Ultra-high performance concrete for expansion joint transition area and preparation method thereof

An ultra-high-performance, transition zone technology, applied in the field of building materials, can solve the problems of insufficient tensile deformation capacity, low service life, bridge design life, poor deformation capacity, etc., to improve the overall deformation capacity and load-bearing performance, excellent work Performance and durability, improving mechanical properties and impermeability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

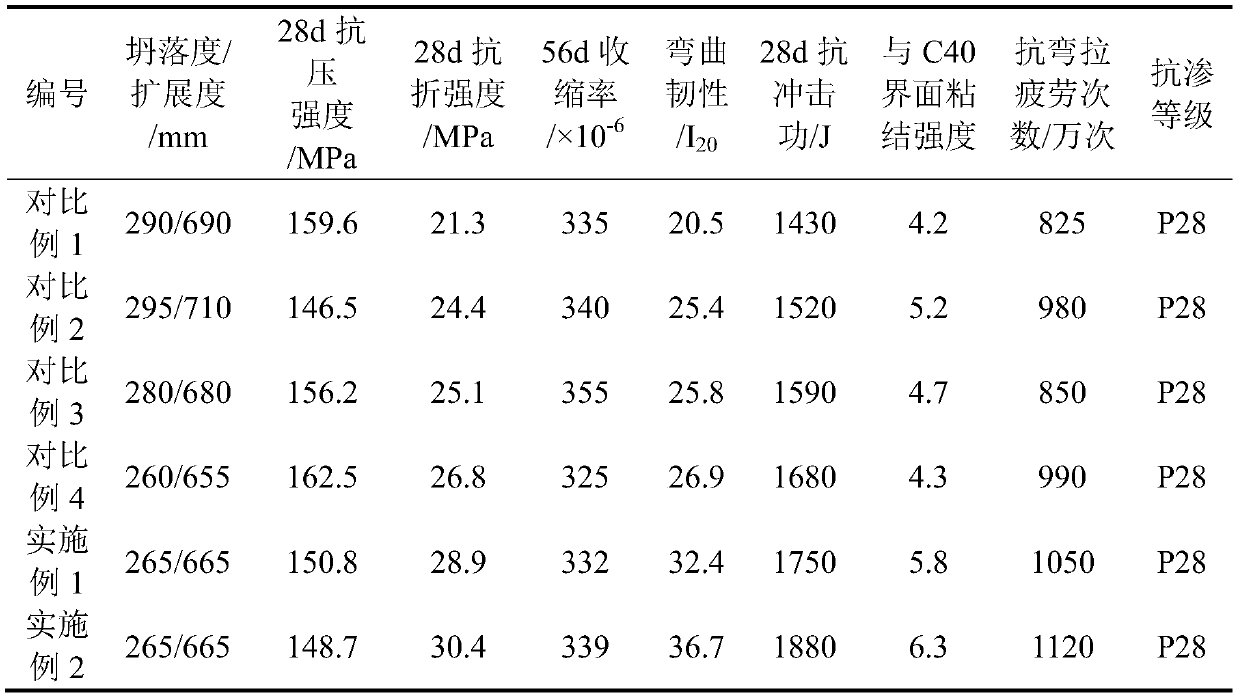

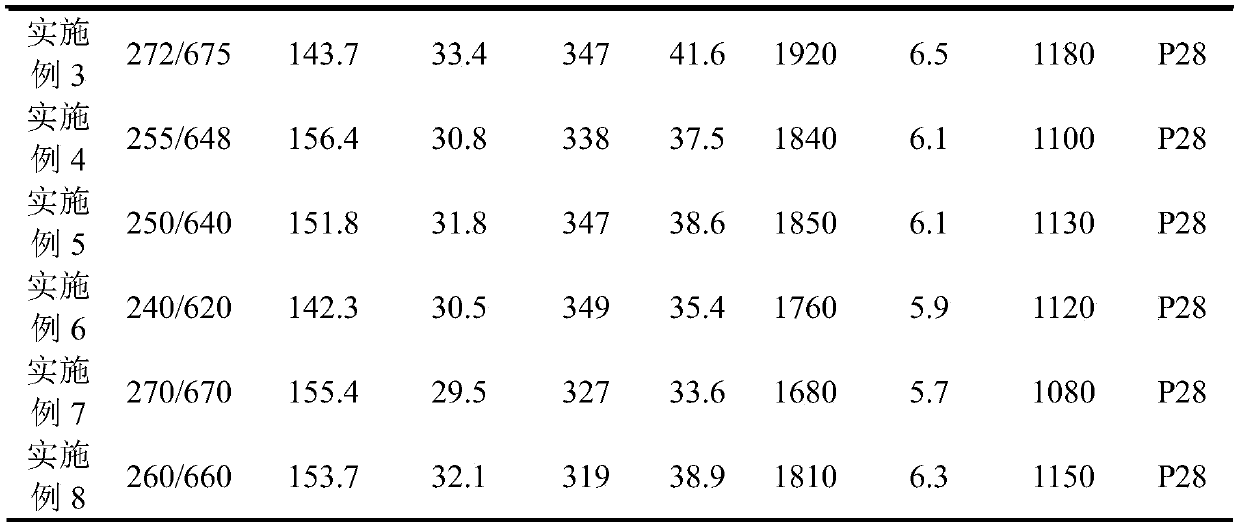

Examples

Embodiment 1~6

[0034] An ultra-high-performance concrete in an expansion joint transition zone, the preparation method of which comprises the following steps:

