Forming machine for making hollow special-shaped biscuit

A molding machine and molding mechanism technology, applied in ceramic molding machines, manufacturing tools, die-casting molds, etc., can solve the problems of poor thickness uniformity, low production efficiency, and high production costs, and achieve low equipment costs, high production efficiency, and high production efficiency. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

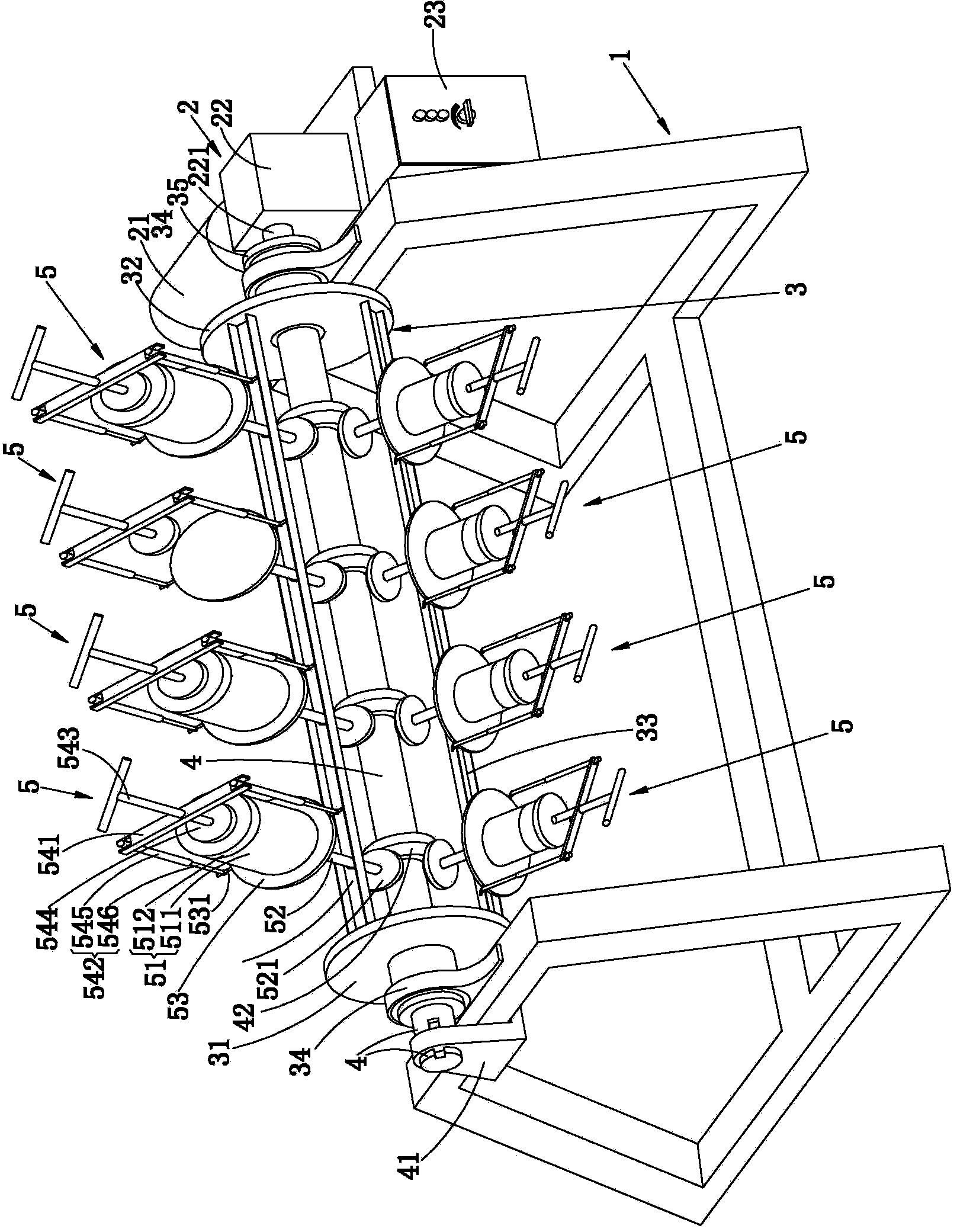

