Low dielectric glass fiber and preparation method, glass fiber product, composite material and application

A glass fiber and composite material technology, which is applied in the fields of composite materials and applications, low dielectric glass fiber and preparation, and glass fiber products, can solve the problem of low dielectric constant and dielectric loss of glass fiber, high mechanical strength, and simple melting. and other problems, to achieve the effect of low wire drawing temperature, improved melting, and simple melting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-28

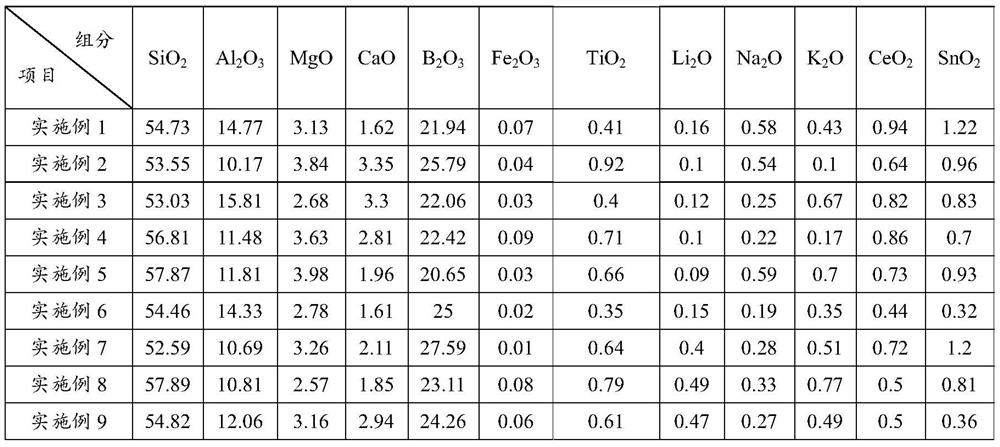

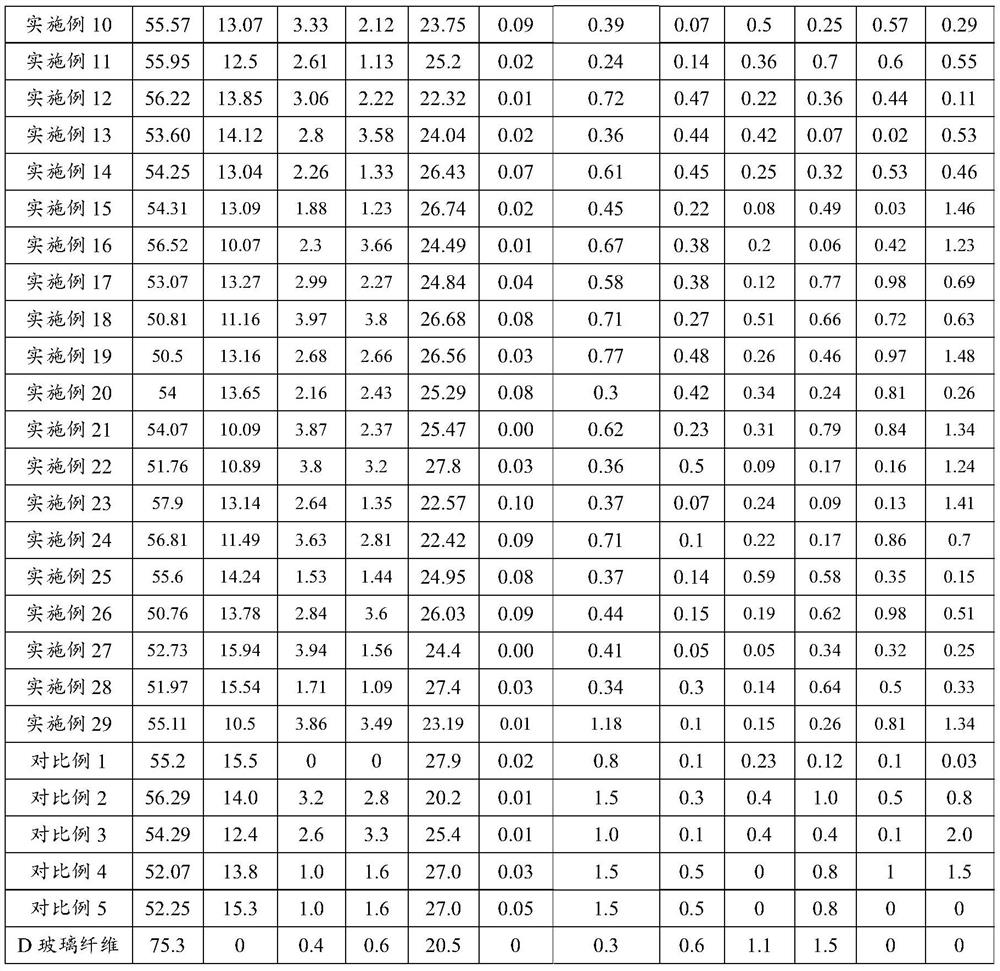

[0069] See Table 1 for the composition of low-dielectric glass fiber raw materials in Examples 1-28.

experiment example

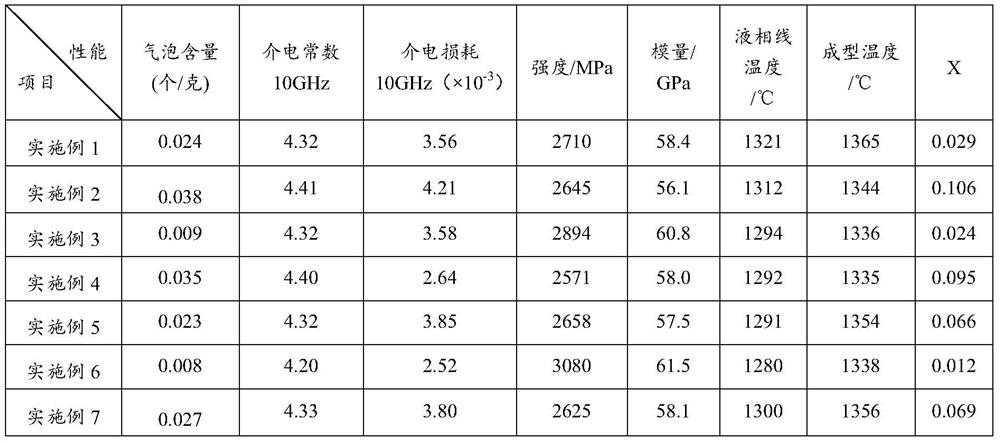

[0083] The glass fibers obtained in the above examples are subjected to performance testing, and the specific testing items include: dielectric properties, bubble content, strength, modulus, liquidus temperature, and molding temperature (drawing temperature). The specific detection method is as follows:

[0084] Dielectric properties: The test uses glass block glass, which is prepared into glass batches according to the glass ratio, put into a platinum crucible, heated to 1500-1550°C in a resistance furnace, clarified for 24 hours, and then poured the glass liquid into the mold , for annealing. According to the test requirements, the glass is processed into a sample to be tested with a diameter of 60mm (±0.1mm), a thickness of 3mm (±0.1mm), and a smooth surface. According to the standard GB / T 5597, the dielectric constant and dielectric loss of glass samples are measured at 10GHz frequency by resonant cavity method.

[0085] Determination of bubble content: use glass blocks,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com