Patents

Literature

66results about How to "Reduce the number of bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

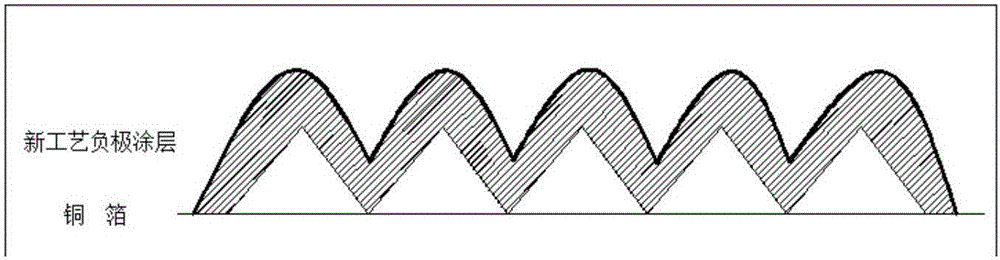

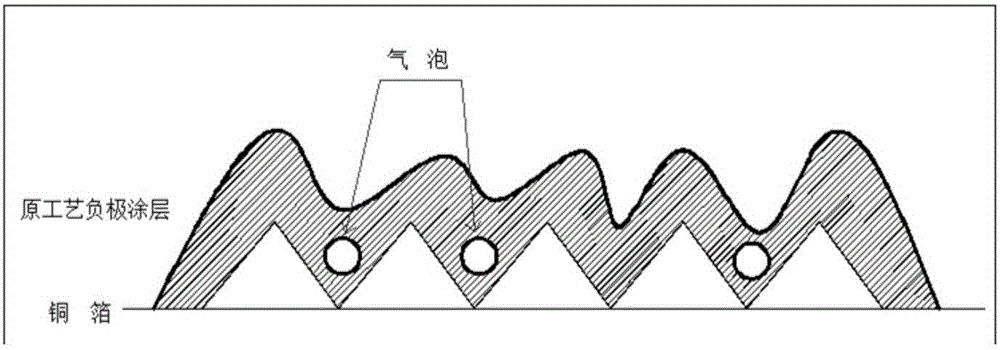

Preparation method of lithium ion power battery cathode

ActiveCN106848205AImproved mixing schemeShorten mixing timeElectrode collector coatingSodium carboxymethylcelluloseButadiene-styrene rubber

The invention relates to the field of power lithium ion batteries, in particular to a preparation method of a lithium ion power battery cathode. The preparation method comprises the following steps: first preparing sodium carboxymethylcellulose glue solution in a number 1 stirring machine, adding conducting carbon black and dry graphite powder in a number 2 stirring machine, uniformly mixing, and then adding the sodium carboxymethylcellulose glue solution in the number 1 stirring machine into the number 2 stirring machine; and adding little alcohol, vacuumizing, defoaming, adding styrene-butadiene latex, mixing, finally vacuum defoaming, and obtaining the lithium ion power battery cathode material. By improving a stirring scheme, the stirring time of the cathode slurry is shortened, the moisturizing coating performance of the cathode slurry is improved, and a bubble-free purpose is achieved.

Owner:HEFEI HENGNENG NEW ENERGY TECH

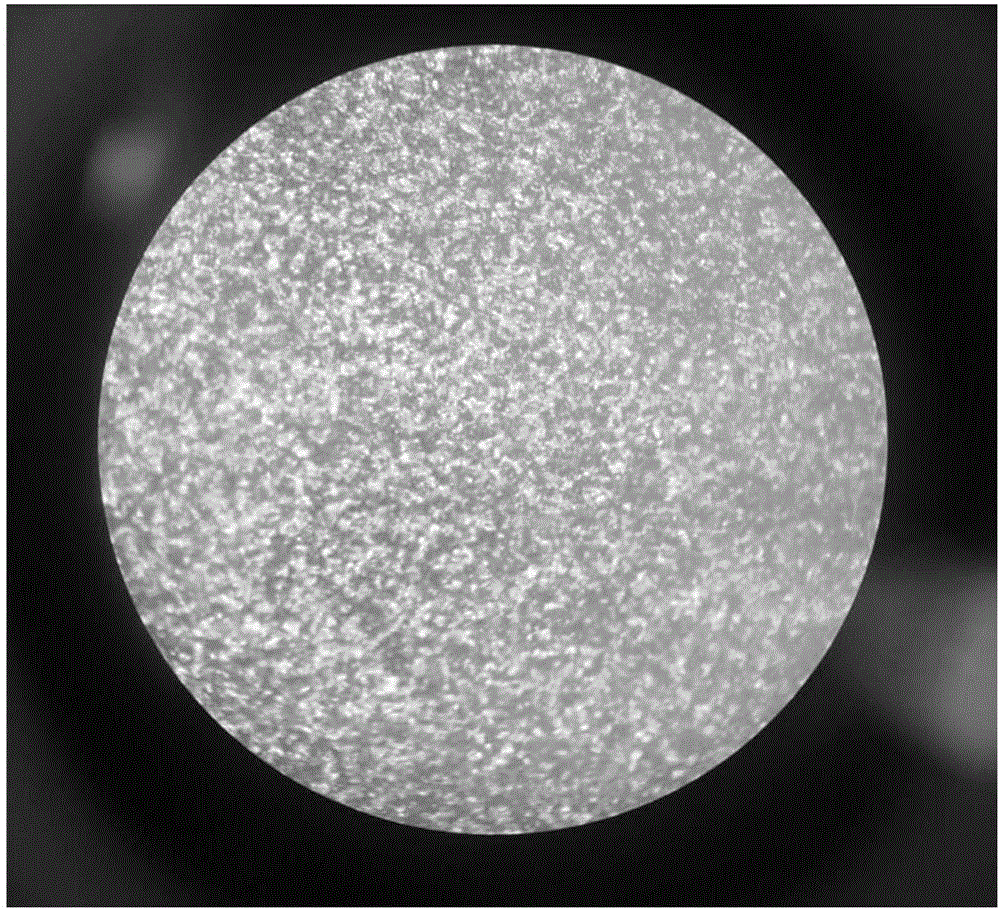

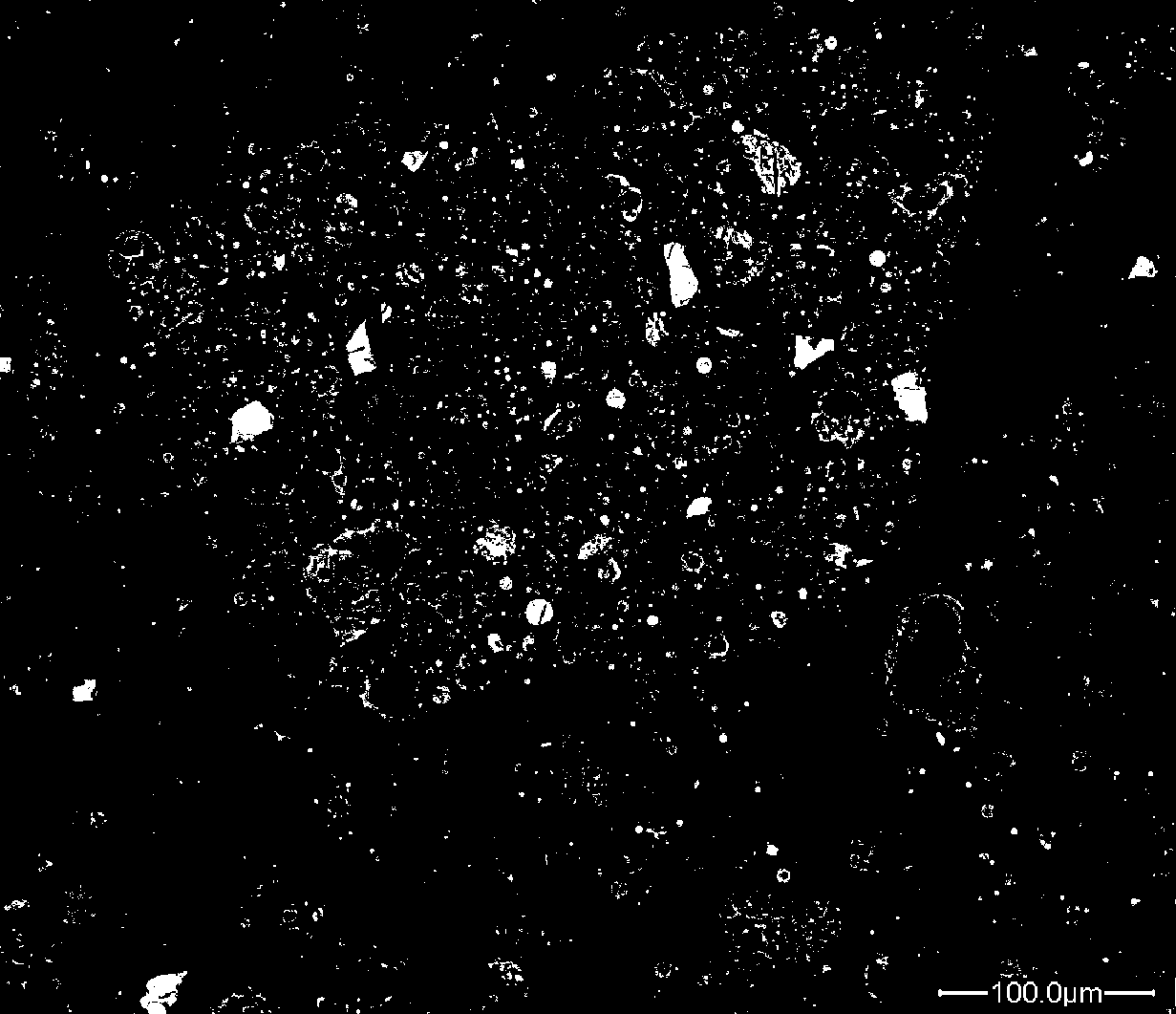

Sample preparation method for inorganic nonmetal powder material for backscattered electron image and energy spectrum study

ActiveCN103411807AImprove liquidityReduce the number of bubblesPreparing sample for investigationEpoxySmall sample

The invention relates to a sample preparation method for inorganic nonmetal powder material for the backscattered electron image and energy spectrum study. The sample preparation method comprises the steps as follows: 1, blending and uniformly mixing a powder sample with epoxy resin, 2, inlaying a sample by adopting a vacuum inlay instrument, 3, curing for 24 h at room temperature, 4, grinding and polishing, 5, performing ultrasonic cleaning, and 6, performing film coating. When the sample number is smaller or a plurality of samples are required to be observed at the same time, a secondary inlaying technology is adopted and comprises the steps as follows: firstly, a smaller die is adopted, and one or more small samples are prepared via the steps 1-3, then, the cured samples are placed into a bigger die, epoxy resin is poured into the vacuum inlay instrument, and the samples are cured at room temperature, and subsequent treatment is performed on the samples according to the steps 4-6. The sample preparation method provided by the invention can improve the sample quality, simplify the operating process and reduce the sample preparation difficulty.

Owner:TONGJI UNIV

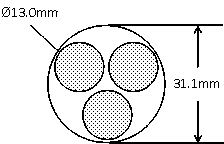

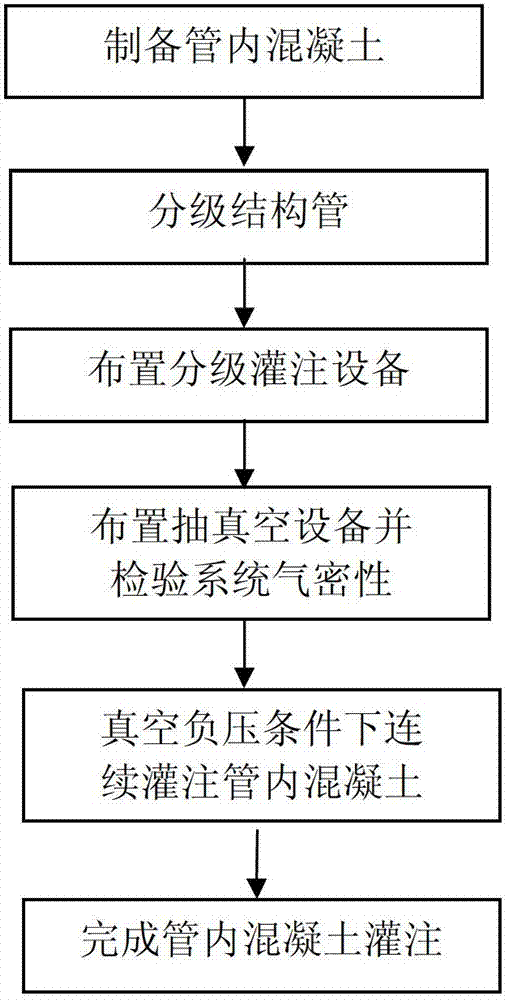

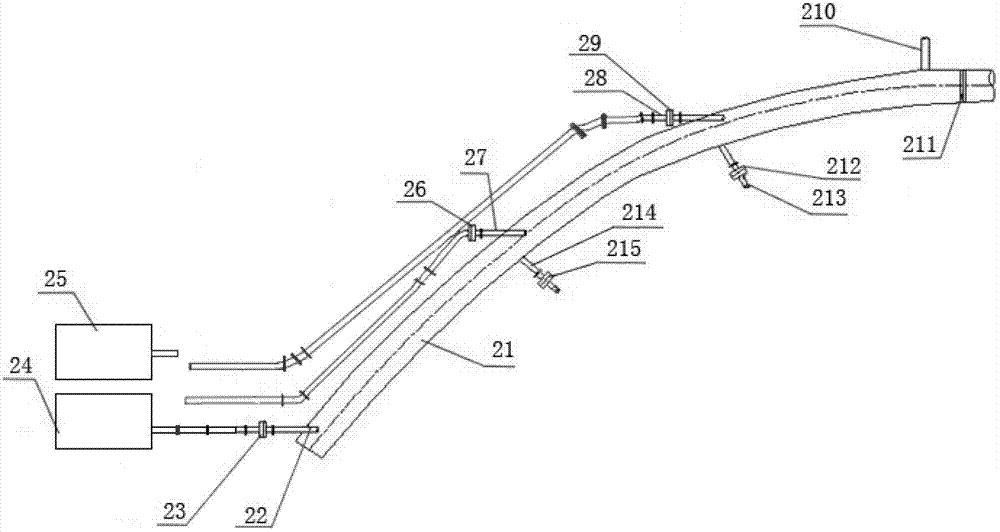

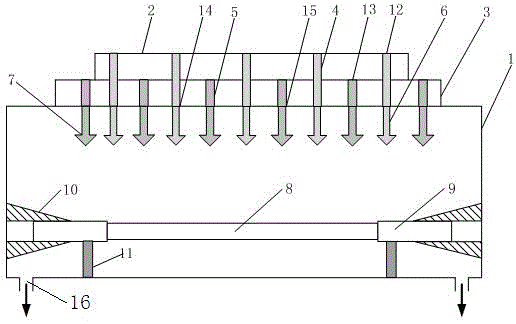

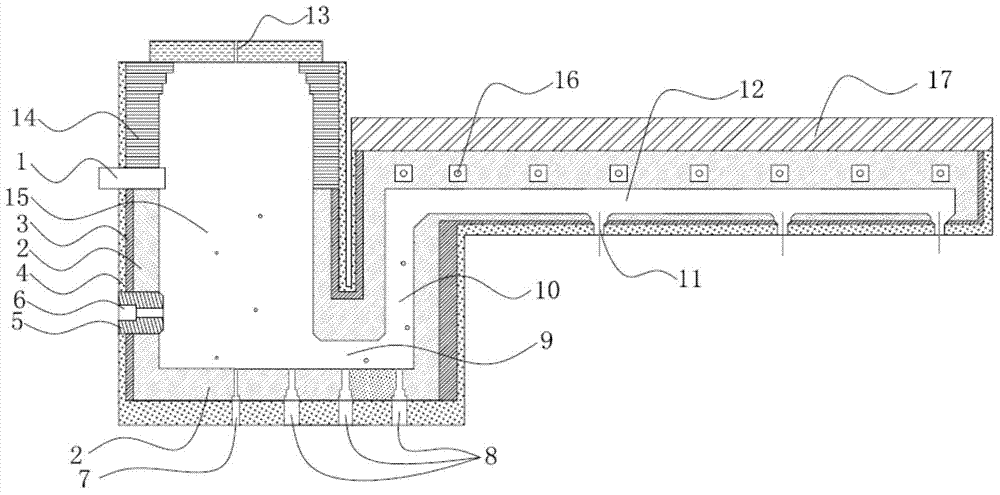

In-pipe concrete vacuum auxiliary filling method for large concrete-filled steel tubular structure and filling method

ActiveCN102758531AQuality improvementReduced number of defects such as cracksBuilding material handlingAir tightnessConcrete pump

The invention discloses an in-pipe concrete vacuum auxiliary filling method for a large concrete-filled steel tubular structure and a filling method. The filling method comprises the following steps: preparing in-pipe concrete, grading structural pipes, placing graded filling devices, placing a vacuumizing device and checking gas tightness of the system, and grading and continuously filling in-pipe concrete under the vacuum negative pressure condition. The concrete is graded and filled, so that the influence of later filled concrete on coagulation of the filled concrete is avoided, and the mechanical property of the large concrete-filled steel tubular structure is improved, meanwhile, the requirement to the pumping capacity of the concrete pumping device is reduced; and the method and thesystem bring good economic effects. The concrete is filled continuously, so that the working period is shortened; under the negative pressure condition, the concrete is filled, thus the compactness of concrete and tightness of the concrete binding with the steel pipes are reinforced; and the quality of the steel pipe concrete structure is further improved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

