A bonding device for curved display panels

A technology for surface display and bonding device, which is applied in the direction of identification device, instrument, etc., can solve the problems of poor, uneven surface bonding pressure distribution, black spot display on the display screen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

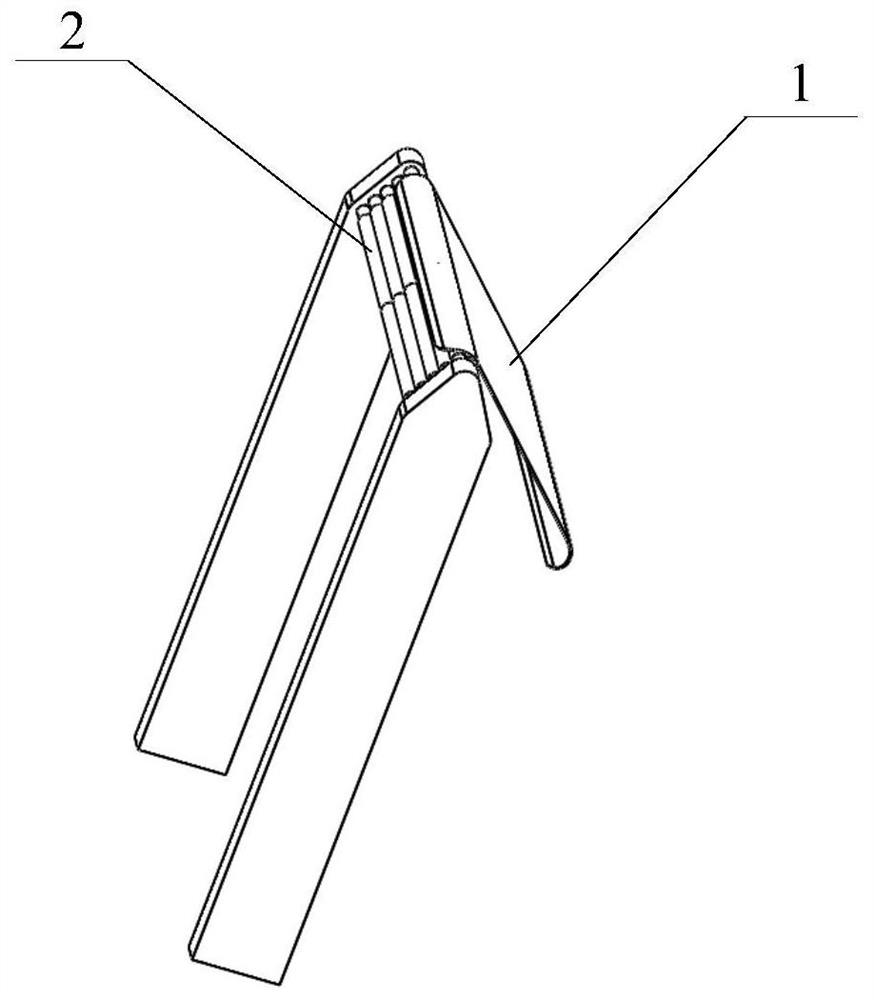

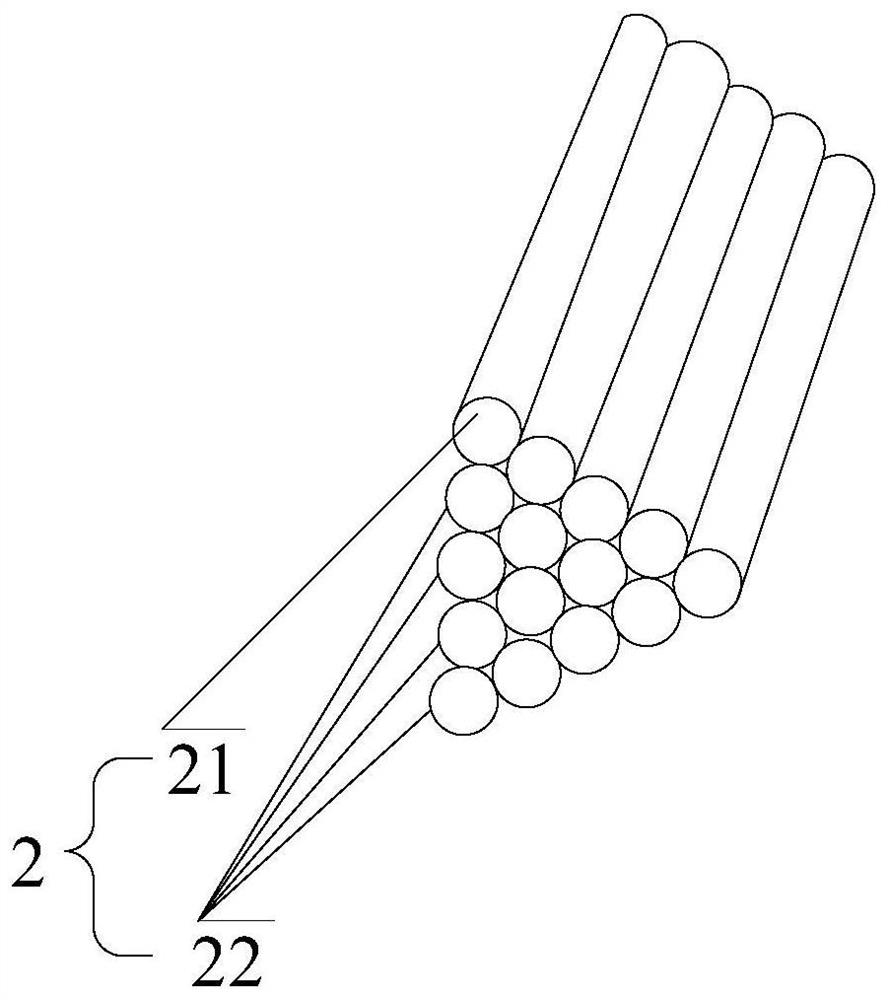

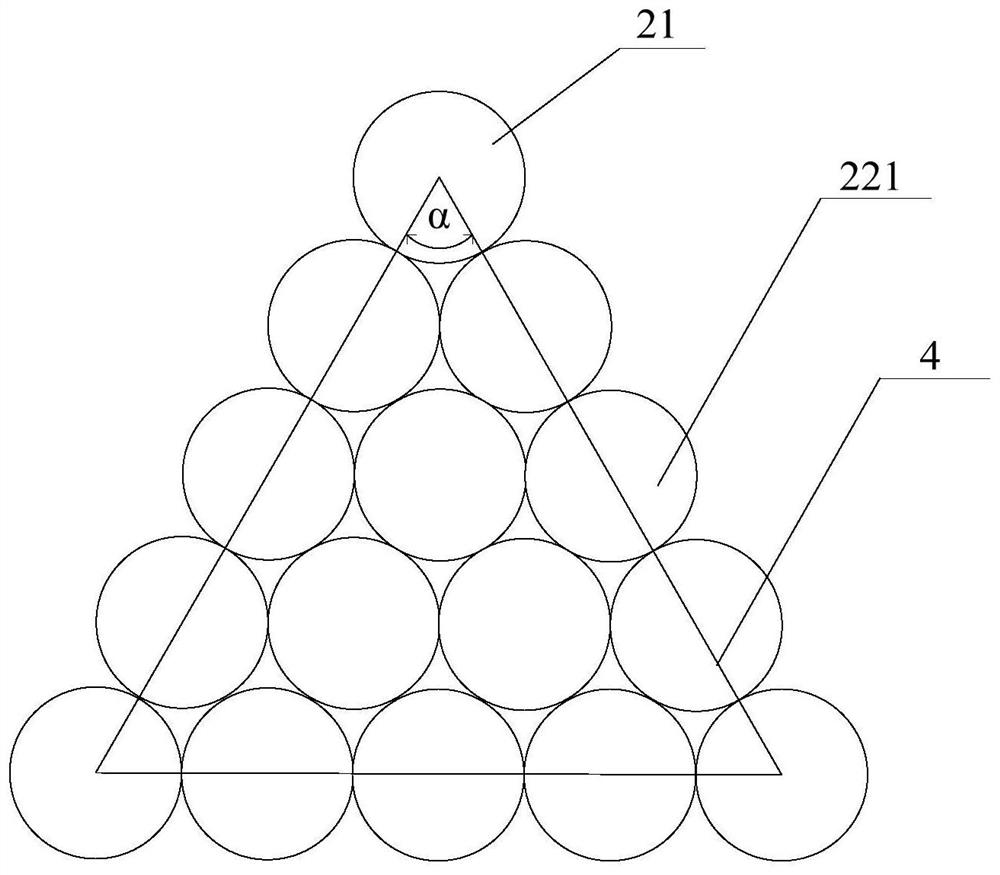

[0020] As mentioned in the background art, in the prior art, the pressure distribution of curved surfaces is uneven, which leads to black spots on the display screen or other technical problems of poor display. The inventor found that the reason for this problem is that when the rollers are used in the lamination process, due to the existence of the curved angles, the compression and lamination of the rollers at the curved corners is not easy to achieve, that is, if the curved corners are bonded, it is necessary to The smaller the diameter of the roller, the better, but if the curved corner is pressed tightly, the greater the pressure that the roller exerts on the fitting place, the better, but the greater the pressure, the larger the diameter of the roller is required, so for the fitting of the curved corner, Both lamination and compression are required, and the diameters of the rollers that need to be used are contradictory. Therefore, in the prior art, it is impossible to sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com