Viscosity reinforcing agent having water reducing function and specially used for cement mixture

A viscosity enhancer and mixture technology, applied in the field of building materials, can solve the problems of adjustment, poor anti-bleeding, poor adaptability, etc., and achieve the effects of inhibiting the generation of bubbles, reducing the number of bubbles, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

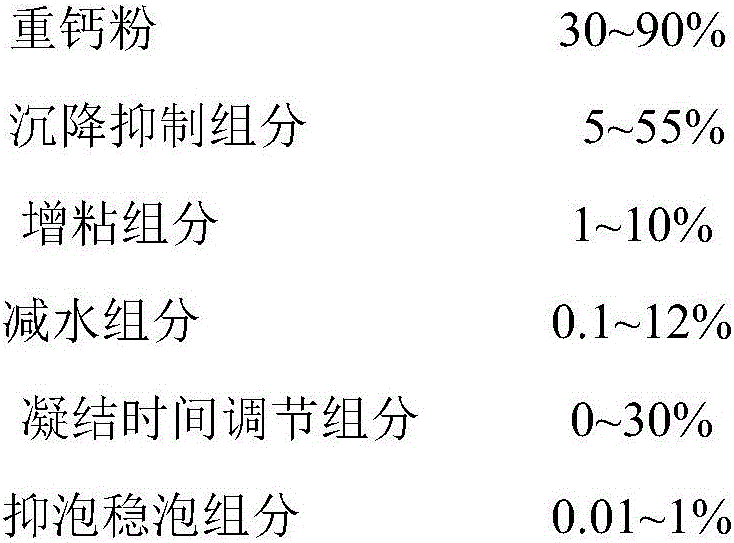

[0021]

[0022] The materials of the present invention are obtained by mixing the above-mentioned component materials according to the above-mentioned proportions. The cement press grout mix ratio that adopts the present invention that above-mentioned formula makes is configured sees Table 1:

[0023] Table 1 Mixing ratio of grout (Kg / m 3 )

[0024] Ordinary silicon 42.5 cement

expansion agent

Class I fly ash

water

Viscosity enhancer of the present invention

1522

209

150

557

209

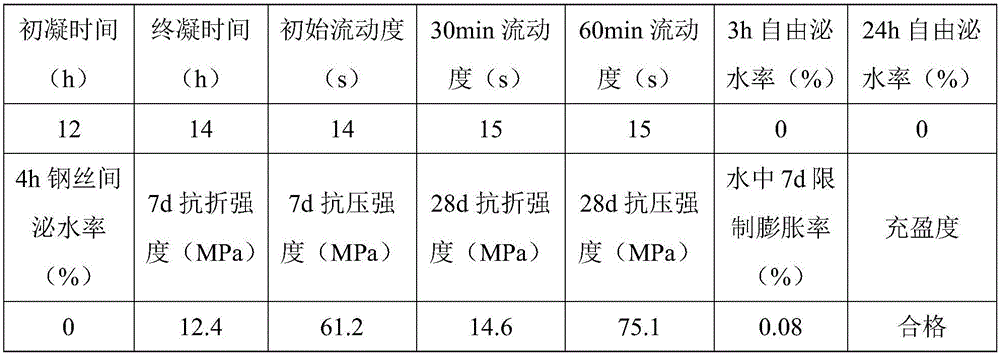

[0025] The configured cement grout of the present invention that adopts above-mentioned formula to make is carried out performance test according to " highway engineering prestressed tunnel grouting material (agent) " JT / T 946-2014, and performance index is shown in Table 2:

[0026] Table 2 cement pressure grout performance (Kg / m 3 )

[0027]

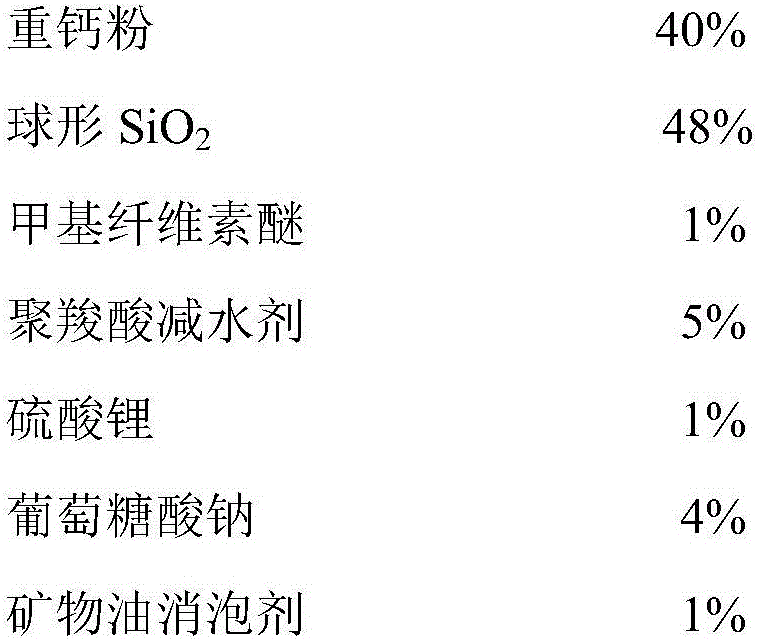

Embodiment 2

[0029]

[0030]

[0031] The materials of the present invention are obtained by mixing the above-mentioned component materials according to the above-mentioned proportions. The cement pressure grout mixing ratio that adopts the present invention that above-mentioned formula makes is configured sees Table 3:

[0032] Table 3 Mixing ratio of grout (Kg / m 3 )

[0033] Ordinary silicon 42.5 cement

expansion agent

water

Viscosity enhancer of the present invention

1858

118

582

104

[0034] The configured cement grout of the present invention that adopts above-mentioned formula to make is tested according to " highway engineering prestressed tunnel grouting material (agent) " JT / T 946-2014, performance index is shown in Table 4:

[0035] Table 4 cement grout performance (Kg / m 3 )

[0036]

Embodiment 3

[0038]

[0039]

[0040] The materials of the present invention are obtained by mixing the above-mentioned component materials according to the above-mentioned proportions. The cement press grout mix ratio that adopts the present invention that above-mentioned formula makes is configured is shown in Table 5:

[0041] Table 5 Mixing ratio of grout (Kg / m 3 )

[0042] Ordinary silicon 42.5 cement

expansion agent

water

Viscosity enhancer of the present invention

1718

103

21

559

228

[0043] The configured cement grout of the present invention that adopts above-mentioned formula to make is carried out performance test according to " highway engineering prestressed tunnel grouting material (agent) " JT / T 946-2014, and performance index is shown in Table 6:

[0044] Table 6 cement grout properties (Kg / m 3 )

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com