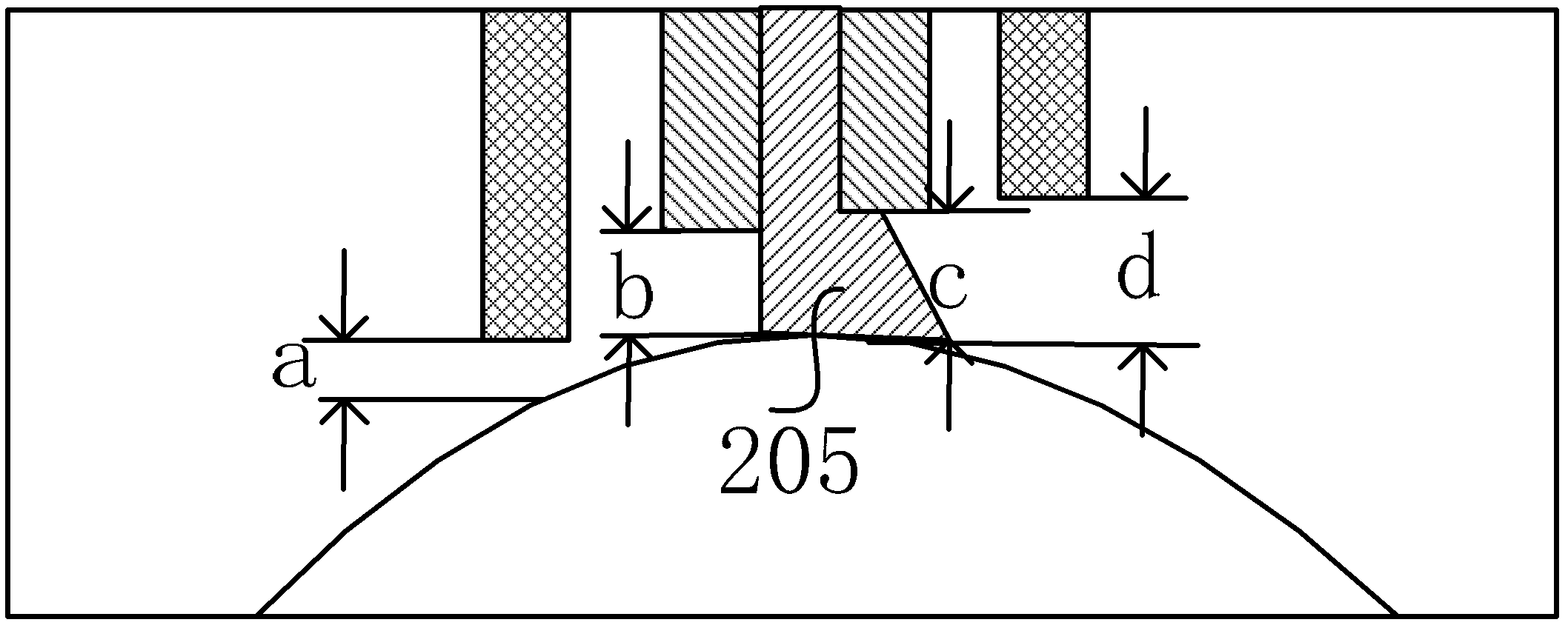

Spray belt bag

ActiveCN102513527AReduce the number of bubblesImprove toughnessMelt-holding vesselsSpray nozzleEngineering

The invention relates to a spray belt bag component, which comprises a spray belt bag, a spray nozzle, a graphite strip and a crystallization roller, wherein the spray belt bag is used for accommodating molten metal, the spray nozzle is communicated with the spray belt bag, the molten metal in the spray belt bag is sprayed out through the spray nozzle, the graphite strip is connected with the spray belt bag and is arranged around the spray nozzle, when the spray nozzle sprays the molten metal, the graphite strip prevents the molten metal from being oxidized, and simultaneously, air is prevented from being blown to the molten metal to generate air bubbles, the crystallization roller is arranged under the spray nozzle and the graphite strip, and the molten metal sprayed by the spray nozzle forms amorphous alloy belts on the crystallization roller. The spray belt bag component provided by the embodiment of the invention has the advantages that the graphite strip is arranged around the spray nozzle, the spray nozzle is surrounded by the graphite strip, and the stable environment is created for the molten metal spraying by the spray nozzle, so the air bubble number of the cooling surface is reduced, and the surface toughness of the amorphous alloy belts is improved; and in the high-temperature environment, the graphite strip is oxidized to generate reducing gas so that the molten metal at the melting pool part cannot be oxidized.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

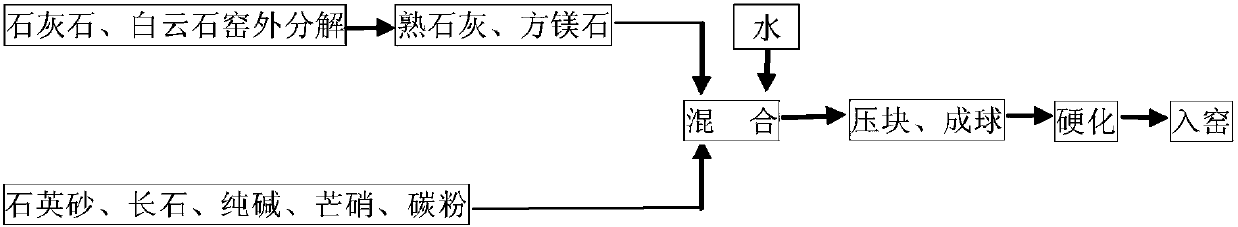

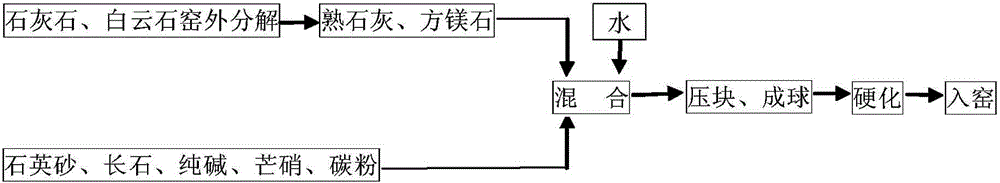

Preparation method of self-bonding and pre-decomposing glass batch

InactiveCN103102057AReduce bubble defectsEliminate potential hazardsGlass productionLower limitUltimate tensile strength

The invention provides a preparation method of a self-bonding and pre-decomposing glass batch. The method comprises the following steps of: pre-decomposing carbonate out of a kiln so as to obtain slaked lime and periclase, then mixing with other glass batch in a proper proportion in a mixing machinery, adding 8-20wt% of water during the mixing process, then pelletizing the mixed batch, standing for more than 72hours, and hardening by hydration to finally obtain the pelletized glass batch with a certain strength. According to the preparation method, the decomposing process of the carbonate is finished out of the kiln, thus the heat consumption can be greatly reduced; the lower limit of the grain size of the raw material is not required, and thus the resource can be used furthest; the cost of the raw material is reduced by adopting the light soda ash; and the pelletizing of the glass batch can be achieved without using an external bonding agent. Therefore, the preparation method has the advantages that the melting rate is improved, the melting temperature is reduced, the melting efficiency is high, and the like.

Owner:YANSHAN UNIV

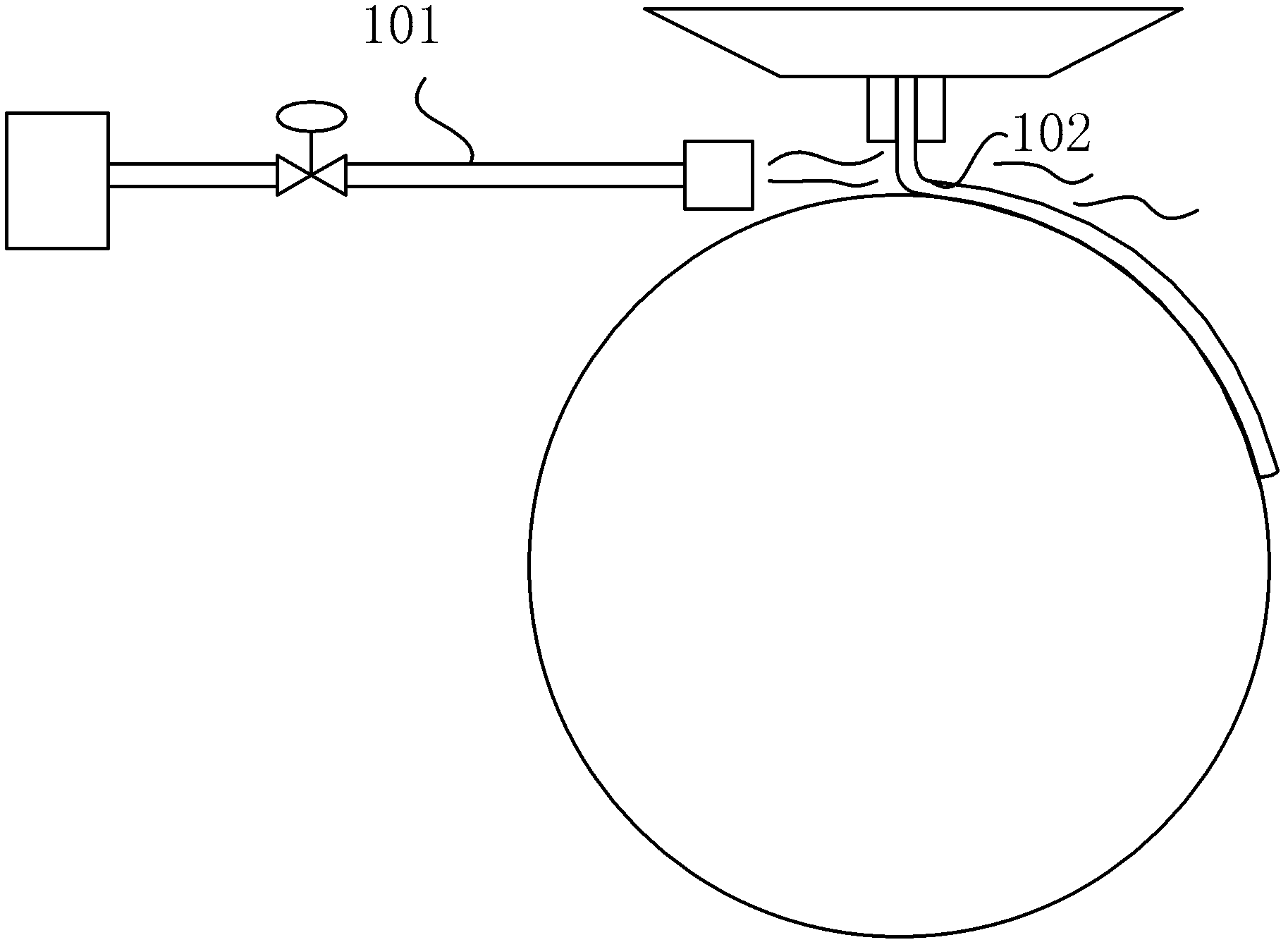

Device and method for reducing impurity and bubble on core cladding interface for large-size optical fiber perform

The invention discloses a device and method for reducing impurities and bubbles on a core cladding interface for a large-size optical fiber perform, relate to the device and method for reducing the impurities and the bubbles on the core cladding interface in the manufacturing process of the large-size optical fiber perform, and aim to remove the impurities, dust and static on the surface of a core rod, and prevent a powder rod formed after the outside vapor deposition of the core rod from having bubbles and impurities on the core cladding interface. The device comprises a box special for holding the core rod, an air purifying fan and an anti-static fan, wherein the box special for holding the core rod comprises a box body; a box door is arranged on the front side of the box body; the air purifying fan and the anti-static fan are mounted at the top of the box body; a purifying air inlet and an anti-static air inlet are formed above the boxy body; the air outlet of the anti-static fan is connected with the anti-static air inlet on the box body through a pipe; a core rod support table is mounted at the bottom of the box body of the box special for holding the core rod and is used for supporting the core rod; a support chuck is mounted on each of the two sides on the lower part of the box body and used for clamping and fixing the core rod.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD

Environment-friendly plastic injection mold

ActiveCN112223684AGuaranteed collision strengthImprove the vibration effectThermal dilatationThermodynamics

The invention discloses an environment-friendly plastic injection mold, and belongs to the field of injection molds. The environment-friendly plastic injection mold is characterized in that through the arrangement of a thermal ball chain, when a molten material is injected, the temperature rises, and air in thermal collision balls is heated to expand, so that the distance between every two adjacent thermal collision balls on the thermal ball chain is reduced; and through cooperation with self-hardening bags, repulsive force exists between every two adjacent thermal collision balls, the thermalcollision balls which are close to each other are in an unstable state, the thermal collision balls continuously move in a self-vibration cavity, and the moving degree of the thermal collision ballsis increased when the thermal collision balls expand increasingly along with continuous injection of molten material, the thermal collision balls collide with the inner wall of the self-vibration cavity, therefore, the thermal ball chain generates a vibration effect on the injected molten material, the number of bubbles in the molten material is remarkably reduced, the quality and strength of a finished product are higher, the situation of local cracking or breaking during use is effectively avoided, and the service life is prolonged.

Owner:佛山市南海区华泰精密机械有限公司

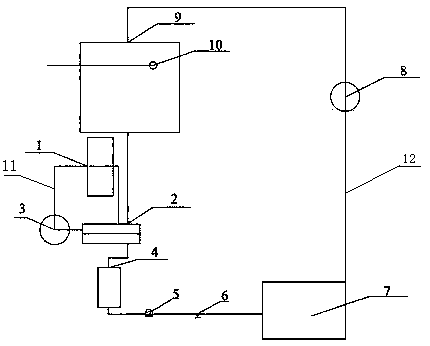

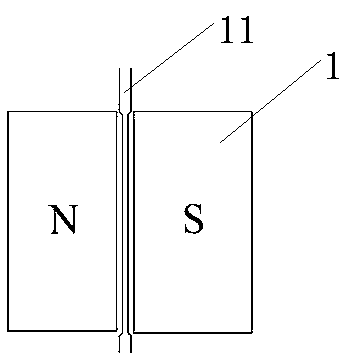

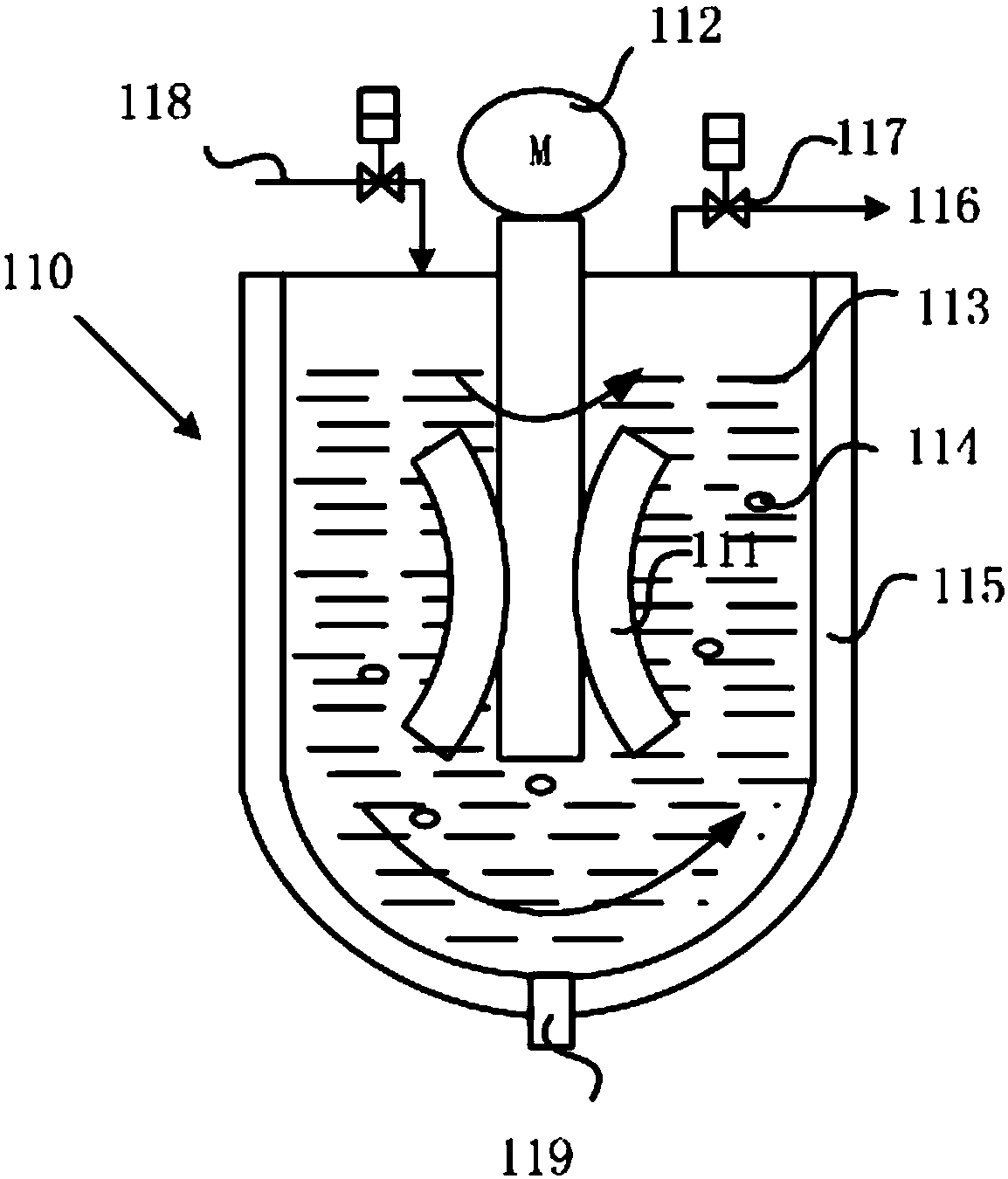

Device and method of industrially carrying out magnetized copper electrolysis

ActiveCN110219018AAddress reactivitySolve quality problemsPhotography auxillary processesElectrolysis componentsMagnetic tension forceElectrolysis

The invention belongs to the technical field of copper electrolysis smelting, and particularly relates to a device and method of industrially carrying out magnetized copper electrolysis. The device comprises a permanent magnet device, a transition tank, an electrolytic tank, a low tank, an elevated tank and a steam heating device. According to the device and method, the large-scale and high-efficiency utilization of the copper magnetic electrolysis technology is achieved by the bypass cycle of a magnetic treatment device, and the magnetic treatment efficiency can be improved in the mode that an electrolyte passes through the permanent magnet device at the high speed. The loren magnetic force borne by the electrolyte in the process that the electrolyte passes through the magnetic field canbe enhanced, the electrolyte is greatly activated, the impurity flocculating setting is reinforced, the clarity of the electrolyte is improved, cathode copper crystal grains are refined, the number ofbubbles in the electrolyte is reduced, and the problem that due to the facts that the air bubbles in the electrolyte are prone to having a reaction on the surface of an anode to generate an oxide film, and anodic passivation happens, the cathode copper quality is affected is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Quick discharging method for tiny bubbles from optical fiber coating

