Modified polycarboxylic acid composite water reducing agent for steam-curing-free and steam-pressing-free PHC tubular pile

A technology of PHC pipe pile and composite water reducer, which is applied in the field of concrete, can solve the problems of low water ash, high viscosity of concrete, and difficulty in production, and achieve the effect of reducing the water-binder ratio, reducing the number of air bubbles, and benefiting the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

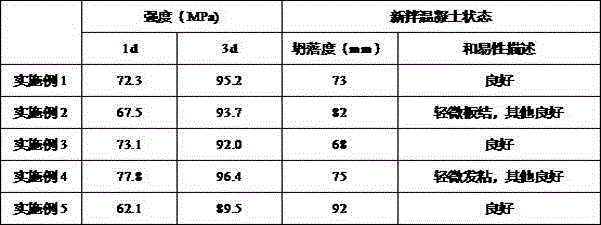

Embodiment 1

[0020] In the embodiment of the present invention, a modified polycarboxylate composite water-reducer for autoclaved PHC pipe piles without steam curing, 50% polycarboxylate water-reducer, 50% polycarboxylate-modified aliphatic water-reducer, Wherein the water-reducing rate of the polycarboxylate water-reducer is ≥ 45%, the polycarboxylate-modified aliphatic water-reducer is the polycarboxylate-modified aliphatic water-reducer disclosed in CN100340518, and the viscosity reducer is the polycarboxylate water-reducer 2% of the total mass of the polycarboxylic acid modified aliphatic water reducer, and the defoamer is 0.6% of the total mass of the polycarboxylate water reducer and the polycarboxylate modified aliphatic water reducer. The prepared modified polycarboxylate composite water reducer is 1.0% of the cementitious material in the concrete, and the water-binder ratio of the concrete is 0.26. The properties and strength of the measured concrete are listed in Table 1.

Embodiment 2

[0022] In the embodiment of the present invention, a modified polycarboxylate composite water reducer for autoclaved PHC pipe piles free of steam curing, 60% polycarboxylate water reducer, 40% polycarboxylate modified aliphatic water reducer, Wherein the water-reducing rate of the polycarboxylate water-reducer is ≥ 45%, the polycarboxylate-modified aliphatic water-reducer is the polycarboxylate-modified aliphatic water-reducer disclosed in CN100340518, and the viscosity reducer is the polycarboxylate water-reducer 3% of the total mass of the polycarboxylic acid modified aliphatic water reducer, and the defoamer is 0.8% of the total mass of the polycarboxylate water reducer and the polycarboxylate modified aliphatic water reducer. The prepared modified polycarboxylate composite water reducer is 1.0% of the cementitious material in the concrete, and the water-binder ratio of the concrete is 0.26. The properties and strength of the measured concrete are listed in Table 1.

Embodiment 3

[0024] In the embodiment of the present invention, a modified polycarboxylate composite water reducer for autoclaved PHC pipe piles free of steam curing, 40% polycarboxylate water reducer, 60% polycarboxylate modified aliphatic water reducer, Wherein the water-reducing rate of the polycarboxylate water-reducer is ≥ 45%, the polycarboxylate-modified aliphatic water-reducer is the polycarboxylate-modified aliphatic water-reducer disclosed in CN100340518, and the viscosity reducer is the polycarboxylate water-reducer 1.5% of the total mass of the polycarboxylic acid modified aliphatic water reducer, and the defoamer is 0.5% of the total mass of the polycarboxylate water reducer and the polycarboxylic acid modified aliphatic water reducer. The prepared modified polycarboxylate composite water reducer is 1.0% of the cementitious material in the concrete, and the water-binder ratio of the concrete is 0.26. The properties and strength of the measured concrete are listed in Table 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com