Patents

Literature

54results about How to "The melting process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

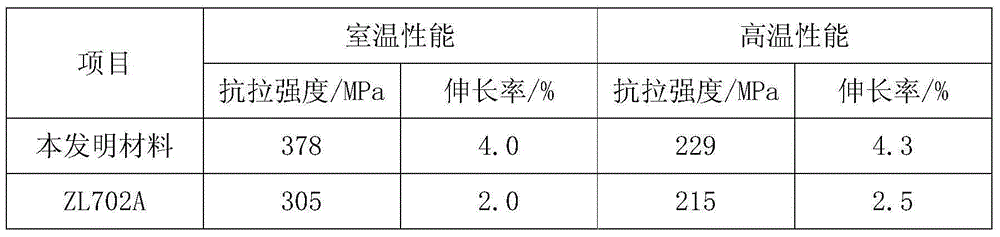

Low-cost multi-component heat-resistant magnesium alloy and preparation method of magnesium alloy

InactiveCN104694805AImprove plasticityImprove high temperature performanceHeat resistanceRoom temperature

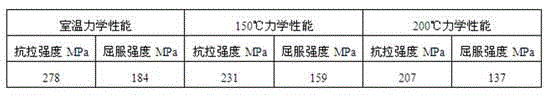

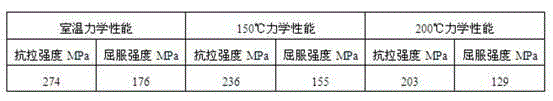

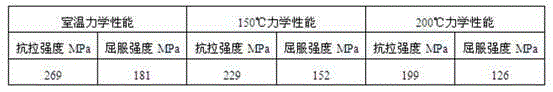

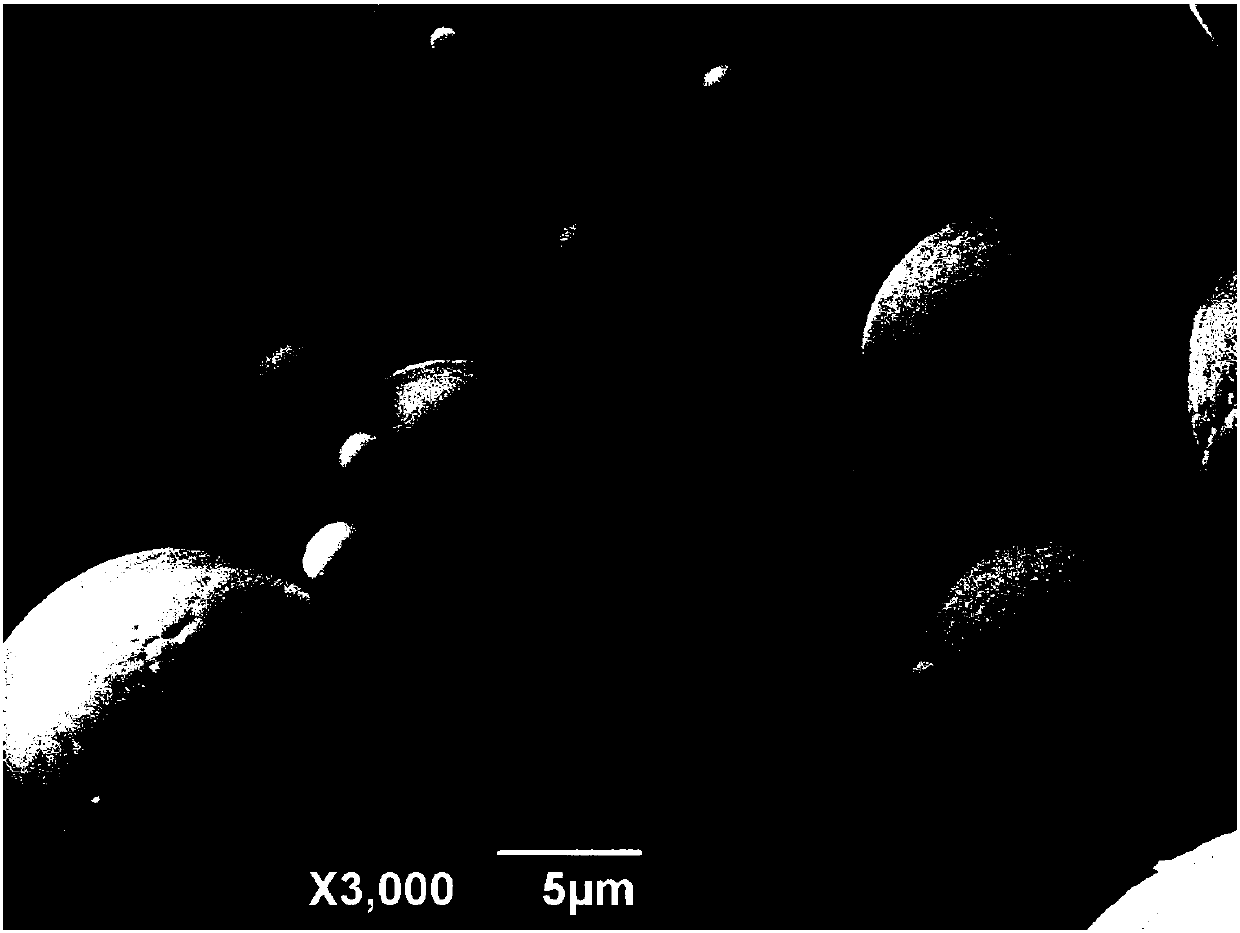

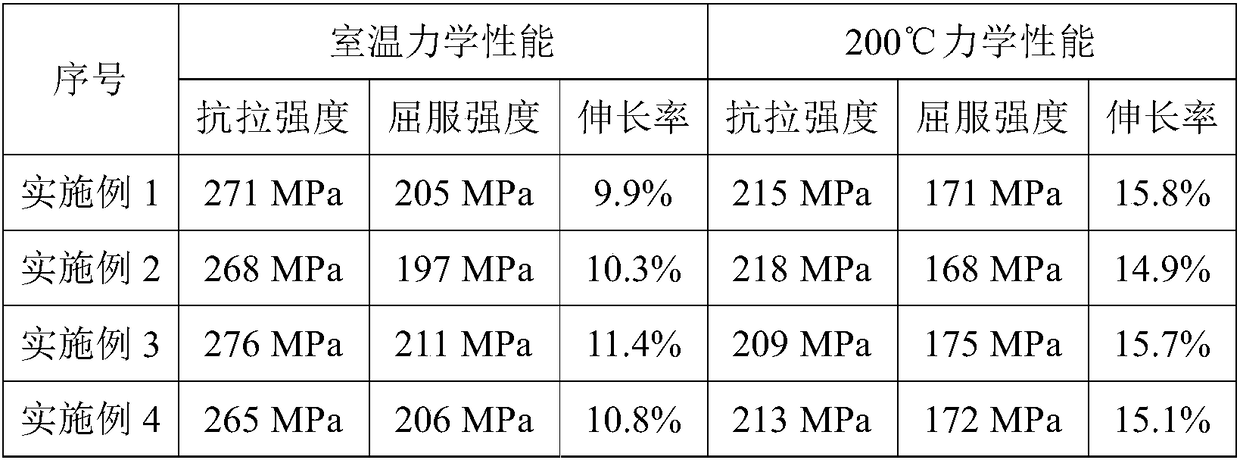

The invention provides a low-cost multi-component heat-resistant magnesium alloy and a preparation method of the magnesium alloy. The low-cost multi-component heat-resistant magnesium alloy comprises the following components in percentage by weight: 4.2-6.7% of Al, 0.5-1.2% of Zn, 0.7-0.9% of Sr, 0.2-0.8% of Ca, 1.1-1.5% of Sn, 0.8-1.3% of Sb, 0.05-0.4% of Mn, 0.2-0.6% of Bi, 0.4-0.9% of Si and the balance of Mg. According to the low-cost multi-component heat-resistant magnesium alloy, a right amount of low-cost alloy elements such as Sr, Ca, Sn, Sb, Mn, Bi and Si are introduced; the high-temperature performance of the magnesium alloy can be remarkable improved; the application range of the magnesium alloy can be expanded; the magnesium alloy is low in cost, simple in smelting and heat treatment process and uniform in microscopic structure; the mechanical performance and the heat resistance of the alloy can be remarkably improved; after the alloy is solidified and aged, the maximum room-temperature tensile strength reaches 278MPa; the maximum tensile strength at 150 DEG C reaches 236MPa; the maximum tensile strength at 200 DEG C reaches 207MPa.

Owner:HENAN UNIV OF SCI & TECH

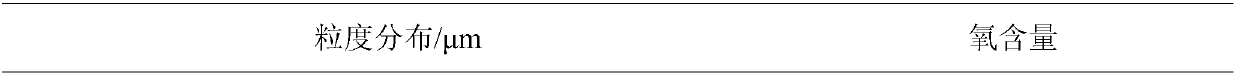

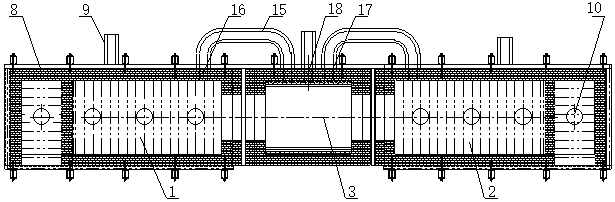

Method for smelting and producing TA10 hot continuous rolling square billet by adopting electron beam cooling bed furnace

InactiveCN104212989AImprove ingot qualityThe melting process is simpleElectric arc furnaceIngot casting

The invention discloses a method for smelting and producing a TA10 hot continuous rolling square billet by adopting an electron beam cooling bed furnace. The production process comprises the following steps that firstly, titanium sponge with the granularity of 6 mm to 10 mm and molybdenum particles with the granularity of 6 mm to 8 mm are mixed, after being evenly mixed, the titanium sponge and the molybdenum particles are pressed into an electrode block, in-furnace welding is adopted to enable the electrode block to be welded into an electrode, a vacuum arc remelting furnace is used for one-time smelting to obtain Ti-Mo intermediate alloy, and the content of Mo in the Ti-Mo intermediate alloy is 15 percent to 25 percent; secondly, the Ti-Mo intermediate alloy manufactured in the first step is broken in an ingot mode to form Ti-Mo intermediate alloy particles with the granularity smaller than or equal to 3 mm; and the like. The method for smelting and producing the TA10 hot continuous rolling square billet by adopting the electron beam cooling bed furnace is simple in process and convenient to operate, the ingot casting quality is improved, meanwhile, the production process is greatly shortened, the yield is improved, the production cost is greatly reduced, and the billet has the good market competition capability.