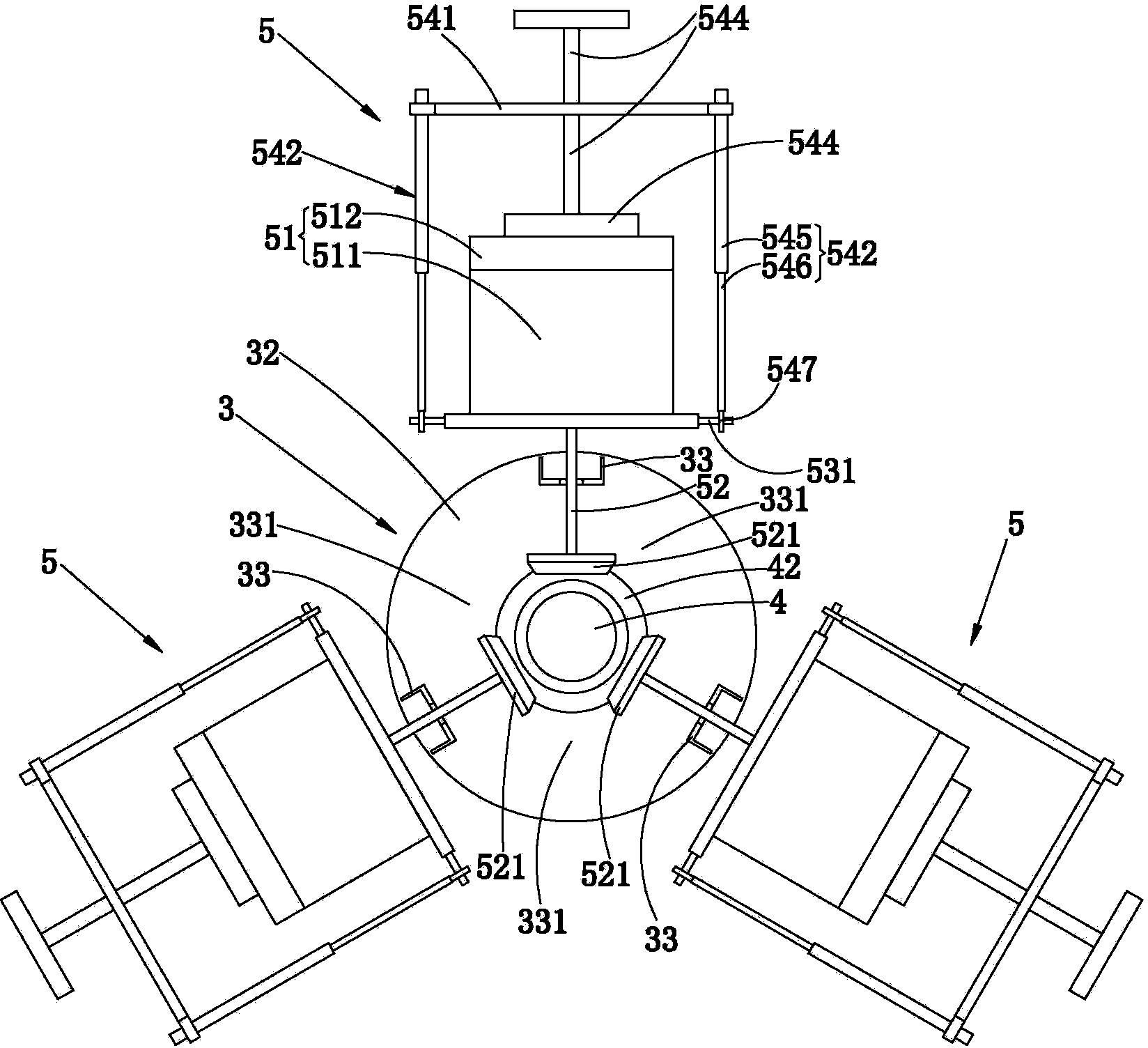

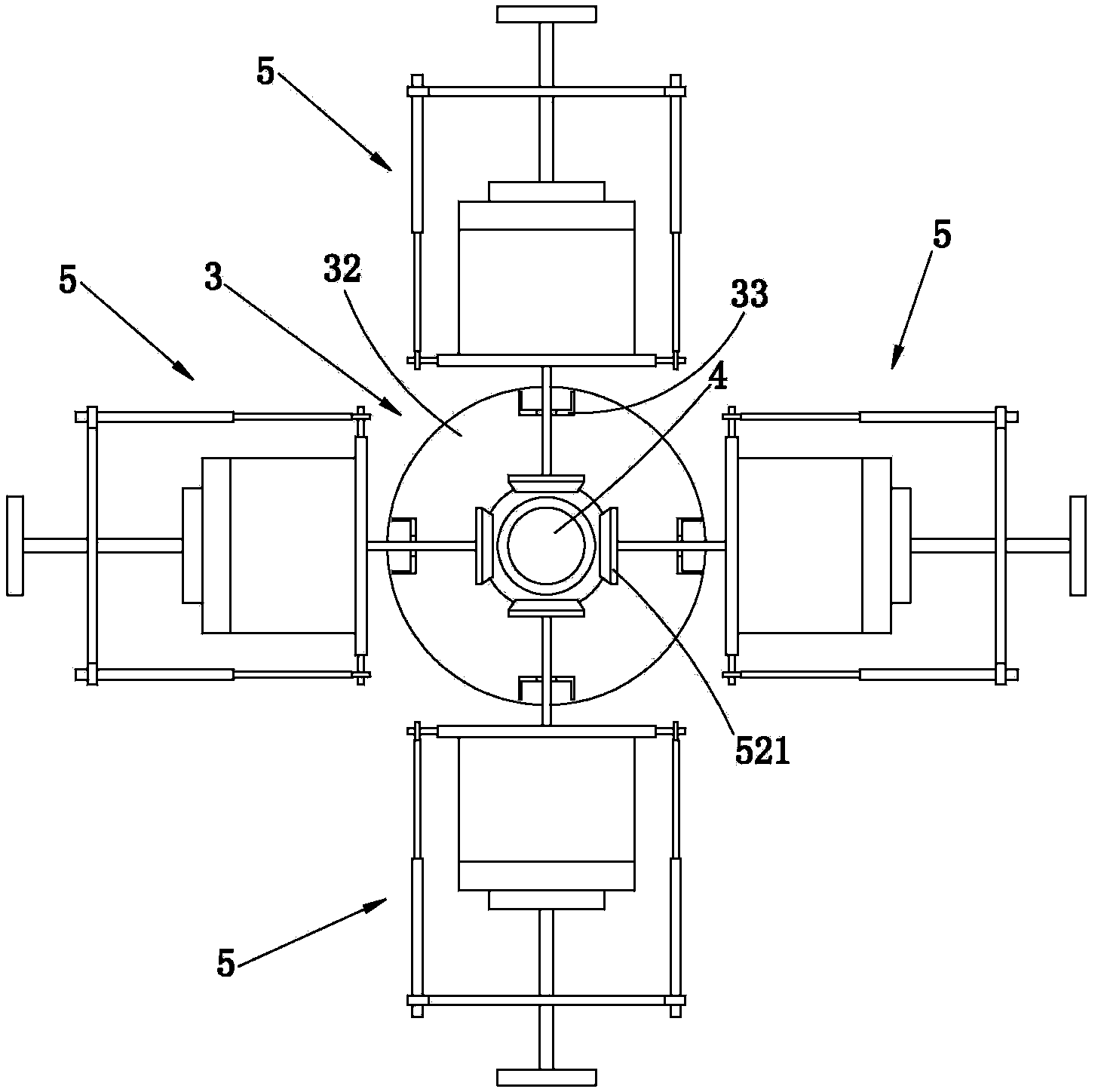

[0017] refer to figure 1 , a forming machine for preparing hollow shaped blanks, which includes a main frame body 1 and a driving mechanism 2, a forming frame 3, and a fixed shaft 4 arranged on the main frame body 1, and the driving mechanism 2 drives the forming frame 3 Fixed axis rotation.

[0018] The driving mechanism 2 includes a motor 21 and a reduction box 22. The motor 21 and the reduction box 22 are respectively fixedly assembled on the main frame body 1. The reduction box 22 is equipped with a power output rod 221. The power of 21 is transmitted to the power take-off rod 221 through the reduction box 22, and the power take-off rod 221 then rotates.

[0019] The forming frame 3 is composed of a left side plate 31 , a right side plate 32 and at least two connecting bars 33 . The quantity of connecting strip 33 can be set according to factors su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com