Fine grinding device for buckwheat high protein flour production and processing

A high-gluten flour, fine-grinding technology, applied in application, cocoa, grain processing and other directions, can solve the problems of unfavorable patients taking, affecting the hygiene and quality of medicinal liquid, easy to burn hands, etc., achieving remarkable results, small flour particle size, The effect of speeding up the cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

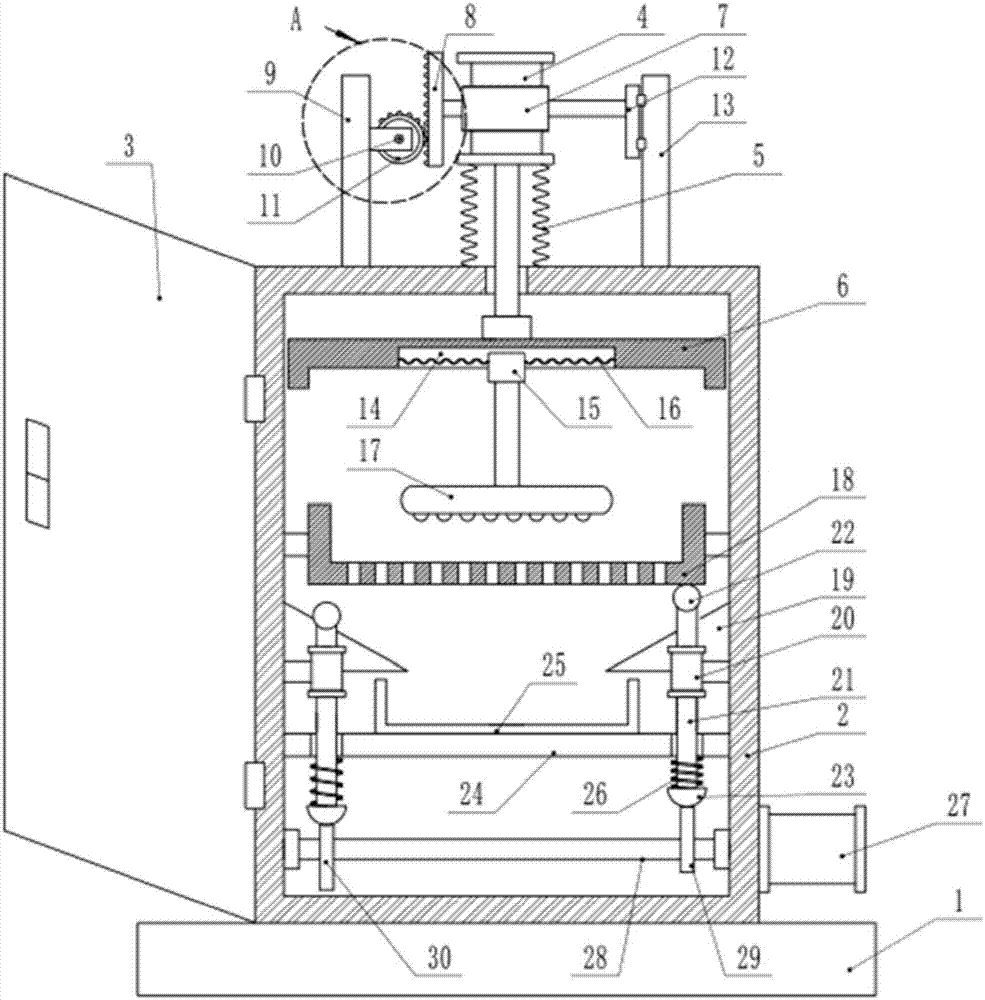

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

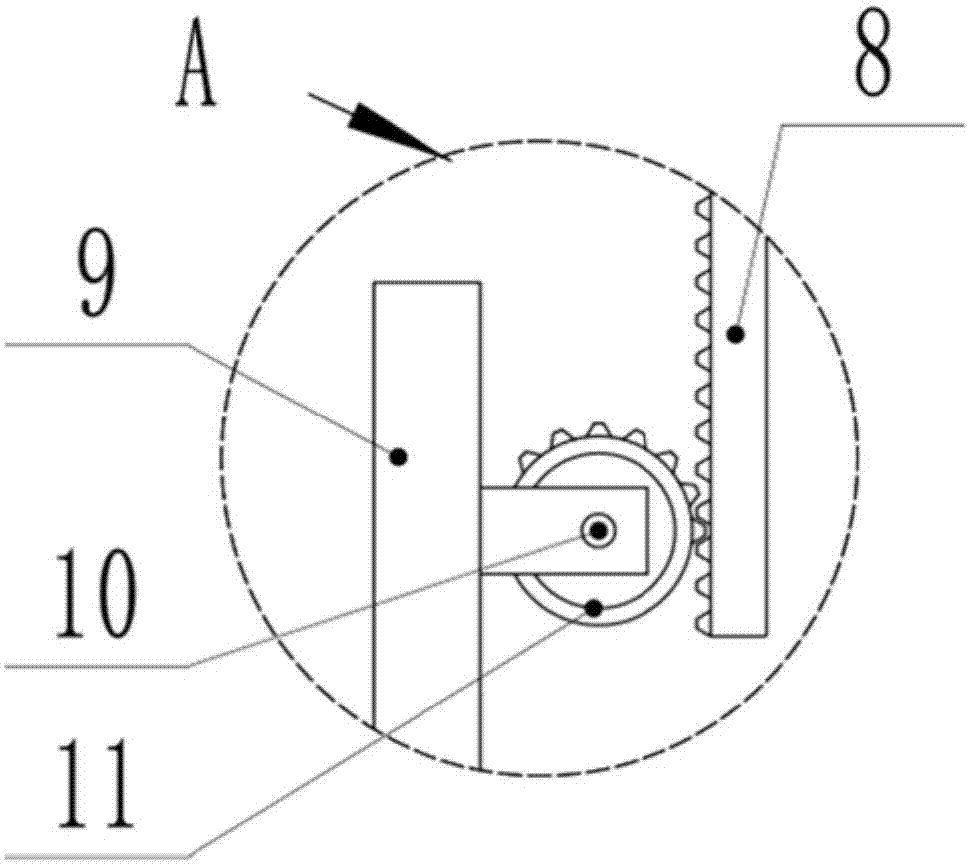

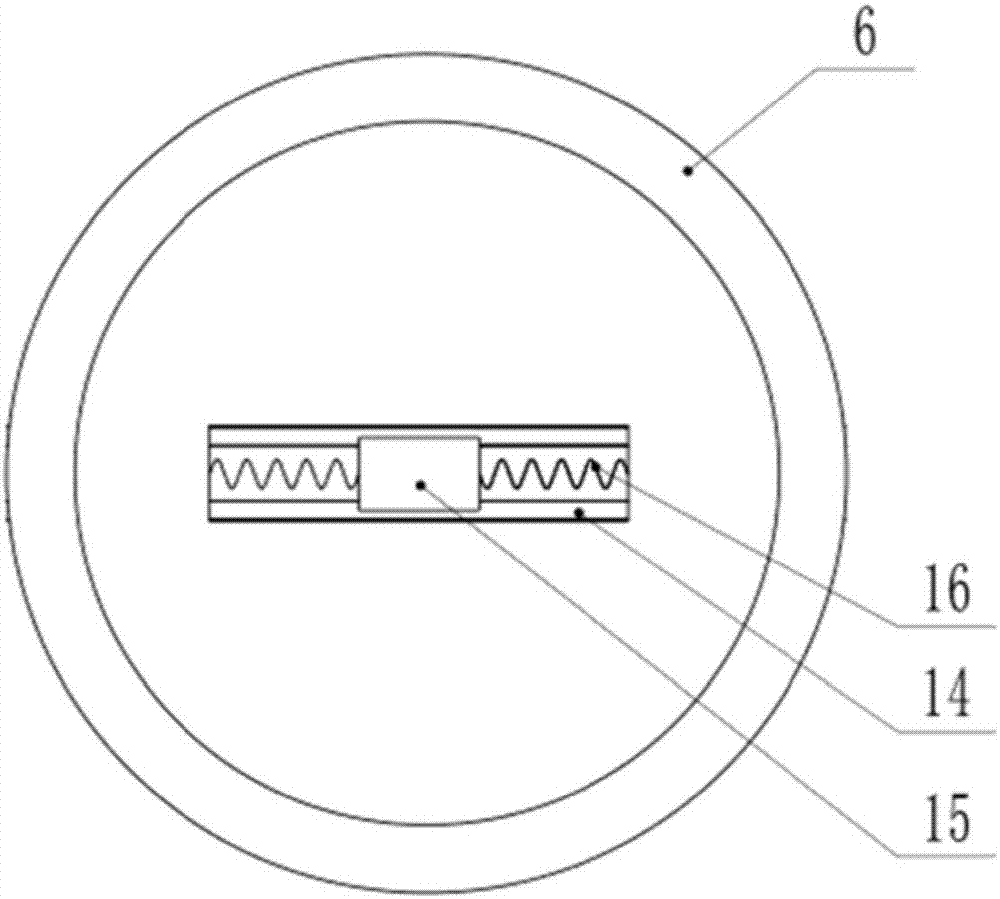

[0021] see Figure 1-3 , a fine grinding device for production and processing of buckwheat high-gluten flour, comprising a grinding box 2, a grinding motor 4, a turntable 6, a grinding device 17, a grinding tank 18, an impact ball 22 and a receiving tank 25, and the base 1 is provided with Grinding box 2, the grinding box 2 and the base 1 are fixedly connected by bolts, the left side of the grinding box 2 is also hinged with a sealed door 3, and a grinding motor 4 is arranged above the grinding box 2, and the grinding motor 4 and the grinding box 2 There is a support spring 5 connected therebetween, and the support spring 5 plays a supporting role to the grinding motor 4. A bracket 7 is fixedly installed on the grinding motor 4 by screws, and the bracket 7 includes a clamp and a hoop, and the clamp and the ring The hoops are connected by bolts and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com