Owner:YUNNAN TITANIUM IND

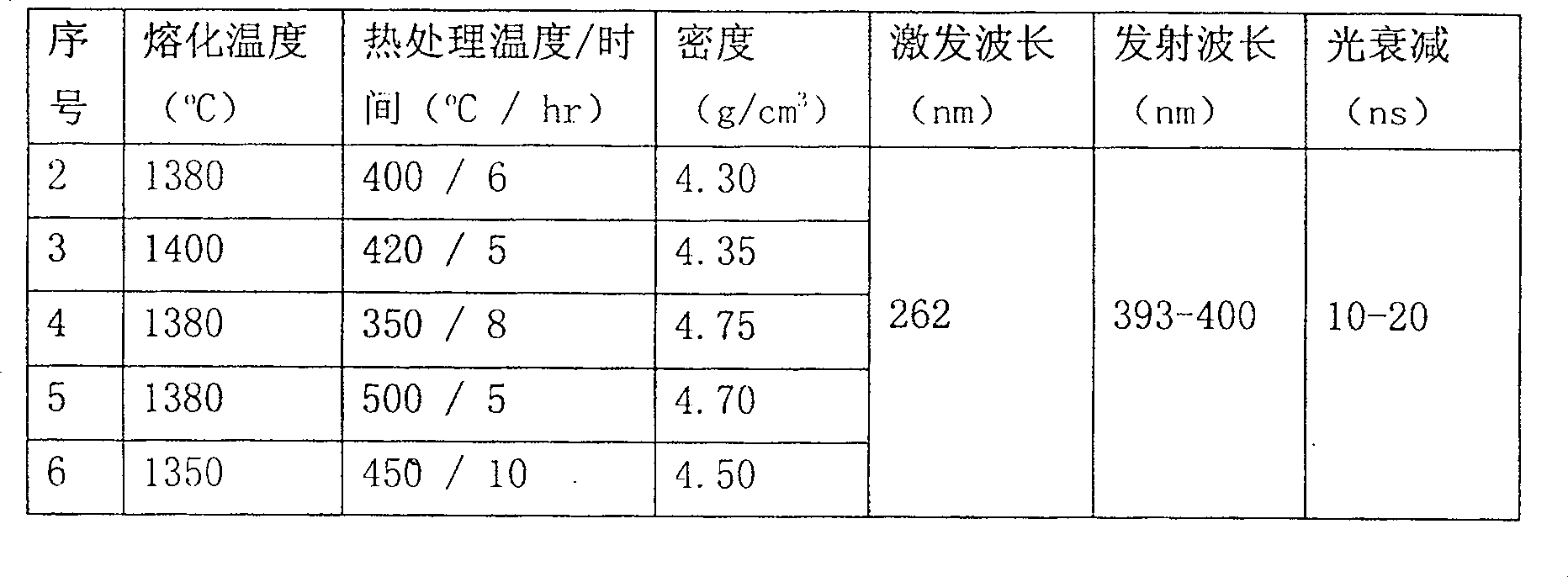

Quick flashing glass and its prepn process

InactiveCN1526673AImprove UV transmittanceImprove the attenuation effectGlass shaping apparatusHigh energyVolumetric Mass Density

The present invention discloses one kind of quick flashing glass for application in high-energy physics, nuclear physics, nuclear medicine, geophysics, industrial detection and other fields and its preparation process. The flashing glass material has silicate glass, germanate glass other heavy metal oxide as main component, and introduced high-density ZnO as luminescent center. It is prepared through three steps of preparing glass material; smelting the material; and heat treatment. Test shows that the serial glass material has the features of simple smelting process, powerful glass forming capacity, easy density regulation and high luminescent ion density. Compared with available Ce3+-doping quick flashing glass, the present invention has the features of high UV transmissibility, fast attenuation and high fluorescent strength.

Owner:EAST CHINA UNIV OF SCI & TECH

High-frequency FeSiAl alloy powder and preparation method thereof

ActiveCN107671298AHigh sphericityUniform compositionTransportation and packagingMetal-working apparatusIngotSilicon

The invention discloses high-frequency FeSiAl alloy powder and a preparation method of the high-frequency FeSiAl alloy powder and belongs to the technical field of powder preparation. According to thepreparation method, rodlike polished iron, bulky metal silicon and pure aluminum ingots are used as raw materials, material mixing and weighing are conducted according to the ratio, and alloy steel liquid of the needed component is obtained through vacuum smelting; and then, alloy raw powder is prepared through inert gas atomization is prepared, and fine powder is obtained after the raw powder iscollected and screened. By the adoption of the high-frequency FeSiAl alloy powder, the alloy powder uniform in component and high in purity is obtained beneficially, the sphericity degree of the powder is high, a uniform compact insulated layer can easily form after insulated cladding, contact of an alloy matrix is effectively isolated, a pressed magnetic powder core has the advantage of low consumption and is suitable for a high-frequency scene.

Owner:马鞍山新康达磁业有限公司

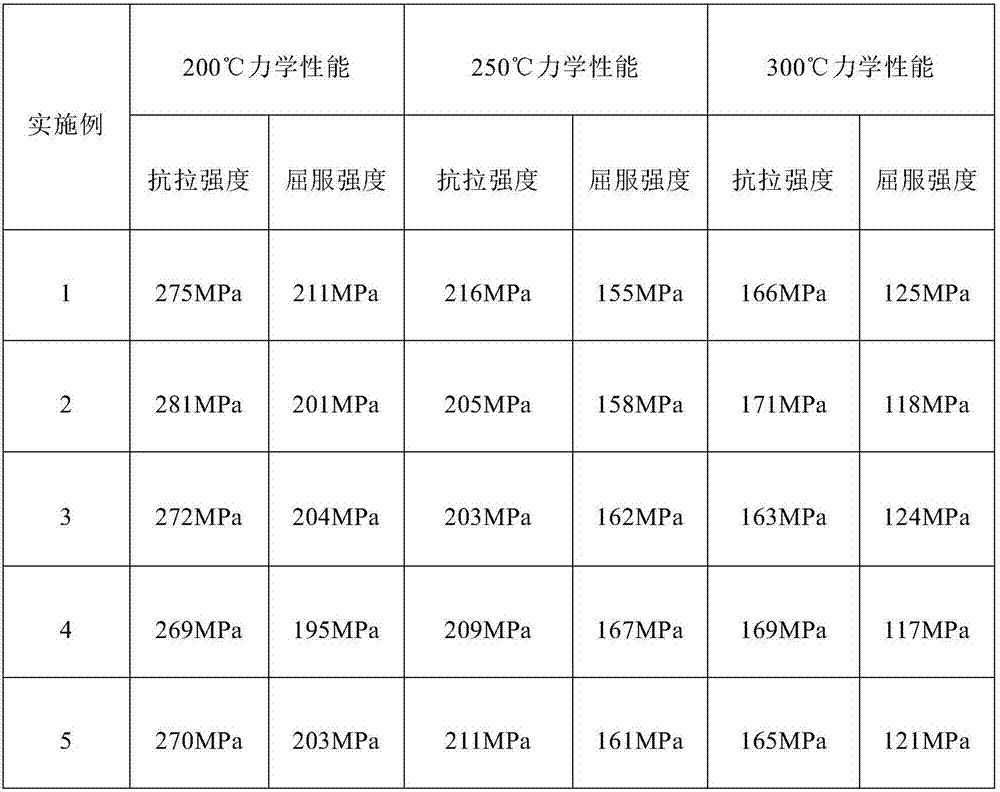

High weld strength Al-Mg-Er-Zr alloy and preparation method of panel made of same

The invention provides a high weld strength Al-Mg-Er-Zr alloy, which comprises the following alloy components in percentage by mass: 2.0-5.0% of Mg, 0.2-0.8% of Er, 0.2-0.6% of Zr, less than 0.4% of Si, 0.05-0.8% of Mn, 0.05-0.2% of Ti, less than 0.1% of Zn, less than 0.4% of Fe, 0.15-0.35% of Cr, less than 0.1% of Cu, less than 0.15% of total amount of other alloy components and the balance of Al. The invention further provides a method for preparing the panel made of the alloy. The Al-Mg-Er-Zr alloy provided by the invention is easy to weld and high in weld strength, low in production cost and cheap in cost and does not contain alloy components which are volatile and difficult to smelt, so that an alloy smelting process is simple, and the preparation method of the panel made of the alloy is also simple in technology.

Owner:SNTO TECH GRP

Flame-retardant and heat-resistant magnesium alloy and preparation method

InactiveCN104630586AImprove plasticityImprove flame retardant performanceRare-earth elementMechanical property

The invention provides a flame-retardant and heat-resistant magnesium alloy and a preparation method, wherein the flame-retardant property and the high-temperature mechanical property of the flame-retardant and heat-resistant magnesium alloy are increased simultaneously; and the flame-retardant and heat-resistant magnesium alloy comprises the following components in percentage by weight: 5-9% of Al, 0.3-1.4% of Zn, 0.1-0.6% of Sm, 0.1-0.8% of Nd, 0.2-1.5% of Y, 0.3-1.7% of Ca, 0.4-2.3% of Sr, and the balance of Mg. By adding proper rare earth elements including Sm, Nd and Y, the magnesium alloy tissue is improved; the flame-retardant property and the heat-resistant property of the alloy are increased; the total addition amount of the rare earth elements in the flame-retardant and heat-resistant magnesium alloy disclosed by the invention is 1-2%; researches show that few alkaline-earth elements including Ca and Sr are capable of obviously increasing the flame-retardant property of the magnesium alloy; furthermore, a high-melting-point strengthening phase is generated in the microscopic structure of the alloy; the microscopic structure of the magnesium alloy is improved; and the high-temperature mechanical property of the magnesium alloy is increased.

Owner:HENAN UNIV OF SCI & TECH

Heat-resistant creep-resistant magnesium alloy and preparing method thereof

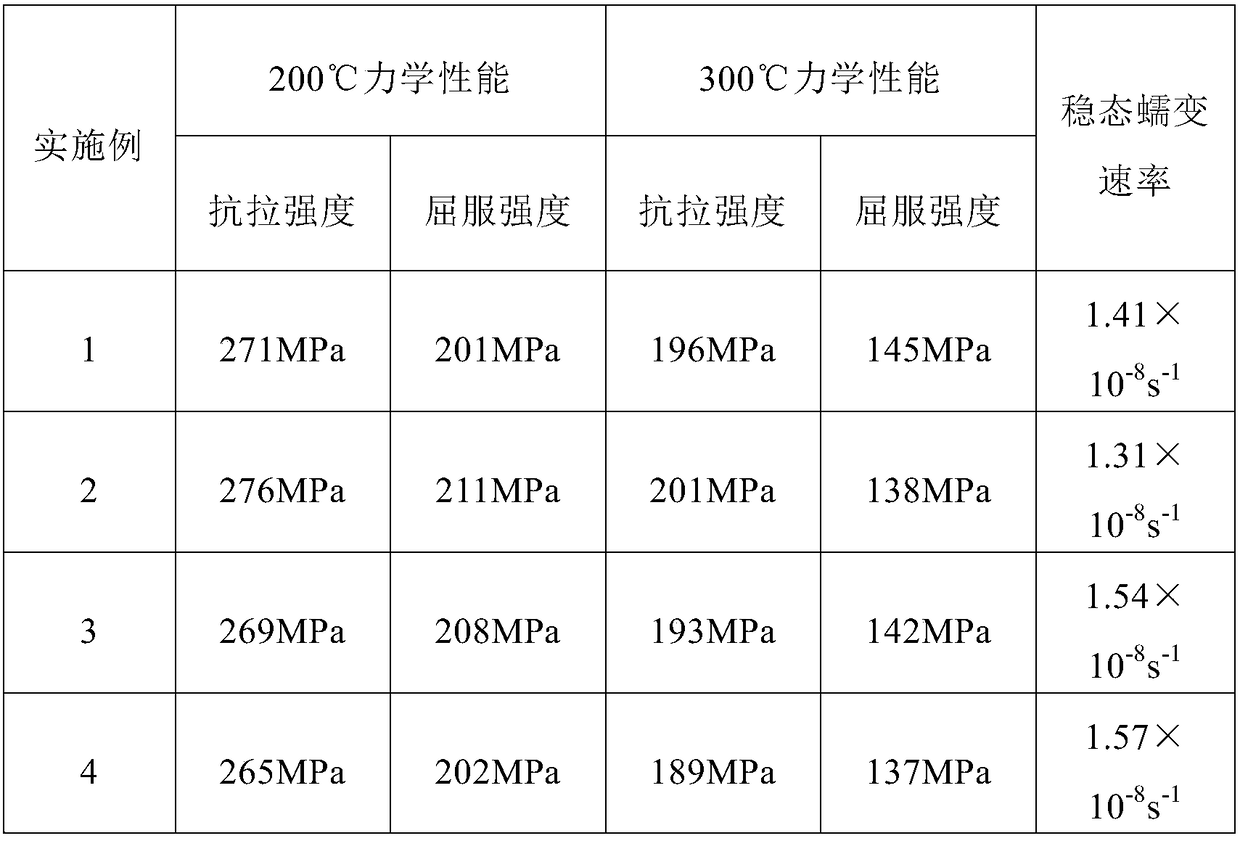

The invention relates to a heat-resistant creep-resistant magnesium alloy and a preparing method thereof, which belong to the field of metal materials and metallurgy. The heat-resistant creep-resistant magnesium alloy is mainly formed by the following components in percent by mass: 7-8% of Sm, 0.7-0.9% of Nd, 1.5-2.0% of Zn, 1.0-1.3% of Ca, 1.2-1.5% of Mn, 1.1-1.3% of Al and the balance of Mg and inevitable impurities. The magnesium alloy in the invention has good tensile strength and better creep resistance under a high temperature, and has better application prospect.

