Environment-friendly plastic injection mold

An injection mold, an environmentally friendly technology, applied in the field of environmentally friendly plastic injection molds, can solve the problems of low hardness, poor quality, fracture and other problems of the finished product, and achieve the effect of reducing the amount of pores, reducing the number of bubbles, and high quality and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

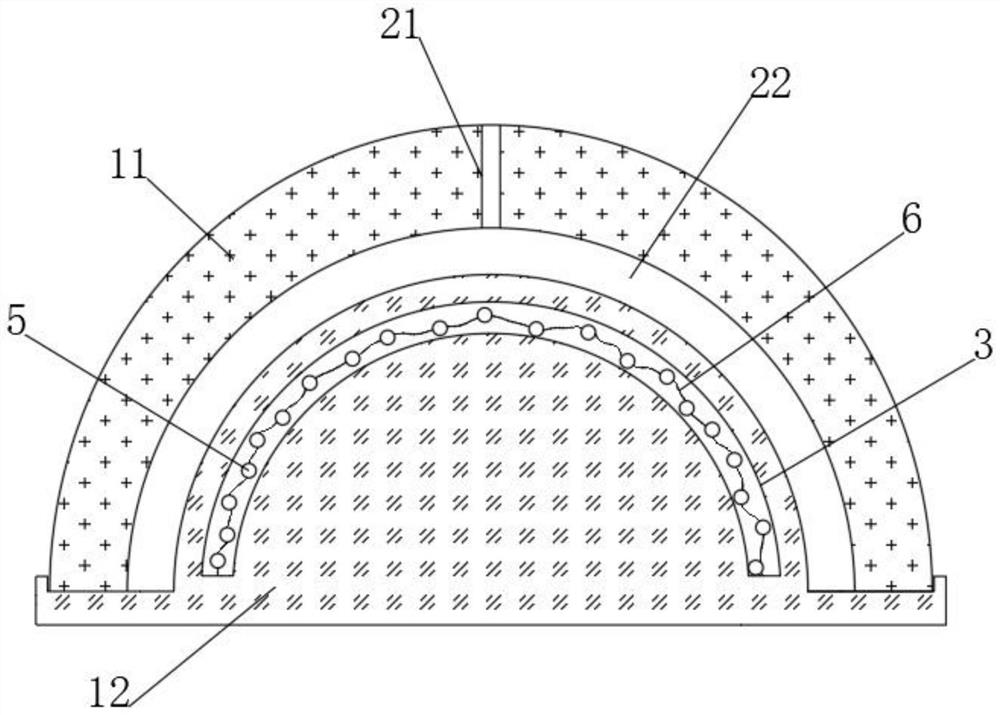

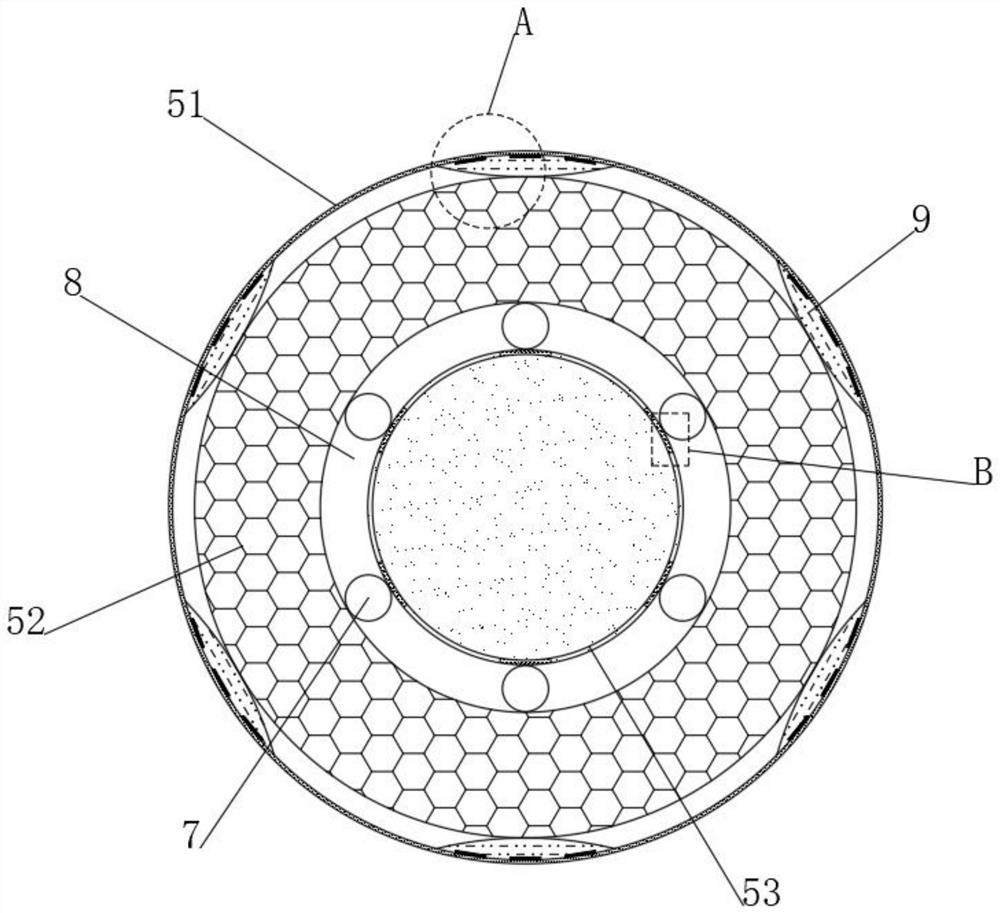

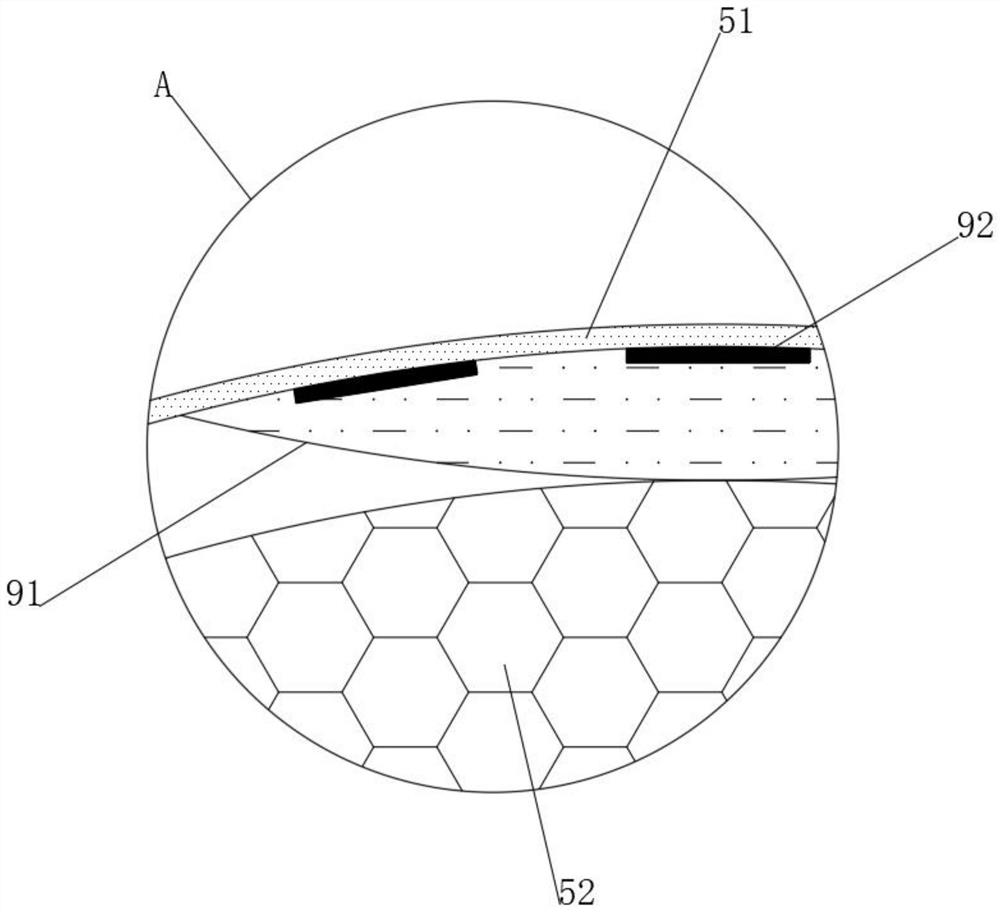

[0043] see figure 1 , an environment-friendly plastic injection mould, comprising an upper mold 11 and a lower mold 12 that match each other, a mold cavity 22 is formed between the upper mold 11 and the lower mold 12, and an injection port 21 is dug in the middle of the upper end of the upper mold 11, and the injection port 21 and The mold cavity 22 is connected, and a self-vibration cavity 3 is excavated inside the lower mold 12. The self-vibration cavity 3 corresponds to the mold cavity 22. A thermal ball chain is connected between the two inner bottom ends of the self-vibration cavity 3 on the left and right sides. The thermal ball chain includes a position control rope 6 fixedly connected to the inner wall of the vibration cavity 3 and a plurality of thermal collision balls 5 fixedly connected to the position control rope 6. The diameter of the thermal collision ball 5 is 1 of the radial width of the self vibration cavity 3. / 2-1 / 3, to effectively ensure the collision forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com