Liquid crystal display panel and manufacturing method thereof

A technology of liquid crystal display panels and array substrates, which is applied to the photographic process of patterned surfaces, static indicators, optics, etc., can solve the problems of uniform cell thickness and poor display, achieve fast recovery speed, and avoid cell thickness uniformity Problems and poor display problems, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

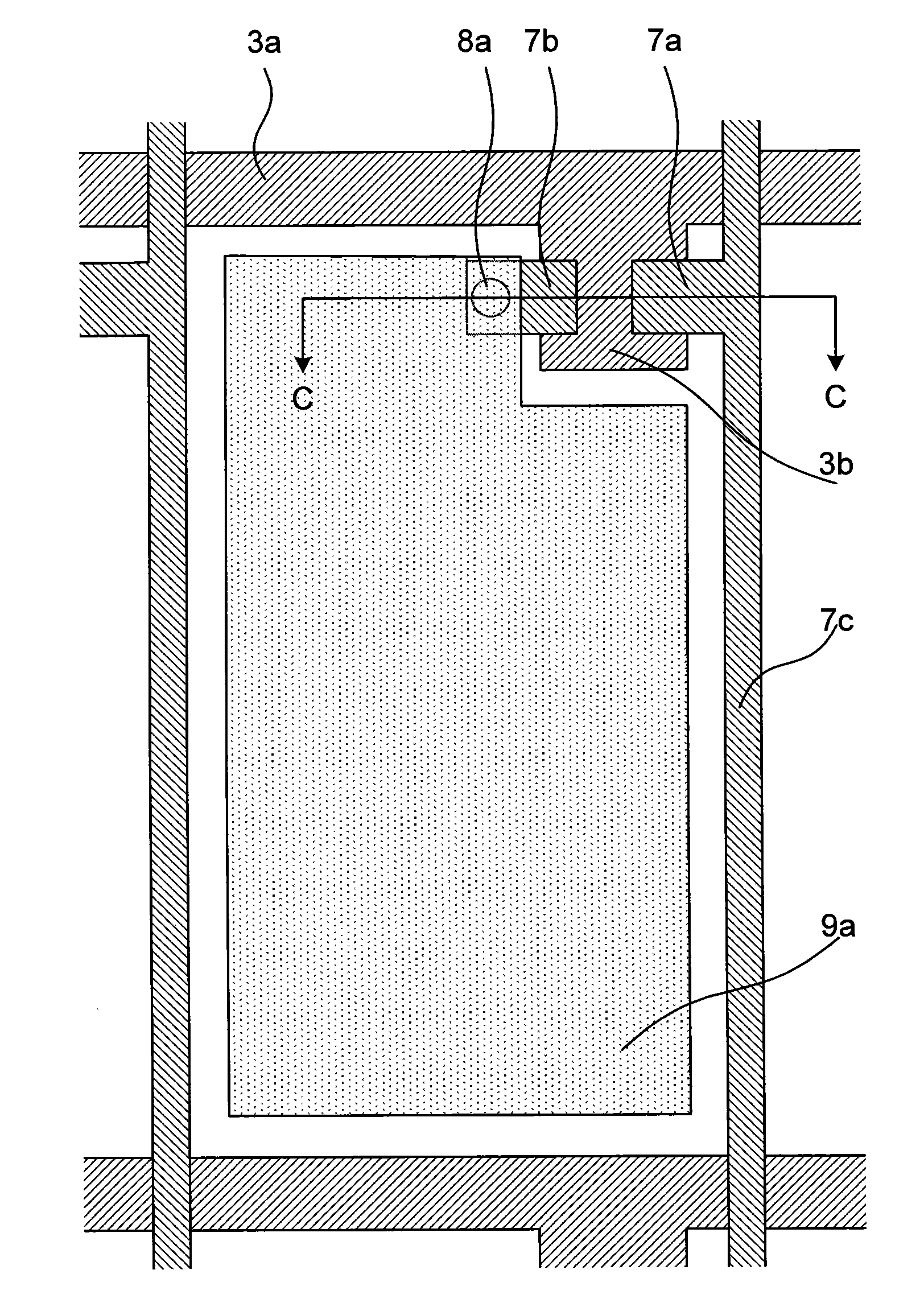

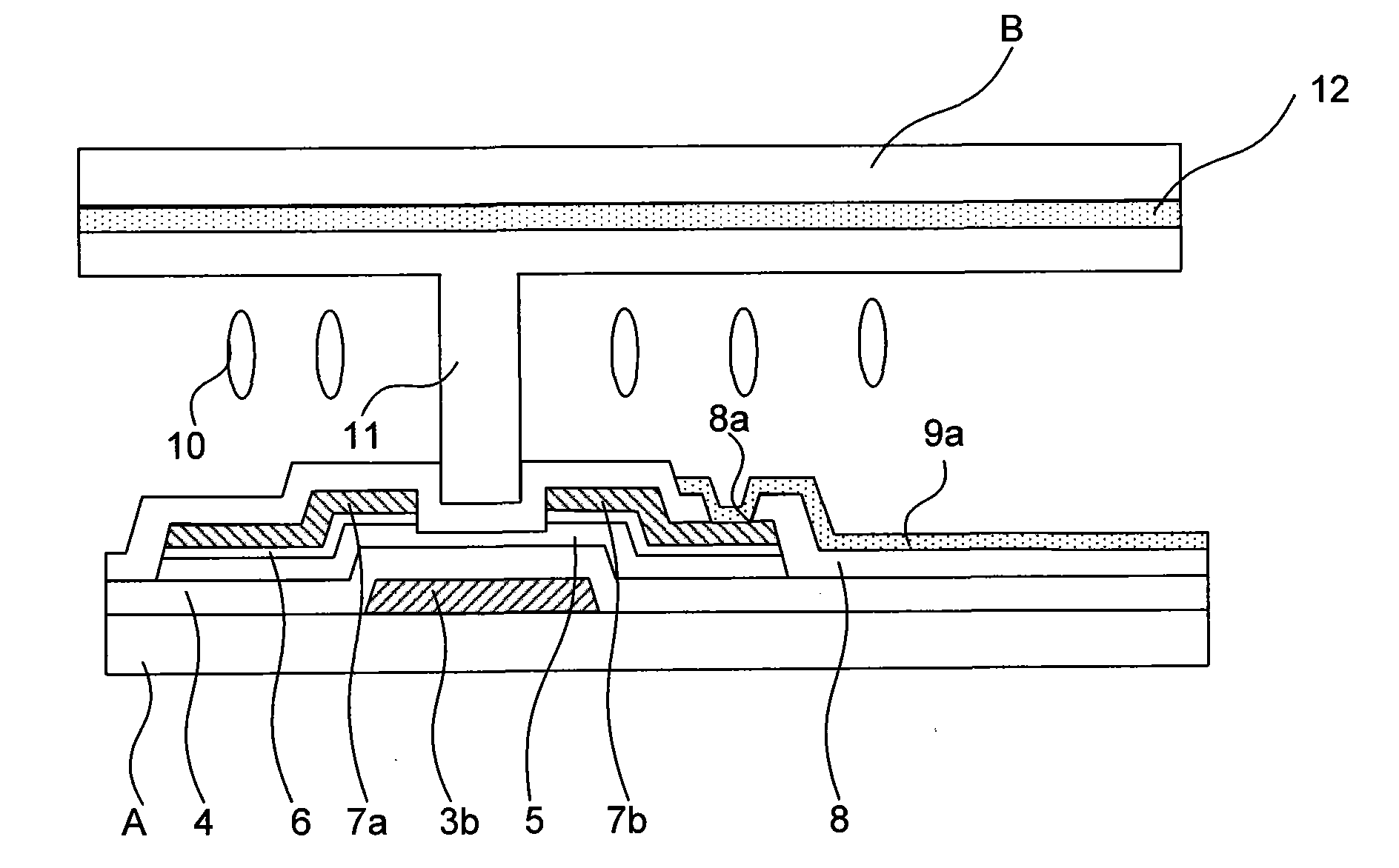

