Indoor high-intensity rapid-setting repairing material and preparation method therefor

A repair material and quick-setting technology, applied in the field of repair materials, can solve the problems of poor bond strength, low early strength, slow setting and hardening time, etc., and achieve the effect of good bond strength, high early strength and short setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

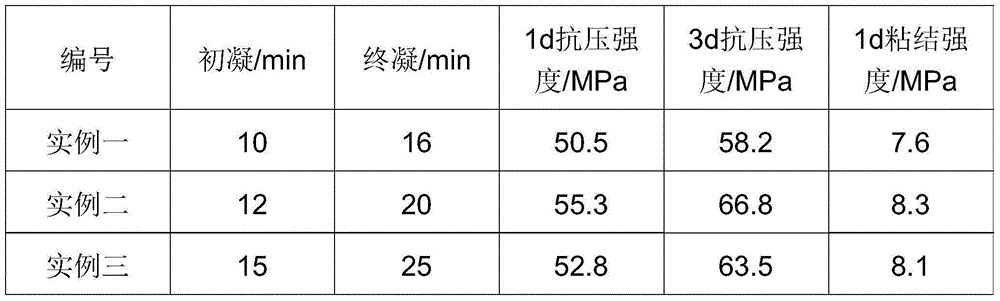

Examples

example 1

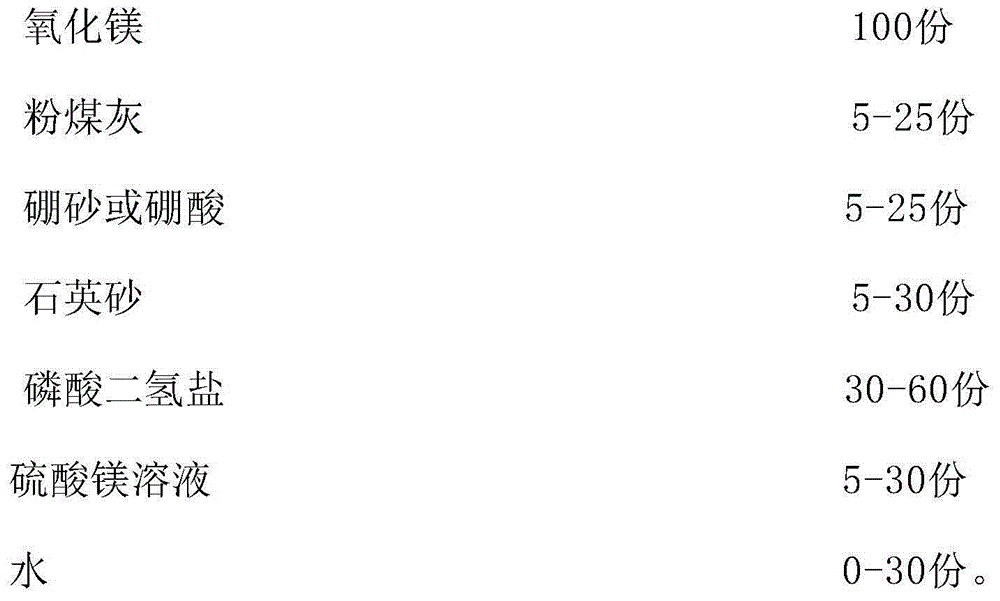

[0032] A high-strength quick-setting repair material for indoor use. The high-strength quick-setting repair material for indoor use is made of the following raw materials with a weight ratio:

[0033] Magnesium oxide 100 parts

[0034] 5 parts of fly ash

[0035] 10 parts borax

[0036] 15 parts of quartz sand

[0037] Potassium dihydrogen phosphate 40 parts

[0038] 10 parts of magnesium sulfate solution

[0039] 20 parts of water

[0040] Preparation method: mix magnesium oxide, fly ash, borax, and quartz sand in a blender evenly according to the ratio to obtain solid raw materials;

[0041] Mix potassium dihydrogen phosphate, magnesium sulfate and water evenly according to the ratio to obtain liquid raw materials;

[0042] The solid raw material and the liquid raw material are uniformly stirred in a mixer, and stirred at 60 rpm for 25 minutes to obtain a high-strength quick-setting repair material for indoor use.

example 2

[0044] A high-strength quick-setting repair material for indoor use. The high-strength quick-setting repair material for indoor use is made of the following raw materials with a weight ratio:

[0045] Magnesium oxide 100 parts

[0046] 10 parts of fly ash

[0047] 15 parts borax

[0048] 15 parts of quartz sand

[0049] Potassium dihydrogen phosphate 45 parts

[0050] 15 parts of magnesium sulfate solution

[0051] 20 parts of water

[0052] Preparation method: mix magnesium oxide, fly ash, borax, and quartz sand in a blender evenly according to the ratio to obtain solid raw materials;

[0053] Mix potassium dihydrogen phosphate, magnesium sulfate and water evenly according to the ratio to obtain liquid raw materials;

[0054] The solid raw material and the liquid raw material are uniformly stirred in a mixer, and stirred at 60 rpm for 25 minutes to obtain a high-strength quick-setting repair material for indoor use.

example 3

[0056] A high-strength quick-setting repair material for indoor use. The high-strength quick-setting repair material for indoor use is made of the following raw materials with a weight ratio:

[0057] Magnesium oxide 100 parts

[0058] 15 parts of fly ash

[0059] Borax 20 parts

[0060] 20 parts of quartz sand

[0061] Potassium dihydrogen phosphate 45 parts

[0062] 10 parts of magnesium sulfate solution

[0063] 25 parts of water

[0064] Preparation method: mix magnesium oxide, fly ash, borax, and quartz sand in a blender evenly according to the ratio to obtain solid raw materials;

[0065] Mix potassium dihydrogen phosphate, magnesium sulfate and water evenly according to the ratio to obtain liquid raw materials;

[0066] The solid raw material and the liquid raw material are uniformly stirred in a mixer, and stirred at 60 rpm for 25 minutes to obtain a high-strength quick-setting repair material for indoor use.

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com