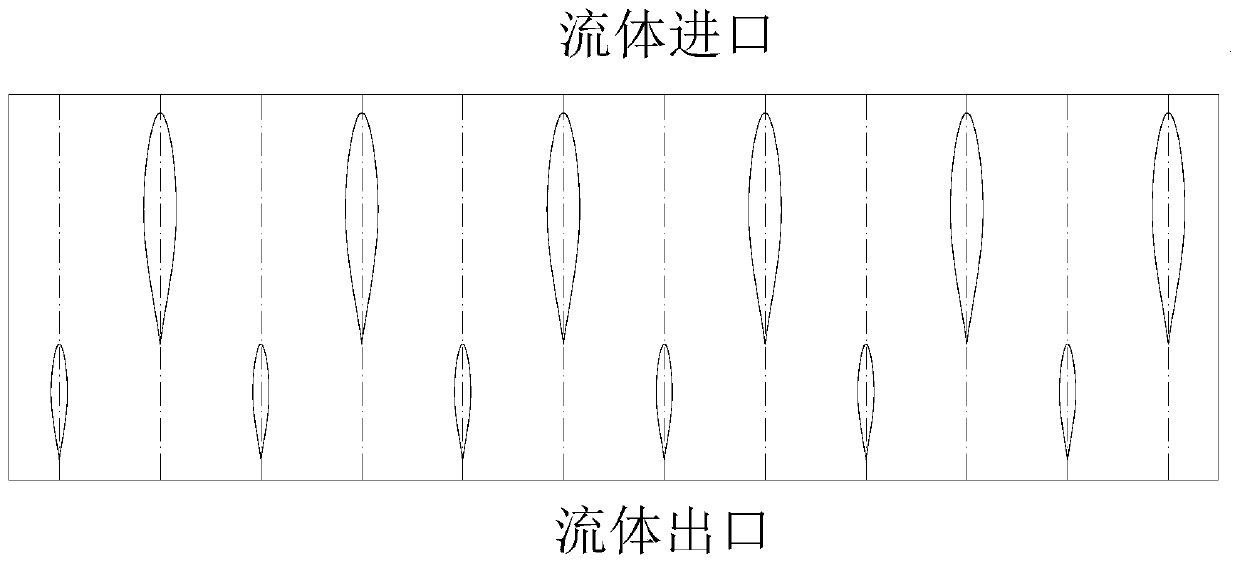

A flow field uniform device designed with large and small blades

The invention relates to a flow field uniformizing device adopting design of large blades and small blades and belongs to the field of control of flow fields of pipe filling pipelines. The flow field uniformizing device comprises a casing pipe, the large blades, the small blades and a lining pipe, wherein the large blades and the small blades are distributed and fixed in the circumferential direction between the casing pipe and the lining pipe, a vortex system can be cut and scattered on multiple rows of front and rear blades through reasonable blade distribution and blade shape design, and large vortexes are changed into small vortexes; a fluid close to the central position of a flow channel flows through the lining pipe, the flow regulation effect of the flow uniformizing device in the center position is enhanced through a flow regulation function of a longer cylindrical flow channel of the lining pipe, and finally, the purpose of flow field uniformizing is achieved. The flow field uniformizing device is compact in structure, requires small mounting space and is suitable for being mounted at an inlet end of a pump inlet with poorer flow inlet state and a downstream position of a valve.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

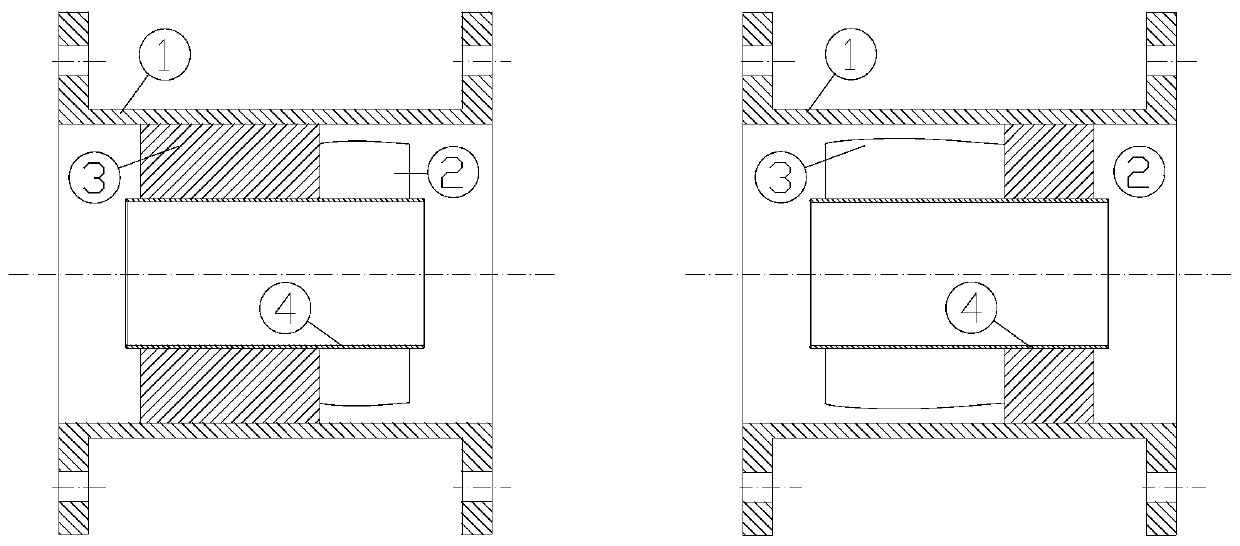

A molding die

The invention discloses a mold for compression molding, which comprises a first mold and a second mold for enclosing a molding cavity, a parting surface is formed between the two, and a first sealing part and a second sealing part are arranged on the parting surface The first mold or the second mold is provided with an exhaust section, one end of the exhaust section communicates with the parting surface and is located between the first sealing section and the second sealing section, and the other end of the exhaust section is connected to the outside atmosphere. When the mold is in the first mold opening stage, the first sealing part fails, and at this time the position of the second sealing part is still in a sealed state, and the gas in the cavity is discharged to the outside atmosphere through the first sealing part and the exhaust part , the exhaust part guides the high-pressure gas in the cavity to realize slow pressure relief, thereby avoiding the loss of mold opening pressure caused by the gas in the cavity being ejected from the parting surface in a large area at once when the mold is opened Imbalance, popping, seal damage, material ejection to the outside of the mold, etc. help to improve the product molding rate.

Owner:QINGDAO HISENSE MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com