ActiveCN103212220AReduce the number of bubblesReduce Coating DefectsFoam dispersion/preventionEngineeringOptical fiber cable

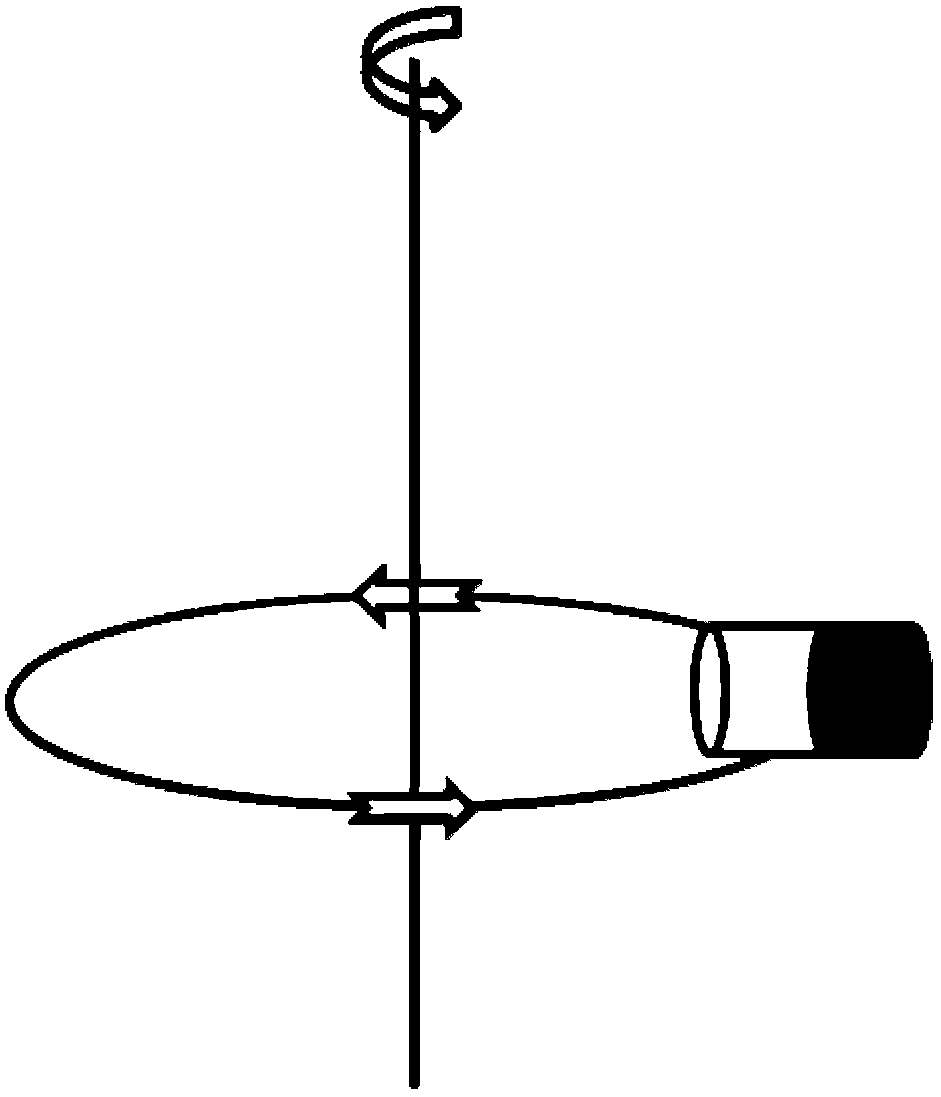

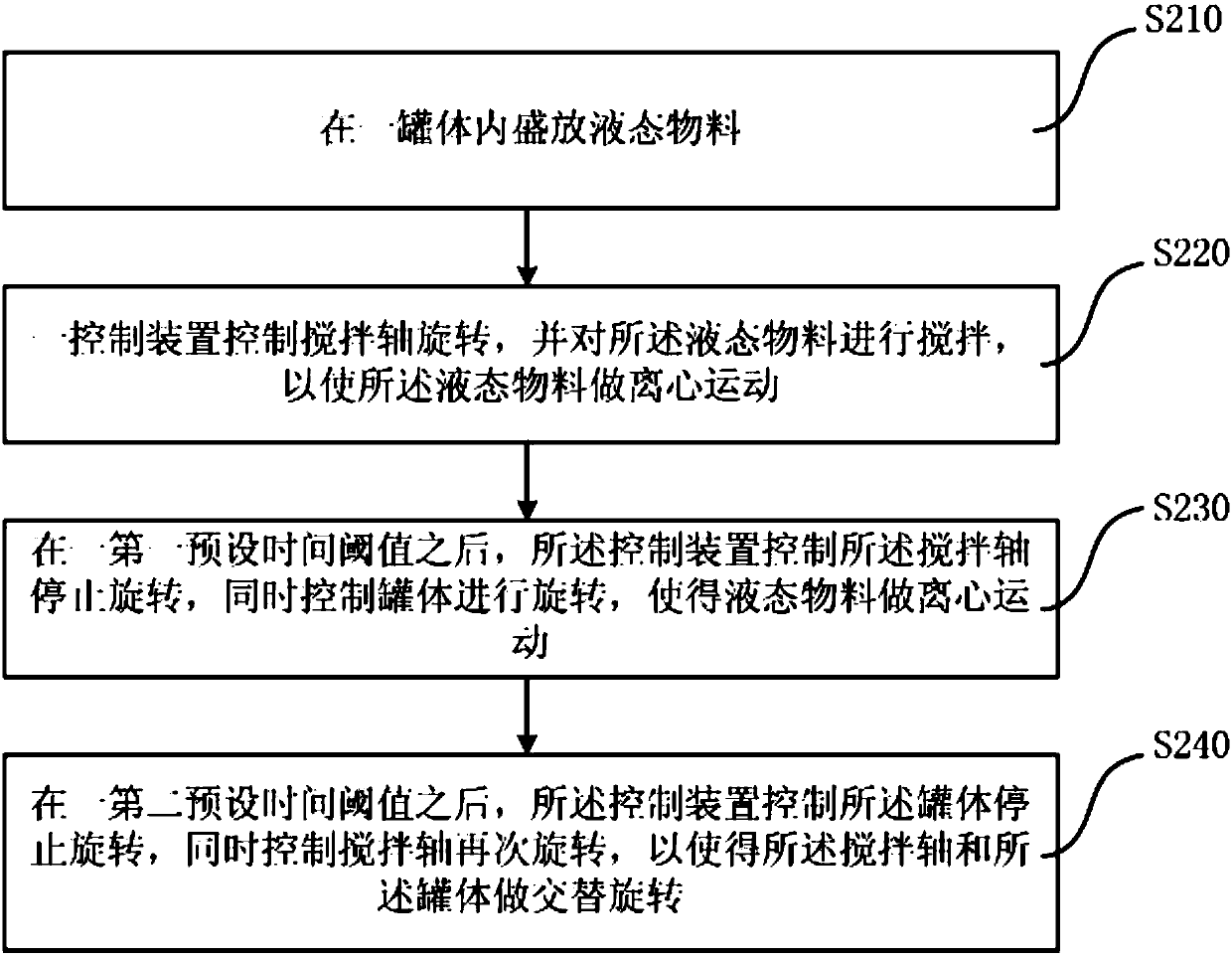

The invention discloses a quick discharging method for tiny bubbles from an optical fiber coating, and relates to the field of optical fiber communication. The quick discharging method comprises the following steps of: introducing the coating into a closed coating tank, heating the coating to the temperature of 30-65 DEG C, preserving the heat, vacuumizing the closed coating tank to 1*10<-4>-5,000 Pa, and retaining the vacuum degree; inclining the middle axis of the sealed coating tank by a certain angle relative to a rotating shaft, so that the sealed coating tank does centrifugal motion around the rotating shaft, and coatings are always positioned at the bottom of the sealed coating tank; and increasing the centrifugal rotating speed from 0 rpm until the centrifugal rotating speed is up to 500-22,000 rpm, performing the centrifugal motion for 5-25 minutes at the centrifugal rotating speed, and then reducing the centrifugal rotating speed until the centrifugal rotating speed is 0 rpm, wherein at most one tiny bubble of which the diameter is 0.01-0.15 mm exists in every cubic centimeters, and bubbles of which the diameters are more than 0.15 do not exist. By the quick discharging method, the time for discharging the tiny bubbles during the heat preservation of the optical fiber coating can be reduced, the discharging speed and the exhaust rate of the tiny bubbles can be improved, and the number of bubbles in the optical fiber coating and the defects of the coating layers are reduced.

Owner:FENGHUO COMM SCI & TECH CO LTD

Fastening jig for a baffle plate for oil pan use and fastening method thereof

InactiveCN1609416AReduce volumeReduce the number of bubblesCasingsMachines/enginesCylinder blockCrankshaft

A baffle plate is arranged between a crankshaft axially supported in a freely rotating manner by a cylinder block and a bearing cap and an oil pan storing lubricating oil supplied to each part of a vehicle engine. The baffle plate is fastened to the bearing cap using parent bolts for fastening the bearing cap and the cylinder block through screwing from the bottom surface of the bearing cap.

Owner:TOYOTA JIDOSHA KK

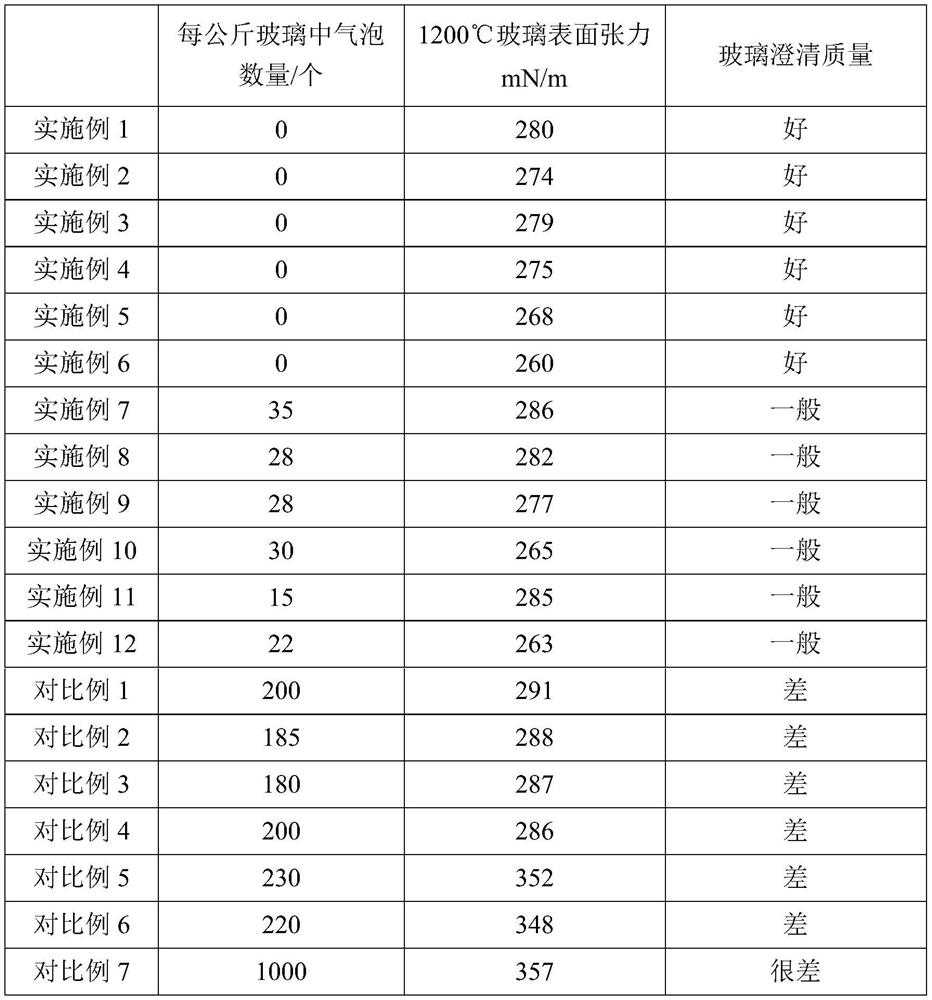

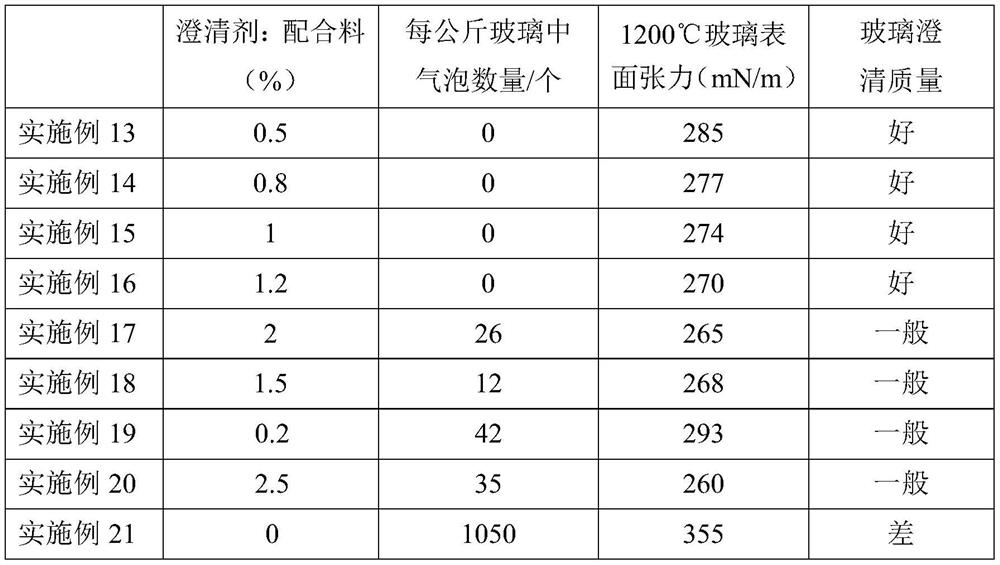

Composite clarifying agent, composition for neutral borosilicate medicinal glass as well as glass prepared from composition, and applications

The invention relates to the field of glass manufacturing, and discloses a composite clarifying agent, a composition for neutral borosilicate medicinal glass as well as glass prepared from composition, and applications. The clarifying agent comprises chlorate, fluoride salt and valence-variable oxide, wherein the chlorate is selected from one or more of sodium chloride, calcium chloride, potassium chloride, barium chloride and ammonium chloride, the fluoride salt is sodium fluosilicate and / or calcium fluoride, and the variable valence oxide is tin oxide and / or cerium oxide. When the composite clarifying agent provided by the invention is applied to neutral borosilicate medicinal glass, the surface tension of molten glass can be remarkably reduced, and a good clarifying effect is achieved by utilizing the discharge of bubbles in the molten glass.

Owner:东旭药玻(北京)科技有限公司 +1

Vacuum defoaming device and foam removal method adopting device

ActiveCN107551607AImprove defoaming abilityReduce the number of bubblesFoam dispersion/preventionSelf weightEngineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Light guide plate manufacturing method

InactiveCN102455460AGood brightness performanceReduce the number of bubblesOptical light guidesLight guideOptoelectronics

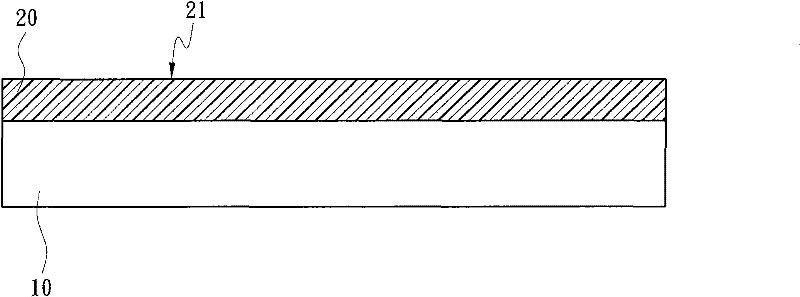

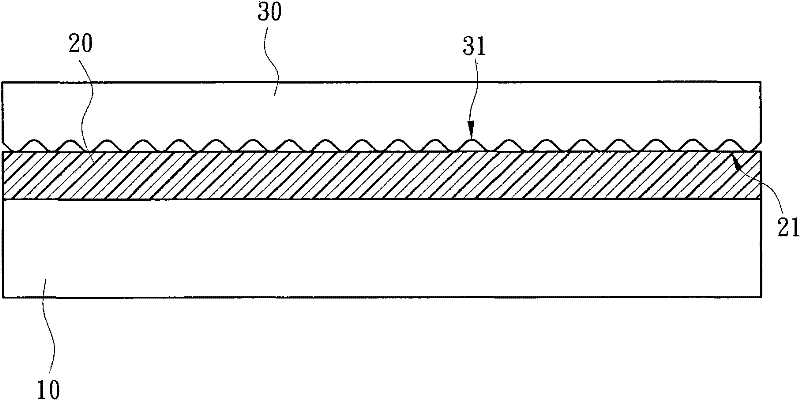

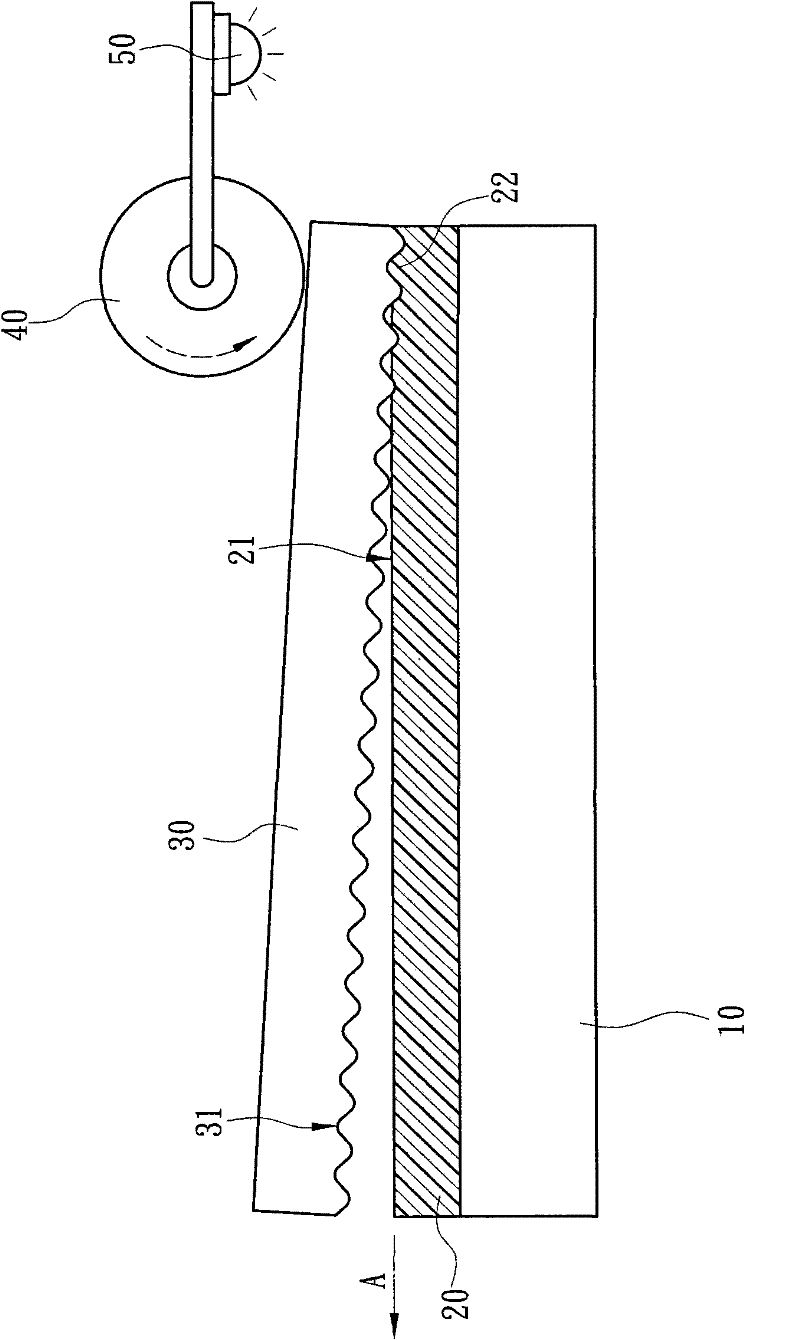

The light guide plate manufacturing method comprises the following steps of: using a rolling depression device comprising an imprinter, wherein the surface of the imprinter comprises a first structure; rolling a resin layer arranged on a substrate by the imprinter, or forming the resin layer on the imprinter to roll the substrate, enabling the resin layer to continuously form a second structure complementary to the first structure, and attaching the second structure on the substrate. The rolling depression area formed by the rolling depression mode is smaller, so the uniformity of pressure application is easy to control, the light guide plate can have high transcription rate, and defects are reduced.