Owner:HENAN UNIV OF SCI & TECH

Aluminum alloy material capable of being used for manufacturing cylinder cover and preparation method for aluminum alloy material

The invention discloses an aluminum alloy material capable of being used for manufacturing a cylinder cover. The aluminum alloy material is characterized by consisting of the following components in percentage by mass: 45-50% of waste aluminum intermediate alloy powder, 7-7.5% of silicon, 3% of glass fiber powder, 0.4-0.45% of zinc, 0.2-0.25% of magnesium, 0.06-0.08% of scandium, 0.01-0.02% of arsenic, 0.05-0.07% of titanium and the balance of aluminum. According to the invention, by optimizing alloy components, adopting a scientific and reasonable thermal treatment process, and adding a rare earth element scandium, the aluminum alloy material has degassing effect; a smelting process is simple, scientific and easy to operate, complex operation equipment is not required, mechanical property, especially high-temperature mechanical property of the alloy can be improved, the stability of a strengthening phase can be improved, separation and growth of the strengthening phase can be prevented, and impact resistance of the alloy is improved. The product has high strength, light weight, good resilience force, and various qualified indexes, and is suitable for producing an engine cylinder cover.

Owner:ANHUI QIANTONG EDUCATION MFG

Method for preparing semisolid slurry for ultralow temperature casting magnesium alloy

The method for preparing semisolid slurry for magnesium alloy ultralow temp. casting includes the processes and steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating and standing still and semicontinuous casing. Said invention utilizes the addition of compound fire-resisting elements to implement magnesium alloy smelting free from covering agent, and utilizes the pouring process which is made under the condition of the temperature of liquid phase line or the temperature below liquid phase link at a certain cooling rate after properly standing still to implement that its interior has no dirt inclusion or porosity.

Owner:NORTHEASTERN UNIV

Alloy material of centrifugal refrigerating compressor impeller and preparation method thereof

The invention discloses an alloy material of a centrifugal refrigerating compressor impeller. The alloy material comprises, by weight, 8-10% of Si, 1-2% of Cu, 0.2-0.5% of Mg, less than 0.3% of Zr, less than 0.3% of Fe, less than 0.2% of Zn, less than 0.1% of Ti, and the balance Al and impurity elements. The comprehensive performance of the alloy material of the centrifugal refrigerating compressor impeller is better than that of an existing domestic cast aluminum alloy, except for Al, Si, Cu and Mg, the content of other elements is controlled to be less than 1.5%, and the domestic cast aluminum alloy requires that the content of other elements is controlled to be within 1% (GB / T1173-1995). The alloy material of the centrifugal refrigerating compressor impeller is easy to smelt, convenient to operate, free of highly pure furnace charge, and capable of achieving good comprehensive mechanical performance indexes after common hot processing. The alloy material of the centrifugal refrigerating compressor impeller is simple in process, low in cost and suitable for batch production, and the cost of the alloy material of the centrifugal refrigerating compressor impeller is only one fourth of aluminum casting alloy.

Owner:CHONGQING GENERAL IND (GRP) LTD

Method for producing huge high-purity nickel ingot square billets through four-gun electron beam cold bed furnace

The invention discloses a method for producing huge high-purity nickel ingot square billets through a four-gun electron beam cold bed furnace. The method comprises the following steps that electrolytic nickel with the purity of 99.5 percent is selected, the surface of the electrolytic nickel is cleaned, the electrolytic nickel is cut into small blocks with the diagonals smaller than or equal to 120 mm, the small blocks are cleaned, dried and smelted in the electron beam cold bed furnace, continuous casting is carried out through a square crystallizer, and the huge high-purity nickel ingot square billets are obtained. According to the method, the electron beam cold bed furnace is used for carrying out smelting, the smelting speed is high, the whole smelting process is carried out under a highly vacuum condition, air pollution is avoided, and gas impurities can be effectively eliminated. As a refining cold bed is arranged, removal of saturated low-steam-pressure impurities, high-density impurities and low-density impurities can be realized in the smelting process, and smelting and purification can be carried out simultaneously. By replacing the crystallizer, the huge high-purity nickel ingot square billets of different specifications can be produced, the processes of skinning, forging and the like in the prior art are simplified, the production cost is reduced, and the production efficiency of nickel plates and strips is largely improved.

Owner:YUNNAN TITANIUM IND

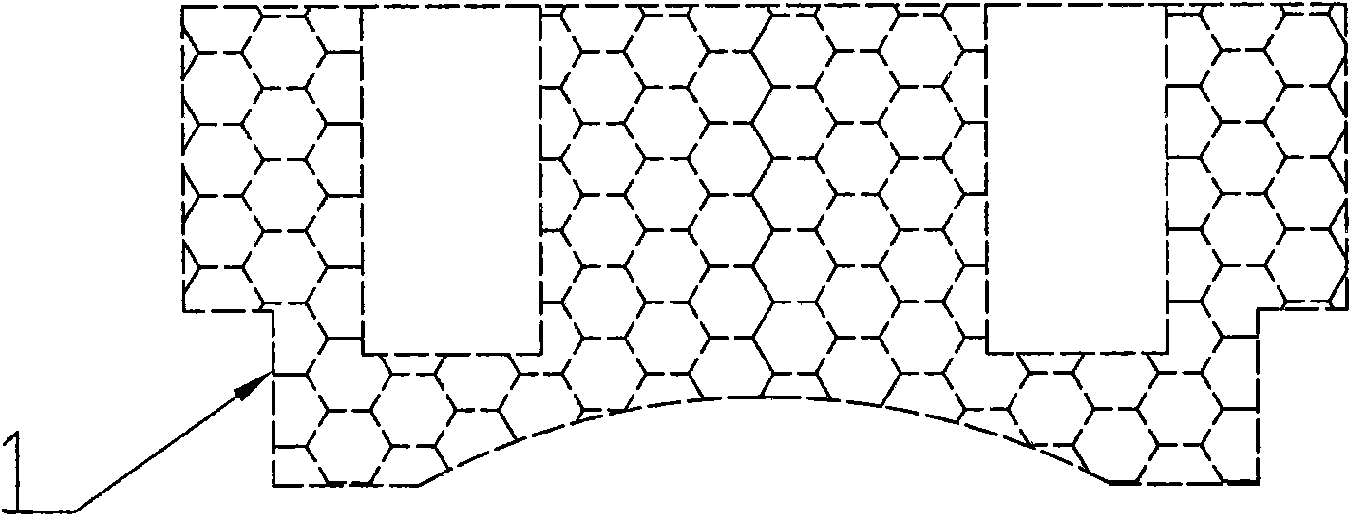

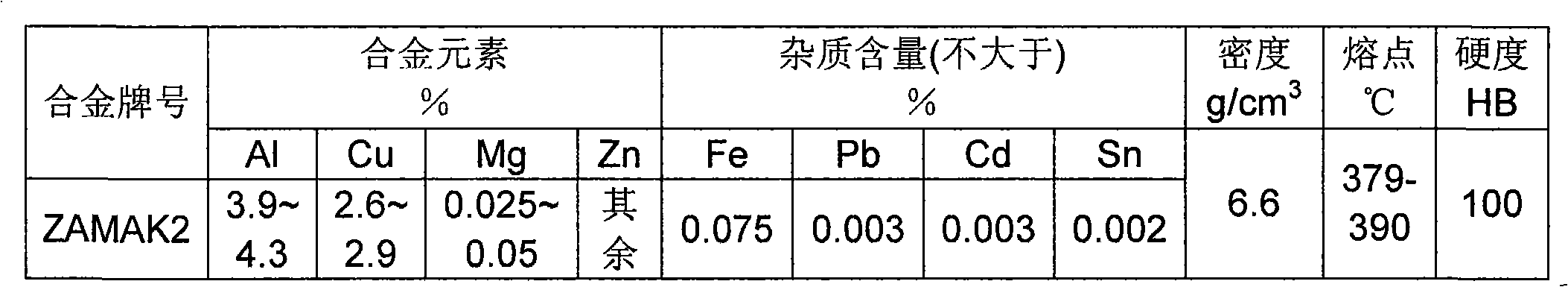

Casting method of zinc base alloy for stamping die basal body

InactiveCN101602103AThe melting process is simpleLow costMolten metal pouring equipmentsMolten stateMetallurgy

The invention discloses a casting method of zinc base alloy for a stamping die basal body, including moulding, pouring, clotting and taking out cast product; wherein molten zinc base alloy is poured in a cavity exposed in the air during pouring. The invention is convenient in raw material (zinc base alloy) selection, a pouring system is not required to be designed during moulding as casting in open is adopted, the technology of removing the pouring system in post cleaning is spared, thus being convenient; the zinc base alloy cast product can be directly molten down to be utilized repeatedly, melting process is simple, cost is low, and casting speed is fast, thereby being especially applicable to making of fast moulding mould for car stamping parts; and especially for sample car mould of a large outer panel, cost can be saved and mould making period can be shortened, thus reducing development cost of entire car and shortening development period of entire car.

Owner:上海赛科利汽车模具技术应用有限公司

Quick flashing glass and its preparation process

InactiveCN100486923CImprove UV transmittanceImprove the attenuation effectGlass shaping apparatusHigh concentrationHigh energy

The invention discloses a fast scintillation glass and a preparation method thereof which can be applied in the fields of high energy physics, nuclear physics, nuclear medicine, geophysics, industrial detection and the like. The invention is a kind of scintillation glass material with silicate glass or germanate glass and other heavy metal oxides as the main components, introducing high-concentration zinc oxide (ZnO) as the luminescence center, and its preparation method includes (a) glass batch material Preparation, (b) melting of batch materials, (c) heat treatment and other three steps. The obtained glass is subjected to surface grinding and polishing treatment for fluorescence performance test. The results show that this series of glasses has the characteristics of simple melting process, strong glass forming ability, easy density adjustment, and high concentration of luminescent center ions, which is different from the existing cerium (Ce 3+ ) compared with fast scintillation glass, it has the characteristics of good ultraviolet transmission performance, fast attenuation, and high fluorescence intensity.

