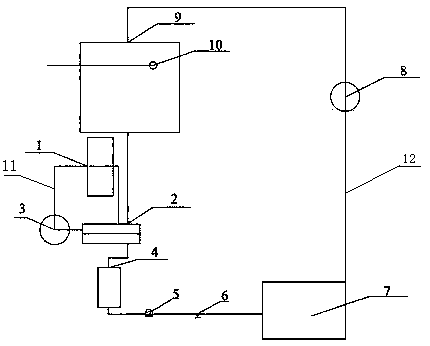

Device and method of industrially carrying out magnetized copper electrolysis

A technology of copper electrolysis and permanent magnet device, which is applied in the field of copper electrolysis and smelting, can solve the problems affecting the quality of cathode copper, and achieve the effect of improving the efficiency of magnetic treatment, improving the clarity, and refining the crystal grains of cathode copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

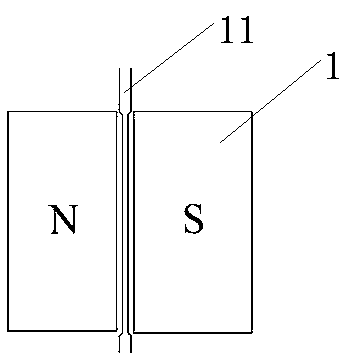

Method used

Image

Examples

Embodiment 1

[0033] Firstly, the concentration of copper ions in the electrolyte is measured to be 50g / L, and the H 2 SO 4 The concentration is 180g / L, the magnetic field strength of the permanent magnet device 1 is 4T, the first circulation pump 3 is off, and then the second circulation pump 8 and the steam heating device 10 are turned on, so that the temperature of the electrolyte is controlled at 65°C, and then Adjust the valve 6 so that the flow rate of the flow meter 5 is displayed as 0.25m / s, then open the first circulation pump 3, so that the flow rate of the bypass circulation system is 0.5 m / s, and simultaneously place the copper anode and the initial plate in the electrolytic cell 4 , set the voltage of electrolytic cell 4 to 0.35V, and the current density: 280A / m 2 , turn on the DC power supply to start electrolysis, and add hydrochloric acid, thiourea, and gelatin dropwise to the electrolytic cell 4 according to the amount of gelatin: 35g / t, thiourea: 35g / t, hydrochloric acid:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com