Device and method for reducing impurity and bubble on core cladding interface for large-size optical fiber perform

An optical fiber preform and large-size technology, which is applied in the direction of manufacturing tools and glass manufacturing equipment, etc., can solve the problems of unintroduced core rod storage device and storage method, impurities and bubbles at the core-clad interface, which cannot be removed, and achieve improvement Product quality, reducing the number of impurities and air bubbles, reducing the effect of fiber breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

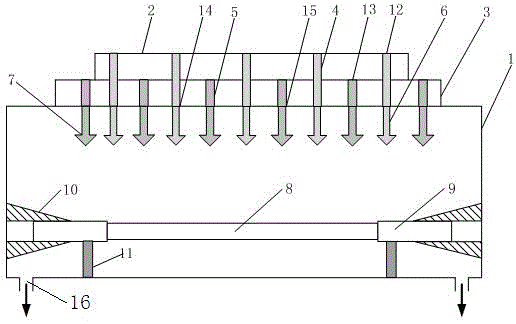

[0054] The core rod is prepared by the VAD process. After the core rod is extended, its refractive index profile is measured, and the required amount of the outer cladding is calculated from the test results.

[0055] The mandrel after the test is docked with the handle bar at both ends. After the mandrel is connected, put the mandrel into the special box for mandrel storage, place the mandrel on the clamping chuck of the mandrel support table, and close the door of the special box for storage. . The purified air is fed from the top of the special box for mandrel storage through the purified air fan, and the static-removing air is fed from the top of the special box for mandrel storage through the anti-static air fan.

[0056] After the mandrel is placed in the special box for storage for 1 hour, it is taken out and installed in the OVD equipment for production. The OVD equipment chuck rotates at 20rpm, and the quartz torch starts to deposit SiO? powder on the surface of the ...

Embodiment 2

[0060] After docking the rod, put the mandrel into the special box for mandrel storage. In the storage box, purified air is sent from the top of the special box for storage through the purified air fan. There is no static-eliminating air fan.

[0061] The transparent glass rod at the end of production is observed under the spotlight in the dark room, and there are 2 impurities and 3 air bubbles at the interface of the core package.

[0062] The test preform was drawn, and the screen breaking rate was 6.8‰, and the drawing qualification rate was 98.9%.

Embodiment 3

[0064] After docking, put the rod and the mandrel into a clean bag made of polyethylene, and take it out after 1 hour and use it directly for production. Others use the same process as in Example 1.

[0065] The transparent glass rod at the end of production is observed under the spotlight in the dark room, and there are 8 impurities and 5 air bubbles at the interface of the core package.

[0066] The test preform was drawn, and the screen breaking rate was 20.8‰, and the drawing pass rate was 97.2%.

[0067] Through the test comparison, the number of impurities and air bubbles at the interface of the core package of the preform is greatly reduced after the special storage box containing the purification air supply device and the static elimination air supply device is used; the wire drawing verification of the test preform is carried out, and the screen fiber breakage rate is obviously reduced. , the wire drawing pass rate is significantly increased, and the effect is remark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com