Owner:EAST CHINA UNIV OF SCI & TECH

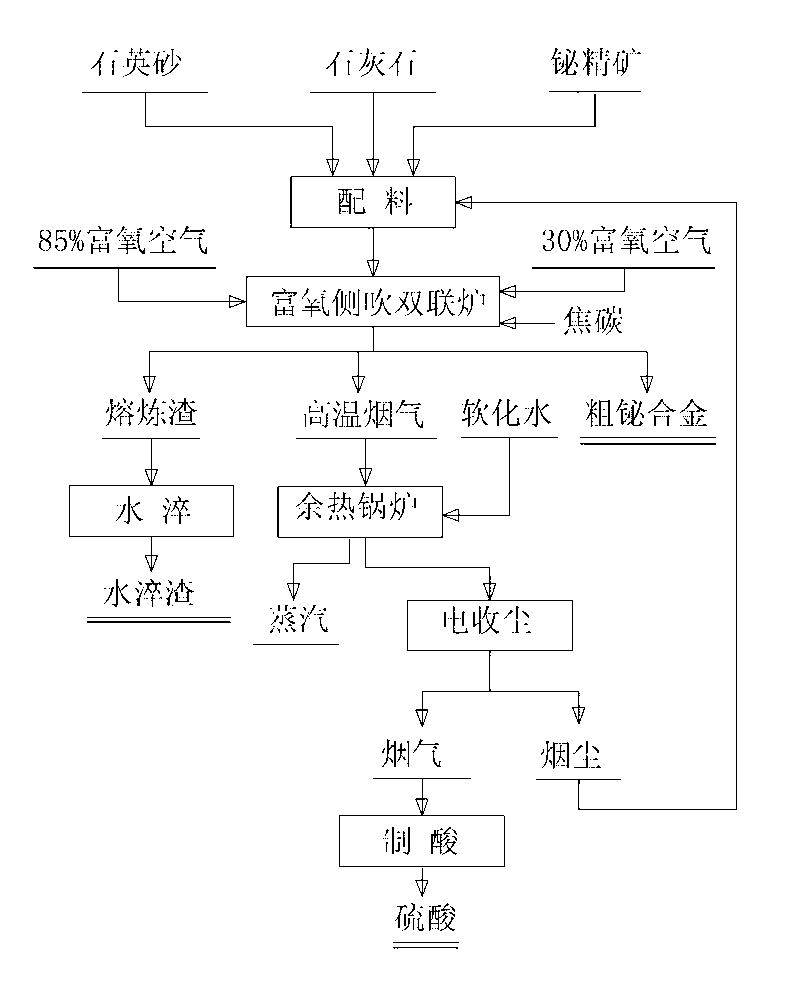

Method for smelting lead-bismuth concentrate in oxygen-rich side-blown duplex furnace

InactiveCN103060578AImprove direct yieldThe melting process is simpleProcess efficiency improvementLead bismuthFlue gas

The invention discloses a method for smelting a lead-bismuth concentrate in an oxygen-rich side-blown duplex furnace, belonging to the technical field of smelting bismuth concentrates. The method comprises the steps of preparing raw materials, and smelting in the oxygen-rich side-blown oxidation-reduction duplex furnace to directly produce a crude bismuth alloy. According to the method, scrap iron is not required to be added, so that the production cost is low; the concentration of SO2 in flue gases generated from oxidizing smelting reaches 10 to 25 percent, and the SO2 can be recycled to prepare acid, so that the problem of environmental pollution caused by the flue gases is solved; and the oxidation-reduction duplex smelting ensures that the direct yield of bismuth is greatly promoted.

Owner:HUNAN JINWANG BISMUTH

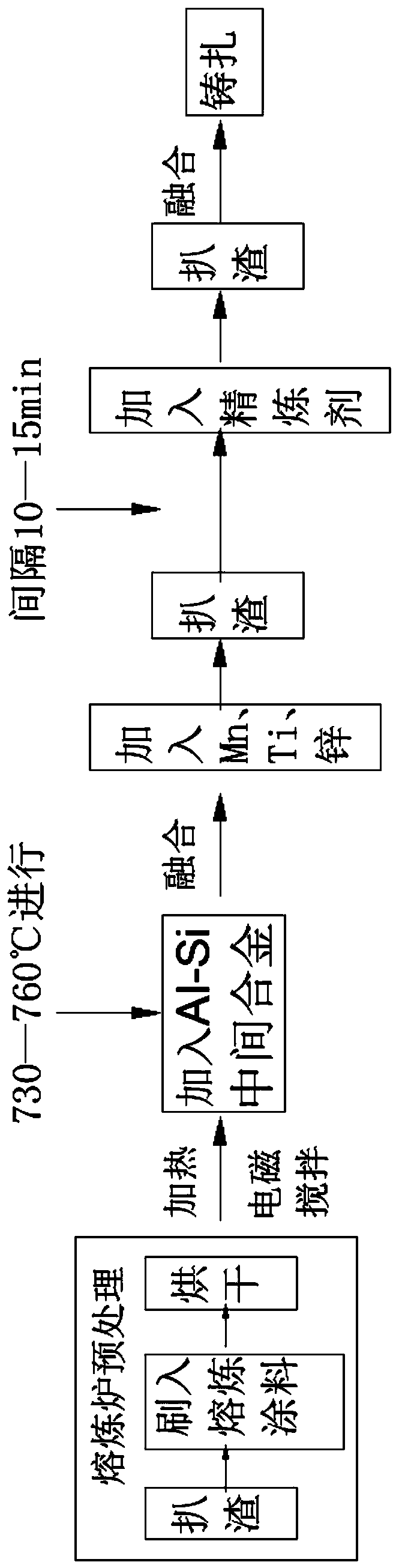

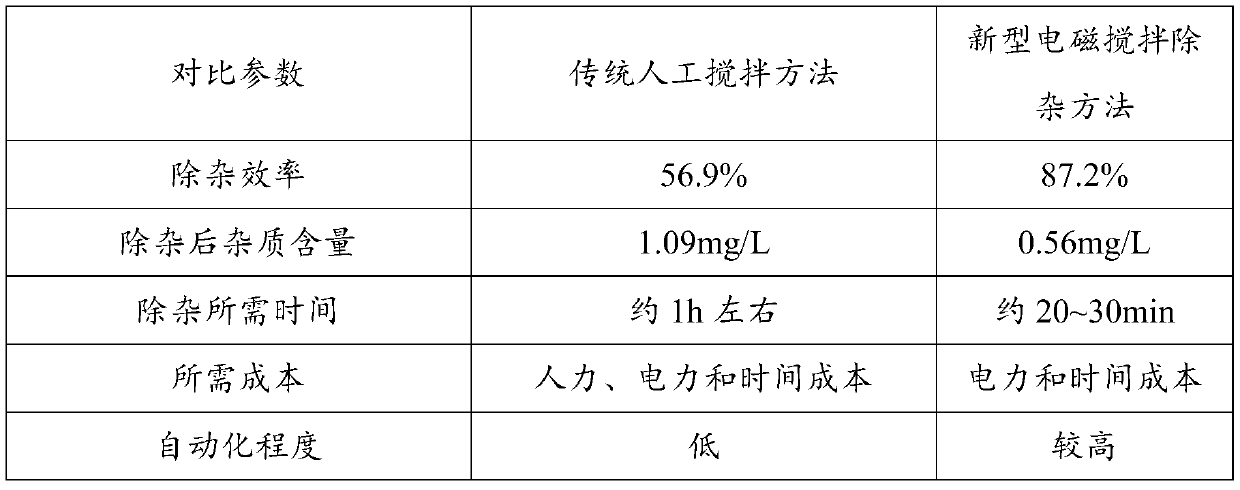

Aluminum alloy smelting and impurity-removing method based on electromagnetic stirring

PendingCN110846527AImprove the efficiency of impurity removalImprove purification effectSmelting processElectromagnetic stirring

The invention discloses an aluminum alloy smelting and impurity-removing method based on electromagnetic stirring, and relates to the field of alloy smelting. A novel aluminum alloy meeting specifications and with high practicability and relatively low manufacturing cost can be obtained. The aluminum alloy smelting and impurity-removing method comprises the following steps that S1, a smelting furnace is pretreated; S2, high-purity aluminum with the purity being 99% or above is added into the pretreated smelting furnace; S3, the smelting furnace is heated; S4, an Al-Si intermediate alloy is added; S5, the high-purity aluminum is fused with the Al-Si intermediate alloy; S6, zinc with the purity being 99% or above, a Mn agent, a Ti agent and a refining agent are added; S7, all metals in the step S5 and S6 are fused; and S8, aluminum alloy melt obtained in the step S7 is subjected to still standing and then transferred to a flow groove for cast rolling. According to the aluminum alloy smelting and impurity-removing method based on electromagnetic stirring, the impurity-removing efficiency and melt purification effect can be greatly improved in the aluminum alloy smelting process; and the fewer steps are used in the aluminum alloy smelting and impurity-removing method, so that the smelting process is simplified.

Owner:CENT SOUTH UNIV

Silicon and aluminum alloy material used for novel cylinder cover and preparation method of silicon and aluminum alloy material

The invention discloses a silicon and aluminum alloy material used for a novel cylinder cover. The silicon and aluminum alloy material used for the novel cylinder cover is characterized by being composed of, by mass, 7-8 parts of silicon, 0.2-0.25 part of magnesium, 0.55-0.6 part of zinc, 2.5-3 parts of nickel, 0.1-0.3 part of titanium, 45-50 parts of aluminum scrap intermediate alloy powder and the balance aluminum. By optimizing alloy components and adopting a scientific and reasonable heat treatment technology, the mechanical property of an alloy can be improved, and particularly the high-temperature mechanical property of the alloy can be improved; besides, stability of chemical phases can be improved, strengthening phases are prevented from being precipitated and growing larger, and the impact resistance of the alloy is improved. The smelting process of the manufactured aluminum alloy material is simple and easy to operate, no complicated operating devices are needed technologically, and the alloy material is universal, beneficial to popularization and capable of being used for manufacturing engine cylinder covers.

Owner:黄振东

Multi-element heat-resistant magnesium alloy and preparation method thereof

ActiveCN108220731AImprove plasticityImprove microstructureRoom temperatureSolid solution strengthening

The invention relates to a multi-element heat-resistant magnesium alloy and a preparation method thereof. The multi-element heat-resistant magnesium alloy comprises, by weight, 5.5%-6.5% of Sm, 3.5%-5% of Sn, 2.5%-4% of Zn, 0.5%-1.0% of V, and the balance Mg and inevitable impurities. According to the multi-element heat-resistant magnesium alloy, the alloy is endowed with good aging precipitationstrengthening and solid solution strengthening effects by the Sm; the Sn is capable of forming a high-melting-point Mg2Sn intermetallic compound in the magnesium alloy, so that the effect of dispersion strengthening is achieved; the performance of a surface film can be improved by the Zn; and the V is added to enable the microscopic structure of the magnesium alloy to be obviously refined, and theeffect of fine grain strengthening can be achieved; The alloy elements mutually support one another and synergistically act in the above proportion range, the room temperature mechanical property andthe high-temperature mechanical property of the magnesium alloy are remarkably improved, the plasticity of the magnesium alloy is improved, and the application range of the magnesium alloy is expanded.