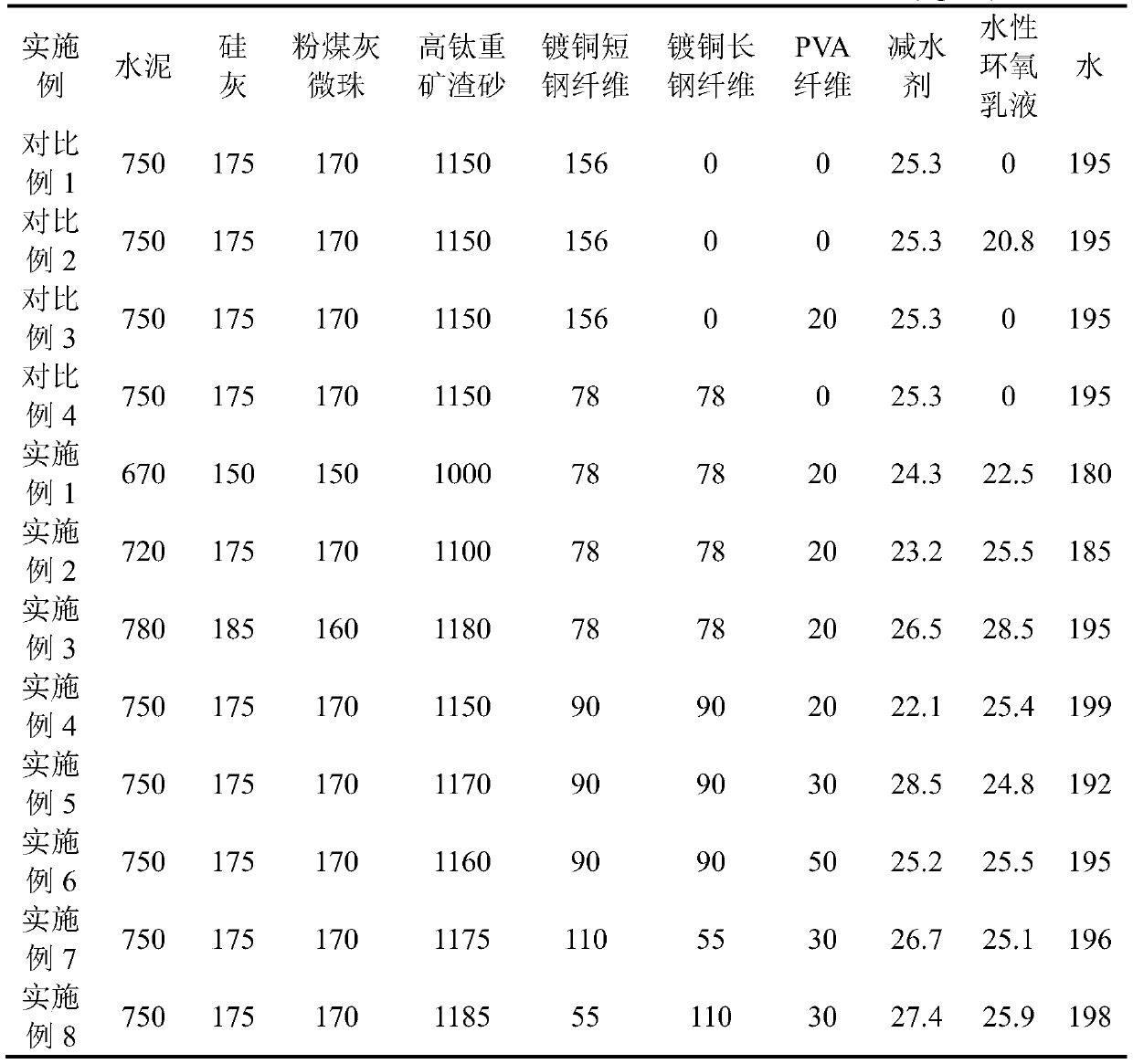

[0035] 1) take each raw material according to the proportioning described in Table 1;

[0036] 2) Add the pre-wetted high-titanium heavy slag sand, cement, silica fume, and fly ash microbeads into the concrete mixer for 1-3 minutes until visually uniform, then pour 70%-80% water and ultra-dispersion shrinkage reducing admixture to wet Stir for 3 to 5 minutes, then add the prepared water-based epoxy emulsion and the remaining water and stir for 3 to 5 minutes, and finally add copper-plated short steel fibers, copper-plated long steel fibers and PVA fibers and stir evenly; After moulding, vibrating, and forming, the surface is covered with an impermeable film for film curing, then the formwork is removed, and finally the standard curing is carried out to the specified age, and the ultra-high performance concrete in the transition zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com