Owner:WIN OPTICAL

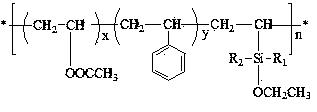

Method for preparing sustained-release coating material with organic silicon

The invention discloses a method for preparing a sustained-release coating material with organic silicon. The method comprises the following steps: 1) dissolving a hydrolysate with sodium carboxymethylcellulose and styrene-vinyl acetate-vinyl silane terpolymer according to the mass ratio of (1-100):1 in water; 2) dissolving gelatin in water, adding into the solution of step 1), wherein the mass ratio of gelatin to the sodium carboxymethylcellulose is (0.5-20):1, adding 1-25% of the total mass of a non-ionic emulsion, stirring and dispersing to obtain an O / W type emulsion; and 3) adding a cross-linking agent, continuously stirring and dispersing, subsequently adding acid or acid and water to adjust the pH value to obtain the sustained-release coating material with organic silicon. The material brings into play the characteristics that the organic silicon is low in surface tension and high in chemical stability, enables a coated layer to be dense, improves the sustained-release effect and reduces the number of bubbles generated in the surface in coating, the prepared coating material is applicable to surface coating on variable fertilizer grains and simple and convenient to operate, the process time is shortened, and the production efficiency is improved.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

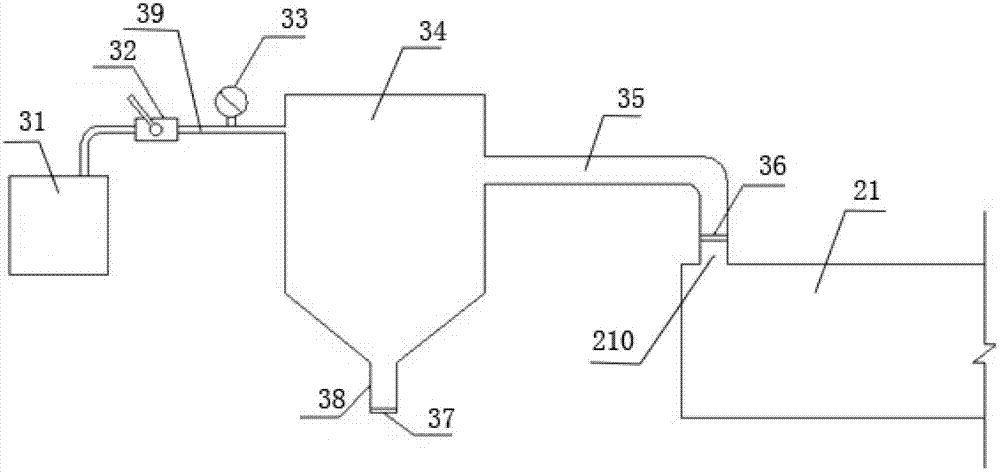

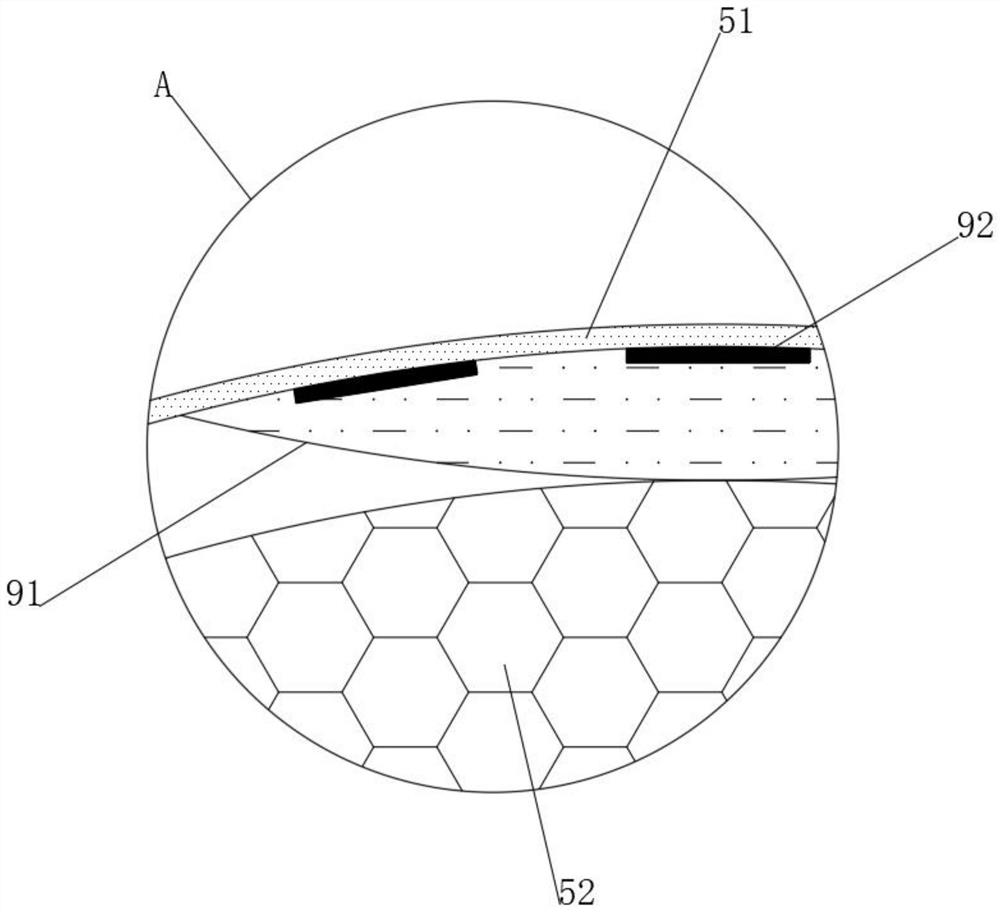

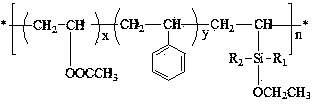

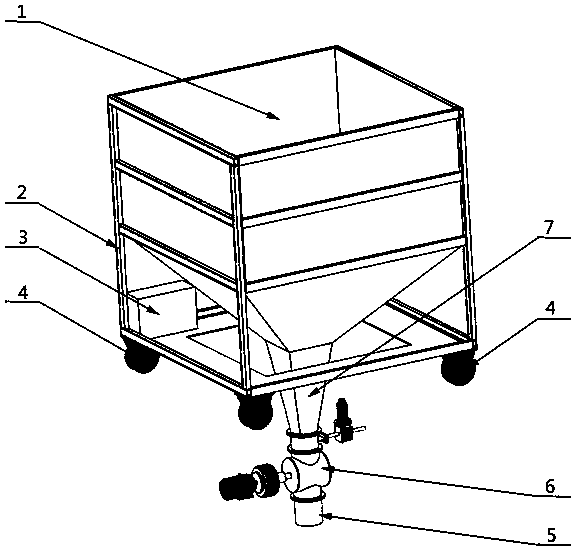

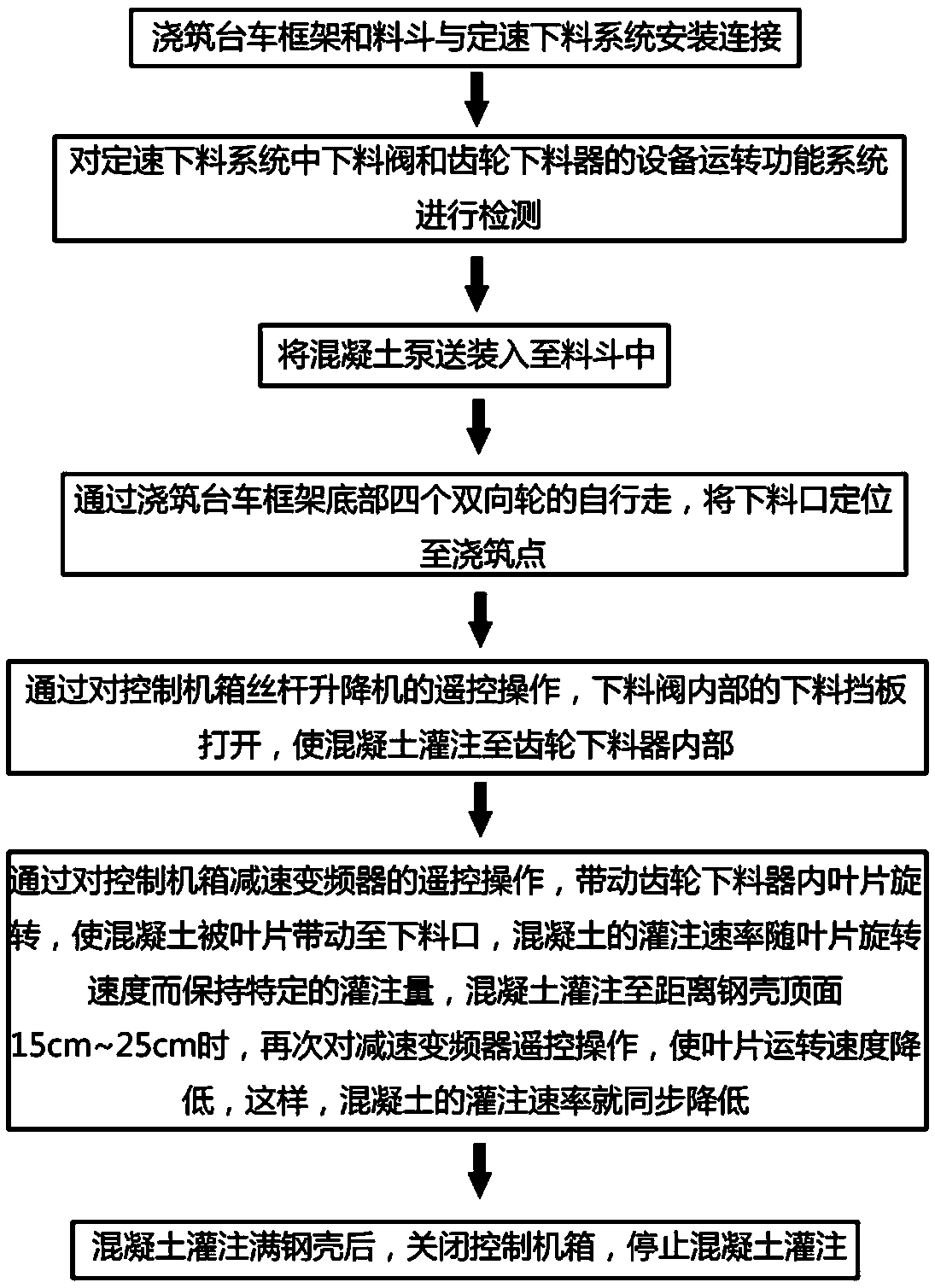

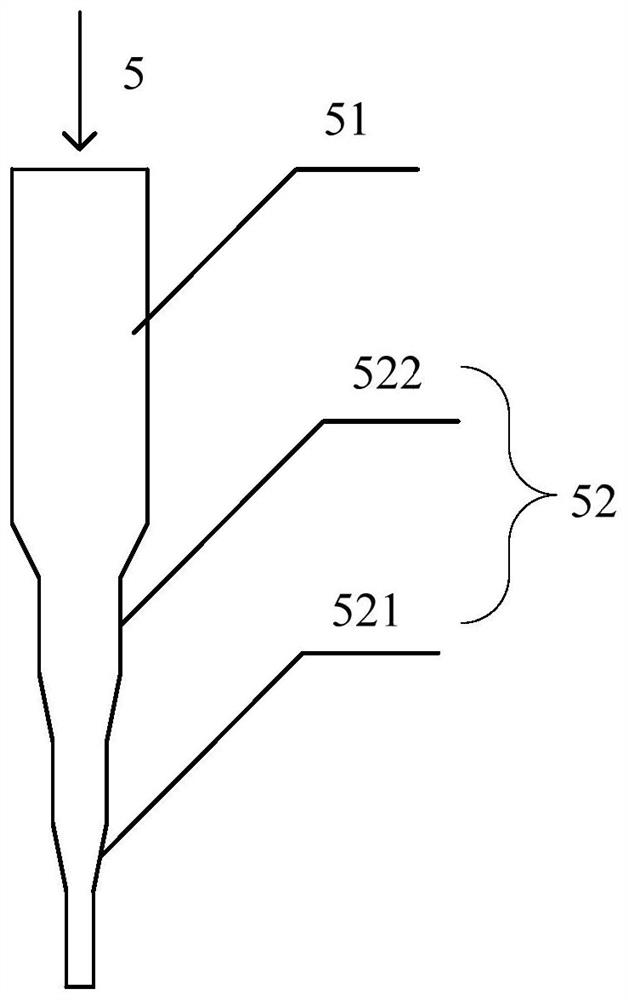

Conveying system and method capable of adjusting blanking speed at constant speed for steel shell concrete

PendingCN109778914AReduce the number of bubblesOvercome the shortcomings that the air cannot be excluded due to unevennessArtificial islandsUnderwater structuresHoneycombEngineering

The invention discloses a conveying system and method capable of adjusting the blanking speed at a constant speed for steel shell concrete. The system comprises a pouring trolley frame, a hopper and aconstant-speed blanking system, the hopper is fixed on the pouring trolley frame, and the constant-speed blanking system is connected with a hopper discharge port. The constant-speed blanking systemis composed of a blanking valve, a gear blanking device, a speed reduction frequency converter, a lead screw lifter and two motors, the inner structure of the blanking valve comprises a blanking baffle and a driving shaft, one motor is arranged at the top end of the lead screw lifter, the lead screw lifter is hinged to a driving shaft, and the driving shaft is connected with the blanking baffle. By means of the system and method, the defects that a concrete surface layer is uneven and air is difficult to remove in a later period of pouring are overcome. And the working efficiency and the capacity are improved, the production cost is reduced, the construction qualification rate is improved, local cavities, large-area air holes and honeycomb pitted surfaces of a steel shell and the concretesurface layer are prevented from being generated during pouring, and the engineering quality is effectively guaranteed.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

Double-penetration type high-performance noise reduction water-based damping coating and preparation method thereof

ActiveCN110982363AOvercoming damping propertiesOvercome mechanical propertiesAnti-corrosive paintsHydrated aluminaAcrylic resin

The invention discloses a double-penetration type high-performance noise reduction water-based damping coating which is mainly prepared from the following raw materials in parts by weight: 20-25 partsof water, 50-60 parts of acrylic resin emulsion, 8-12 parts of styrene-acrylic emulsion, 0.5-2.0 parts of defoaming agent, 0.5-1.0 part of nano graphite flake, 2-3 parts of dispersing agent, 0.1-0.3part of preservative, 1.0-1.5 parts of antirust agent, 215-280 parts of hydrated alumina powder and 1.5-2.5 parts of thickening agent. In addition, the invention further provides a preparation methodthe double-penetration type high-performance noise reduction water-based damping coating. The double-penetration type high-performance noise reduction water-based damping coating has noise reducing performance, the weighting sound insulation index of a base material coated with the coating is increased by 4 dB to 4.2 dB, the technical requirements of water-based damping coatings for high-speed trains are met and the defects that single-resin emulsion coatings are poor in damping performance, mechanical performance, corrosion resistance and the like are overcome.