Owner:HENAN UNIV OF SCI & TECH

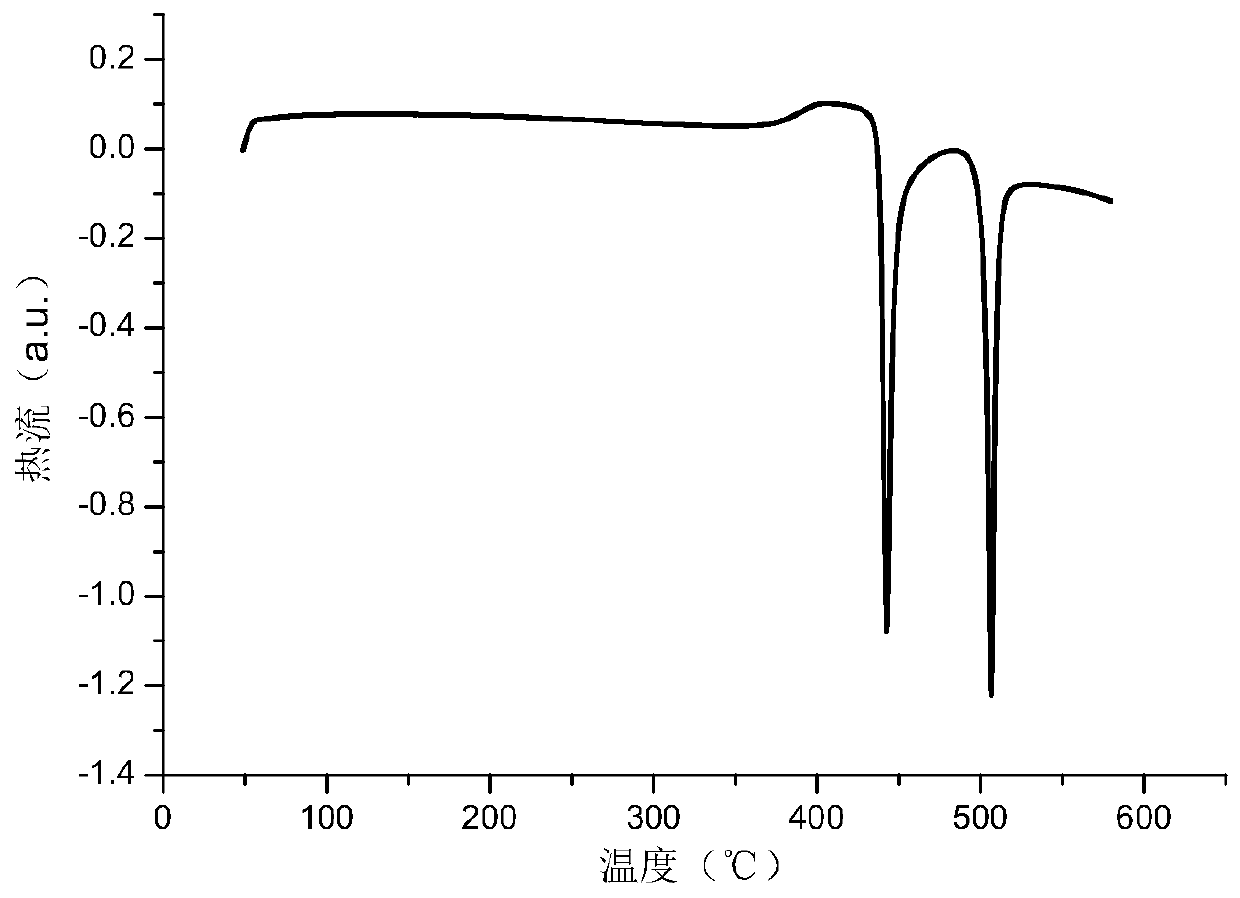

Non-aluminium low-calcium lead-silver-calcium rare earth alloy and preparation method thereof

ActiveCN101654750AImprove microstructureReduce intergranular corrosion tendencySlagPotential difference

The invention discloses a non-aluminium low-calcium lead-silver-calcium rare earth alloy and a preparation method thereof; the non-aluminium low-calcium lead-silver-calcium rare earth alloy comprisesthe following components by weight percent: 0.15 to 0.7 percent of silver, 0.03 to 0.09 percent of calcium, 0.02 to 0.08 percent of rare earth metal, and the balance lead. The preparation method comprises the following steps: raising the temperature to 400 to 500 DEG C, to melt the lead in a lead-melting furnace and then holding the temperature; adding the silver, calcium and rare earth metal withweight ratio in lead solution, stirring, and applying a direct-current potential difference of 3 to 36V between a melt and the furnace in the stirring process; standing 30 to 50 minutes after the melt is evenly alloyed, removing oxidizing slag on the surface of the melt and obtaining the non-aluminium low-calcium lead-silver-calcium rare earth alloy. The invention is characterized by low impedance of an anodic oxide film, good corrosion resistance and long service life.

Owner:苏向东

Pure copper smelting cleaner and preparation method thereof

The invention relates to a pure copper smelting cleaner and a preparation method thereof. The pure copper smelting cleaner comprises the components in percentage by weight as follows: 20-30% of Aoki powder, 20-30% of cullet 7SiO2.2Na2O, 40-50% of calcium carbide CaC2, 5-10% of borax Na2B4O7 and less than or equal to 1% of other impurities. The preparation method comprises the following steps of: burning Aoki to block charcoal; preparing cullet in sheet which is 10-15mm; preparing calcium carbide in a drying environment to particles which are 10-20mm, and then vacuum packaging; placing borax crystalline to a resistance furnace, first, melting to remove crystal water at about 900 DEG C, then condensing to block; then, preparing particles which are 5-10mm; and preparing and packaging the components in the drying environment, packaging and vacuumizing, and then, storing in the drying environment for later use.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

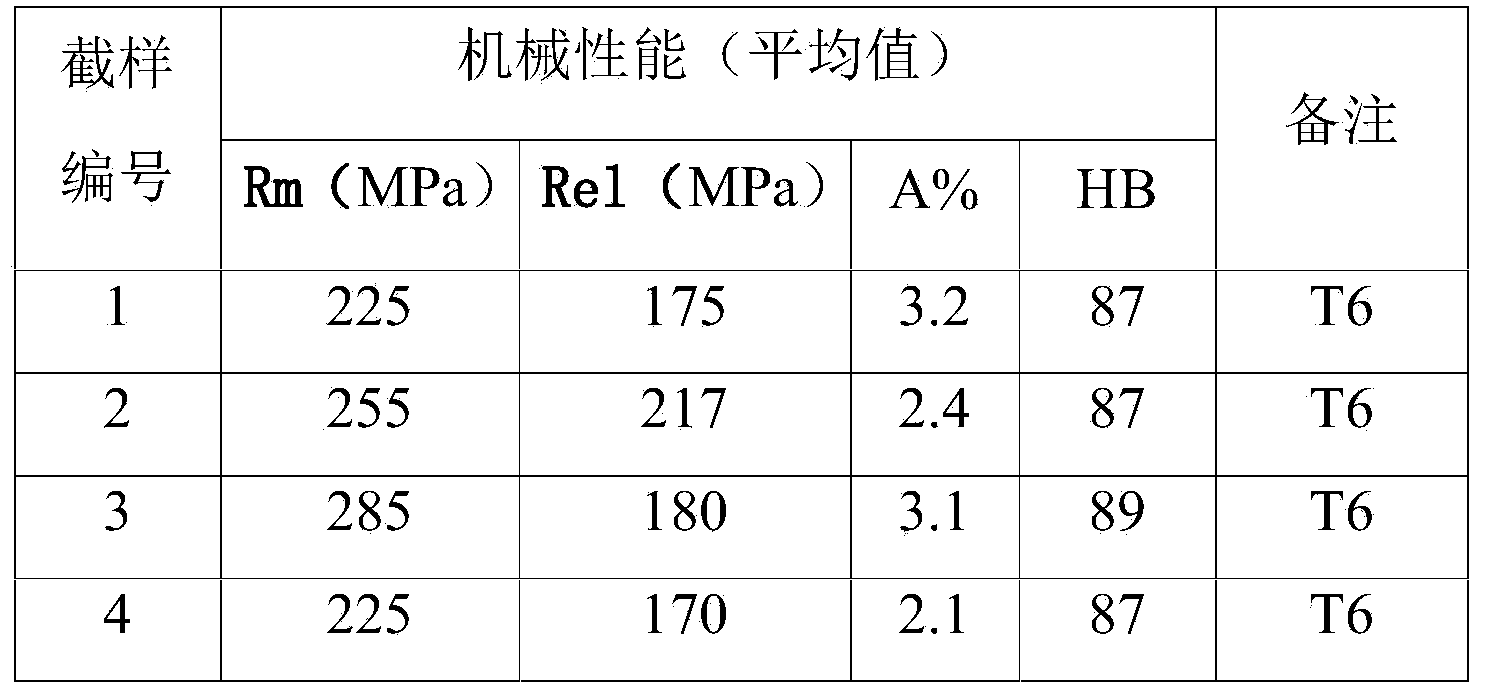

A kind of heat-resistant magnesium alloy and preparation method thereof

The invention relates to a heat-resisting magnesium alloy and a preparation method thereof, and belongs to the technical field of magnesium alloys. The heat-resisting magnesium alloy is composed of the following components of, by mass, 10-12% of Sm, 0.8-1.0% of Al, 1.2-1.5% of Sn, 1.0-1.2% of Si, 1.5-2.0% of Mn, 0,8-1.0% of Ag, 1.0-1.5% of Zn, 0.43-0.71% of Ca and the balance Mg and inevitable impurities. According to the heat-resisting magnesium alloy, on the basis that 10-12% of the Sm rare earth element is added as the first component, appropriate amounts of additives including the Al, Sn, Si, Mn, Ag, Zn, CaO and the like are introduced, an Mg-Sm alloy is modified in a multicomponent microalloying method, an obtained as-cast alloy is subjected to T6 heat treatment, and the obtained heat-resisting magnesium alloy has excellent high-temperature tensile strength and creep resistance.

Owner:HENAN UNIV OF SCI & TECH

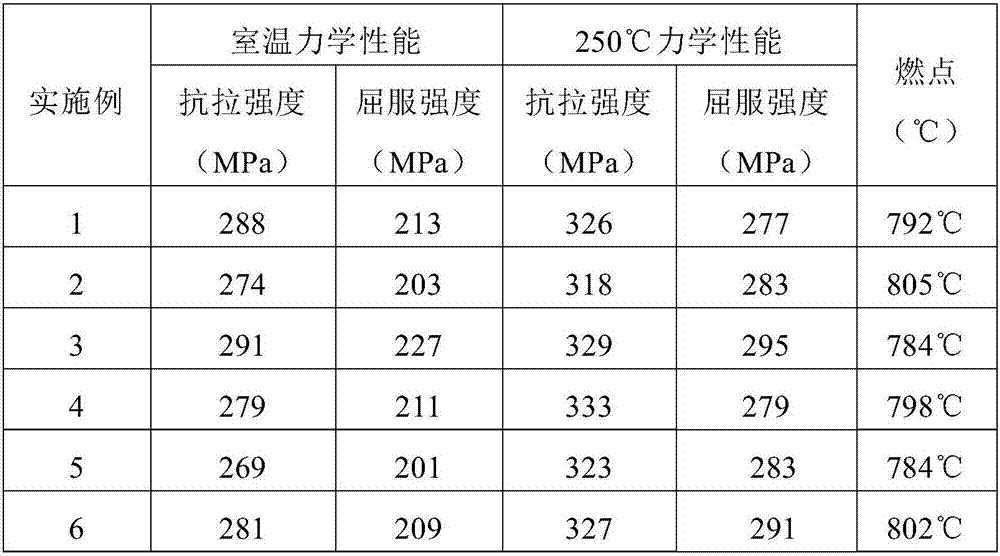

Flame retardant magnesium alloy material and preparation method thereof

ActiveCN107130159AImprove overall performanceImproved mechanical properties and flame retardant propertiesMechanical properties of carbon nanotubesMagnesium alloy

The invention relates to a flame retardant magnesium alloy material and a preparation method thereof, and belongs to the technical field of magnesium alloys and manufacturing thereof. The flame retardant magnesium alloy material is prepared from the following components in percentage by mass: 8.6 to 10.4 percent of Gd, 2.6 to 3.4 percent of Nd, 1.6 to 2.9 percent of Ce, 1.1 to 1.5 percent of Al, 1.1 to 1.6 percent of Sb, 0.26 to 0.38 percent of Sr, 0.78 to 1.0 percent of Ca and the balance of Mg and unavoidable impurities. Compared with the prior art, the flame retardant magnesium alloy material disclosed by the invention has the advantages that by reasonable matching of different elements, the comprehensive performance of the flame retardant magnesium alloy material is obviously improved, particularly the mechanical performance and the flame retardancy characteristic at room temperature and high temperature are obviously improved; and meanwhile, the tensile strength of the flame retardant magnesium alloy material has an abnormal temperature effect, namely with the increase of tensile temperature, the tensile strength is also improved.

