Aircraft rotor cross beam aluminum alloy profile and preparation method thereof

A technology of aluminum alloy profiles and rotors, which is applied in the field of aircraft rotor beam aluminum alloy profiles and its preparation, to achieve strong solid solution strengthening, simple smelting and heat treatment processes, and improved high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

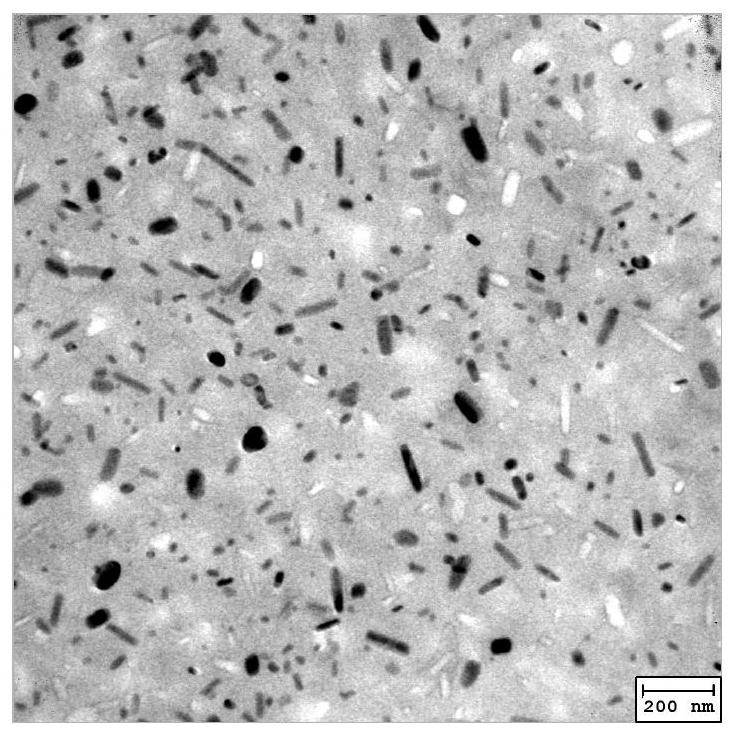

Image

Examples

Embodiment 1

[0026] Step 1: Accurately weigh AL, Mg, master alloy Al- Cu, master alloy Al-Ag, master alloy Al-Mn and master alloy Al-Zr are fed into the preheating kettle for preheating;

[0027] Step 2: Send aluminum and magnesium into the melting kettle for melting, heat up to 730°C after melting, add master alloy Al-Cu, master alloy Al-Ag, master alloy Al-Mn and master alloy Al-Zr, keep warm for 8 minute;

[0028] Step 3: After all the metals are melted, remove impurities, raise the temperature to 775°C, stir evenly, then lower the temperature, and let it stand for 5 minutes to obtain the alloy liquid;

[0029] Step 4: Casting, pour the alloy liquid into the mold for casting, and naturally cool to cast aluminum alloy block;

[0030] Step 5: Perform solid solution treatment and effect treatment on the cast aluminum alloy in sequence.

Embodiment 2

[0032] Step 1: Accurately weigh AL, Mg, master alloy Al- Cu, master alloy Al-Ag, master alloy Al-Mn and master alloy Al-Zr are fed into the preheating kettle for preheating;

[0033] Step 2: Send aluminum and magnesium into the melting kettle for melting, heat up to 730°C after melting, add master alloy Al-Cu, master alloy Al-Ag, master alloy Al-Mn and master alloy Al-Zr, keep warm for 8 minute;

[0034] Step 3: After all the metals are melted, remove impurities, raise the temperature to 775°C, stir evenly, then lower the temperature, and let it stand for 5 minutes to obtain the alloy liquid;

[0035] Step 4: Casting, pour the alloy liquid into the mold for casting, and naturally cool to cast aluminum alloy block;

[0036] Step 5: Perform solid solution treatment and effect treatment on the cast aluminum alloy in sequence.

Embodiment 3

[0038] Step 1: Accurately weigh AL, Mg, master alloy Al- Cu, master alloy Al-Ag, master alloy Al-Mn and master alloy Al-Zr are fed into the preheating kettle for preheating;

[0039] Step 2: Send aluminum and magnesium into the melting kettle for melting, heat up to 730°C after melting, add master alloy Al-Cu, master alloy Al-Ag, master alloy Al-Mn and master alloy Al-Zr, keep warm for 8 minute;

[0040] Step 3: After all the metals are melted, remove impurities, raise the temperature to 775°C, stir evenly, then lower the temperature, and let it stand for 5 minutes to obtain the alloy liquid;

[0041] Step 4: Casting, pour the alloy liquid into the mold for casting, and naturally cool to cast aluminum alloy block;

[0042] Step 5: Perform solid solution treatment and effect treatment on the cast aluminum alloy in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com