Owner:蒋丹烈

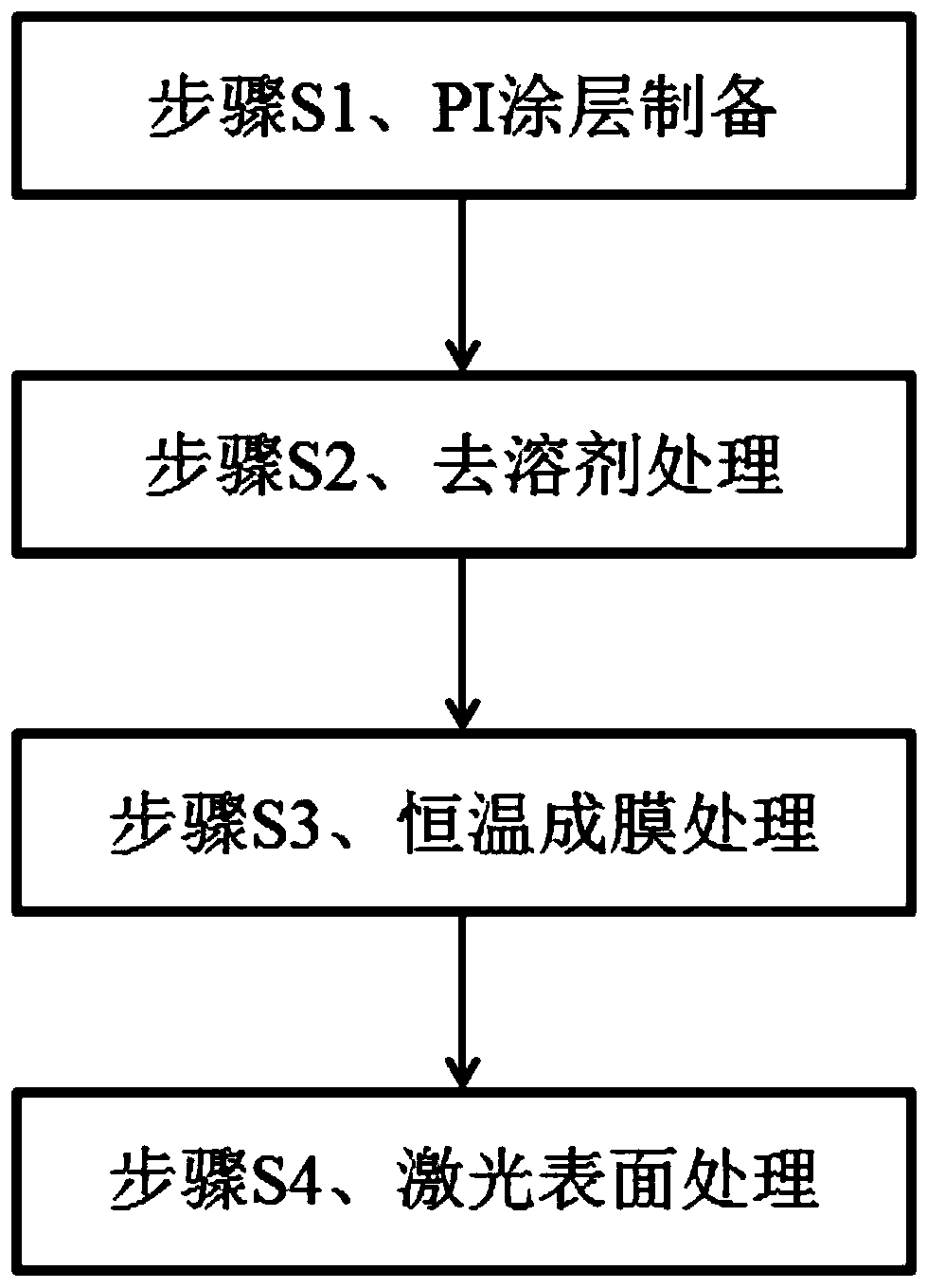

Preparation method of PI substrate and display device thereof

ActiveCN110491993ASteps to add laser treatmentGood defoaming performanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention provides a preparation method of a PI substrate. The preparation method comprises a PI coating preparation step S1, a solvent removal treatment step S2, a constant-temperature film forming treatment step S3 and a laser surface treatment step S4. According to the invention, laser surface treatment is carried out on the PI film layer, when irradiation laser irradiates the surface of the PI film layer, heating treatment can be formed in the PI film layer, bubbles in the PI film layer are heated to go upwards and then are released from the surface of the PI film layer, and thereforePI bubbles existing in the PI film layer in the PI substrate prepared through the preparation method are few.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Process and kiln for producing high-performance alkali-free glass

InactiveCN103588383ALower resistanceGuaranteed normal operationGlass furnace apparatusElectric furnaceAlkali freeMaterials science

The invention discloses a process and a kiln for producing high-performance alkali-free glass. The process for producing the glass is characterized by sequentially comprising the followings steps: (1), preheating a glass material to 600 DEG C-900 DEG C to form eutectic sinter; (2), heating the sinter to over 1650 DEG C to form molten glass; (3), clearing the molten glass; (4), forming glass.

Owner:CHONGQING POLYCOMP INT

Novel high-strength glass fiber

The invention provides a novel high-strength glass fiber which comprises the following components in parts by weight: 55-65 parts of SiO2, 15-25 parts of Al2O3, 5-10 parts of CaO, 5-10 parts of MgO, 0.05-0.1 part of K2O, 0.05-0.1 part of Na2O, 0.05-0.1 part of B2O3, 0.05-0.1 part of Li2CO3, 0.05-0.1 part of CeO2, 0.05-0.1 part of Fe2O3, 0.05-0.1 part of WO3, 0.05-0.1 part of TiO2, 0.05-0.1 part of MnO2 and 0.05-0.1 part of ZrO2. The novel high-strength glass fiber has the technical effects that a few bubbles are generated and both the acid resistance and the high temperature resistance are greatly improved.

Owner:NANTONG SUZHONG TEXTILE

Process for the preparation of self-adhesive and pre-disintegrated glass batches

InactiveCN103102057BReduce bubble defectsEliminate potential hazardsGlass productionLower limitPericlase

The invention provides a preparation method of a self-bonding and pre-decomposing glass batch. The method comprises the following steps of: pre-decomposing carbonate out of a kiln so as to obtain slaked lime and periclase, then mixing with other glass batch in a proper proportion in a mixing machinery, adding 8-20wt% of water during the mixing process, then pelletizing the mixed batch, standing for more than 72hours, and hardening by hydration to finally obtain the pelletized glass batch with a certain strength. According to the preparation method, the decomposing process of the carbonate is finished out of the kiln, thus the heat consumption can be greatly reduced; the lower limit of the grain size of the raw material is not required, and thus the resource can be used furthest; the cost of the raw material is reduced by adopting the light soda ash; and the pelletizing of the glass batch can be achieved without using an external bonding agent. Therefore, the preparation method has the advantages that the melting rate is improved, the melting temperature is reduced, the melting efficiency is high, and the like.