Owner:HENAN UNIV OF SCI & TECH

A heat-resistant and creep-resistant magnesium alloy and its preparation method

Owner:HENAN UNIV OF SCI & TECH

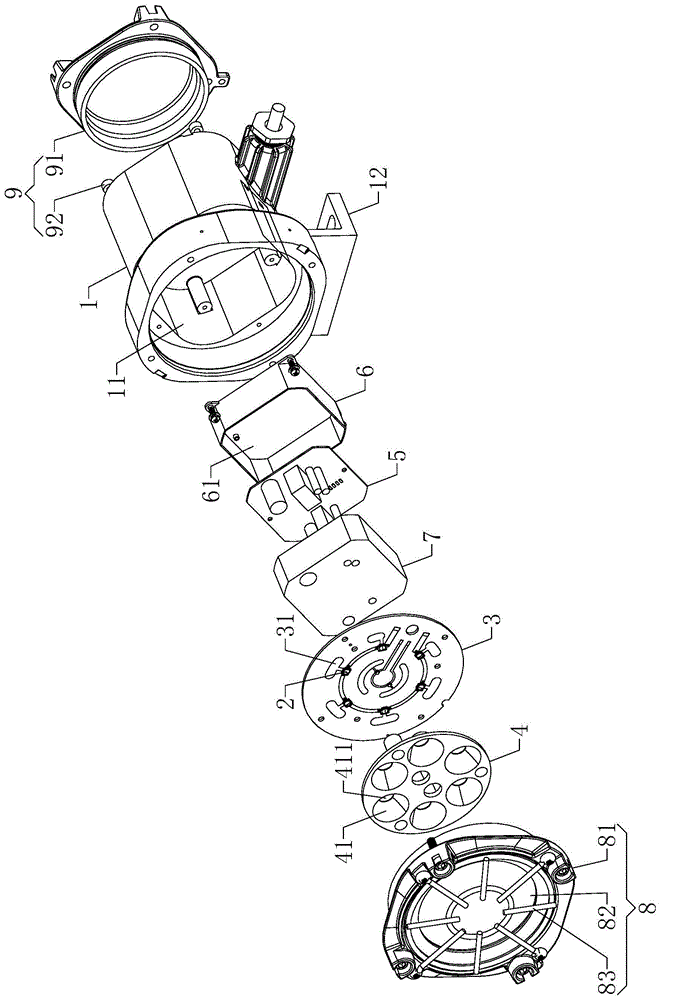

Light fixture

InactiveCN104930426ABurn out preventionAvoid damagePoint-like light sourceLighting heating/cooling arrangementsCopper foilSilica gel

The invention belongs to the technical field of illumination and provides a light fixture comprising a main housing cast by iron-sand, a light source, an aluminum base plate, a reflection cup for light condensation and a driving circuit plate controlling work states of the light source. The main housing is provided with an accommodating cavity having a forward opening; the light source is arranged on the aluminum base plate; the reflection cup covers the light source and is connected with the aluminum base plate; the aluminum base plate is disposed in the accommodating cavity; the light fixture further comprises a filling box having a filling cavity; the driving circuit plate is disposed in the filling cavity; solid silicon gel formed by condensation of liquid silicon gel is filled in the filling cavity; the driving circuit board is covered with the solid silicon gel; the filling box is disposed in the accommodating cavity of the main housing; the surface of the aluminum base plate is provided with copper foil; and the light source is arranged on the copper foil. The driving circuit board is covered with the solid silicon gel, so heat emitted by the driving circuit board can be drove away in time and driving circuit board burn due to excessively high temperature can be prevented; and heat of the light source can be quickly transmitted to the aluminum base plate via the copper foil, so burn of the light source due to excessive heat accumulation can be prevented.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

Method for rapidly smelting zirconium-based amorphous alloy master alloy

InactiveCN110358987AGood for induction meltingAvoid uneven ingredientsCooking & bakingAdditive ingredient

The invention relates to the technical field of amorphous alloys, in particular to a method for rapidly smelting a zirconium-based amorphous alloy master alloy. The method comprises the following steps that a niobium block and sponge zirconium are pretreated to obtain niobium particles and a zirconium electrode; the niobium particles, the zirconium electrode and the rest alloy raw materials are uniformly mixed to obtain alloy raw materials; a crucible is installed in an inductor, baking and vacuumizing are carried out, and the crucible is preheated through coil induction heating; the alloy rawmaterials are added into the crucible, protective gas is introduced, and the raw materials are heated to be molten uniformly through coil heating, poured into a mold and cooled, and therefore the zirconium-based amorphous alloy master alloy is obtained. The raw materials are pretreated, the sponge zirconium is mechanically compacted, zirconium is change from a honeycomb structure to a solid structure, induction melting is facilitated, and ingredient uneven caused by element nonmelting in the melting process can be avoided; the niobium block is crushed into small niobium particles, therefore niobium is easier to melt, and the problem that niobium is not thorough in melting due to the high melting point is solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