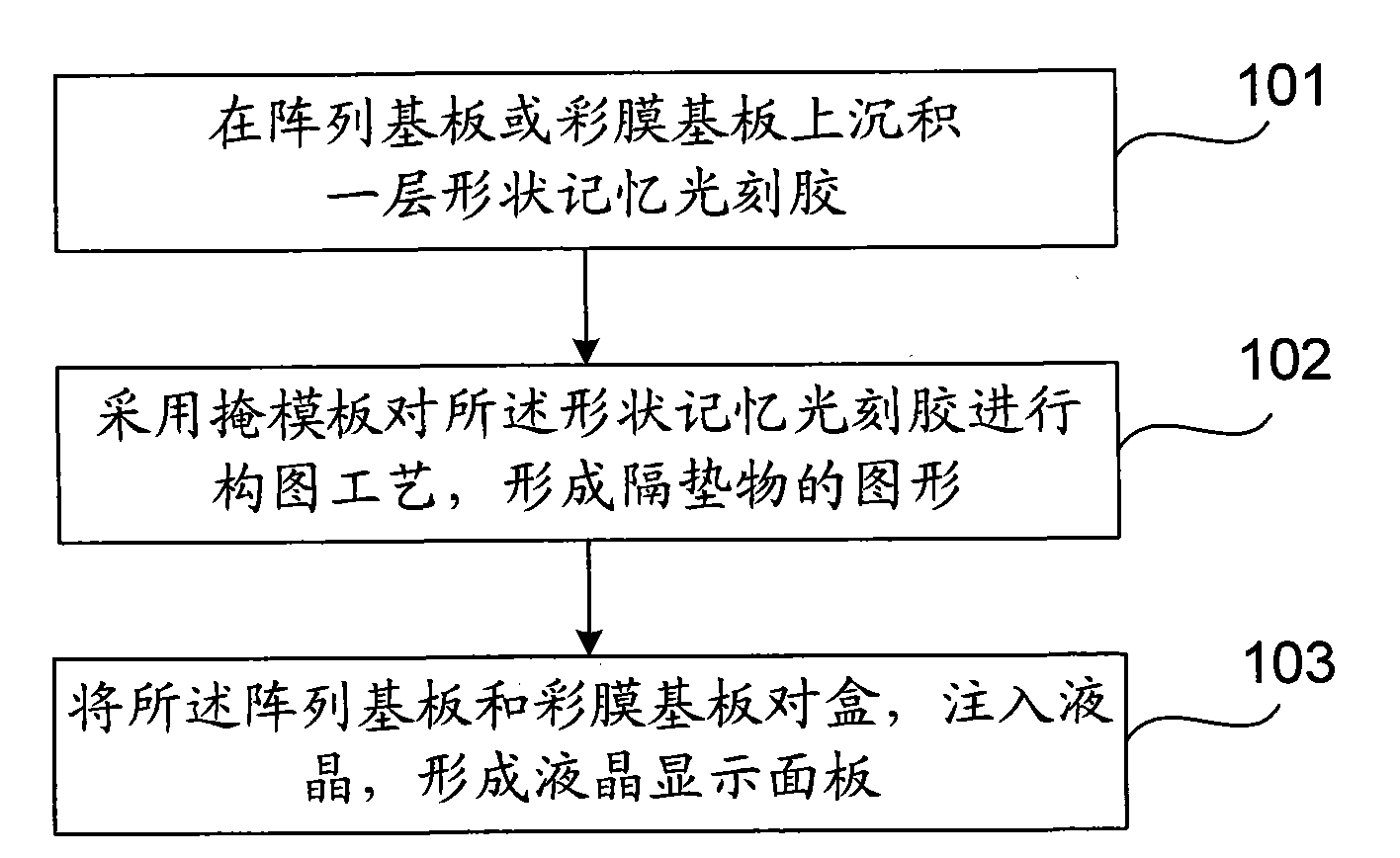

[0020] The present invention provides a liquid crystal display panel, comprising an array substrate and a color filter substrate, a spacer is arranged between the array substrate and the color filter substrate, and the material of the spacer is a shape memory polymer.

[0021] Shape memory polymers can be polymeric substances composed of soft segments and hard segments. The molecular chains in the polymer are fixed in shape when the temperature drops below the transition temperature. When heated above the transition temperature again, the oriented molecular chains in the polymer will return to their original form. The hard segment is a substance that determines the shape characteristics of the shape memory polymer, and the soft segment is a substance for freely absorbing external force.

[0022] The shape memory polymer can specifically be polymethyl methacrylate (Poly (methyl methacrylate)); Polynorbornene (polynorbornene); Cyclopentane methylene (poly (methylene-1,3-cyclope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com