Owner:YANSHAN UNIV

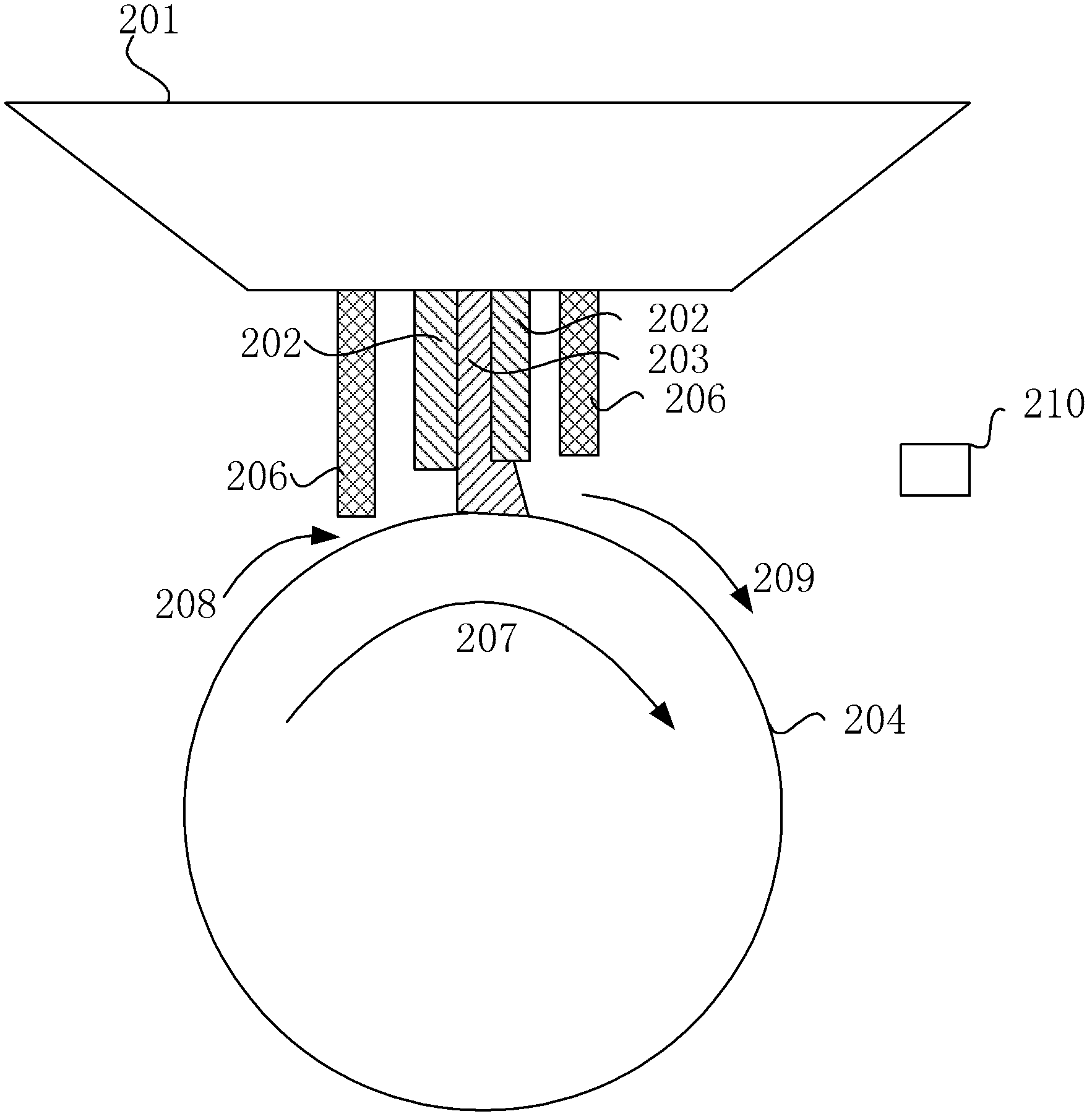

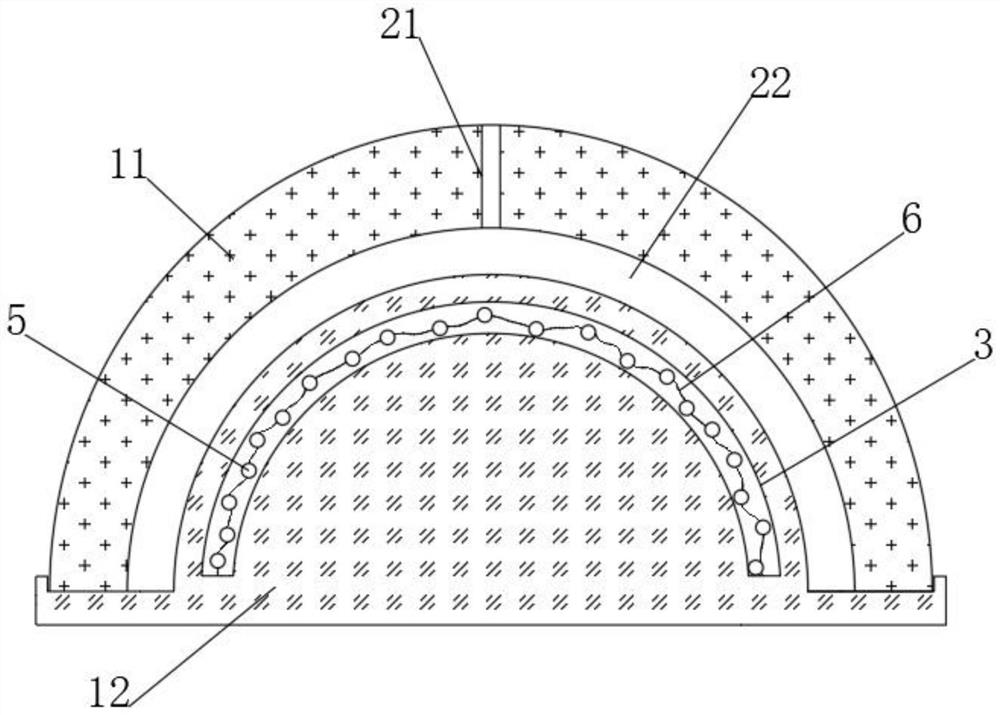

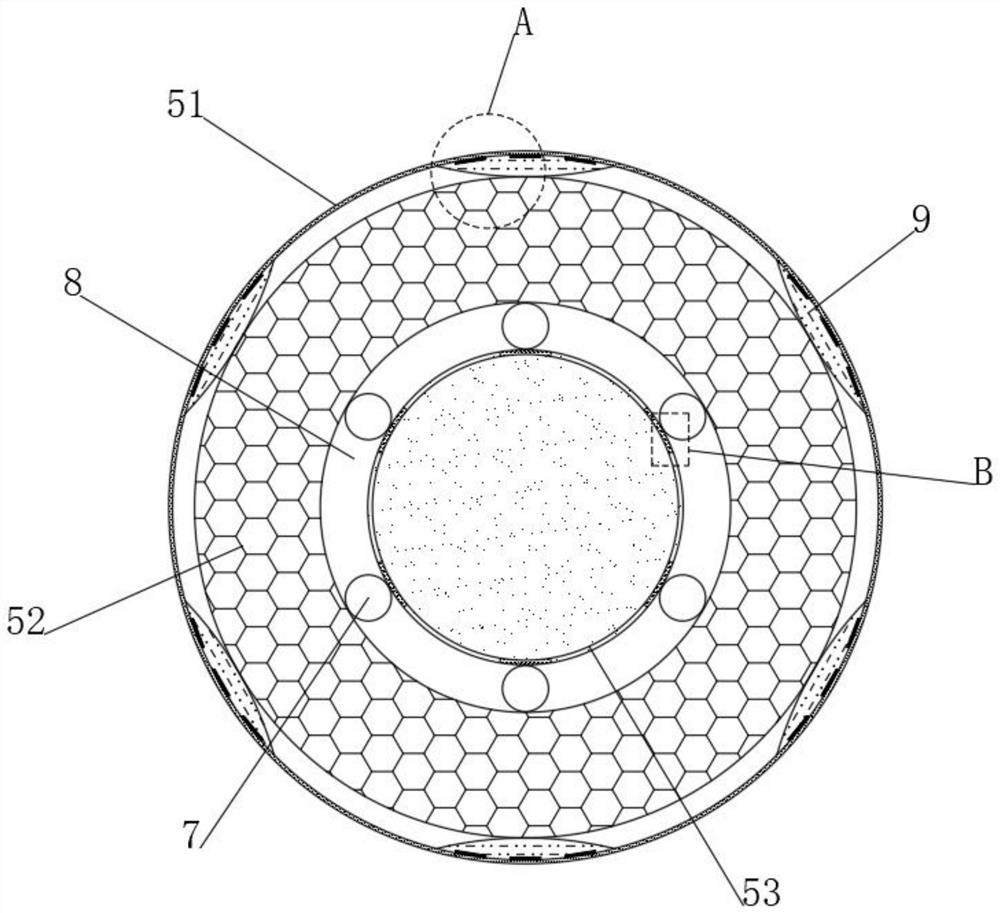

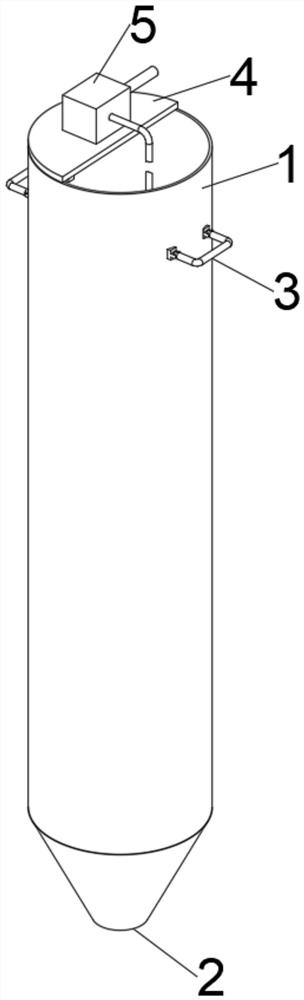

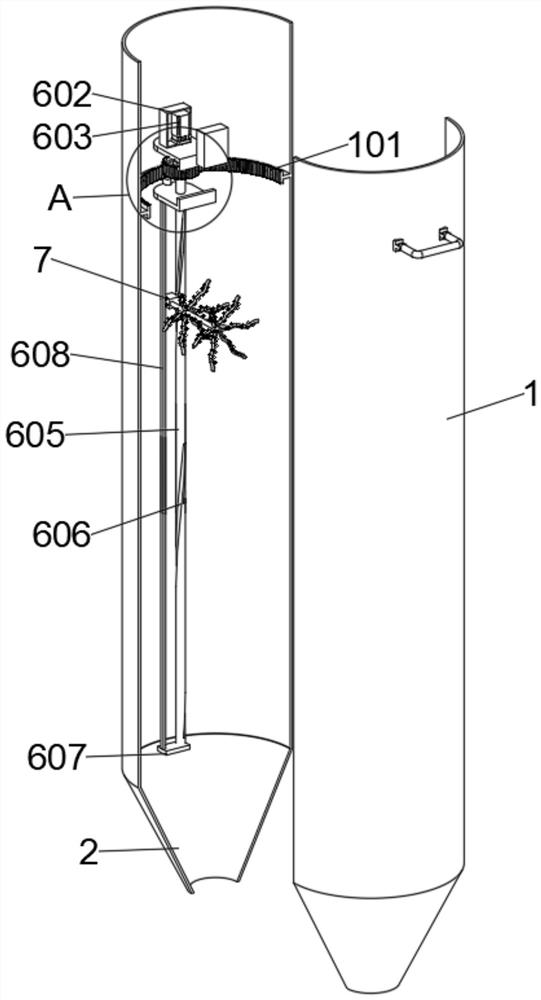

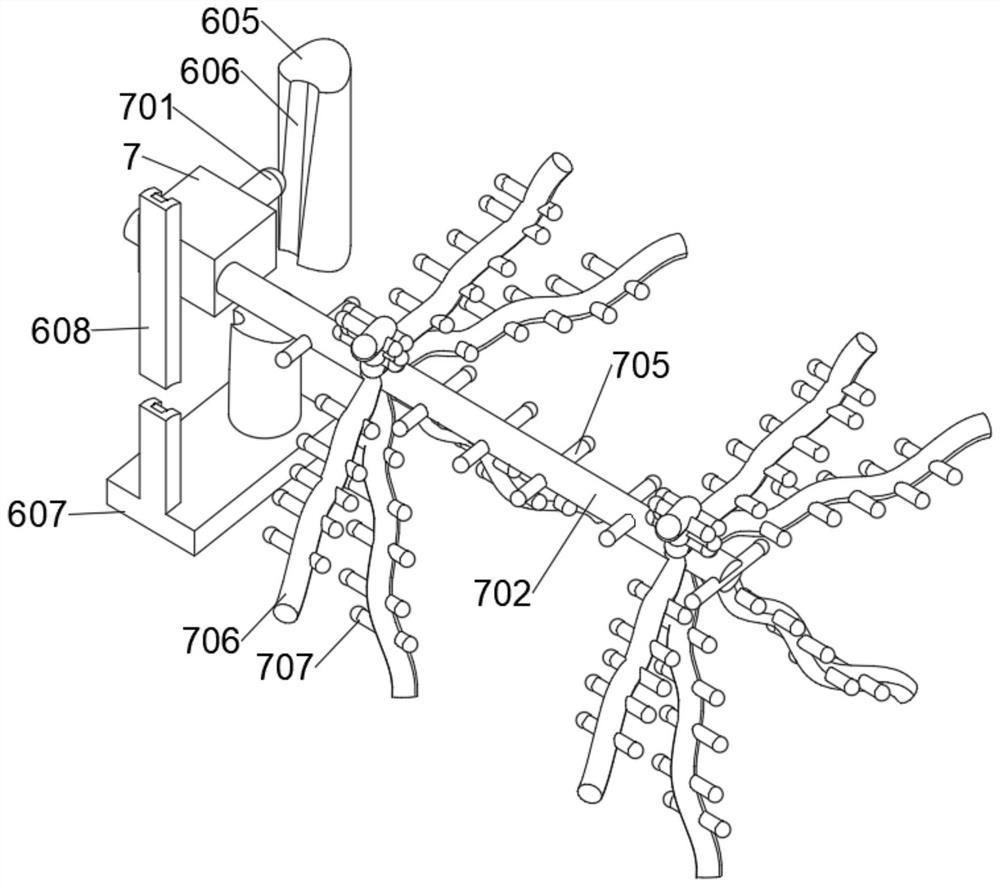

Vortex air flotation device

PendingCN113461096ALarge diameterReduce the number of bubblesWater/sewage treatment by flotationElectric machineryAir pump

The invention discloses a vortex air flotation device, and belongs to the technical field of air flotation. The vortex air flotation device comprises a pipe barrel, the pipe barrel is communicated with a conical water gap, and two handles are symmetrically arranged at the upper end of the circumferential outer wall of the pipe barrel. A semicircular plate is arranged above the pipe barrel, and an air pump is arranged in the middle of the upper portion of the semicircular plate. A U-shaped fixing block is arranged on the upper side in the pipe barrel, and two limiting columns are symmetrically and fixedly arranged in the middle of the outer side in the U-shaped fixing block. A mechanical box is arranged at the outer end of the upper part of the U-shaped fixing block, a motor is fixed in the mechanical box through a screw, and the output end of the motor penetrates through the outer wall of the U-shaped fixing block, extends into the U-shaped fixing block and is sleeved with a gear A. Through close fit of the structures, the device moves up and down to perform air flotation treatment on wastewater. Meanwhile, the internal wastewater can be stirred through revolution to break bubbles. The problems that bubbles generated by many air flotation devices used at present are large in diameter and small in number, the contact time of the bubbles and suspended solids is short, and the air flotation effect is poor are effectively solved.

Owner:汪洋

Dough band type fried puffed food and preparation method thereof

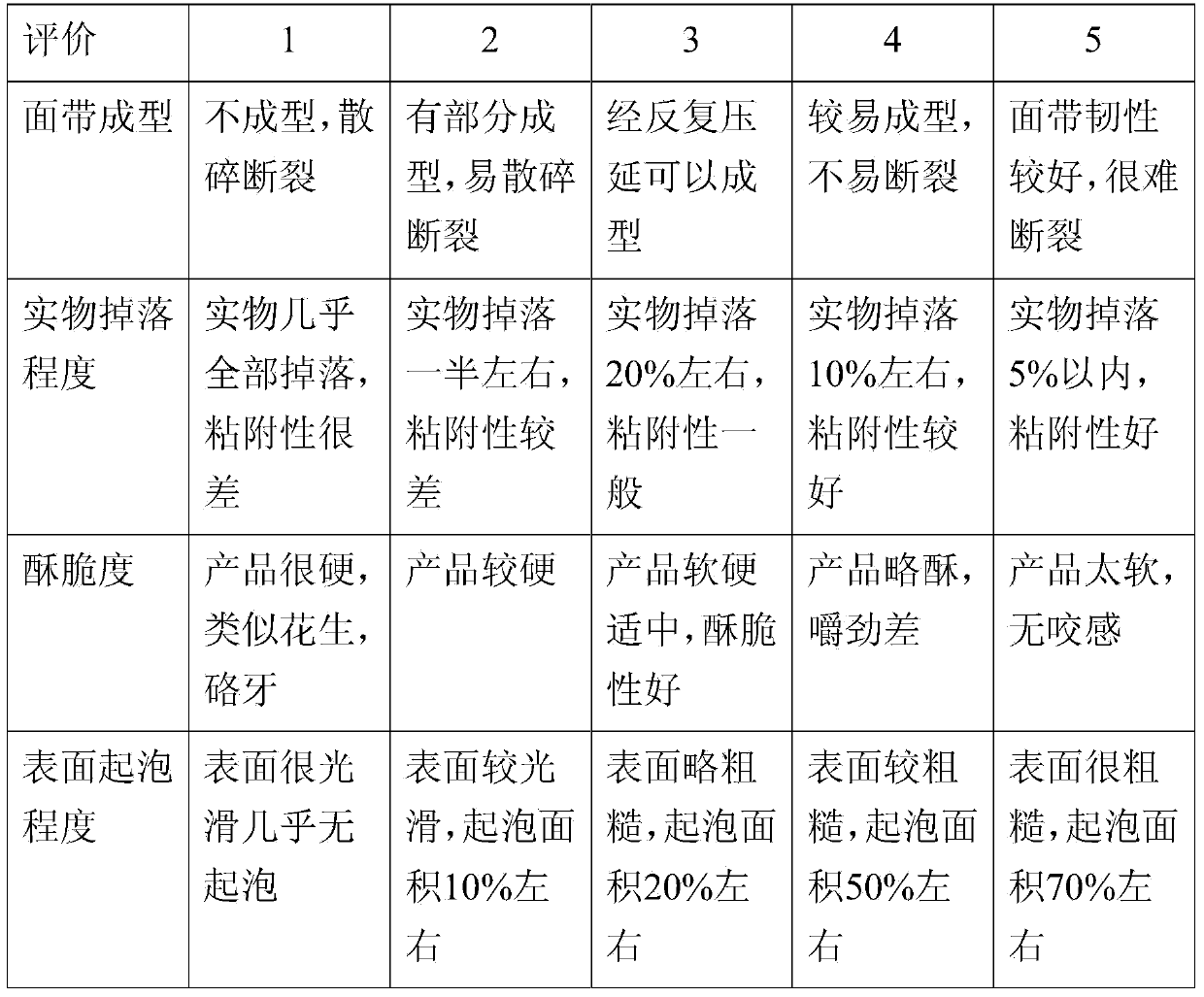

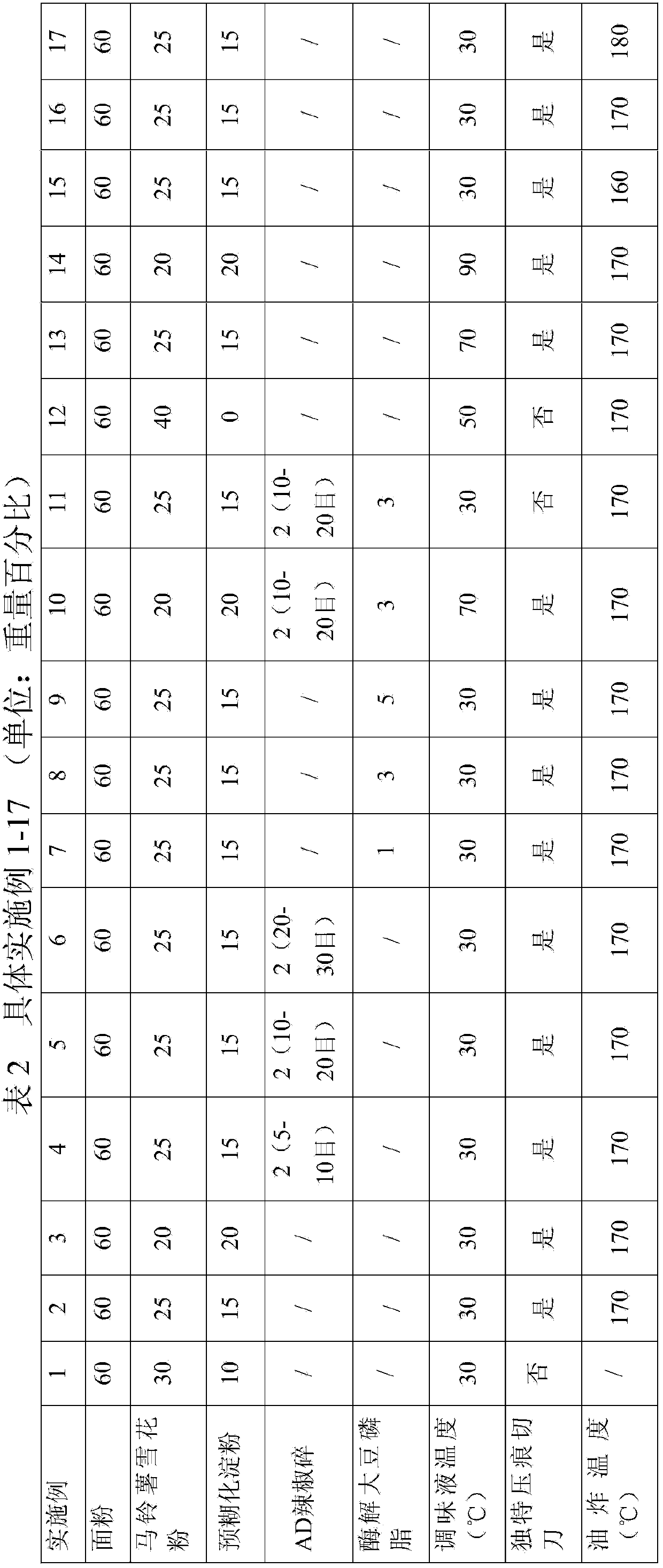

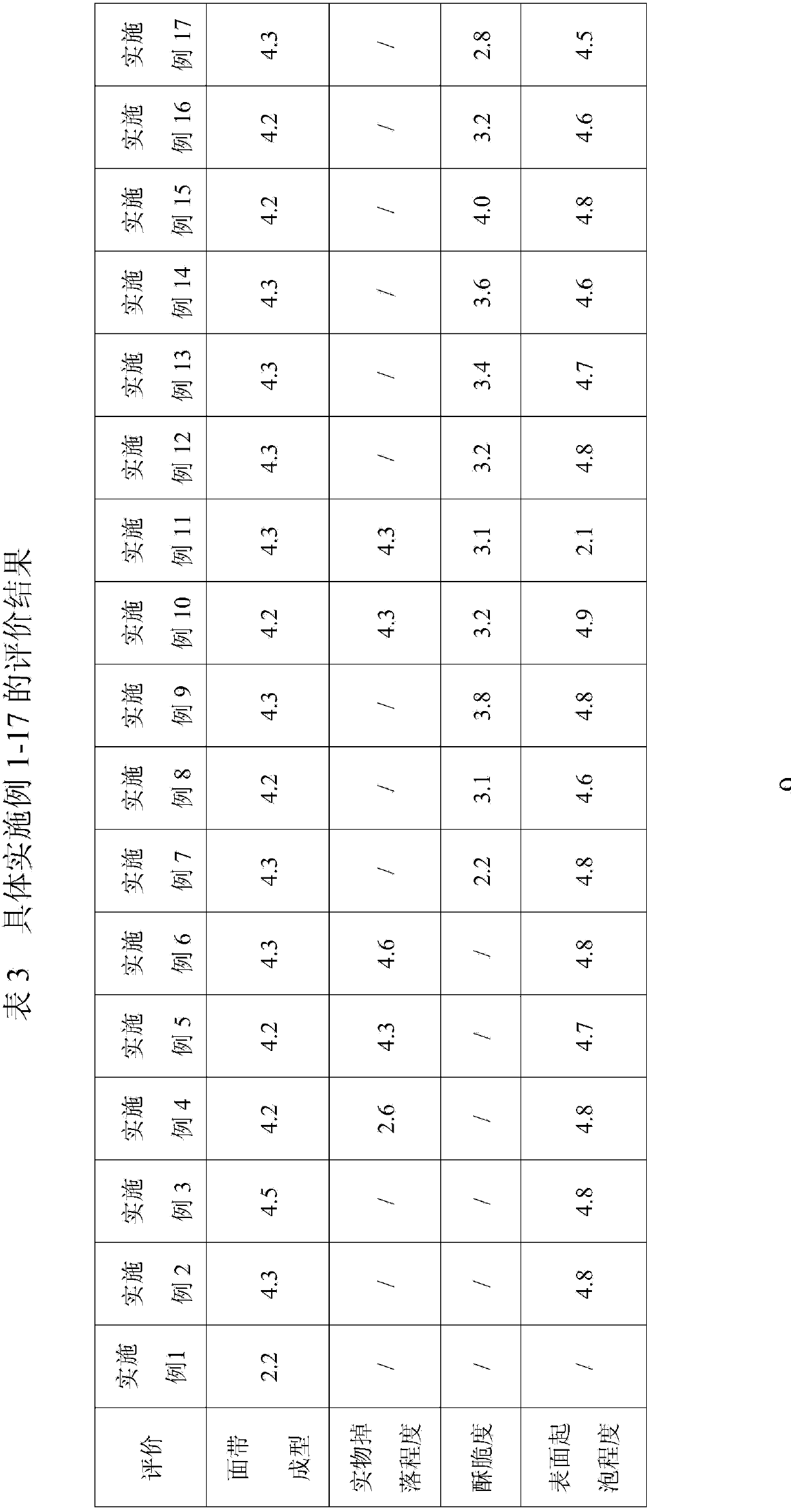

ActiveCN104207029AAvoid breakingPrevent fallingFood ingredientsFood shapingFlavorAdditive ingredient

The invention discloses a dough band type fried puffed food and a preparation method thereof. The preparation method disclosed by the invention improves the problems that dough bands are difficult to shape due to adhesion and substance granules are easy to drop by adding pregelatinized starch to ingredients of a traditional dough band type fried puffed food, and the condition that the dough bands have relatively few bubbles under the condition of ensuring the excellent crispness of finished products when the widths of the dough bands are more than 5mm can be realized by adopting a particular indentation technology, and thus the taste of the finished products is improved; in addition, in the preparation method disclosed by the invention, the continuous frying without interruption is realized by delivering semi-finished products into a fryer to be subjected to immersion type continuous frying by adopting a continuous delivering net belt in industrialized production, and thus the production efficiency under the precondition of ensuring the flavor and the taste of the finished products is greatly improved.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

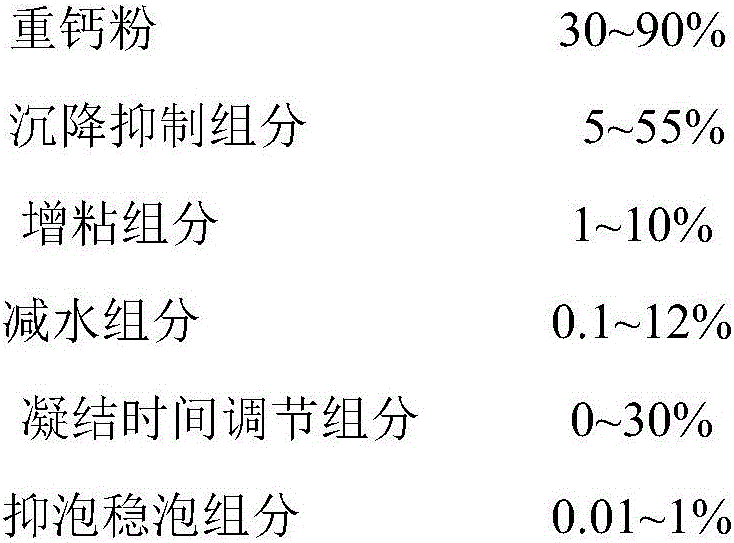

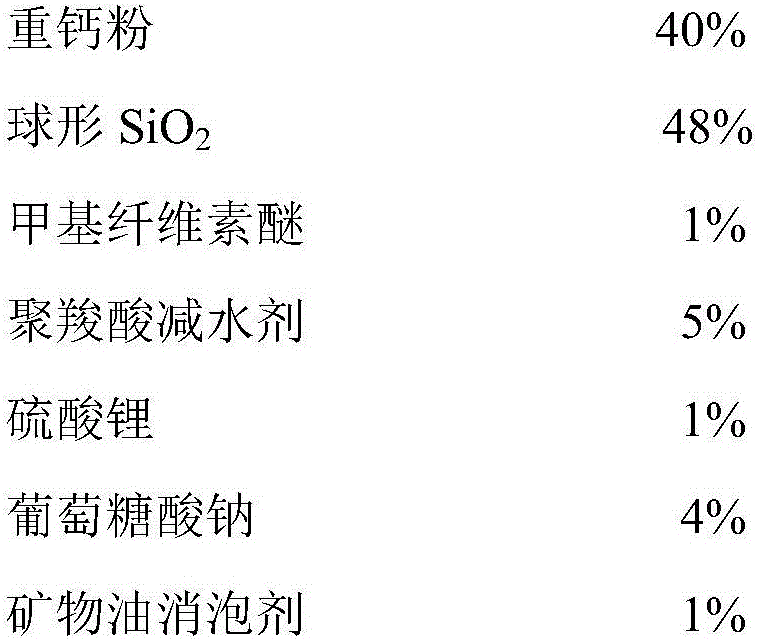

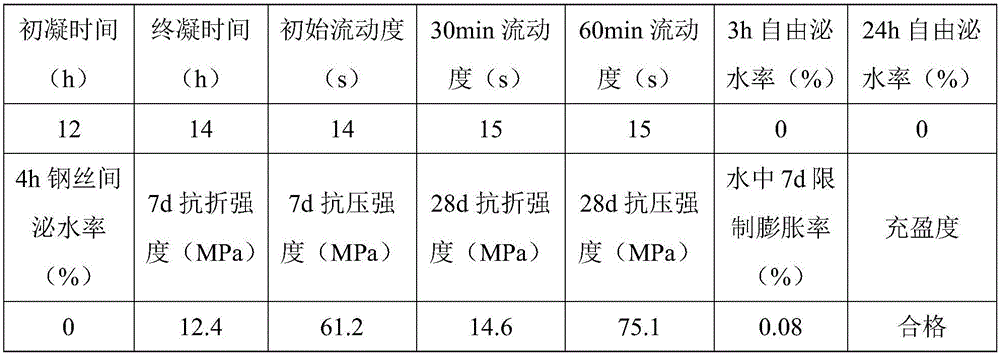

Viscosity reinforcing agent having water reducing function and specially used for cement mixture

The invention provides a viscosity reinforcing agent having a water reducing function and specially used for a cement mixture. The viscosity reinforcing agent is prepared from, by mass, coarse whiting powder 30-90%, a sedimentation inhibition component 5-55%, a viscosity reinforcing component 1-10%, a water reducing component 0.1-12%, a setting time adjusting component 0-30% and a foam inhibition and stabilization component 0.01-1%, wherein the coarse whiting powder is formed by conducting high energy ball milling on limestone mines and calcite, and the sedimentation inhibition component is one or two of spherical SiO2 with the particle size of 50-200 nm and light calcium carbonate. The viscosity reinforcing agent further has the water reducing function while the technical problems of bleeding, slurry floating and the like of a cement-based composite material are solved, the usage amount of the water reducing agent of the cement-based composite material is decreased, the usage amount of the viscosity reinforcing agent can be adjusted according to different air temperatures and different construction applications to meet the construction requirements, and the viscosity reinforcing agent has the advantages of being wide in application range and convenient to use.