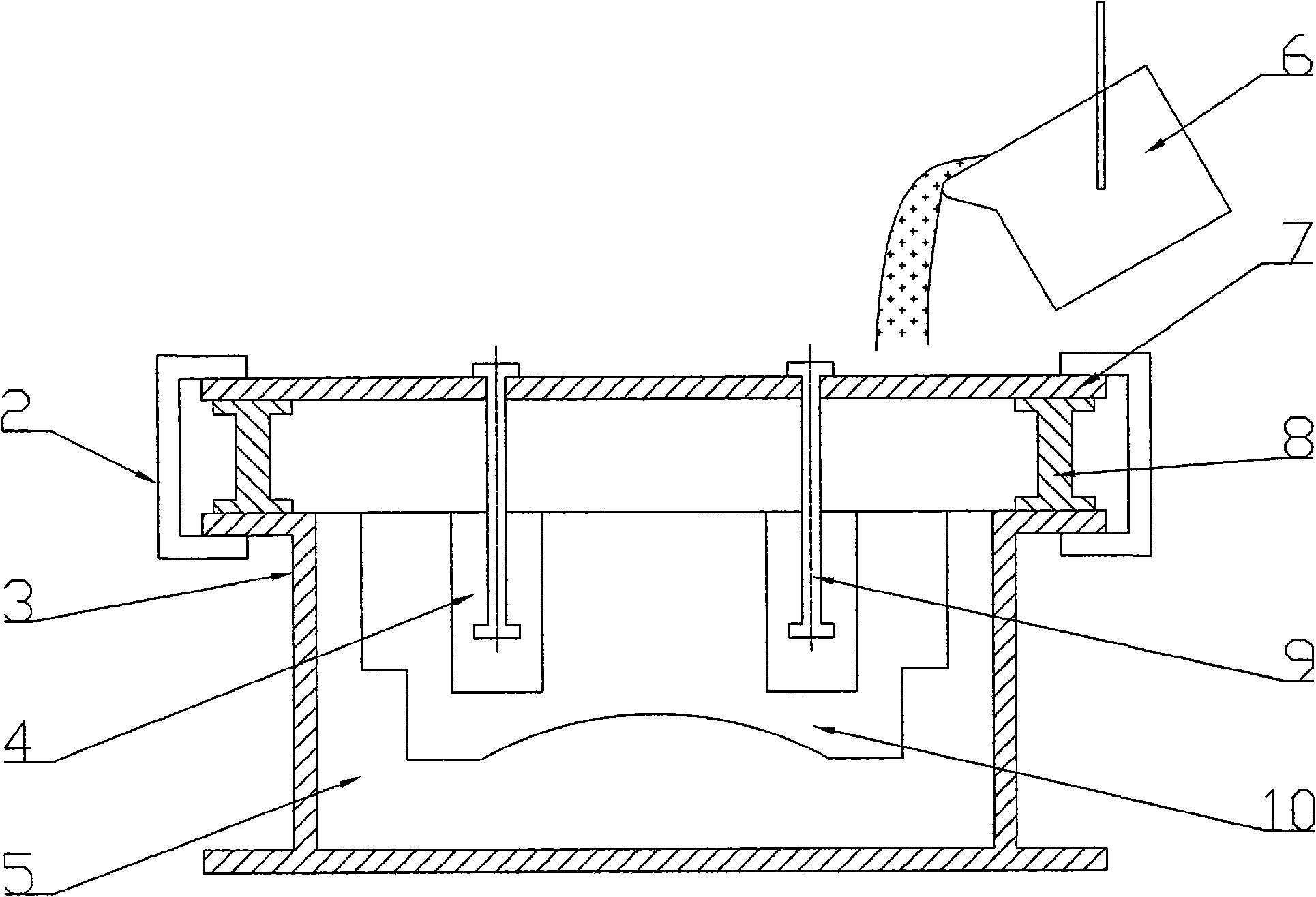

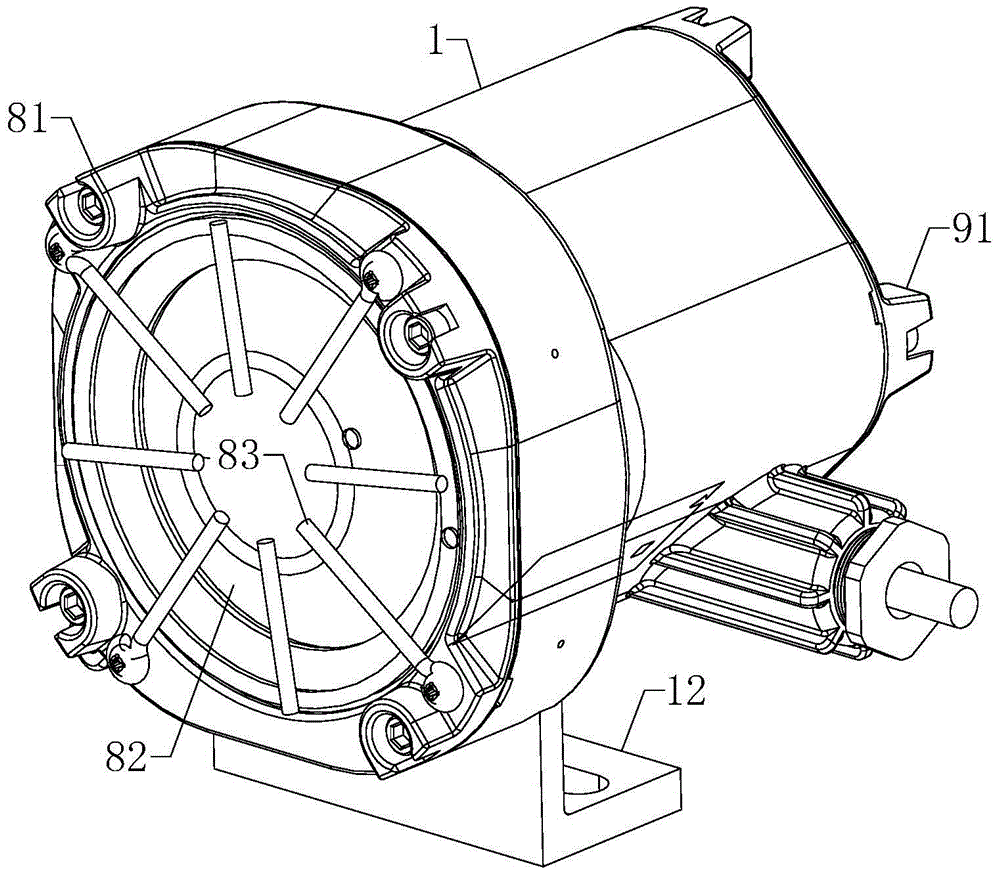

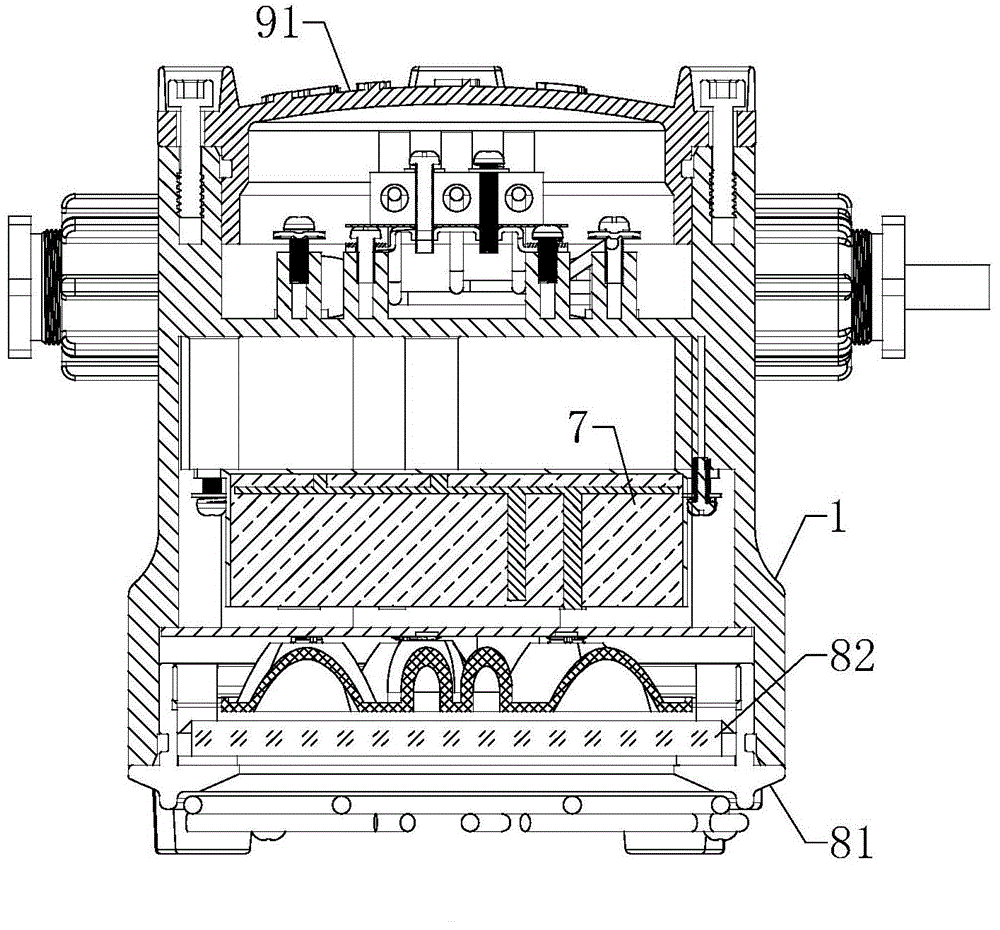

Manufacturing process of bimetallic sliding bearing

InactiveCN103899650ANot prone to segregationQuality assuranceBearing componentsMasterbatchSlider bearing

The invention discloses a manufacturing mould and manufacturing method of a bimetallic composite sliding bearing. The mould comprises an upper mould (1), a lower mould (4), a cavity (2), and a bearing (3). The manufacturing method is characterized by comprising the following steps: preparing an inner sleeve material according to the mass percentage of the following components, pre-mixing the prepared components in a high-speed mixer; further granulating and granulating in a granulation extruder to obtain the inner sleeve material masterbatch; and finally conducting curing heat treatment on a metal injection molding bearing to obtain a finished product. The mold provided by the invention is reliable in operation, has the advanategs of less energy consumption of the equipment, high speed, mass production, good product consistency, few personnel, raises the utilization rate of materials, and can effectively improve the production efficiency and reduce the manufacturing cost.

Owner:DALIAN HONGRUN COMPOSITE BEARING

A construction method for producing asphalt recycled material by using solid granular regenerant

ActiveCN106567307BThe melting process is simpleGuaranteed accuracyRoads maintainenceParticulatesPrill

The invention relates to a constructing method for producing asphalt reclaimed materials adopting solid state particulate regenerants. The constructing method comprises the following steps of (1) mixing the solid particulate regenerants with RAP according to a material compounding ratio in room temperature so as to obtain mixed materials, and after mixing, according to certain weight, loading the mixed materials into packing bags which can be dissolved at high temperature; and (2) conveying the packing bags loaded with the mixed materials loading the solid particulate regenerants and the RAP to heating equipment, and performing heating and melting so that the solid particulate regenerants are melted into liquid, then liquid regenerants are fully merged with and fully infiltrated in old asphalt on the surface of the RAP to react with the old asphalt, and qualified RAP reclaimed materials are obtained. According to the constructing method disclosed by the invention, the accuracy of the material compounding ratio of the regenerants and the RAP can be guaranteed, before construction, the melting process of the liquid regenerants in a storing tank can be greatly simplified, the scale checking link of measurement scales for the liquid regenerants is omitted, and relative to conventional working conditions of on-spot material taking and on-spot using for a road surface, the constructing method has the advantage that the control accuracy of aggregate gradation is high.

Owner:FUJIAN TIETUO MACHINERY

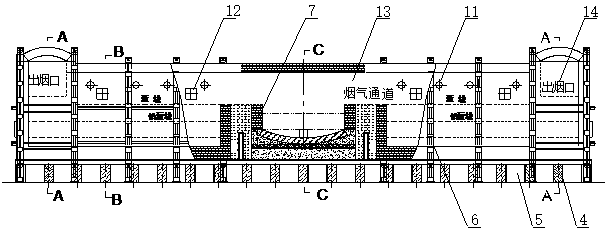

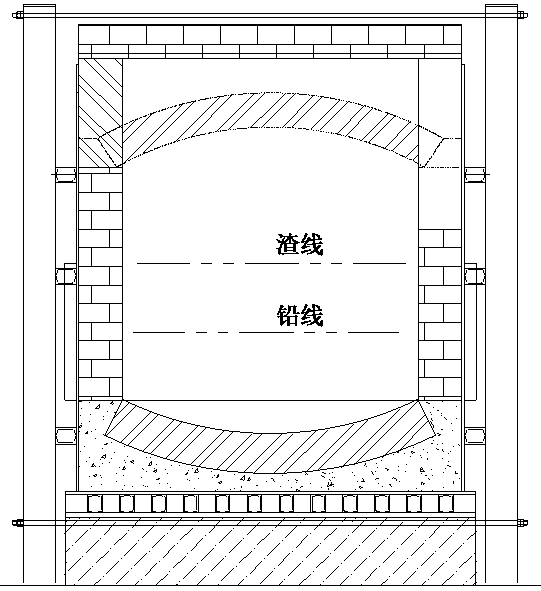

Energy-saving environment-protecting secondary lead multi-chamber metal smelting furnace and treatment method

PendingCN109518000ALess investmentSave energyWaste accumulators reclaimingBattery recyclingSocial benefitsLiquid slag

The invention discloses an energy-saving environment-protecting secondary lead multi-chamber metal smelting furnace and a treatment method and belongs to the technical field of secondary metal smelting. A furnace shell is mounted on a furnace foundation; a smelting furnace device and a gasification furnace are connected into a whole; a furnace steel frame is disposed outside the furnace shell to tightly hoop the furnace shell; a refractory material furnace building body is disposed on the inner side of the furnace shell; the smelting furnace device communicates with the upper portion of the interior of the gasification furnace through a smoke channel; liquid slag chutes are disposed between the smelting furnace device and the gasification furnace; the two ends of the liquid slag chutes communicate with liquid slag outlets of the smelting furnace device and liquid slag inlets of the gasification furnace correspondingly; smoke outlets are formed in the smelting furnace device and communicate with flues; and flue gates are disposed on the flues. The two sides of the top of the gasification furnace are connected with the flues of smelting furnaces, straight flowing of liquid hot slag can be achieved, the flues mutually communicate, the gates are opened and closed to control the smoke flowing direction so as to perform smelting, gasification, heat preservation and pre-heating on materials, continuous material feeding is performed during production, continuous melting is performed, latent heat of the liquid slag and waste heat of the smoke are utilized, the environment-protectingeffect is good, and the economic benefits and social benefits are remarkable.

Owner:JIANGSU NEW CHUNXING RESOURCE RECYCLING CO LTD

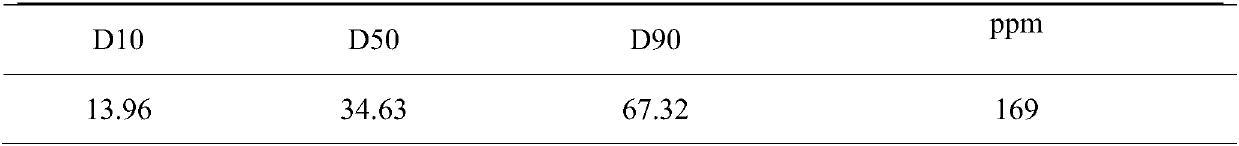

Aircraft rotor cross beam aluminum alloy profile and preparation method thereof

The invention relates to an aircraft rotor cross beam aluminum alloy profile and a preparation method thereof, and belongs to the field of aircraft rotor cross beam aluminum alloy profile manufacturing. The aircraft rotor cross beam aluminum alloy profile is prepared from the following substances in percentage by mass: 5.0-8.0% of Cu, 1.5-2.5% of Mg, 0.5-1.5% of Ag, 0.3-0.6% of Mn, 0.2-0.5% of Zr,and the balance of Al and inevitable impurities. By introducing a proper amount of cheap alloy elements such as Cu, Mg, Ag, Mn and Zr, the high-temperature performance of the aluminum alloy can be remarkably improved, and the application range of the aluminum alloy is expanded; and the aluminum alloy is low in cost, simple in smelting and heat treatment process and uniform in microstructure, andthe mechanical property and heat resistance of the alloy are remarkably improved.

