Multi-element heat-resistant magnesium alloy and preparation method thereof

A magnesium alloy, heat-resistant technology, applied in the field of magnesium alloy, can solve the problems of poor mechanical properties at room temperature and high temperature, and achieve the effect of simple alloy melting and heat treatment process, uniform microstructure, solid solution strengthening and precipitation strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

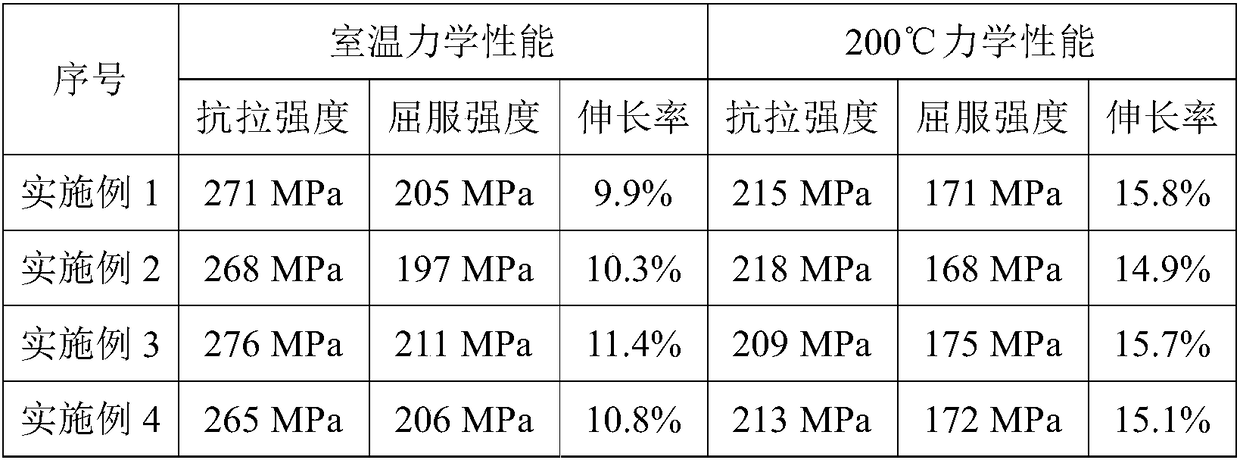

Examples

Embodiment 1

[0024] The multi-component heat-resistant magnesium alloy of this embodiment is composed of the following components in weight percentage: Sm 5.5%, Sn 5%, Zn 4%, V 0.9%, and the balance is Mg and unavoidable impurities.

[0025] The preparation method of the multi-component heat-resistant magnesium alloy of the present embodiment adopts the following steps:

[0026] 1) Take pure magnesium ingots, pure zinc particles, pure tin particles, Mg-Sm master alloy and Mg-V master alloy according to the ratio, and place them in a drying oven at 200 ° C for 2 hours to dry and preheat;

[0027] 2) Put the preheated pure magnesium ingots, pure zinc particles, and pure tin particles in CO 2 , SF 6 The formed mixed gas (volume ratio is 99:1) is melted under protection, and when heated to 700°C, Mg-Sm master alloy and Mg-V master alloy are added and kept for 8 minutes. After the alloy is completely melted, the surface scum is removed, and the temperature is continued to Stir evenly after 73...

Embodiment 2

[0030] The multi-component heat-resistant magnesium alloy of this embodiment is composed of the following components in weight percentage: Sm 6%, Sn 3.5%, Zn 3%, V 1.0%, and the balance is Mg and unavoidable impurities.

[0031] The preparation method of the multi-component heat-resistant magnesium alloy of the present embodiment adopts the following steps:

[0032] 1) Take pure magnesium ingots, pure zinc particles, pure tin particles, Mg-Sm master alloy and Mg-V master alloy according to the ratio, and place them in a drying oven at 200 ° C for 2.5 hours to dry and preheat;

[0033] 2) Put the preheated pure magnesium ingots, pure zinc particles, and pure tin particles in CO 2 , SF 6 The formed mixed gas (volume ratio is 99:1) is melted under protection, and when heated to 690°C, Mg-Sm master alloy and Mg-V master alloy are added and kept for 12 minutes. After the alloy is completely melted, the surface scum is removed, and the temperature continues to rise to Stir evenly ...

Embodiment 3

[0036] The multi-component heat-resistant magnesium alloy of this embodiment is composed of the following components by weight percentage: Sm 6%, Sn 4%, Zn 4%, V 0.5%, and the balance is Mg and unavoidable impurities.

[0037] The preparation method of the multi-component heat-resistant magnesium alloy of the present embodiment adopts the following steps:

[0038] 1) Take pure magnesium ingots, pure zinc particles, pure tin particles, Mg-Sm master alloy and Mg-V master alloy according to the ratio, and place them in a drying oven at 210°C for drying and preheating for 2.5 hours;

[0039] 2) Put the preheated pure magnesium ingots, pure zinc particles, and pure tin particles in CO 2 , SF 6 The formed mixed gas (volume ratio is 99:1) is melted under protection, and when heated to 710°C, Mg-Sm master alloy and Mg-V master alloy are added and kept for 10 minutes. After the alloy is completely melted, the surface scum is removed, and the temperature is continued to Stir evenly af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com