Owner:WUHAN BILLION TECH DEV CO LTD

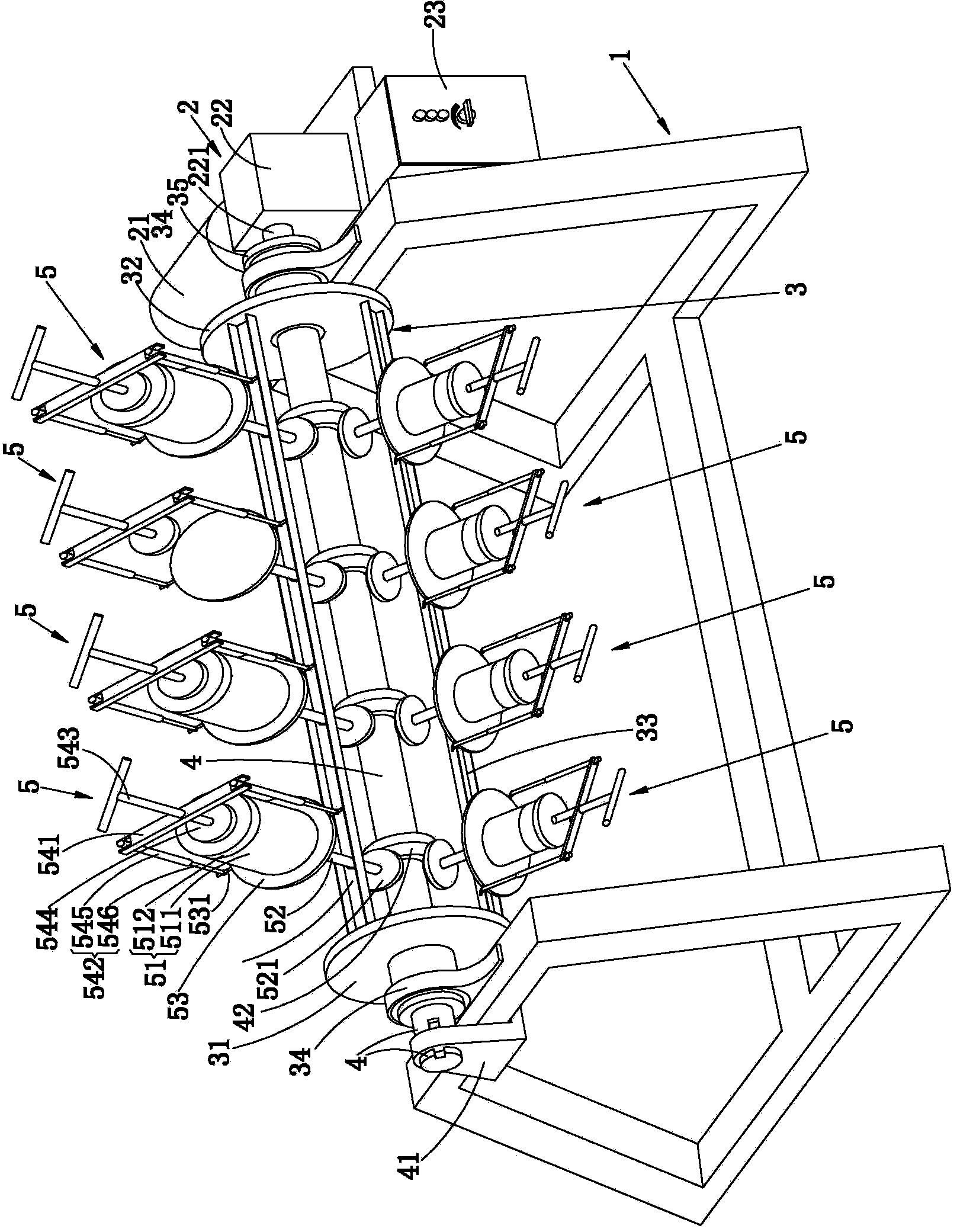

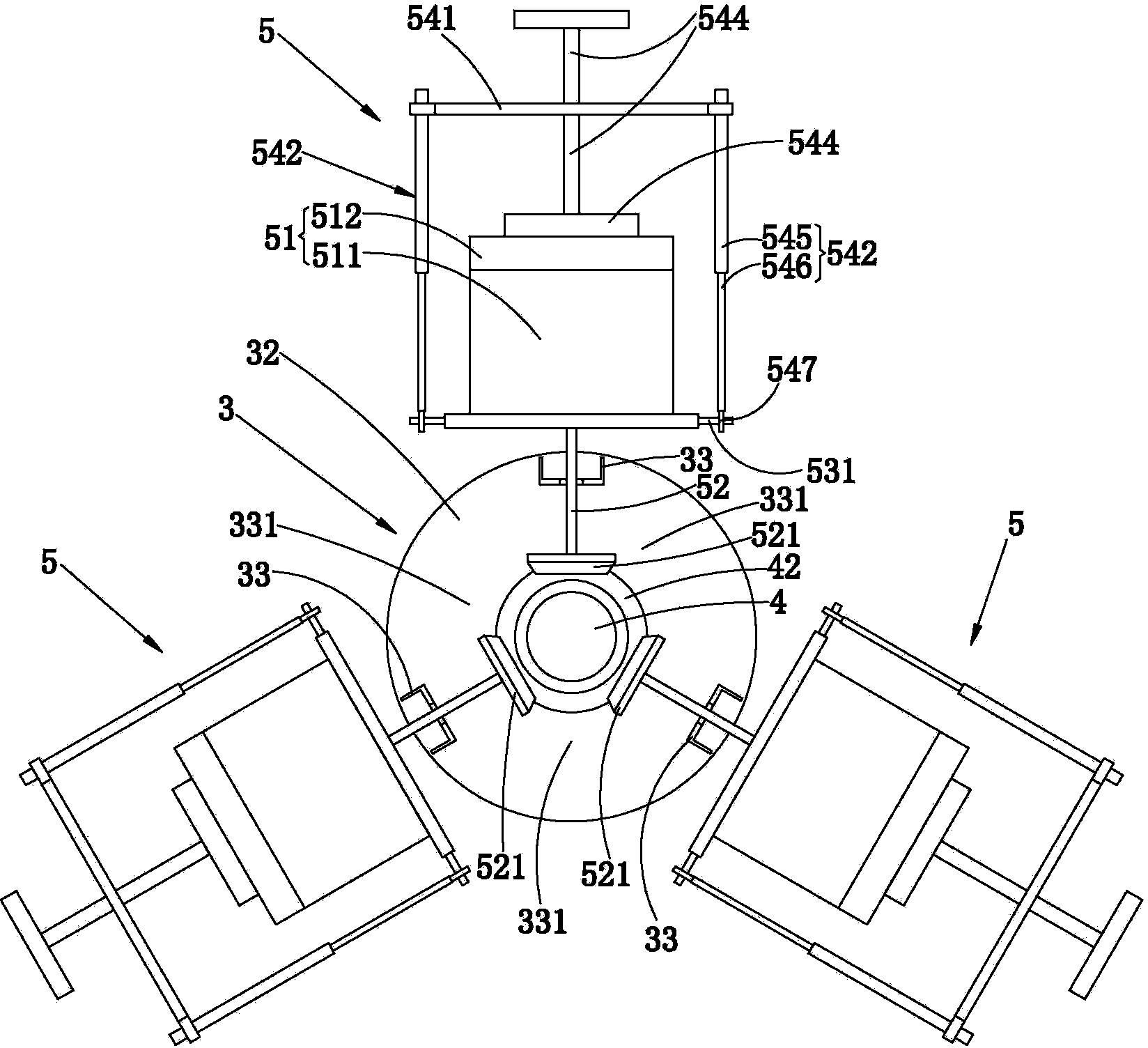

Forming machine for making hollow special-shaped biscuit

The invention relates to a forming machine for making a hollow special-shaped biscuit. The forming machine comprises a main frame, a driving machine, a forming frame and a fixed shaft, wherein the driving mechanism, the forming frame and the fixed shaft are arranged on the main frame. The driving mechanism drives a forming frame fixed shaft to rotate, a fixed part is fixedly arranged on the main frame, and one end of the fixed shaft is fixedly connected with the fixed part. At least one forming mechanism is arranged on the forming frame. The forming mechanism comprises a forming mold and a rotary shaft. The rotary shaft is movably arranged on the forming frame and drives the forming mold to rotate. A forming cavity used for containing slurry is formed in the forming mold. A first bevel gear is fixedly arranged on the fixed shaft. One end of the rotary shaft is provided with a second bevel gear and the second bevel gear is connected with the first bevel gear in a meshed mode.

Owner:DEHUA HONGSHUN CERAMICS CO LTD

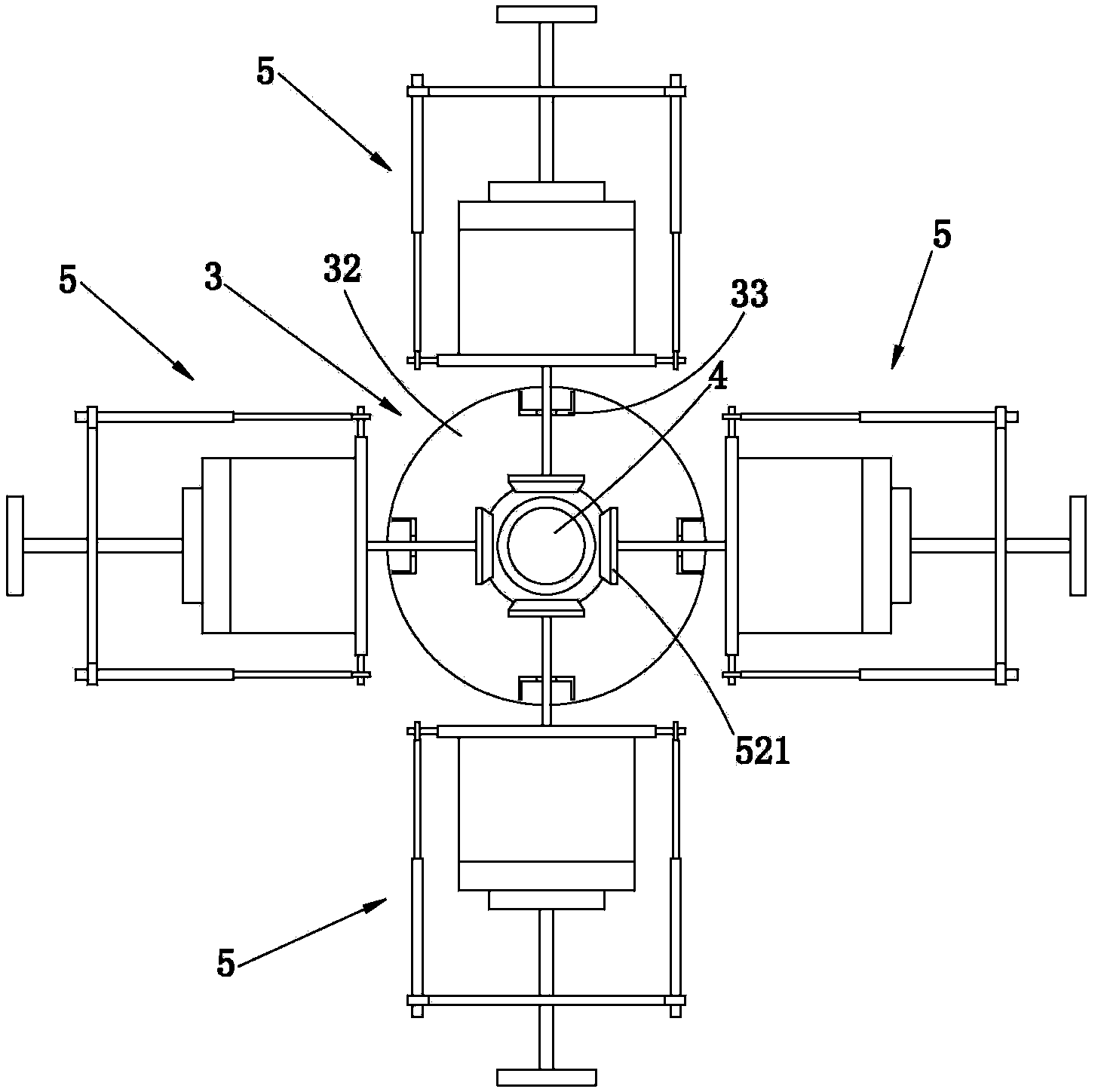

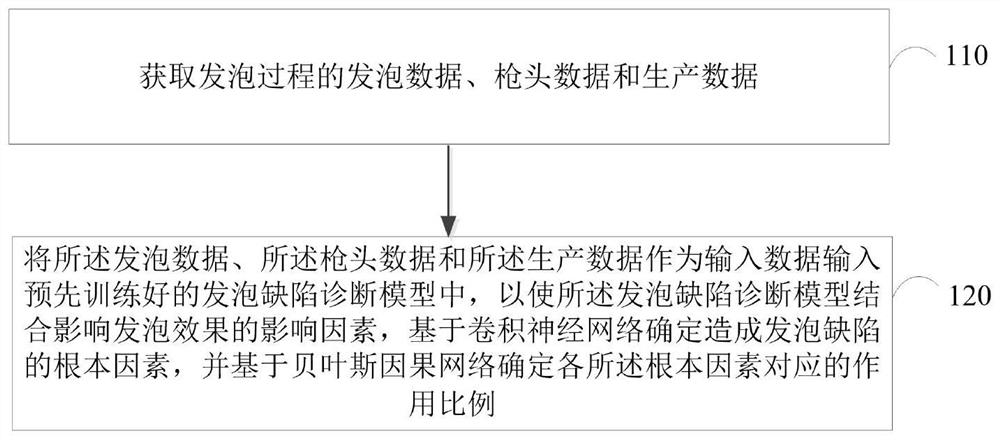

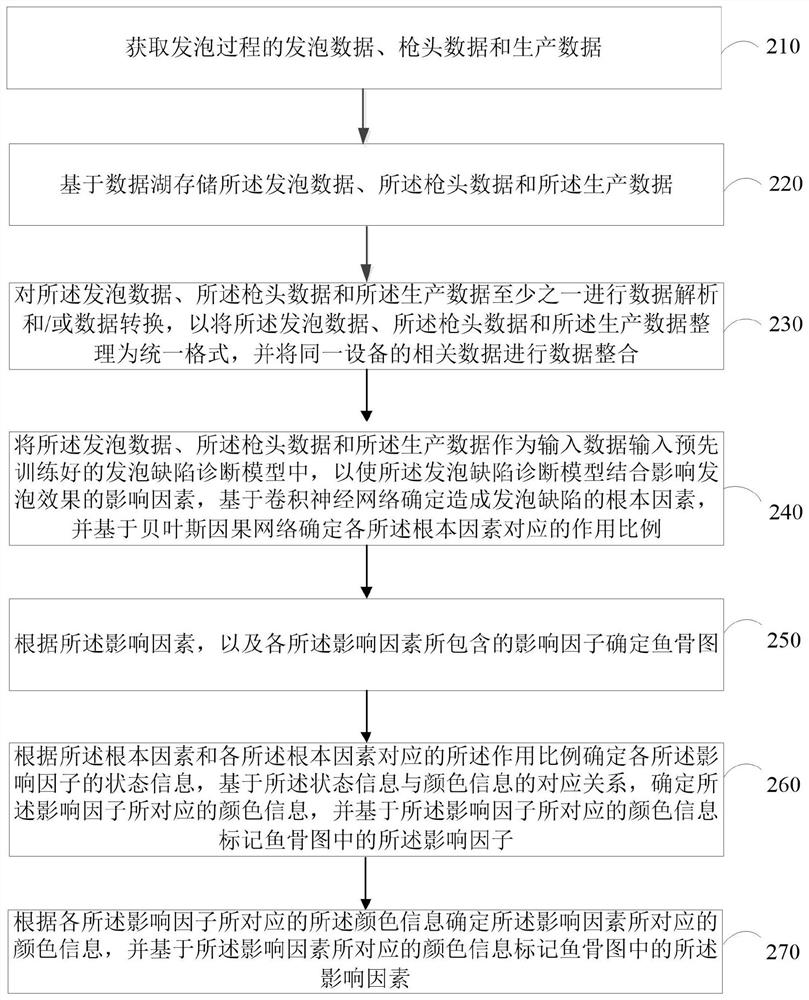

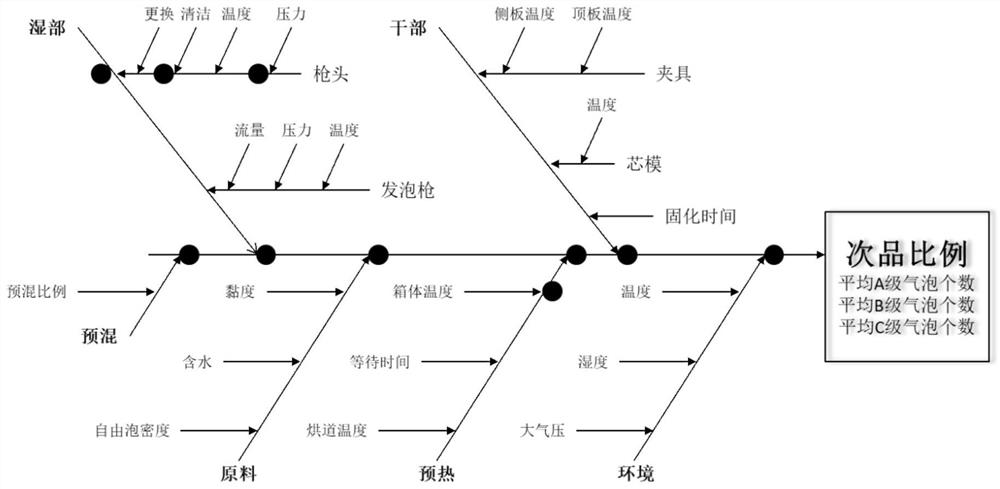

Foaming defect diagnosis method, device and equipment and storage medium

PendingCN114462576AImprove pass rateGood foaming effectMathematical modelsNeural architecturesEngineeringConvolution