Owner:SHANDONG NANSHAN ALUMINUM

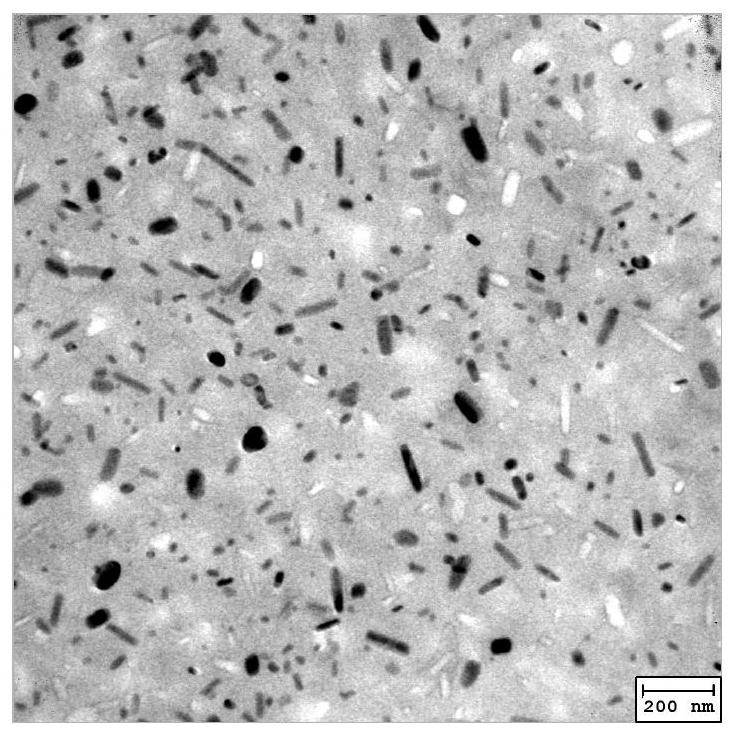

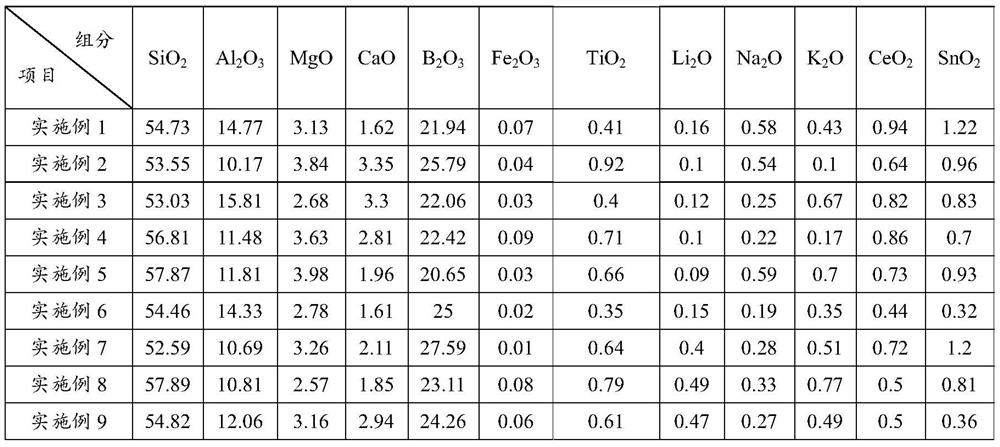

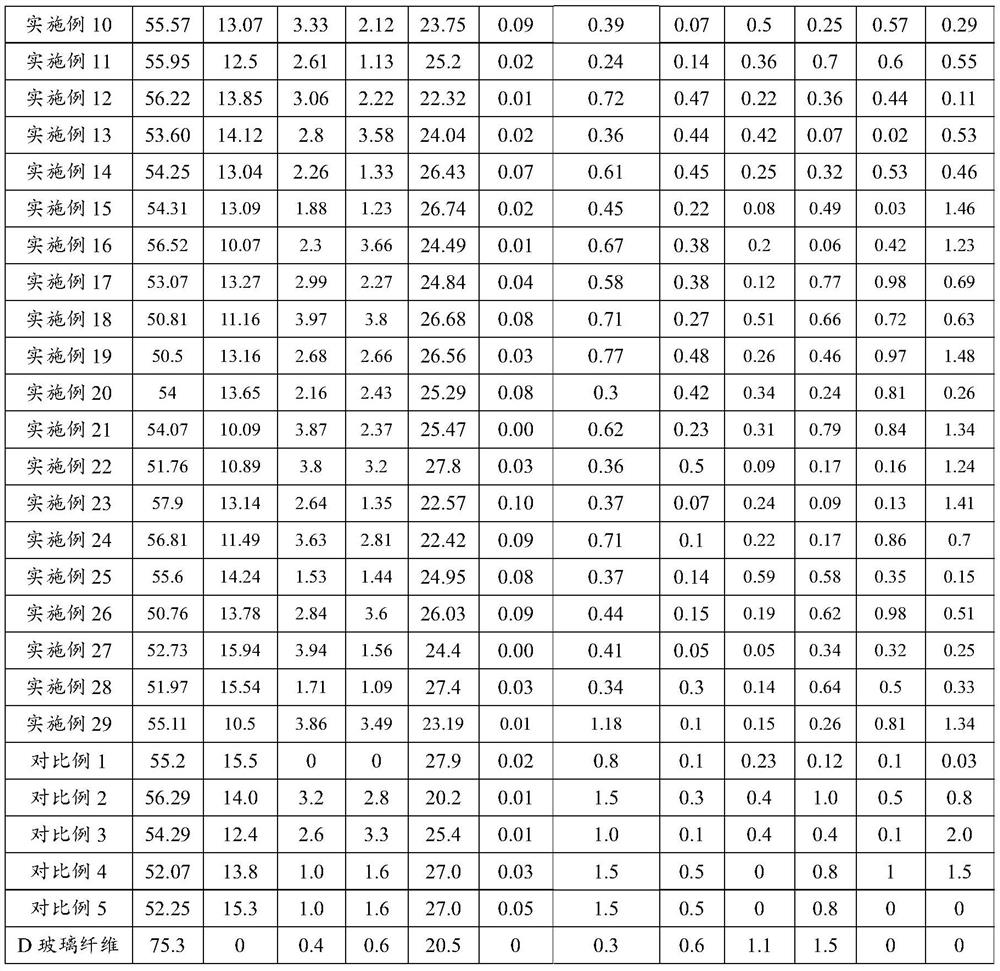

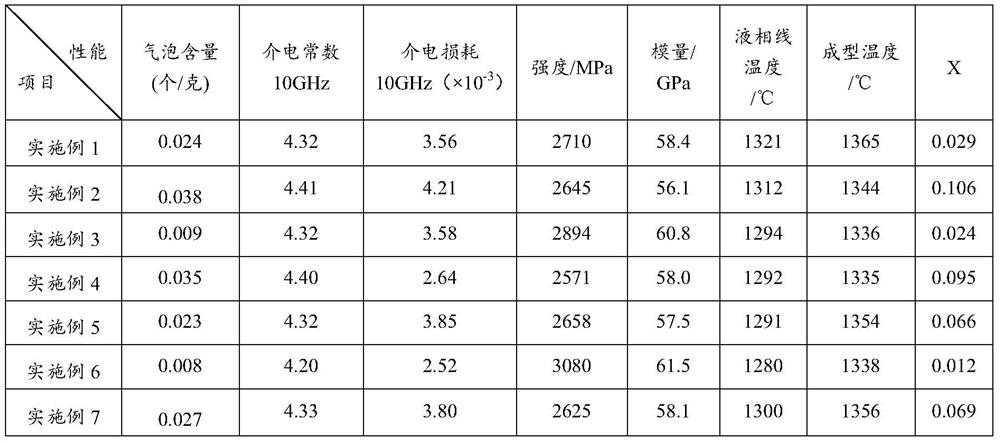

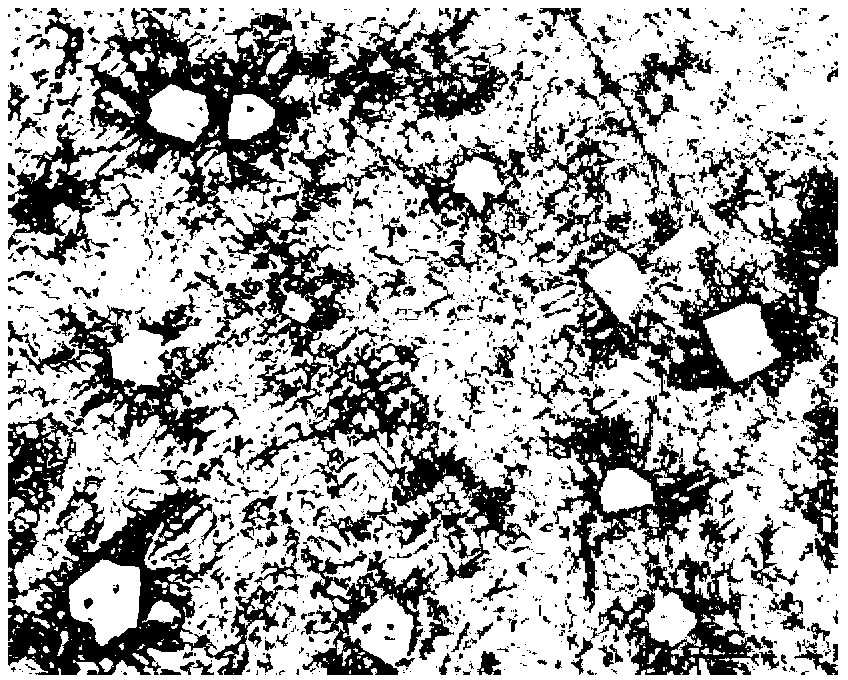

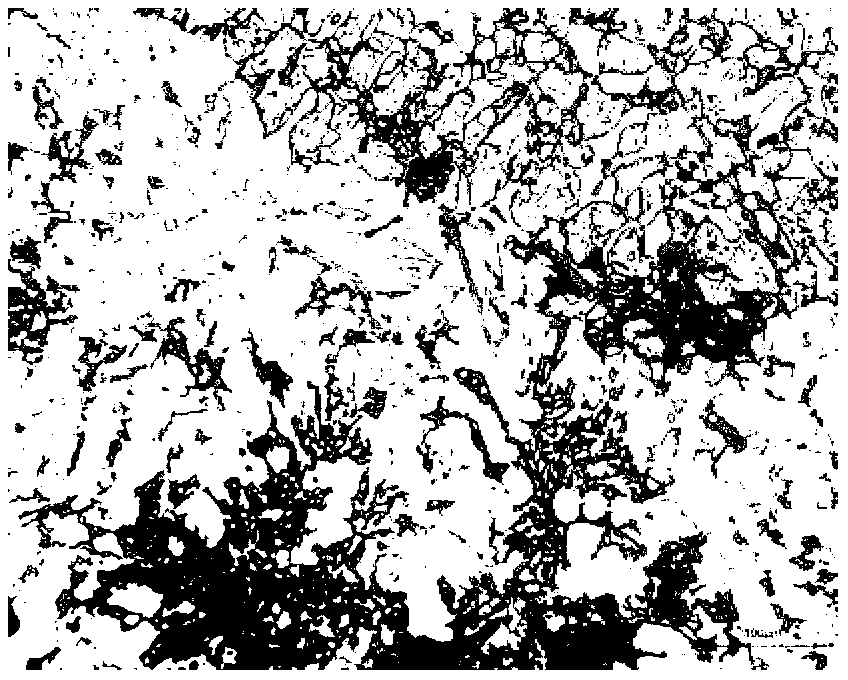

Low dielectric glass fiber and preparation method, glass fiber product, composite material and application

ActiveCN113135666BLow dielectric constantImprove performanceCasings/cabinets/drawers detailsQuartz/glass/vitreous enamelsGlass fiberAlkali metal oxide

The invention provides a low-dielectric glass fiber and its preparation method, glass fiber product, composite material and application. The invention reasonably adjusts the ratio of each oxide in the glass component to obtain high mechanical strength, good dielectric performance and melting Low-dielectric glass with excellent comprehensive performance such as simpler process. Specifically, by reasonably setting the ratio of silicon oxide, aluminum oxide and boron oxide, the glass fiber has a lower dielectric constant and dielectric loss, and the viscosity of the glass is properly adjusted. At the same time, considering the dielectric properties and mechanical strength Under the premise, through reasonable setting of alkaline earth metal oxides, alkali metal oxides, TiO 2 , CeO 2 and SnO 2 The dosage of the glass further improves the melting and clarifying performance of the glass, the temperature of the wire drawing is lower, the stability and yield are higher, the density is lower, and it has excellent workability.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

High-temperature antioxidant heat storage aluminum alloy

InactiveCN103215479AReasonable design of ingredientsImprove performanceRare-earth elementOxidation resistant

The invention discloses a high-temperature antioxidant heat storage aluminum alloy, which aims to overcome the problem of high-temperature easy oxidation of heat storage aluminum alloy. The heat storage aluminum alloy comprises the following components by weight percent: 10.0-14.0 percent of Si (silicon), 1.0-4.0 percent of Mg (magnesium), 10.0-20.0 percent of Cu (copper), 0-0.5 percent of RE (rear earth) and the balance of Al (aluminum); the heat storage aluminum alloy has good comprehensive performance, especially higher oxidation resistance, due to the addition of trace mixed rare earth elements; the oxidation kinetics curve is coincident with the parabolic law based on 650-DEG C quasi-isothermal oxidation experiments and the oxidation time of less than 250 hours and shows that the oxidant film has better protection; after 150 thermal circulations, the latent heat of phase change is maximally reduced only by 3.53 percent, the starting phase change temperature is just reduced by 0.1 DEG C, the final phase change temperature is just increased by 3.1 DEG C, and therefore the heat storage aluminum alloy shows better thermal stability. The heat storage aluminum alloy has good high-temperature oxidation resistance, simple melting process, and is easily achieved industrial production; and the raw materials of the alloy are rich and obtained easily.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com