Method for preparing semisolid slurry for ultralow temperature casting magnesium alloy

A magnesium alloy, semi-solid technology, applied in the field of metal material forming, can solve the problems of complexity, high equipment investment and working capital, etc., and achieve the effects of dendrite growth suppression, simple pulping process and equipment, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

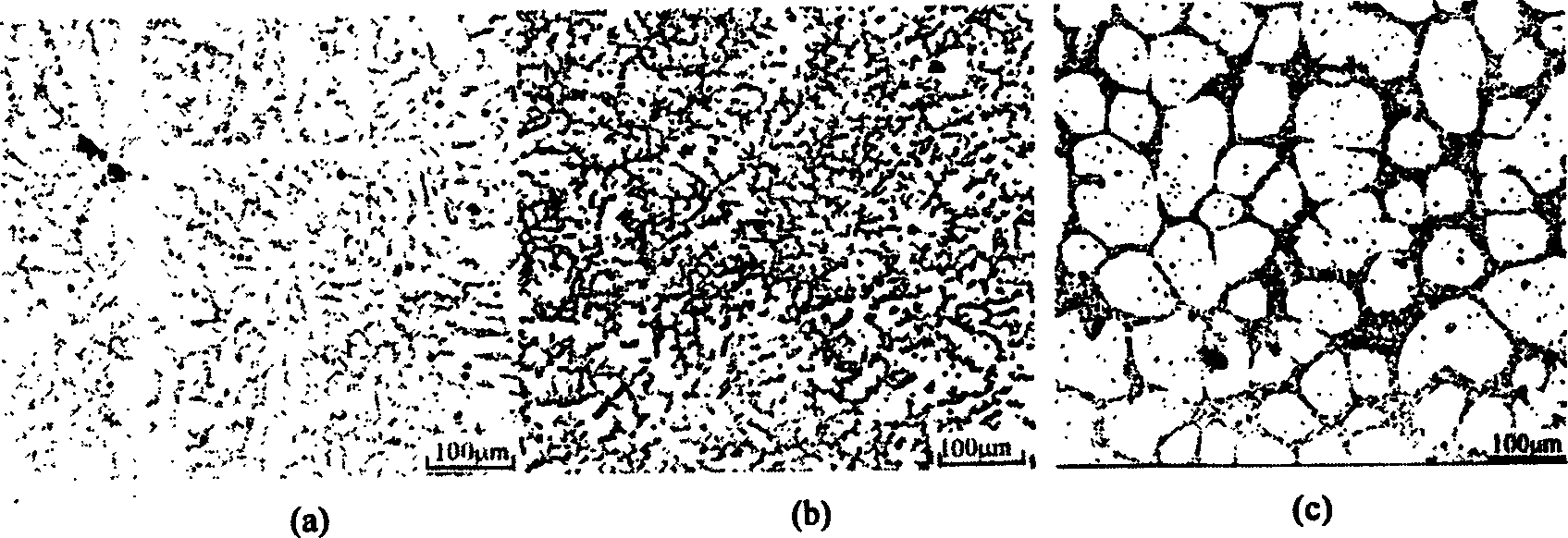

[0038] The ultra-low temperature casting of AZ91D magnesium alloy is used to produce semi-solid slurry. According to the aforementioned process steps, the casting temperature is 590°C and the casting speed is 150mm / min. The comparison between the obtained slurry structure and the traditional casting and the chilled structure of the semi-solid slurry ingot after secondary heating (partial remelting) such as figure 1 shown. It can be seen that the ultra-low temperature casting grains are obviously refined, the dendrites degenerate significantly, and the microstructure presents a fine degenerated dendrite or rose structure. After secondary heating (partial remelting), the solid phase particles are round and uniform, which can fully meet the requirements of semi-solid forming.

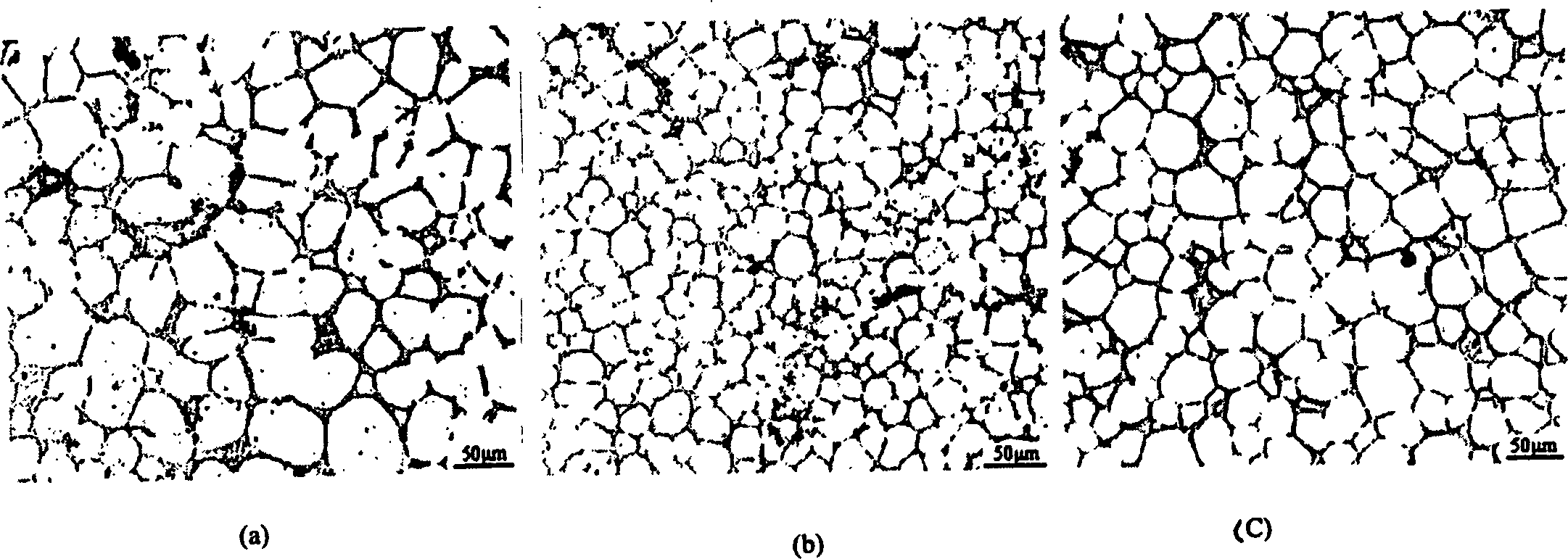

[0039] Ultra-low temperature casting of ZK60 magnesium alloy is used to produce semi-solid slurry. According to the aforementioned process steps, the casting temperature is 620°C and the casting speed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com