The invention discloses a foaming defect diagnosis method, device and equipment and a storage medium. The method comprises the following steps: acquiring foaming data, gun head data and production data in a foaming process; the foaming data, the gun head data and the production data serve as input data to be input into a pre-trained foaming defect diagnosis model, so that the foaming defect diagnosis model determines basic factors causing foaming defects on the basis of a convolutional neural network in combination with influence factors influencing the foaming effect, and based on a Bayesian causal network, determining an action proportion corresponding to each root factor. According to the technical scheme, the foaming data, the gun head data and the production data obtained in the foaming process are input into the foaming defect diagnosis model, and the model processes the foaming data, the gun head data and the production data in combination with the influence factors influencing the foaming effect; determining the basic factors causing the foaming defect and the action proportion of each basic factor on the foaming defect, and realizing analysis and tracing of the basic factors causing the foaming defect.

Owner:QINGDAO HAIER INST OF IND INTELLIGENCE CO LTD +2

Foamed polyolefin resin sheet

InactiveCN103642107AReduce the number of bubblesHigh flexural modulusSynthetic resin layered productsAntistatic agentPolyolefin

PURPOSE: A foamed polyolefin resin sheet is provided to use in a container or glass substrate and to replace as a board alternative. CONSTITUTION: A foamed polyolefin resin sheet has 60-350 g / L of exterior density, 0.2-1.5 mm of thickness and 50-200 g / m^2. The number of foam in a thickness direction of the foamed sheet is 1-3. A polyolefin resin layer is laminated at least one side of the foamed sheet. 5-55 weight% of polymeric antistatic agent is mixed in the substrate resin with a resin layer.

Owner:JSP CORP

Modified polycarboxylic acid composite water reducing agent for steam-curing-free and steam-pressing-free PHC tubular pile

The invention discloses a modified polycarboxylic acid composite water reducing agent for a steam-curing-free and steam-pressing-free PHC tubular pile. The modified polycarboxylic acid composite water reducing agent for the steam-curing-free and steam-pressing-free PHC tubular pile consists of the following raw materials in percentages by mass: 30-60% of a polycarboxylic acid water reducing agent and 70-40% of a polycarboxylic acid modified aliphatic water reducing agent, wherein the water reducing rate of the polycarboxylic acid water reducing agent is greater than or equal to 45%, and the polycarboxylic acid modified aliphatic water reducing agent is a polycarboxylic acid modified aliphatic water reducing agent disclosed in the patent of CN100340518. A viscosity reducer and a defoamer can also be added in the modified polycarboxylic acid composite water reducing agent, the addition amount of the viscosity reducer is 1-5% of the total mass of the polycarboxylic acid water reducing agent and the polycarboxylic acid modified aliphatic water reducing agent, and the addition amount of the defoamer is 0.2-1.0% of the total mass of the polycarboxylic acid water reducing agent and the polycarboxylic acid modified aliphatic water reducing agent. The modified polycarboxylic acid composite water reducing agent for the steam-curing-free and steam-pressing-free PHC tubular pile effectively reduces water-binder ratio of concrete, and has characteristics of quick dispersion and low viscidity to meet requirements of strength of concrete of the PHC tubular pile, so that a curing process of normal-pressure steam curing and high-temperature steam pressing for the concrete of the PHC tubular pile is omitted.

Owner:NANCHANG YICHENG CHEM

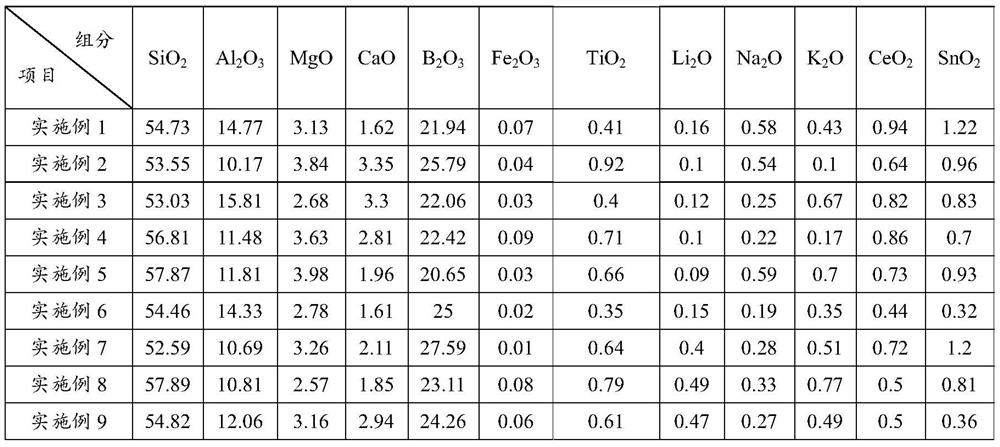

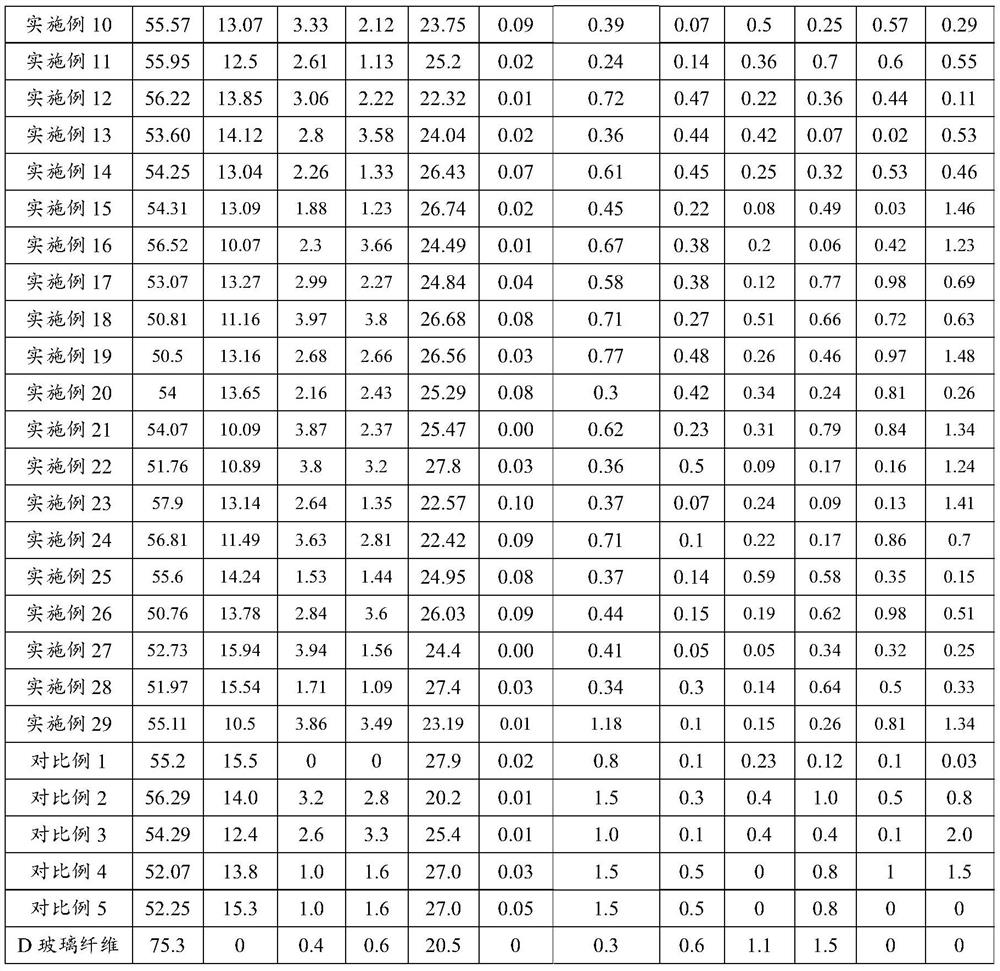

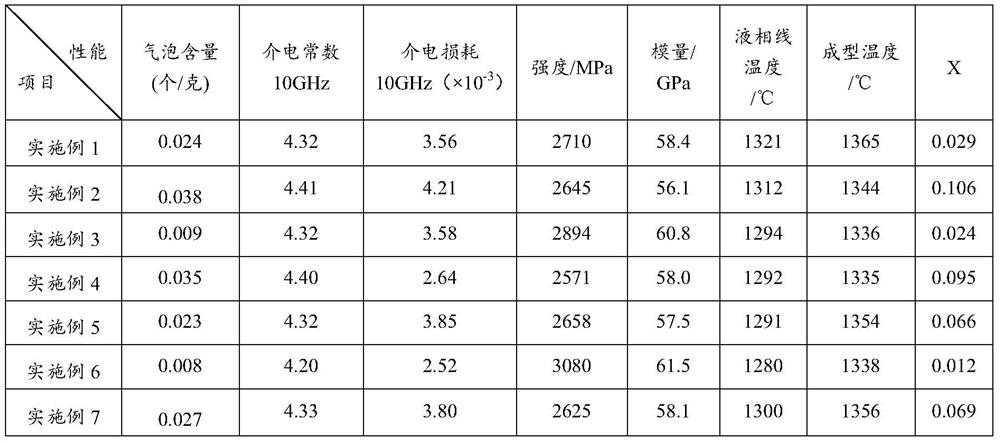

Low dielectric glass fiber and preparation method, glass fiber product, composite material and application

ActiveCN113135666BLow dielectric constantImprove performanceCasings/cabinets/drawers detailsQuartz/glass/vitreous enamelsGlass fiberAlkali metal oxide

The invention provides a low-dielectric glass fiber and its preparation method, glass fiber product, composite material and application. The invention reasonably adjusts the ratio of each oxide in the glass component to obtain high mechanical strength, good dielectric performance and melting Low-dielectric glass with excellent comprehensive performance such as simpler process. Specifically, by reasonably setting the ratio of silicon oxide, aluminum oxide and boron oxide, the glass fiber has a lower dielectric constant and dielectric loss, and the viscosity of the glass is properly adjusted. At the same time, considering the dielectric properties and mechanical strength Under the premise, through reasonable setting of alkaline earth metal oxides, alkali metal oxides, TiO 2 , CeO 2 and SnO 2 The dosage of the glass further improves the melting and clarifying performance of the glass, the temperature of the wire drawing is lower, the stability and yield are higher, the density is lower, and it has excellent workability.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

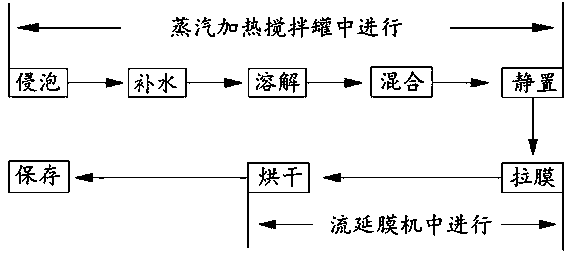

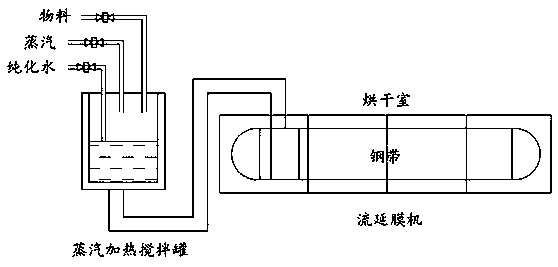

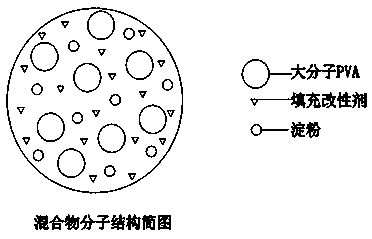

Degradable film and preparation method thereof

The invention discloses a degradable film. The degradable film is prepared from the following raw materials by weight percentage: 50%-60% of PVA, 20%-30% of corn starch, 20%-30% of glycerin, 2.5%-3% of a cross-linking agent PLA, 20%-30% of a filling modifier sugarcane fiber and 870%-1000% of purified water. The invention discloses a preparation method of the degradable film. The method includes the steps of: A. soaking: adding 50%-60% of PVA and 500%-600% of purified water into a steam heating stirring tank, stirring the substances evenly and performing standing for standby use. According to the invention, the macromolecular PVA and starch structure is filled with the micromolecular filling modifier sugarcane fiber to obtain the PVA film with higher strength, the water resistance of the film is strengthened, the film still keeps certain strength and elasticity after being soaked in water for a period of time, can be recycled, and is finally hydrolyzed and broken after being soaked in water for a long time, the degradation process is rapid, waste discarding is reduced, and stepwise heating and stepwise mixing avoid overheating decomposition of starch and other organic raw materialsand the influence on cross-linking.

Owner:青海益洁生物工程有限公司

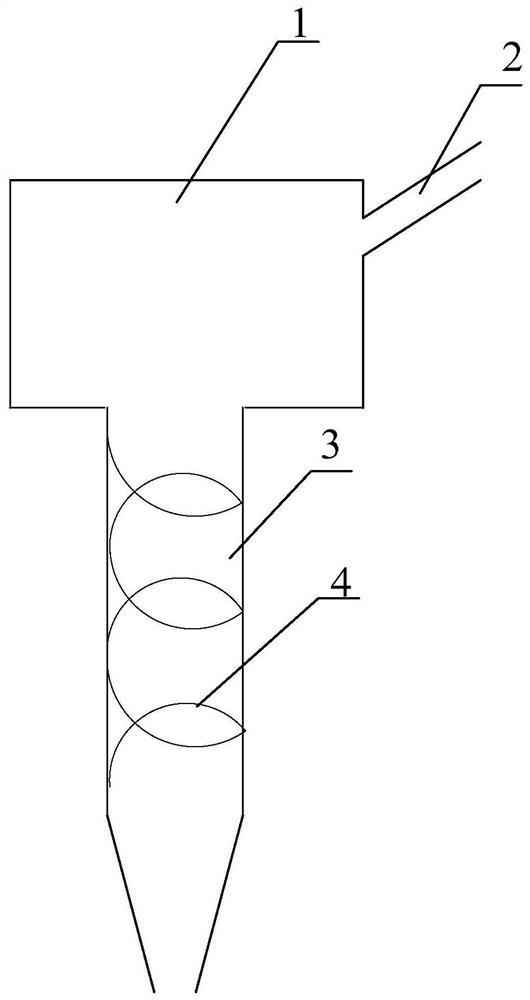

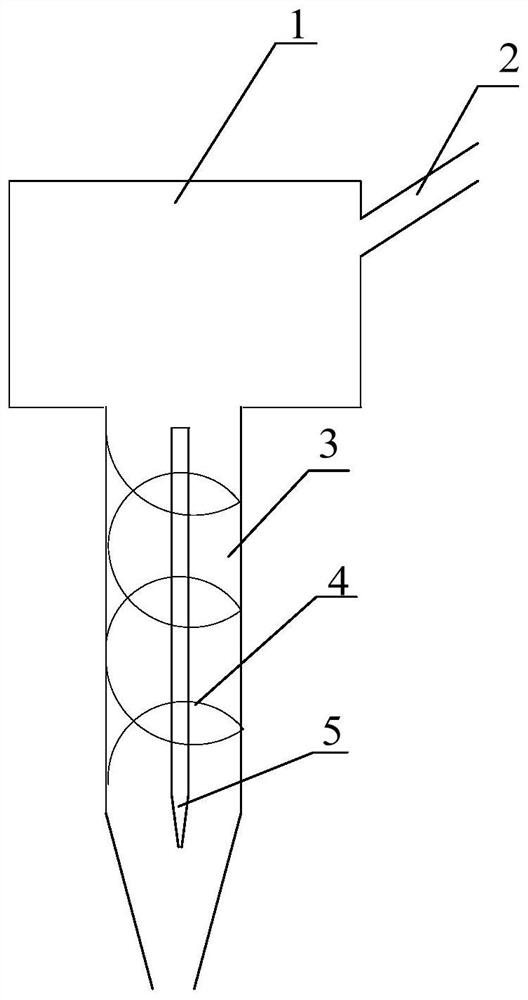

An inkjet printing nozzle

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com